Page is loading ...

0171--976 1

Mounting Instruction

A newsletter from YORK Refrigeration, Technology & Products

Christian X’s Vej 201, P O Box 1810, DK-8270 Højbjerg, Denmark

Phone +45 87 36 70 00, Fax +45 87 36 77 05

29 May 2001

Subject: Mounting of New Type of Capacity Rod on

SAB 81 Screw Compressors

As described in Technical Information 2001/03, a new capacity measuring system for SAB 81

screw compressors was introduced in May/June 2001.

The electronic control systems used so far can still be used for the new system, but the capacity

rod (capacity transmitter) on the compressor must be replaced. The capacity rod can be re-

placed by following a straightforward mounting procedure, which is described in this Mounting

Instruction. This instruction also describes how the capacity measuring system is adjusted to

the new sensor.

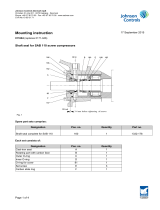

A kit is used for mounting the new capacity rod. This kit consists of the parts mentioned below

(see fig. 1).

Fig. 1

45

42 167

280

233

282

44a

43

203

141

280a

281

283

0171--976

2

Quantity Pos. no. Part no.

Complete Kit 3084-637

Capacity rod with threaded

bushing pos. 280a 1 280 1553-273

Retainer for regulating piston 1 42 3013-365

Stop screws M6X6 2 44a 1413-229

Bushing for capacity transmitter 1 281 3043-251

Dowty ring 1 167 1331-433

Aluminium pipe 1 282 1116-029

Hexagon socket screw M6X35 2 283 1413-344

O-ring ID 104.5x3 1 203 1331-374

Cover 1 45 3013-305

Dismounting

When the pressure in the compressor has been reduced to atmospheric pressure and the com-

pressor has been secured against unintentional start-up as described in the Instruction

Manual, proceed as follows (see sectional views in the instruction manual):

SDismount the electric plug on the existing capacity rod.

SDismount the existing capacity rod pos. 280 by means of an open-end spanner JW 24

and pull it out of the compressor carefully. Both the capacity rod and the gasket pos. 141

arenotgoingtobereused.

SDismount the hexagon socket screws pos. 233 (Allen key JW 8) and push out the cover

pos. 45 by mounting the screws pos. 233 in the two threaded holes in the flange.

The cover and the O-ring pos. 203 are not going to be reused.

SDismount the Seeger ring pos. 141 by means of a pair of seeger ring pliers and remove

manually the two magnets pos. 44.

0171--976 3

Mounting

When the parts to be mounted have been cleaned and suitably oiled, proceed as follows:

SPlace the retainer for the regulating piston pos. 42 on the aluminium pipe pos. 282 with

adistanceof10mmfromtheendasillustratedinfig.2.Tightenthetwostopscrews

(Allen key JW 2.5).

Fig. 2 10

250

282 42

44a

SPlace the arrangement in the retainer pos. 43 as shown in fig. 1 and lock it with the

Seeger ring pos. 141.

SWhen the new O-ring pos. 203 has been mounted on the new cover pos. 45, the cover

is mounted on the compressor as shown in fig. 1.

STighten the screws pos. 233.

SMount the Dowty ring pos. 167 and tighten the threaded bushing pos. 280a.

SBy pressing the bushing pos. 281 against the cover pos. 45 (remember to turn the

bushing as illustrated in the drawing), place the capacity rod pos. 280 in its position

and tighten the screws pos. 283.

0171--976

4

The same electric plug can be used for the new capacity rod as for the previous rod. It is how-

ever recommended to check that the wiring connections comply with fig. 3.

1 = OUT 4--20mA

2 = SUPPLY +24V DC

3 = COMMON --

=GND

Fig. 3

Adjusting capacity measuring system

As shown in fig. 4 the capacity transmitter is equipped with a single calibration button sur-

rounded by a green and red LED.

Fig. 4

During normal operation, the red LED is flashing at a rather slow rate. The green LED is con-

stantly on when the transmitter is in its 100% position, and it flashes quickly when it is in the

0% position.

0171--976 5

The calibration is done as follows:

Note! Make sure that the Unisab II is not in alarm.

1. Apply supply voltage minimum 5 minutes before calibration.

2. Press the calibration button for 5 seconds to get the transmitter in calibration

mode. The red LED changes from normal flash to OFF.

3. Decrease the capacity to its minimum, and then press the calibration button

once. The red LED turns immedially ON. After 10 seconds the red LED turns

OFF again, indicating that it is ready for 100% calibration.

4. Increase the capacity to its maximum, and then push the calibration button

twice. The red LED starts flashing quickly. After 10 seconds the red LED

changes to normal flash rate, indicating thatthe calibration has been completed.

5. The calibration will be remembered, even if a power failure occurs.

To return to “Factory Set Point”, press the CAL. Switch for 20 seconds.

Indication of this is shown by a short flash of the green and red led (one after the other).

The 4--20 mA signal from the transmitter is permanently available, however, during calibration

the signal is based on the default calibration values, so it will not show 0% at minimum capacity

nor 100% at maximum capacity! Note that it is possible to reset to the default calibration by

pressing the button pressed for 20 seconds, however, it is the transmitter manufacturer’s de-

fault values, which might differ very much from the proper values for the actual compressor.

The reset is indicated by the red and the green LED flashing briefly in turn a couple of times.

0171--976

6

0171--976 7

0171--976

8

YORK REFRIGERATION

Chr. X’s Vej 201 ·P. O . B o x 181 0 ·DK-8270 Højbjerg ·Denmark

Phone+4587367000 ·Fax +45 87 36 77 05

/