Page is loading ...

0171--977 1

Mounting Instruction

A newsletter from YORK Refrigeration, Technology & Products

Christian X’s Vej 201, P O Box 1810, DK-8270 Højbjerg, Denmark

Phone +45 87 36 70 00, Fax +45 87 36 77 05

4 Dec 2001

Subject: Mounting of New Type of Capacity Rod on

SAB 83, 85, 87 and 89 Screw Compressors

As described in Technical Information 2001/03, a new capacity measuring system for SAB 83,

85, 87 and 89 screw compressors was introduced in May/June 2001.

The electronic control system used so far can still be used for the new system, but the capacity

rod (capacity transmitter) must be replaced. The capacity rod can be replaced by following a

straightforward mounting procedure, which is described in this Mounting Instruction. This in-

struction also describes how the capacity measuring system is adjusted to the new sensor.

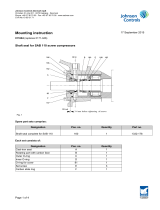

A kit is used for mounting the new capacity rod. This kit consists of the parts mentioned below

(see fig. 1).

Fig. 1

200/203 143 208 241

281

167

280

45

232

42

283

280a

282 40

f

44a

39

0171--977

2

Compressor SAB 83

Quantity Pos no Part no

Complete Kit 3084-638

consists of:

Capacity rod with threaded

bushing pos. 280a 1 280 1553-274

Cover 1 45 3013-299

Bushing for capacity transmitter 1 281 3043-251

Dowty ring 1 167 1331-433

Retainer with aluminium pipe 1 282/44a/42 3045-072

Hexagon socket screw M6X35 2 283 1413-344

O-ring ID 104.5x3 1 208 1331-355

O-ring ID 79.5x3 1 200 1331-353

Mounting Instruction 0171-977

Compressor SAB 85

Quantity Pos no Part no

Complete Kit 3084-639

consists of:

Capacity rod with threaded

bushing pos. 280a 1 280 1553-275

Cover 1 45 3013-264

Bushing for capacity transmitter 1 281 3043-251

Dowty ring 1 167 1331-433

Retainer with aluminium pipe 1 282/44a/42 3045-072

Hexagon socket screw M6X35 2 283 1413-344

O-ring ID 104.5x3 1 208 1331-364

O-ring ID 79.5x3 1 200 1331-353

Mounting Instruction 0171-977

0171--977 3

Compressor SAB 87

Quantity Pos no Part no

Complete Kit 3084-640

consists of:

Capacity rod with threaded

bushing pos. 280a 1 280 1553-276

Cover 1 45 3013-244

Bushing for capacity transmitter 1 281 3043-251

Dowty ring 1 167 1331-433

Retainer with aluminium pipe 1 282/44a/42 3045-074

Retainer for regulating piston 1 42 3013-365

Stop screws M6X6 2 44a 1413-229

Hexagon socket screw M6X35 2 283 1413-344

O-ring ID 104.5x3 1 208 1331-360

O-ring ID 109.5x3 1 203 1331-354

Mounting Instruction 0171-977

Compressor SAB 89

Quantity Pos no Part no

Complete Kit 3084-641

consists of:

Capacity rod with threaded

bushing pos. 280a 1 280 1553-277

Cover 1 45 3013-278

Bushing for capacity transmitter 1 281 3043-251

Dowty ring 1 167 1331-433

Retainer with aluminium pipe 1 282/44a/42 3045-075

Hexagon socket screw M6X35 2 283 1413-344

O-ring ID 104.5x3 1 208 1331-368

O-ring ID 109.5x3 1 203 1331-354

Mounting Instruction 0171-977

Dismounting

When the pressure in the compressor has been reduced to atmospheric pressure and the com-

pressor has been secured against unintentional start-up as described in the instruction

manual, proceed as follows (see sectional views in the instruction manual):

SDismount electric plug on existing capacity rod.

0171--977

4

SDismount existing capacity rod pos. 280 with open-end spanner (JW 24) and pull it out

of compressor carefully. Both capacity rod and gasket pos. 167 are not going to be re-

used.

SDismount hexagon socket screws pos. 241 (Allen key, JW 10) and push out cover pos.

45 by mounting screws pos. 241 in the two treaded holes in flange. Cover pos. 45 and

O-ring pos. 208 are not going to be reused.

Important!

For compressors without economizer, check that there is no excess pressure in capacity slide

chamber pos. 40. This is carried out as follows:

SIf one of the two threaded holes in retainer for regulating piston pos. 42 is marked with

an”X”,therewillbea2mmholeinbottomofthreadedholetoequalizepressurein

chamber, and disassembly may thus proceed as described below.

SIf retainer for regulating piston pos. 42 is not marked with an ”X”, a 2 mm hole must be

bored in retainer. This must be carried out before dismounting Seeger ring pos.143 and

two hexagon socket screws pos. 232 as excess pressure in chamber may project re-

tainer with great force.

Bore equalization hole as shown in drawing fig. 1. Mark the side turning outwards with an “X”,

which will facilitate subsequent compressor service.

Equalization hole must not be blanked off, but remain open for permanent pressure

equalization.

Fig. 1

dia. 2 mm

42

X

X

SAfter having checked that there is no excess pressure in capacity slide chamber, dis-

mount Seeger ring pos. 143 and two hexagon socket screws pos. 232 (Allen key, JW 8).

SBy mounting two hexagon socket screws pos. 232 in threaded holes, retainer for regulat-

ing piston pos. 42 can be pulled out. Both retainer for regulating piston and O-ring pos.

200 are not going to be reused.

0171--977 5

Mounting

When the parts to be mounted have been cleaned and suitably oiled, proceed as follows:

SPlace retainer for regulating piston pos. 42 on aluminium pipe pos. 282 with distance A

as illustrated in fig. 2. Tighten two stop screws pos. 44a (Allen key, JW 2.5).

A

B

282 42

44a

AB

S83

S85

S87

S89

320

359

399

439

23

8

8

8

Fig. 2

SWhen O-ring pos. 200 has been mounted, place arrangement with retainer for regulating

piston pos. 42 in regulating piston pos. 39/40 as illustrated in fig. 1.

Lock arrangement with Seeger ring pos. 143.

Mount and tighten two hexagon socket screws pos. 232.

SWhen O-ring pos. 208 has been mounted on cover pos. 45, mount cover on compressor

as shown in fig. 1.

SMount and tighten screws pos. 241 (Allen key, JW 10).

SMount Dowty ring pos. 167 and tighten threaded bushing pos. 280a.

SBy pressing bushing pos. 281 against cover pos. 45 (remember to turn bushing as il-

lustratedindrawing),place capacity rod pos. 280 in its position.

Mount and tighten screws pos. 283.

The same electric plug can be used for the new capacity rod as for the previous rod. It is, how-

ever, recommended to check that the wiring connections comply with fig. 3.

0171--977

6

1 = OUT 4--20mA

2 = SUPPLY +24V DC

3 = COMMON --

=GND

Fig. 3

Term in al 3 1

Term in al 2 9

Term in al 3 0

UNISAB II

Nottobeused

Adjusting capacity measuring system

As shown in fig. 4 the capacity transmitter is equipped with a single calibration button sur-

rounded by a green and red LED.

Fig. 4

During normal operation the red LED is flashing at a rather slow rate. The green LED is con-

stantly on when the transmitter is in 100% position, and it flashes quickly when the transmitter

is in 0% position.

Calibration is carried out as follows:

0171--977 7

Note! Make sure that UNISAB II is not in alarm.

1. Apply supply voltage minimum 5 minutes before calibration.

2. Press calibration button for 5 seconds to get transmitter in calibration

mode. Red LED changes from normal flash to OFF.

3. Decrease capacity to minimum and press calibration button

once. Red LED turns immediately ON. After 10 seconds red LED turns

OFF again, indicating that it is ready for 100% calibration.

4. Increase capacity to maximum and push calibration button

twice. Red LED starts flashing quickly. After 10 seconds red LED

changes to normal flash rate, indicating that calibration has been completed.

5. Calibration will be remembered even in case of power failure.

To return to “Factory Set Point”, press CAL. Switch for 20 seconds.

Indication of this is shown by a short flash of green and red LED (one after the other).

The 4--20 mA signal from the transmitter is permanently available. However, during calibration

the signal is based on the default calibration values so it will not show 0% at minimum capacity,

nor 100% at maximum capacity! Note that it is possible to reset to the default calibration by

keeping the button pressed for 20 seconds. However, it is the transmitter manufacturer’s de-

fault values which may differ very much from the correct values for the actual compressor. The

reset is indicated by the red and the green LED flashing briefly in turn a couple of times.

0171--977

8

YORK REFRIGERATION

Chr. X’s Vej 201 ·P. O . B o x 1 81 0 ·DK-8270 Højbjerg ·Denmark

Phone+4587367000 ·Fax +45 87 36 77 05

/