Page is loading ...

General Information: Many Artizan Free-standing Sterilization Centers are custom de signed

and b uilt to the customers spec ifications using our standard sterilization modules. Follow

these general ins truction s using your specific order drawings to properly erect your steriliza-

tion center.

Customer Service and Technic al Support:

8:00 AM to 5:0 0 PM central (M-Th)

8:00 AM to 4:3 0 PM central (Fri)

Phone: 800-257-7407 or 270-651-7407

Fax: 270-651-1732

INSTAL LATION AND CUSTOMER CARE

INFORMATION FOR SC96- 200

FREESTANDING STERIL IZATION CENTERS

INDEX

GENERAL DESCRIPTION OF CABINET SE CTIONS

PAGE 3 Parts List

PAGE 4 Assembling the base cabinets

PAGE 5 Attaching side and back walls

PAGE 6 Installing upper ca binets

PAGE 7 Installing task lights and service pan el

PAGE 8 Installing counter top and sink

PAGE 8 Assembling the sterilizer tower

PAGE 9 Installing toe-kick /

Locating wired circuits

PAGE 10 Finalizing Installation

PAGE 11 Solid su rface c are and maintenanc e

PAGE 12-16 Circuit diagrams

PAGE 17 Hardware ad justments

PAGE 18-22 Airglide™ pa rts and schematics

TABLE TOP

OR OPTIONAL

REC ESSED

ULTRASONIC

AUTOCLAVE

STATIM

4.00

5.00

12.00

4.00

4.00

9.00

9.00

TIMER

11.00

21" RECESSED

TASK LIG HT

21" RECESSED

TASK LIGHT

Upper Wall Cabinets

Base Cabinet s

Service Panel

Sterilizer

Tower

page 2

S C96-200

Free-standing S ter il ization

- PARTS LIST -

PAGE 3 OF 22

Note - Parts may vary according to cabinet configuration

Note - Parts NOT shown ac tual size

20 - Leg Levelers

SKU# H8480

4 - #6 X 1" Black Wood Screw

SKU# S19100

48 - 1/4-20 X 1 1/ 4" Machine Screw

SKU# S19151

48 - Finish Washers

SKU# S16914

22 - Connecting Screws

SKU# S19072

22 - Connecting Sleeves

SKU# S19073

16 - Euro Screws

SKU# 19000

8 - #6 X 1 5/8" Black Wood S cre w

SKU# S19102

85 - #6 X 3/4" Wood S cre w

SKU# S19027

page 3

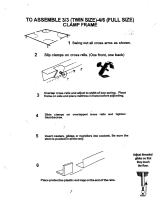

CLAMPS

Free-standing Sterilization

- Step #1 Assembling The Base cabinets -

LEVELING

ATTACHING CABINETS TOGETHER

USING CONNECTING SCREWS

2. Hold or clamp the front edges together

and using th e through holes located at

the top and botto m near the face of the

cabinets insert one end of the con necting

screw into the h o le and tap lightly with a

hammer until seated against side wall.

Thread the oth e r end into the adjacent

hole an d tighten using a phillips tip in a

cordless screwgun or drill. Repeat with the

through holes near the rear of the cabinet.

INSTALLING LEG LEVELERS

1. Remove all doors and

drawers from cabinets.

Check the floor area with

a 4 foot level and determine

the amount of fall. Lay the

first cabinet on its back and

tap legs in with a hammer.

Pre-adjust legs to 5 1/8" -

5 1/4". Stand the first cabinet

and set upright. Repeat the

process with the next cabinet

and level it next to the first

cabinet.

Note - See page 17 for proper

drawer removal procedure.

3. Continue setting and leveling

cabinets using a 4 foot level.

Check the ent ire run of cabinets

after assembling. Make sure all

legs are touching the floor and

optimally are bearing an equal

portion of the weight.

Note - legs can be adju sted

either by turning from the

outside or by removing the

white cover cap and using

a narrow flat blade screwdriver

from inside the cabinet and

through the center of t he leg.

5 1/8" - 5 1/4"

Right Side View

Back of Cabinet

FLOOR

4. Assemble base cabinets together us ing the layout shown in your drawing.

PAGE 4 OF 22

page 4

1 1/4“ x 1/4” x #20

flathead machine

screws and finish

washers.

3/4" Wood Screws

Note:

Back panels

rest onto

extended base

cabinet

bottom panels.

Note:

Back and side wall panels

are held toget he r at the top

end by the attachment of the

upper wall cabinets in the next

step.

2. Att ach all back panels to base cabinets using

1 1/4“ x 1/4” x #20 flathead machine screws and

finish washers.

3. Sec ure the back wall pane ls t ogether by attaching

the wall cabinet hang rail using 3/4" wood screws.

Free-standing Sterilization

- Step #2 Attaching Side and Back Wa lls -

1. Att ach the side wall to the base cabi-

nets u sing 1 1/4“ x 1/4” x #20 flathead

machine screws and finish washers.

Note - Side walls o verlap the back o f the

base cabinets by approximately 3/4".

PAGE 5 OF 22

CONTOURED

SIDE WALL

PANEL

page 5

PAGE 6 OF 22

INTERNAL ADJUSTMENT ARMS

2. Align cabinets together

using adjustme nt arms and

secure with co nnecting s crews

provided.

HANGING CABINETS

ATTACHING CABINETS TOGETHER

CLAMPS

1. Hang all uppers onto rail and

secure one end cabin et to side

wall using 1 1/4" flathead screws

and finish washers.

1 Extend the ad justment arm

outward enough to easily catch

the top of the rail by turning the

bottom screw counterclockwise.

Adjustmen ts:

A - Top Screw - Up/Down

B - Bottom Screw - In/Out

Important Note:

Do not over-tighten adjustment

screws.

3. Hold or clamp the front edges together and using

the throu gh holes located at the top and bottom near

the face of th e cabinets inser t one end o f the con-

necting screw into the hole and tap lightly with a

hammer until seated against side wall. Thread t he

other end into the adjacent hole and tighten using a

phillips tip in a cordless screwgun or drill. Repeat

with the through holes near the rear of the cabinet.

A

B

page 6

PAGE 7 OF 22

Wire Raceway

The Service Panel is

designe d to provide a

hidden chase for wires to

run behind cabinets.

2. Install service panel/s into notch on top

of bas e cabinets and snap into clips

mounted underneath upper wall cabinets.

Be sure to leave task lights in front of ser-

vice panels.

SERVICE PANEL

1. Run task light wires downward into

the floor of the sink compartment. DO

NOT attach task lights at this time.

3. Att ach task lights to bottom of wall cabinets.

page 7

PAGE 8 OF 22

1. Atta ch the countertop using 1 5/8“

screws for base cabinets with a wood

top pane l and 1” wood screws for

sink base cabinets with L-brackets.

Note - if a laminate counter top is

supplied, Apply silicone sealer to

the unde r-side of sink flange prior

to mounting.

- Step #6 Assembling t he Sterilizer Tower -

1. Assemble t he tower

using the s ame p roce-

dure utilized in the

past st eps.

2.Attach th e Sterilizer

slide ou t shelves to

the side walls using

the su pplied e uro

screws.

3. Att ach the Sterilizer

tower to the other

assembled cabinet s

using 1 1/4" x 1/4" x

#20 flathead m achine

screws and finish

washers.

Note - Side walls o ver-

lap the back of the

base cabinets by

approximately 3/4".

1 5/8“

wood

screws

1 5/8“

wood screws

1“

wood screws

Sink Base

1 5/8“

wood screws

page 8

PAGE 9 OF 22

1. Lay the toe-board face down in front of attached levelers with

notch facing away from legs. Align plastic receivers with each

leg and tap into the continuous notch o n back sid e of

toe-board. Inst all metal leg clips into receivers. St and to e-

board up-right and tap lightly on face until clips snap against

legs.

Notch Facing

away from legs

Plastic Receivers

with Metal clip

All wires s hould termina te at the floor of the sink ba se and connections made by a licens ed

electricia n in conjunction with loc al wiring codes.

ELECTRICAL

TABLE TOP

OR OPTIONAL

RECES SED

ULTRASONIC

LIGHT

CIRCUIT

ULTRASONIC

STERILIZER

1

STERILIZER

2

120V

20A

STERILIZER

1

STERILIZER

2

LIGHT

CIRCUIT

ULTRASONIC

120V

20A

120V

20A

120V

20A

ELECTRICAL

page 9

Reinstall all drawers and d oors removed in the first step. Install s helf pegs and insert shelving

into appropriate compartm ents. Ma ke final hinge adjustments.

Note - Drawers are numbered starting at the top a nd run downward to insure they are returned

to the same position.

PAGE 10 OF 22

Note: See pages 19- 22 for installati on of optional Pneumatics

TABLE TOP

OR OPTIONAL

RECES SED

ULTRASONIC

AUTOCLAVE

STATIM

4.00

5.00

12.00

4.00

4.00

10.00

10.00

TIMER

9.00

21" RECESSED

TASK LIGHT

21" RECESSED

TASK LIG HT

OPTIONAL

TAPMAST ER FAUCET

FOOT CONTROL

OPTIONAL AIRGLIDE

KICK OPEN UPPER

CABINET DOORS AND

WASTE MODULE

page 10

PAGE 11 OF 22

S olid Surface Care & Maintenance

CARE AND MAINTENANCE

Caring for your Wilsona rt Gibraltar Solid Surface countertop or surface is as simple as wiping th e surface

with a damp cloth. If a stain develops, wipe it away with so ap and water. Or if you prefer wipe it clean with

Windex.

If a stain doesn’t resp ond to soap and water, for a matte finish, apply an abrasive cleanser and buff with a

Scotch-Brite pad using a circular motion. The same te chnique can be used for ciga rette burns.

If you hav e a gloss finish, p lease contact your dealer or fabricator before attempting repairs.

For minor cuts and scratches, simply sand lightly with a medium (220 grit) sandpaper, the n follow with a

fine (320 grit) sandpaper. Finally, touch up the finish by buff ing with a Scotch -Brite pad.

PRECAUTIONS

Do not expose the surface to harsh chemicals, such as paint remover, turpentine, nail polish remover or

stove and drain cleaners. If these chemicals come in contact with the surface, immediately wash them off

with water, u sing appropriate safety measures to avoid injury.

Always use a cutting board instead of cutting directly on the surface. While mino r cuts and sc ratches can

be repaired, care should be take n to prevent them in order to keep the surface looking as good as new.

page 11

PAGE 12 OF 22

Circuit Dia gra ms

PREFABRICAT ED DENTAL ASSEM BLY

FILE #E231530

Hospit al Grade / R edundant Ground

page 12

HOSPITAL GRAD E

DUPLEX

RECEP TACLE

STERILIZER #1

+ BLACK

(HOT)

GREEN INSULATED

GROUNDING WIRE

DUAL STERILIZER RECEPTACLE

SEPARATE CIRCUITS (SAME BOX)

WIRING DIAGRAM ITEM #EL-280

Mark for sterilizers 1 & 2

STERILIZER #2

HOSPITAL GRAD E

DUP LEX

RECEP TACLE

+ BLACK

(HOT)

ROUGH-IN BOX

RATED

120VOLT 20 AMP

CIRCUIT

ROUGH-IN BOX

RATED

120VOLT 2 0 AMP

CIRCUIT

PAGE 13 OF 22

page 13

SINGLE POLE

SWITCH

HOSPITAL GRADE

GFCI (GROUND FAULT)

RECEPTACLE

FLORESCENT LIGHT FIXTURE

GREEN INSULATED GROUNDING WIRE

FREE-S TANDING STERILIZATION

WIRING DIAGRAM ITEM #EL-250

LIGHT CIRCUIT SINK AREA (STANDARD)

TASK LIGHT

MOUNTED UNDERNEATH

UPPER CABINET

DEDICATED LIGHT CIRCUIT

120VOLT, 20 AMP

12-2 WIRE

LABEL

ROUGH-IN BOX

RATED 20 AMP

CIRCUIT

PAGE 14 OF 22

page 14

HOSPITAL GRADE

GFCI DUPLEX

RECEPTACLE

GFCI

RECEPTACLE

GREEN INSULATED GROUNDING WIRE

FREE-S TANDING STERILZATION

WIRING DIAGRAM ITEM #2 12

DUAL RECEPTACL E CIRCUIT SINK AREA (OPTIONAL)

ROUGH-IN BOX

RATED 20 AMP

CIRCUIT

REGULAR

RECEP TACLE

HOSPITAL GRADE

DUPLEX

RECEPTACLE

COMBINE WITH

LIGHT CIRCUIT ITE M #EL-240

120VOLT, 20 AMP

12-2 WIRE

LABEL

PAGE 15 OF 22

page 15

HOSPITAL GRADE

GFCI DUPLEX

RECEPTACLE

GREEN INSULATED GROUNDING WIRE

FREE-S TANDING STERILZATION

WIRING DIAGRAM ITEM #220

ULTRASONIC RECEPTACLE CIRCUI T (OPTIONAL)

ROUGH-IN BOX

RATED 20 AMP

CIRCUIT

REGULAR

REC EPTACLE

DEDICATED ULTRASONIC

120VOLT, 20 AMP

12-2 WIRE

LABEL

PAGE 16 OF 22

page 16

Drawer Installation

A) Fully extend drawer glides from the cabinet. (Optional)

B) Place the drawer on the glides.

C) Push the drawer in completely.

D) Cycle drawer a couple times to ensure that the drawer is

securely attached to the glides.

Drawer Removal

A) Open drawer completely.

B) Lift up on the drawer front until the front of the box releases from the glide.

C) Pull out on the drawer slightly.

D) Lower the drawer back down while pulling out on the drawer.

Drawer Front Adjustment and Removal

1) Remove the cover caps on the drawer side by hand.

2) Height Adjustment: Rotate in either direction to adjust the drawer front vertically.

3) Tilt Adjustment: Adjust after the drawer front is installed to ensure the drawer sides meet

square with the drawer front. (Only available on large drawer boxes.)

4) Side Adjustment: Adjusts the drawer front horizontally. Turn in either direction.

5) Tension/Removal: For large drawers, turn the screw toward the front of the drawer until the

front detaches from the box. Repeat this procedure on both sides of the drawer. For small

and medium drawer boxes, turn the screw toward the back of the drawer to remove the

front.

Drawer Removal, Installation and Adjustment

Removal

A) Extend the glide to its outermost position.

Push the release levers in and remove the

drawer member of the sides.

Full Extension Glide Removal & Installation...

PUSH

PULL

Cabinet Member

Drawer Member

Installation

A) Line up the drawer member to the cabinet

member and push the drawer into its

compartment.

A

B

C

D

GA1106

GA1107

4

5

32

GA1105

A

B

C

Hinge 1 & 2 Adjustment

Direction Guide

Hinge 1 & 2 Adjustments

Use a phillips head screw driver for the following steps...

A) Screw A adjusts the door in direction A seen in the

Adjustment Direction Guide

B) Screw B adjusts the door in direction B. Equal

adjustment must be made to all hinges on the door for it

to move the desired distance.

C) Screw C adjusts the door in the C direction. Make

adjustments to top and bottom hinge as necessary.

Note: Use a level to ensure the door is level and plumb. Preferred gaps are

approximately 1/8” between doors and 1/16” between accents and doors.

180° Hinge Adjustments

D) Loosen screw D and adjust door gap

and angle using a level. Tighten screw D

when positioned correctly,

180° Hinge

D

Hinge 1 & 2 Removal

E) Press button at point E at the back of

the hinge and pull away from cabinet.

Door Removal, Installation, and Adjustment

B

C

A

Hinge 1

E

Hinge 1, 2, & 3 Installation

F) Hook the hinge to the mounting block at

point F

G) Latch at point G by pressing the hinge

against the hinge block.

F

G

Hinge 2

A

B

C

E

GA1044

BE

CA

Hinge 3

Soft Close

Switch

Door

Removal

PAGE 18 OF 22

ARTIZAN

page 18

PAGE 19 OF 22

page 19

/