INSTRUCTION SHEET

Page 1

#30741 4” ECONOMY LIFT KIT – JEEP TJ

Warrior recommends this system be installed by a certified technician. In

addition to these instructions, professional knowledge of

disassemble/reassembly procedures as well as post installation checks must

be known. Attempts to install this system without this knowledge and

expertise may jeopardize the integrity and/or operating safety of the vehicle.

Please read instructions before beginning installation. Check the kit

hardware against the parts layout and list found on the last page of these

instructions. Be sure you have all needed parts and know where they go.

With the installation of all lift kits and larger tires it is important to check

the condition of your steering stabilizer. If the stabilizer is worn or is

leaking it should be replaced. Steering stabilizers are designed to restrain

“bump steering” and front end vibration, giving added life to tires, ball

joints, and other steering components. A multiple stabilizer kit is

recommended for vehicles equipped with a winch or larger tires

PRODUCT USE INFORMATION

1. As a general rule, the taller a vehicle is, the easier it will roll. Offset, as much as possible, what is lost in rollover resistance by

increasing tire track width. In other words, go "wide" as you go "tall". Many sportsmen remove their mud tires after hunting

season and install ones more appropriate for street driving; always use as wide a tire and wheel combination as possible to

enhance vehicle stability.

2. We strongly recommend, because of rollover possibility, that the vehicle be equipped with a functional roll-bar and cage

system. Seat belts and shoulder harnesses should be worn at all times. Avoid situations where a side rollover may occur

3. Generally, braking performance and capability are decreased when significantly larger/heavier tires and wheels are used. Take

this into consideration while driving.

4. Do not add, alter, or fabricate any factory or after-market parts to increase vehicle height over the intended height of the

Warrior product purchased. Mixing component brands is not recommended.

5. Warrior makes no claims regarding lifting devices and excludes any and all implied claims. We will not be responsible for any

product that is altered.

6. The required installation time for this system is approximately 8 hours.

7. This suspension system was developed using a 33 x 12.50R – 15 tire, on a 8” wheel. Before installing other combinations,

please consult your local tire and wheel specialist.

8. The following tools and supplies are recommended for proper installation of this kit.

a. Spring Compressor b. Pitman Arm Puller

c. Silicone Spray d. Drill Motor

e. Drill Assortment (1/8” to 1/2") f. Torque Wrench (250 ft lbs. Capacity)

g. Hammer h. ½” Drive Ratchet and Sockets

i. Combination Wrenches j. Allen Wrenches

k. Torx Key Socket l. Hacksaw

m. File n. Large “C” Clamps and/or Bench Vise

o. Hydraulic Floor Jacks p. Heavy Duty Jack Stands

q. Wheel Chocks (Wooden Blocks) r. Molybdenum Grease or Anti Seize Compound

s. Safety Glasses – Wear safety glasses at all times

If question exist we will be happy to answer any questions concerning the design, function, and correct use of our products.

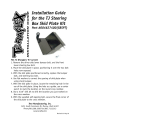

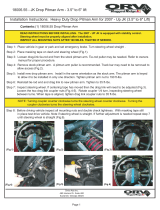

FIGURE 1

INSTRUCTION SHEET

Technical Assistance - (888) 220-6861 Page 2

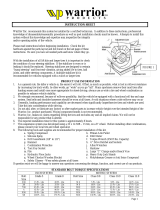

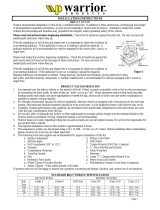

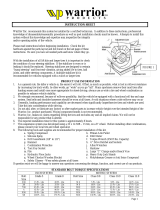

STANDARD BOLT TORQUE SPECIFICATIONS

INCH SYSTEM METRIC SYSTEM

Bolt

Size Grade 5 Grade 8 Bolt Size Class 9.8 Class 10.9 Class 12.9

5/16 15 Ft – Lbs 20 Ft – Lbs M 6 5 Ft – Lbs 9 Ft – Lbs 12 Ft – Lbs

3/8 30 Ft – Lbs 35 Ft – Lbs M 8 18 Ft – Lbs 23 Ft – Lbs 27 Ft – Lbs

7/16 45 Ft – Lbs 60 Ft – Lbs M10 32 Ft – Lbs 45 Ft – Lbs 50 Ft – Lbs

½ 65 Ft – Lbs 90 Ft – Lbs M12 55 Ft – Lbs 75 Ft – Lbs 90 Ft – Lbs

9/16 95 Ft – Lbs 130 Ft – Lbs M14 85 Ft – Lbs 120 Ft – Lbs 145 Ft – Lbs

5/8 135 Ft – Lbs 175 Ft – Lbs M16 130 Ft – Lbs 165 Ft – Lbs 210 Ft – Lbs

¾ 185 Ft – Lbs 280 Ft – Lbs M18 170 Ft – Lbs 240 Ft – Lbs 290 Ft – Lbs

NOTICE TO DEALER AND VEHICLE OWNER

Any vehicle equipped with any Warrior product should have a “Warning to Driver” decal installed on the inside of the windshield

or on the vehicle’s dash. The decal should act as a constant reminder for whoever is operating the vehicle of its unique handling

characteristics.

INSTALLING DEALER - it is your responsibility to install the warning decal and forward these installation instructions on to the

vehicle owner for review. These instructions should be kept in the vehicle for its service

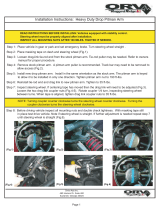

INSTALLATION INSTRUCTIONS

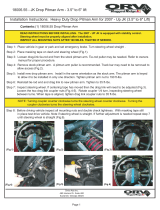

1. The front-end components are installed first.

2. Place the vehicle on a level surface. Set the parking brake. Center front wheels and chock rear wheels. From inside the engine

compartment, remove the upper stud nut, retainer and grommet form both of the front shocks Jack up the vehicle and place

jack stands on the frame rail behind the lower control arm mount on the frame. Installation is done one end at a time.

3. Remove the front tires and wheels.

4. Place a floor jack underneath the axle for support and complete the removal of the front shock absorbers (DO NOT REUSE

THE ORIGINAL SHOCK ABSORBERS).

5. Remove the track rod from the axle housing and secure out of the way. Save the bolt and flag nut they will be reused in a later

step. Remove both of the front sway bar end links.

6. Remove the brake calipers and secure out of the way.

7. Mark the position of the lower control arm cam bolt and axle brackets for installation reference. (See Figure #1) If equipped

with ABS brakes, Remove the sensor wires and clamps for the inside of the lower arms and save clamps for re-use.

8. Remove the coil spring clip located on the bottom coil seat on both sides of the vehicle. Lower the axle and remove the coil

spring. A coil spring or strut compressor may be needed to remove the stock coil spring.

9. Install the coil spring. A coil spring or strut compressor will be needed for the new coil spring installation. Compress the

new coil spring to 16” in length. Install the new spring into the upper and lower spring pockets and carefully remove the

compressor. Make sure the coil is seated properly in the coil seat by rotating the spring so the pig tail end fits in the spring

pocket. Install the coil spring clamp and torque the spring clip bolt to 16ft.-lbs.

10. Repeat steps on other side.

11. Assemble the boots on the front shock absorbers, part #60506 and install in the factory lower mounts. Install the upper stud

bushings and tighten the upper mounting point. Tighten the bar pin on the bottom of the shock with the stock hardware.

Repeat this on the opposite side of the vehicle. Install the tires, wheels and lug nuts. Lower the vehicle to the ground.

12. Align the reference marks on the adjustment cams and lower arm axle brackets and tighten to 85 ft. lbs.

Note: Longer brake lines are not required in the front with this kit unless the sway bar is disconnected. If disconnects are used,

longer brake lines are required. Install tires and wheels.

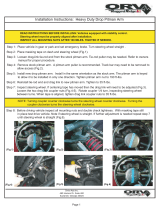

13. Chock the front wheels. Jack up the rear of the vehicle and remove the tires and wheels. Place jack stands on the frame rail

to support the vehicle. Place a floor jack under the differential. Remove the stock shock absorbers and sway bar links. Retain

the factory shock hardware it will be reused.

14. On the rear of the vehicle unbolt the track rod from the axle and secure out of the way.

15. Carefully lower the axle with the floor jack and remove the coil springs. NOTE: It may be necessary to use a coil spring or

strut compressor to remove the stock coil springs. Be careful not to overextend the vent tube on the axle. It may be

necessary to disconnect the hose during installation and reroute the hose after installation.

16. Install the new Warrior coil springs making sure that the rubber damper is positioned in the upper mount. It will be necessary

to use a coil spring or strut compressor to install the new coil springs. Jack up the axle to compress the coil spring and to align

the track rod with the new mounting point and install the stock mounting hardware.

17. Assemble shock # 60507 with the shock bushings and sleeves in the shock bag on the larger barrel end. Install the shocks on

the vehicle with the factory hardware.

INSTRUCTION SHEET

Technical Assistance - (888) 220-6861 Page 3

18. Reinstall the wheels, tires. Lower the vehicle to the ground and tighten the lug nuts to the factory torque specifications (80-

110 ft-lbs.)

19. Tighten lower arm pivot bolts to 130 ft. lbs and the track bar mounting bolts to 74 ft. lbs.

20. A brake line bracket is supplied with this kit for the rear of the vehicle. Remove the brake line at the frame mount. Do not

remove the rubber line from the steel line. This will cause the brakes not to function properly unless the lines are bled. Mount

the bracket to the factory location with the supplied hardware and tighten. Place the factory line at the other end of the bracket

in the slotted hole.

21. To install the transfer case, place the transmission in neutral and place a floor jack under the transmission mount skid plate to

support it.

22. Slightly loosen the bolts on the transfer case skid plate on both sides to allow for some movement. Do not remove the bolts.

23. Proceed to other side. NOTE: Do not attempt to take out the bolts on both sides simultaneously. Installation is done one side

at a time. Remove the three bolts holding the transfer case skid plate to the frame rail.

24. Using the floor jack, slightly lower the skid plate and insert the six transfer case spacers.

25. Using the bolts and conical washers supplied with the kit slightly tighten the bolts. Do not fully tighten to allow for some

movement for the opposite side. Conical end of the washer must fit over the mounting hole in the cross-member.

26. After installing both sides, tighten bolts to 45ft lbs.

27. Center the steering wheel and mark the position of the original pitman arm. Remove the nut and washer from the steering

gear box.

28. Remove the pitman arm from the steering gear with a pitman arm puller.

29. Align and install new pitman arm on the steering gear shaft. Install the washer and nut. Tighten to 185 ft. lbs.

30. Install the drag link ball stud to the pitman arm. Install the nut and tighten to 60 ft lbs. Install a new cotter pin.

POST INSTALLATION INSTRUCTIONS

1. Check all fasteners for proper torque. Check to ensure there is adequate clearance between all rotating, mobile, fixed and

heated members. Check steering gear for interference and proper working order. Test brake system.

2. Readjust headlamps. Have the vehicle aligned to the following specifications:

Adjustment Preferred Range

Caster 7° ± 1°

Camber - 0.25° ± .63°

Toe In (each wheel) 0.15° ± .15°

Thrust Angle 0° ± .15°

3. Perform steering sweep. Check to ensure brake hoses have sufficient slack and will not contact rotating, mobile, or fixed

members, adjust lines/brackets to eliminate interference and maintain proper working order. Failure to perform inspections

may result in component failure.

4. Re torque all fasteners after 500 miles. Visually inspect components and re torque fasteners during routine vehicle service.

MAINTENANCE INFORMATION

It is the ultimate buyers responsibility to have all bolts/nuts checked for tightness after the first 100 miles and then every

1000 miles. Wheel alignment, steering system, suspension and driveline systems must be inspected by a qualified professional

mechanic at least every 3000 miles. PARTS LIST

FRONT COIL SPRINGS TRANSFER CASE SPACER

KIT FRONT SHOCK Black Shock Boots (4)

800001 800029 60506 (2) Boot Ties (4)

Installation Instructions

REAR COIL SPRINGS REAR SHOCK TJ Shifter Linkage Brkt

800002 60507 (2)

-

1

1

-

2

2

-

3

3

Warrior Products 30841 Installation guide

- Type

- Installation guide

- This manual is also suitable for

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

Warrior Products 30840 Installation guide

Warrior Products 30840 Installation guide

-

Warrior Products 30740 Installation guide

Warrior Products 30740 Installation guide

-

Warrior Products 30631 Installation guide

Warrior Products 30631 Installation guide

-

Warrior Products 1770 Installation guide

Warrior Products 1770 Installation guide

-

Warrior Products 897 Installation guide

Warrior Products 897 Installation guide

-

Warrior Products 30630 Installation guide

Warrior Products 30630 Installation guide

-

Warrior Products 30930 Installation guide

Warrior Products 30930 Installation guide

-

Warrior Products 1750 Installation guide

Warrior Products 1750 Installation guide

-

Warrior Products 90710 Installation guide

Warrior Products 90710 Installation guide

-

Warrior Products 30640 Installation guide

Warrior Products 30640 Installation guide

Other documents

-

Skyjacker TCL35 Installation guide

-

DayStar KJ09152BK Installation guide

DayStar KJ09152BK Installation guide

-

Teraflex 4627400 Installation guide

Teraflex 4627400 Installation guide

-

Rough Country 68530 Installation guide

Rough Country 68530 Installation guide

-

Rough Country 4in Suspension Lift Kit Installation guide

Rough Country 4in Suspension Lift Kit Installation guide

-

Rugged Ridge 18006.55 Installation guide

Rugged Ridge 18006.55 Installation guide

-

Rugged Ridge 18006.50 Installation guide

Rugged Ridge 18006.50 Installation guide

-

Rough Country 69620 Installation guide

Rough Country 69620 Installation guide

-

Rough Country 1126 Installation guide

Rough Country 1126 Installation guide

-

Rough Country 6in Suspension Lift Kit Installation guide

Rough Country 6in Suspension Lift Kit Installation guide