5

© 2011 Midmark Corp. | 60 Vista Drive Versailles, OH 45380 USA | 1-800-643-6275 | 1-937-526-3662 |

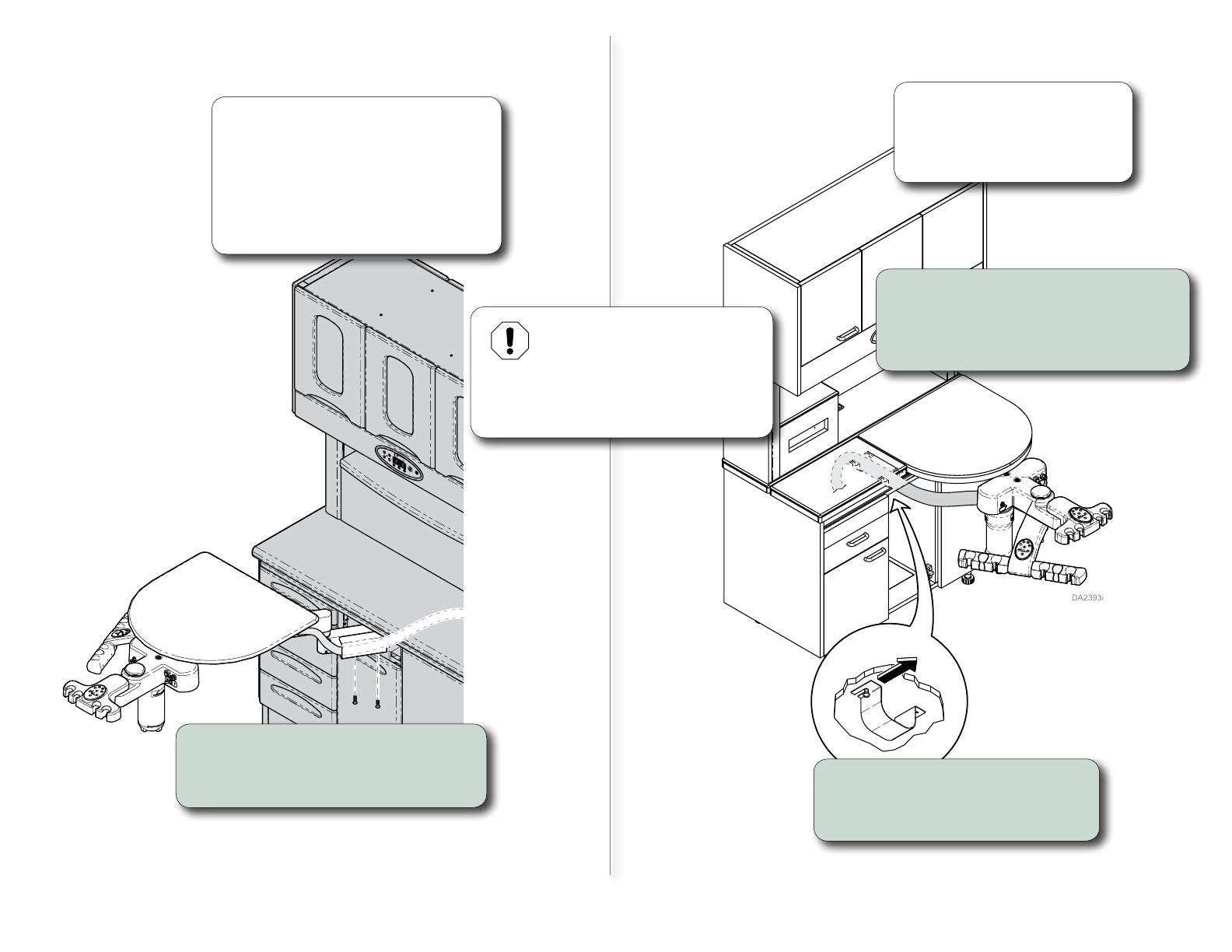

Routing / Securing Tubing

Equipment Alert

When securing tubing, allow

sufficient slack in tubing for

movement of control panel / mounting

arm. Failure to do so could result in tub-

ing becoming disconnected or damage.

Step 2: Bundle tubing from control

panel and install bracket; then

secure bracket with screws.

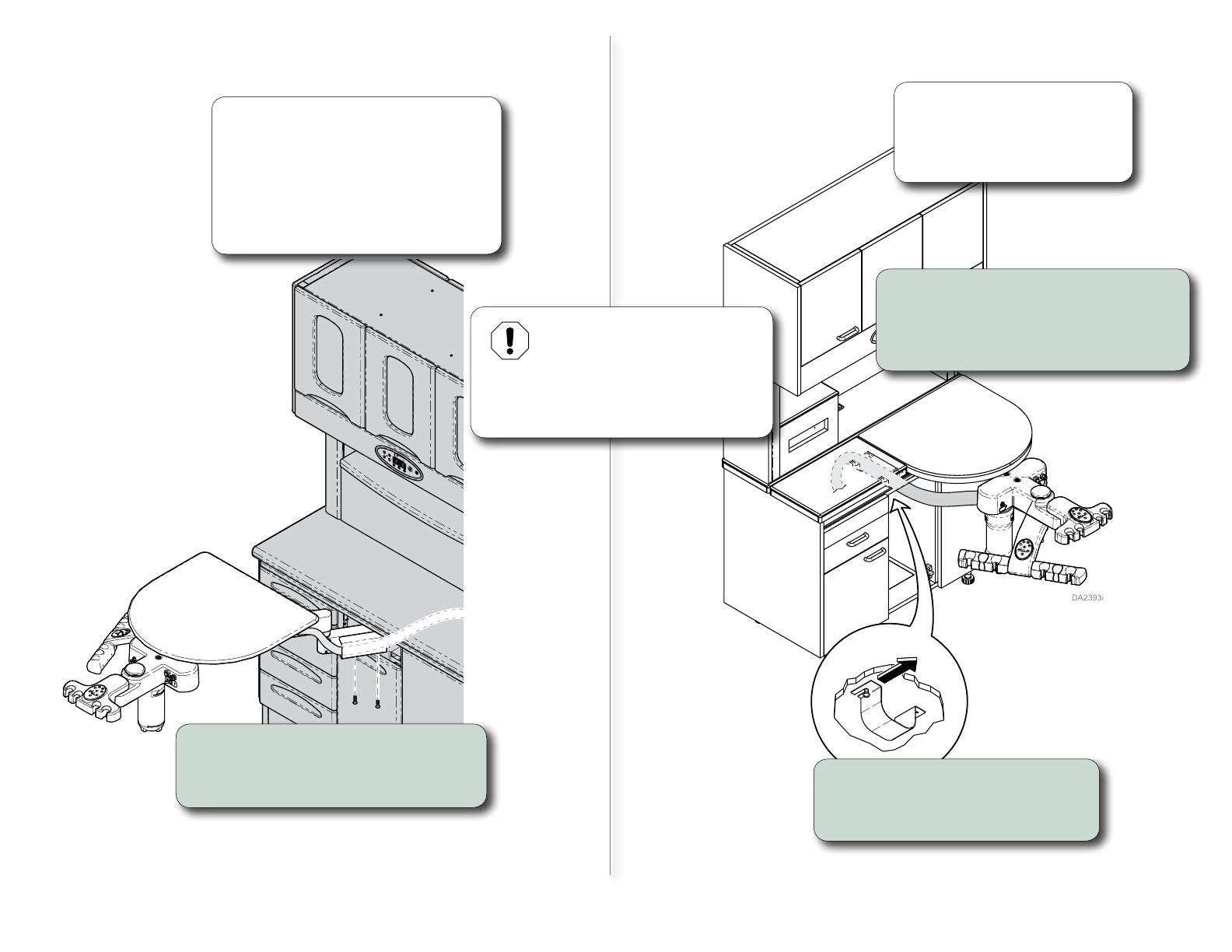

Cabinet Mount

(Pivoting)

Note

Adhesive backed mounting platforms

are provided for units without control

panel.

Apply mounting platform to inside of

cabinet and secure vacuum with wire

tie: then go to step 2.

Cabinet Mount

(Pull Out)

Step 1: Loosen screws on both

side of mounting brackets

and remove bracket..

Step 2: Bundle tubing from Doctor’s /

Assistant’s Delivery Units and

install in brackets then secure

with screws.

Note

For ease of installation it may

be helpful to extend the work

surface by pulling it outward.