Copyright HK Instruments 2022 www.hkinstruments. Installaon version 9.0 2022

INSTALLATION

INSTRUCTIONS

AIR FLOW AND VELOCITY TRANSMITTERS

DPT-Flow Series

• READ THESE INSTRUCTIONS CAREFULLY BEFORE

ATTEMPTING TO INSTALL, OPERATE OR SERVICE THIS

DEVICE.

• Failuretoobservesafetyinformaonandcomplywith

instruconscanresultinPERSONALINJURY,DEATHAND/OR

PROPERTY DAMAGE.

• Toavoidelectricalshockordamagetoequipment,disconnect

powerbeforeinstallingorservicinganduseonlywiringwith

insulaonratedforfulldeviceoperangvoltage.

• Toavoidpotenalreand/orexplosiondonotuseinpotenally

ammableorexplosiveatmospheres.

• Retaintheseinstruconsforfuturereference.

• Thisproduct,wheninstalled,willbepartofanengineered

systemwhosespecicaonsandperformancecharacteriscs

arenotdesignedorcontrolledbyHKInstruments.Review

applicaonsandnaonalandlocalcodestoassurethatthe

installaonwillbefunconalandsafe.Useonlyexperiencedand

knowledgeabletechnicianstoinstallthisdevice.

ThankyouforchoosinganHKInstrumentsDPT-Flowseriesairow

transmier.TheDPT-Flowseriesisintendedforuseincommercial

environments.TheDPT-Flowmeasuresairow,velocityanddier-

enalpressure.Itisdesignedtobeusedincombinaonwithairow

measuring probes (i.e. FloXact), dampers or with centrifugal fans

thatprovidedierenalpressureconneconsandK-values.

TheDPT-FlowseriesofairowtransmiersiscomprisedofDPT-

Flow-1000, DPT-Flow-2000, DPT-Flow-5000 and DPT-Flow-7000

withmeasurementrangesof0–1000Pa,0–2000Pa,0–5000Paand

0–7000Parespecvely.Allmodelscomewithdisplayandmanual

pushbuon zeropoint calibraon. Oponal autozero calibraonis

also available.

DPT-FlowseriesdevicesarecommonlyusedinHVAC/Rsystemsfor:

•airowmonitoringacrosscentrifugalfansandblowers

•in-ductairowmonitoring

•VAVapplicaons

SPECIFICATIONS

Performance

Accuracy (from applied pressure):

Models1000and2000:

Pressure<125Pa=1%+±2Pa

Pressure>125Pa=1%+±1Pa

Models5000and7000:

Pressure<125Pa=1.5%+±2Pa

Pressure>125Pa=1.5%+±1Pa

(Accuracyspecicaonsinclude:generalaccuracy,

linearity,hysteresis,longterm

stability,andrepeonerror)

Overpressure:

Proofpressure:25kPa

Burstpressure:30kPa

Zero point calibraon:

Automacautozeroor

manualpushbuon

Response me:

1.0−20s,selectableviamenu

Technical Specicaons

Media compability:

Dryairornon-aggressivegases

Pressure units (select via menu):

Pa,kPa,mbar,inWC,mmWC,psi

Pressure output scale (select via menu):

Measuring element:

MEMS,noow-through

Environment:

Operangtemperature:-20...50°C,

-40Cmodel:-40...50°C

Modelswithautozerocalibraon:-5...50°C

Temperaturecompensatedrange0…50°C

Storagetemperature:-40...70°C,

Humidity:0to95%rH,noncondensing

Physical

Dimensions:

Case:90.0x95.0x36.0mm

Weight:

150g

Mounng:

2each4.3mmscrewholes,onesloed

Materials:

Case:ABS

Lid:PC

Protecon standard:

IP54

Display

2-linedisplay(12characters/line)

Line1:Volumeorvelocitymeasurement

Line2:Pressuremeasurement

Size:46.0x14.5mm

Electrical connecons:

4-screwterminalblock

Wire:0.2–1.5mm2(16–24AWG)

Cable entry:

Strainrelief:M16

Knockout:16mm

Pressure ngs

Maleø5.0mmand6.3mm

Electrical

Voltage:

Circuit:3-wire(VOut,24V,GND)

Input:24VACorVDC,±10%

Output:0–10V/2-10V,selectableviajumper

Powerconsumpon:<1.0W

-40Cmodel:<4.0Wwhen<0°C

Resistanceminimum:1kΩ

Current:

Circuit:3-wire(mAOut,24V,GND)

Input:24VACorVDC,±10%

Output:4–20mA,selectableviajumper

Powerconsumpon:<1.2W

-40Cmodel:<4.2Wwhen<0°C

Maximumload:500Ω

Minimumload:20Ω

Conformance

Meetsrequirementsfor:

CE: UKCA:

EMC: 2014/30/EU S.I.2016/1091

RoHS: 2011/65/EU S.I.2012/3032

WEEE: 2012/19/EU S.I.2013/3113

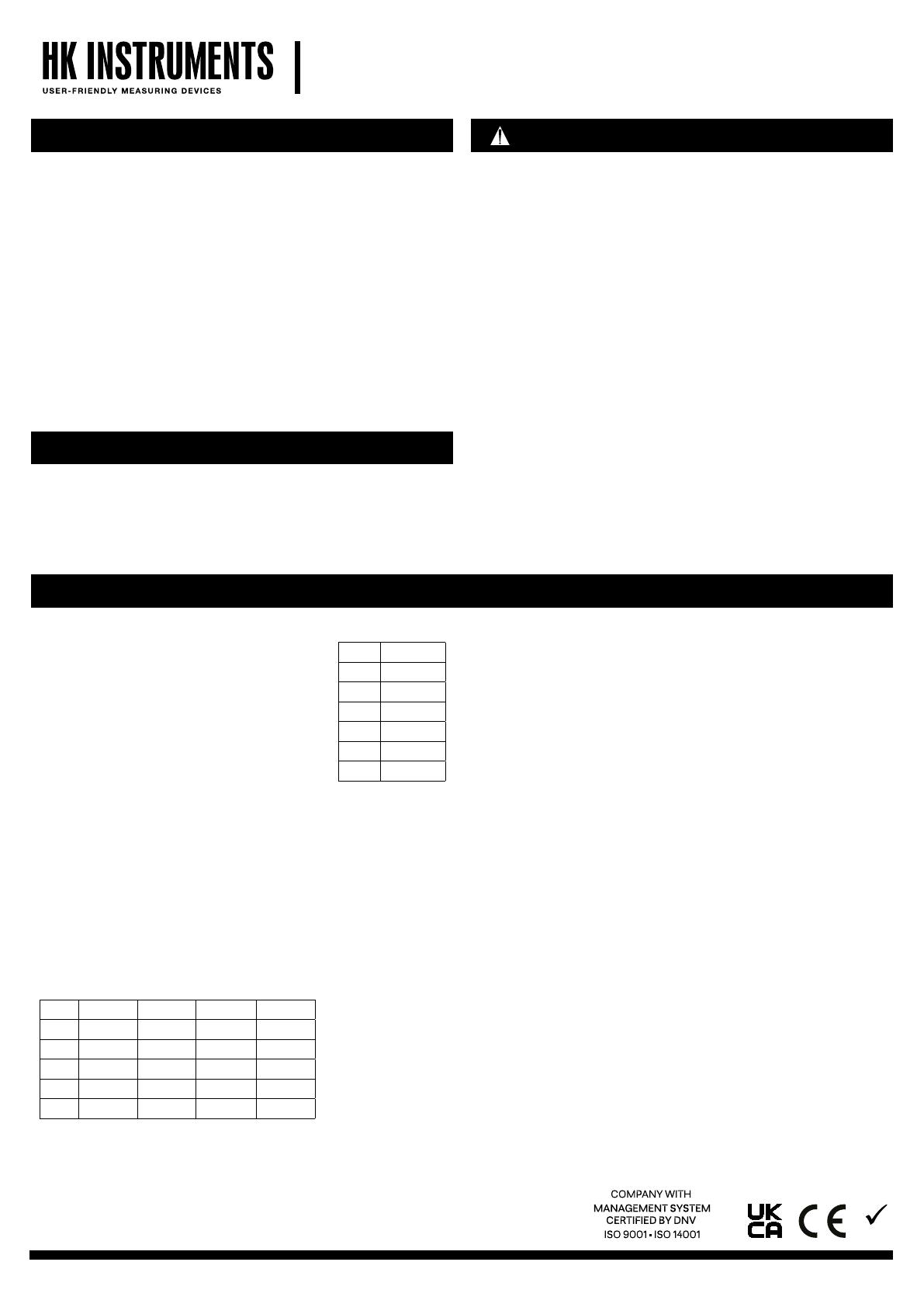

DPT-Flow-1000

DPT-Flow-

2000 DPT-Flow-5000 DPT-Flow-7000

Pa 100-1,000 200-2,000 500-5,000 700-7,000

kPa 0.1-1.0 0.2-2.0 0.5-5.0 0.7-7.0

mbar 1-10 2.0-20 5.0-50 7. 0-70

mmWC 10-100 20-200 50-500 70-700

inWC 0.4-4.0 0.8-8.0 2.0-20 2.5-30

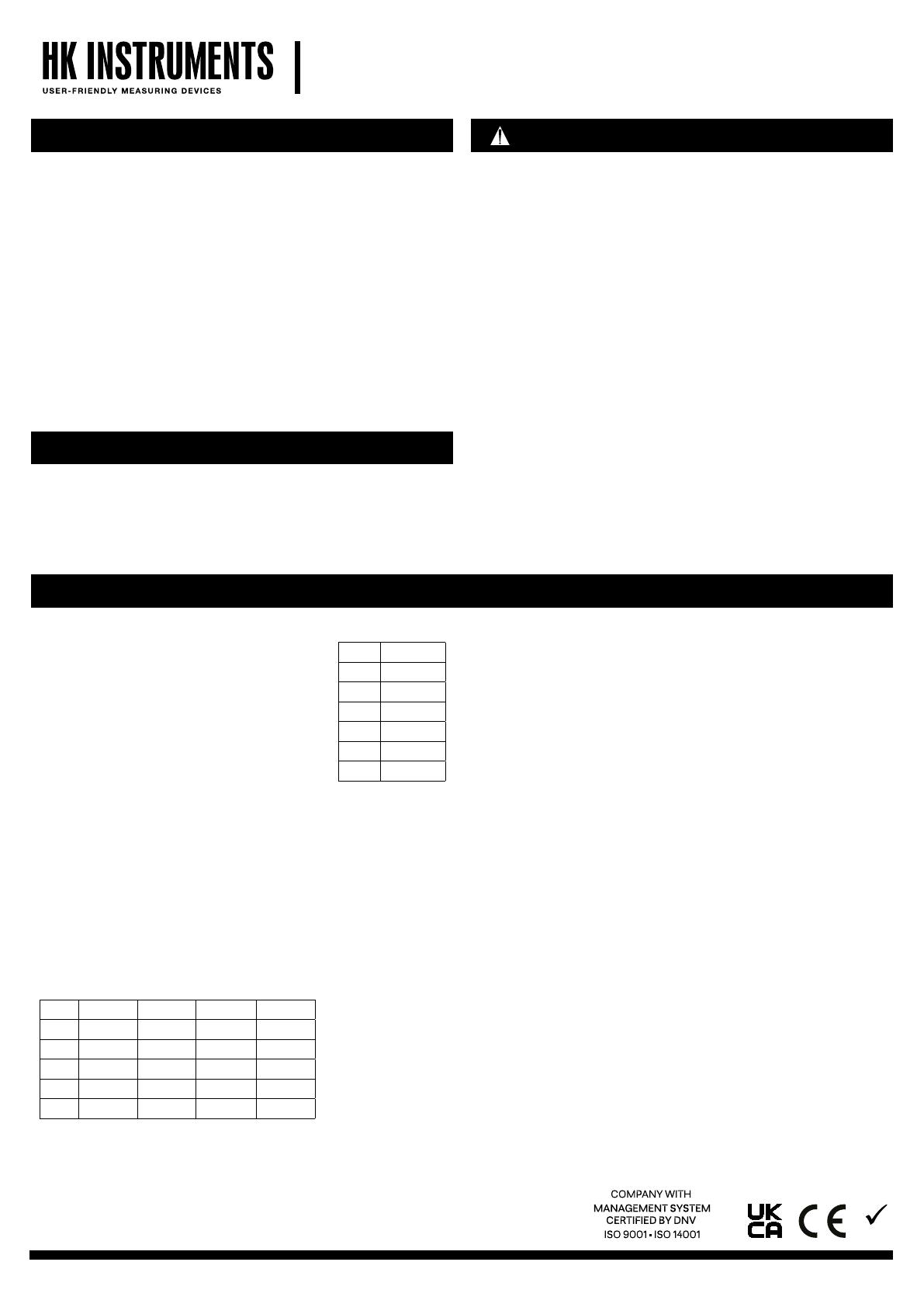

Flow output scale (select via menu):

Units Range

m3/s 0.025-50

m3/hr 100-200,000

cfm 50-100,000

l/s 25-50,000

m/s 1-100

f/min 200-20,000

APPLICATIONS

INTRODUCTION WARNING

RoHS

Flow units (select via menu):

Volume:m3/s,m3/hr,cfm,l/s,none

Velocity:m/s,/min