Page is loading ...

Instructions

Manitowoc Foodservice Sellersburg, 2100 Future Drive, Sellersburg, IN 47172, Tel: 812-246-7000, www.manitowocbeverage.com

00206960

12/09

Subject: SL282-84 C02 KIT - Export

INTRODUCTION

The CO

2 control kit consists of four basic pre-assembled

assemblies that must be attached to the front or back pre-

punched panels of either the Model 11 or 38 remote

refrigeration units. Follow numerical assembly sequence.

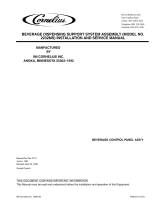

FIGURE 1

4

Low CO

2 Alarm

Assembly

10

Connect the fifth 61” CO

2

line to the low pressure

regulator if one of the

beverages is sugar free

8

Hold Down Clip for Cap

Tube of Pressure Control

1

Medium & Low Pressure

Regulator Assembly

If all Syrups are Sugar

Based, remove cap nut and

install fifth CO

2 line. Place

cap nut on outlet of low

pressure regulator outlet

9

Connect the four or five 61”

CO

2 gas lines to the medium

pressure regulator assembly

2

Air/CO

2 Changeover

Valve Assembly

5

Copper line assembly connecting the

medium & low pressure regulator

assembly to the Air/CO

2 changeover valve

6

Copper line assembly connecting the Air/CO

2

changeover valve assembly to the changeover

valve assembly for the CO

2 tanks 1&2

7

Nut connecting the pressure switch to

the Air/CO

2 changeover valve

assembly

Attach the CO2 line from the

carbonator tank of the

remote unit to the remaining

flare fitting of the CO

2 tank

1&2 change over valve

assembly

3

CO

2 Tank 1&2

changeover valve

assembly

13

Connect to power supply

11

Connect the remaining two

120” CO

2 lines to the two

outlets of the CO

2 tank 1&2

changeover valve

12

Attach the two primary CO

2

tank regulators to the 120”

CO

2 lines of thee CO2 tank

1&2 changeover valve

assembly

!

Caution

To Avoid Serious Injury Read the following warnings

before beginning an installation. Failure to do so may

result in possible death or serious injury.

SL282-84 C02 KIT - Export 00206960

Manitowoc Foodservice Sellersburg, 2100 Future Drive, Sellersburg, IN 47172, Tel: 812-246-7000, www.manitowocbeverage.com

DO Adhere to all National and Local Plumbing and

Electrical Safety Codes.

DO Turn “Off” incoming electrical service switches

when servicing, installing, or repairing

equipment.

DO Check that all flare fittings on the carbonation

tank(s) are tight. This check should be

performed with a wrench to ensure a quality

seal.

DO Inspect pressure on Regulators before starting

up equipment.

DO Protect eyes when working around refrigerants.

DO Use caution when handling metal surface

edges of all equipment.

DO Handle CO

2 cylinders and gauges with care.

Secure cylinders properly against abrasion.

DO Store CO

2 cylinder(s) in well ventilated areas.

DO NOT Throw or drop a CO

2 cylinder. Secure the

cylinder(s) in an upright position with a chain.

DO NOT Connect the CO2 cylinder(s) directly to the

product container. Doing so will result in an

explosion causing possible death or injury. Best

to connect the CO2 cylinder(s) to a regulator(s).

DO NOT Store CO

2 cylinders in temperature above 125˚

F (51. 7˚ C) near furnaces, radiator or sources

of heat.

DO NOT Release CO

2 gas from old cylinder.

DO NOT Touch Refrigeration lines inside units, some

may exceed temperatures of 200˚ F (93.3˚ C).

NOTE: Water pipe connections and fixtures directly connected to a

potable water supply shall be sized, installed and maintained in

accordance with Federal, State, and Local codes

.

KIT INSTRUCTIONS

Refer to FIGURE 1 for the following procedures.

1. The medium and low pressure regulator assembly must

be attached to the panel by two sheet metal screws

diagonally.

2. The air/C0

2 changeover valve assembly must be

positioned at the bottom of the panel with two sheet metal

screws horizontally.

3. The CO

2 changeover valve assembly for the CO2 tanks

1& 2 must be positioned on the left and slightly above the

air/CO

2 changeover valve assembly with two sheet metal

screws horizontally.

4. The low CO

2 alarm assembly must be positioned on the

upper left side and attached with two sheet metal screws

diagonally to expose the two mounting holes. The cover

must be removed to expose the two mounting holes.

5. Connect the medium and low pressure regulator

assembly to the air/C0

2 changeover valve assembly by

using the longer of the two 1/4" copper tube assemblies.

6. Connect the air/C0

2 changeover assembly to the C02

tank changeover valve assembly by using the short “U”

shaped 1/4" copper tube assembly.

7. Connect the small copper cap tube extending from the

bottom of the C0

2 control assembly box to the 1/4" MF of

the tee fitting attached to the air/C0

2 changeover valve

assembly.

8. Position the hold down clip over one section of copper

cap tube coil and attach clip to side of unit with sheet

metal screw.

9. Connect four or five 61" CO

2 gas lines to the 1/4" MF

fitting of the manifold assembly of the medium pressure

regulator.

NOTE: The fittings have check valves.

10. Connect the fifth 61" CO

2 line to the 1/4" MF fitting of the

low pressure regulator if one of the beverages is sugar

free. If all syrups are sugar based, remove the cap nut

from the remaining fitting of the medium pressure

regulator and attach the fifth CO

2 line. Install the cap nut

on the 1/4" MF fitting of the low pressure regulator.

11. Connect the two remaining 120" CO

2 plastic lines to the

CO

2 tank changeover valve. Attach the C02 line

connected to the carbonator tank in the remote unit to the

remaining 1/4" MF fitting of the C0

2 tank changeover

valve assembly.

12. Attach the two CO

2 primary regulators to CO2 tanks then

connect the two 120" CO

2 lines from the C02 tank

changeover valve assembly to the regulators. Do not

open the CO

2 tank valves at this time. Attach the C02 gas

quick disconnects to the five CO

2 gas plastic lines.

!

Warning

DANGER OF ELECTRICAL SHOCK - Disconnect and

lock out all electrical power sources before performing

service or maintenance on this machine -- except when

electrical tests are being performed by qualified service

personnel.

SL282-84 C02 KIT - Export 00206960

Manitowoc Foodservice Sellersburg, 2100 Future Drive, Sellersburg, IN 47172, Tel: 812-246-7000, www.manitowocbeverage.com

Testing For CO2 Leaks

To test the assembly to make Sure there are no leaks, the

CO

2 gas line previously installed from the carbonator tank

to the CO

2 tank changeover valve assembly will have to

be removed. Remove the cap nut from the sir/CO

2

changeover valve. Turn the knob with the directional

pointer to the left, counterclockwise.

Screw the cap nut onto the 1/4" MF where the CO

2 line to

the carbonator was removed. Turn the knob with the

directional pointer to either CO

2 tank 1 or 2. Open that

CO

2 cylinder. Adjust the primary regulator to 90 P.S.I., set

the medium pressure regulator to 60 P.S.I, and set the

low pressure regulator to 14-16 P.S.I.

Allow the CO

2 tank pressure to remain on for three

minutes, then turn the CO

2 tank handle to the "OFF"

position. The CO

2 tank gauge should remain constant, no

drop in pressure.

If the CO

2 tank gauge drops in pressure, locate source of

leak and correct. A soap solution when applied to the

connections will pinpoint the leak.

Remove the cap nut, replace the CO

2 gas line from the

carbonator tank, and screw the cap nut back on the air/

CO

2 changeover valve.

13. Wire the electrical supply to the transformer as shown in

the wiring diagram in FIGURE 2. The CO

2 control

buzzer should sound and the lamp should illuminate

when the CO

2 pressure on the primary CO2 tank

regulator drops to 70 P. S. I. and shut off when the

pressure reached 90 P.S.I.

FIGURE 2

TRANS.

RED

GRD.

220

VOLTS

LIGHT

BLU

WHT

BUZZER

PRESSURE

SW.

/