1

Visit our website at http://watt-age.globalhobby.com for information on other Wattage products

The Wattage Tubby Cubby EP is distributed exclusively by Global Hobby Distributors 18480 Bandilier Circle, Fountain Valley, CA 92728

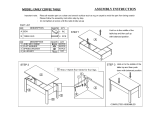

INSTRUCTIONS FOR FINAL ASSEMBLY

FOR YOUR INFORMATION

To make your modeling experience totally enjoyable, we recommend that you get experienced, knowledgeable help with

assembly and during your first flights. Your local hobby shop has information about flying clubs in your area whose

membership includes qualified instructors. If there is no hobby shop in your area, we recommend that you contact the

AMA at the address below. They will be able to help you locate a flying field near you.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie IN 47302-9252

(800) 435-9262

www.modelaircraft.org

Specifications:

●●

●●

●

Wing Span: 37 Inches

●●

●●

●

Wing Area: 250 Square Inches

●●

●●

●

Length: 24.5 Inches

●●

●●

●

Weight RTF: 10 - 11.5 Ounces

●●

●●

●

Functions: Elevator, Rudder & Throttle

●●

●●

●

Power: 370 Motor w/3.7:1 Gear Box

●●

●●

●

Radio: 3 Channel Micro System w/2 Micro Servos

Product Part Number 128436

All contents copyright © 2002, Global Hobby Distributors Version V1.0 January 2002

2

Need help or have any questions? Call us at 1-714-963-0329 or send us an email to service@globalhobby.net

TABLE OF CONTENTS

This R/C airplane is not a toy! If misused or abused, it can cause serious bodily injury and/or damage to property. Fly only

in open areas and preferably at a dedicated R/C flying site. We suggest having a qualified instructor carefully inspect your

airplane before its first flight. Please carefully read and follow all instructions included with this airplane, your radio

control system and any other components purchased separately.

SAFETY WARNING

OUR GUARANTEE

Wattage guarantees this kit to be free from defects in both material and workmanship, at the date of purchase. This does

not cover any component parts damaged by use, misuse or modification. In no case shall Wattage's liability exceed

the original cost of the purchased kit.

In that Wattage has no control over the final assembly or material used for final assembly, no liability shall be assumed

for any damage resulting from the use by the user of the final user-assembled product. By the act of using the final user-

assembled product, the user accepts all resulting liability.

Safety Warning ..........................................................................................................2

Introduction ...............................................................................................................3

Section 1: Our Recommendations ....................................................................4

Section 2: Kit Contents .....................................................................................5

Section 3: Tools and Supplies Required ...........................................................6

Section 4: Metric Conversion Chart .................................................................6

Section 5: Replacement Parts............................................................................7

Section 6: Fuselage Assembly...........................................................................7

Section 7: Stabilizer Installation .......................................................................9

Section 8: Gear Box & Landing Gear Installation .........................................12

Section 9: Cowling & Propeller Installation ...................................................14

Section 10: Elevator & Rudder Control System Installation.........................16

Section 11: Wing Assembly & Installation....................................................19

Section 12: Final Assembly............................................................................24

Section 13: Balancing the Tubby Cubby EP..................................................26

Section 14: Control Throws ...........................................................................27

Section 15: Preflight Check & Safety ............................................................27

Section 16: Flying the Tubby Cubby EP........................................................29

Section 17: Glossary of Terms .......................................................................29

Product Evaluation Sheet........................................................................................31

3

Visit our website at http://watt-age.globalhobby.com for information on other Wattage products

INTRODUCTION

Thank you for purchasing the new Wattage Tubby Cubby EP. Before completing the

final assembly of your new airplane, please carefully read through this instruction

manual in its entirety. Doing so will ensure your success the first time around!

Wattage Tubby Cubby EP Features:

●

Compact, Lightweight Design for Small Field Flying

●

Slow, Forgiving Flight Characteristics

●

Molded Foam Construction

●

Preassembled 370 Size Motor and 3.7:1 Gear Box

●

Prepainted Molded Plastic Cowling & Wing Mount

●

Fiberglass Wing Spars for Added Strength

●

All Hardware and Decal Sheet Included

●

Quick and Easy Assembly - Over 40 Photos Included

This instruction manual is designed to guide you through the entire final assembly process of your new airplane in the

least amount of time possible. Along the way you'll learn how to properly assemble your new airplane and also learn

tips that will help you in the future. We have listed some of our recommendations below. Please read through them

before beginning assembly.

●

Please read through each step before beginning

assembly. You should find the layout very complete

and straightforward. Our goal is to guide you through

assembly without any of the headaches and hassles

that you might expect.

●

There are check boxes next to each step. After

you complete a step, check off the box. This will

help prevent you from losing your place.

●

Cover your work table with brown paper or a soft

cloth, both to protect the table and to protect the parts.

●

Keep a couple of small bowls or jars handy to put

the small parts in after you open the accessory bags.

●

We're all excited to get a new airplane in the air, but

take your time. This will ensure you build a straight,

strong and great flying airplane.

●

If you come across this symbol

☞

, it means that

this is an important point or an assembly hint.

If you should find a part missing or damaged, or have any questions about assembly, please

contact us at the address below:

Wattage Customer Service

18480 Bandilier Circle

Fountain Valley CA 92728

Phone: (714) 963-0329 Fax: (714) 964-6236 E-mail: service@globalhobby.net

4

Need help or have any questions? Call us at 1-714-963-0329 or send us an email to service@globalhobby.net

This section describes the items you will need to purchase for your new Tubby Cubby EP. These suggestions are not set

in stone, but they should provide you with a good starting point.

SECTION 1: OUR RECOMMENDATIONS

Here's what you'll need to finish the airplane:

P/N 443526 Cirrus MRX-4 FM Super-Micro Receiver

Hitec Single Conversion FM RX Crystal

P/N 444052 Cirrus CS-10 Super-Micro Servos (2)

P/N 128482 Wattage IC-5A Micro ESC

P/N 128526 Wattage 6 Cell 650Mah NiMH Flight Battery

P/N 130103 Wattage 6-8 Cell 1 amp AC/DC Peak Charger

IMPORTANT

The Tubby Cubby EP is a lightweight, slow-flying electric-powered model. When choosing accessories like servos,

ESC, and receiver, it's very important to take the weight of these items into consideration. Remember, the lighter the

overall weight of the finished airplane, the better the airplane will fly.

What Servos Do I Use?

The servos you use should be the lightest available, yet still have an adequate amount of torque. We suggest using servos

that weigh no more than 0.19 ounces and have a torque rating of no less than 7.0 ounces per square inch.

What Receiver Do I Use?

The receiver should be as light as possible, preferably 1/2oz. or less. Most four-channel micro receivers will be a good

choice. If you plan on using the Hitec 555 Micro receiver or the HAS-3MB included with the Focus 3 radio system, we

suggest removing the case to reduce the receiver's weight. If you do remove the case from your receiver we strongly

suggest wrapping the receiver with heat-shrink material to protect the internal components.

What Electronic Speed Control Do I Use?

The ESC you choose should be capable of handling 5 amps continuous current. Again, lighter is better. Your ESC should

weigh no more than 1/2 ounce including the wiring and switch.

What Flight Battery Do I Use?

For the best flight performance the flight battery used should be a 6 cell 2/3AA 270Mah NiCD or a 6 cell 5/4AAA 650Mah

NiMH. NiMH batteries don't give quite as much power, but, more importantly, they are lighter and give significantly

more flight time. We do not suggest using 7 or 8 cell flight batteries because the airplane will be heavier and may not fly

quite as well. The trade-off is not worth the minor added performance.

IMPORTANT

The part numbers listed for the Cirrus receiver, Cirrus servos and Wattage ESC are compatible with Hitec and JR (receiver

is compatible with Hitec and Futaba only) radio control systems. These items are also available with connectors that are

compatible with Futaba and Airtronics radio control systems. (MRX-4 receiver is also available for Airtronics and JR

radio systems.)

When you purchase the Cirrus MRX-4 receiver, you must also purchase a Hitec brand crystal compatible with the

receiver. The crystal must also be on the same frequency as your transmitter. Note that the Cirrus MRX-4 receiver uses

a single conversion FM Hitec crystal. A dual conversion crystal will not work with it.

Flight Battery Warning

To ensure extended battery life and the best

performance from your flight battery, the

flight battery should be charged at no more

than 1 amp. Always allow the battery to

cool before recharging. Never charge the

flight battery when it's hot.

5

Visit our website at http://watt-age.globalhobby.com for information on other Wattage products

We have organized the parts as they come out of the box for easier identification during assembly. Before you begin

assembly, group the parts like we list them below. This will ensure that you have all of the parts before you begin

assembly and it will also help you become familiar with each part. If you find any parts missing or damaged, please

contact us at the address below:

AIRFRAME ASSEMBLIES

❑ (1) Fuselage

❑ (1) Left Wing Panel

❑ (1) Right Wing Panel

❑ (1) Horizontal Stabilizer w/Elevator

❑ (1) Vertical Stabilizer w/Rudder

❑ (1) Plastic Cowling

SECTION 2: KIT CONTENTS

Wattage Customer Service

18480 Bandilier Circle

Fountain Valley CA 92728

Phone: (714) 963-0329 Fax: (714) 964-6236 E-mail: service@globalhobby.net

LANDING GEAR ASSEMBLY

❑ (1) Prebent Main Gear Wire

❑ (2) Nylon Main Gear Wheels

❑ (2) Nylon Wheel Retainers

MOTOR ASSEMBLY

❑ (1) 370 Motor w/Gear Box

❑ (1) 7.5 x 5 Propeller

❑ (1) 3mm Flat Washer

❑ (2) 3mm Hex Nuts

❑ (3) 3mm x 12mm Wood Screws

WING ASSEMBLY

❑ (1) Prebent Aluminum Tube

❑ (2) Fiberglass Dowels

❑ (2) Double-Sided Tape - Strips

❑ (1) Plastic Wing Mount

❑ (1) Plastic Wing Brace

❑ (4) Rubber Bands

PUSHROD ASSEMBLIES

❑ (2) 1.5mm x 400mm Threaded Wires

❑ (2) Nylon Control Horns w/Backplates

❑ (2) Nylon Clevises

❑ (1) Servo Mounting Board - 2 Parts

MISCELLANEOUS ITEMS

❑ (1) Fuselage Reinforcement Board - 2 Parts

❑ (1) 100mm Wooden Dowel

❑ (1) 70mm Wooden Dowel

❑ (1) 12mm Square Plywood Plate

❑ (3) 1.5mm x 4mm Wood Screws

❑ (1) Double-Sided Foam Tape

❑ (1) Velcro

®

Strip

❑ (1) Decal Sheet

6

Need help or have any questions? Call us at 1-714-963-0329 or send us an email to service@globalhobby.net

❑ Kwik Bond 5 Minute Epoxy # 887560

❑ # 0 Phillips Head Screwdriver

❑ # 1 Phillips Head Screwdriver

❑ Magnum Z-Bend Pliers # 237473

❑ Wire Cutters

❑ Needle Nose Pliers

❑ Adjustable Wrench

❑ Excel Modeling Knife # 692801

❑ Scissors

❑ Electric Drill

❑ Assorted Drill Bits

❑ Ruler

❑ Pencil

❑ Masking Tape

❑ Builder's Triangle

❑ 220 Grit Sandpaper w/Sanding Block

❑ Paper Towels

❑ Rubbing Alcohol

❑ NHP Epoxy Mixing Sticks # 864204

❑ NHP Epoxy Mixing Cups # 864205

❑ K&S 30 Watt Soldering Iron # 598120

❑ Solder

SECTION 3: TOOLS AND SUPPLIES REQUIRED

To convert inches into millimeters: Inches x 25.4 = mm

1/64" = .4mm

1/32" = .8mm

1/16" = 1.6mm

3/32" = 2.4mm

1/8" = 3.2mm

5/32" = 4.0mm

3/16" = 4.8mm

1/4" = 6.4mm

3/8" = 9.5mm

1/2" = 12.7mm

5/8" = 15.9mm

3/4" = 19.0mm

1" = 25.4mm

2" = 50.8mm

3" = 76.2mm

6" = 152.4mm

12" = 304.8mm

18" = 457.2mm

21" = 533.4mm

24" = 609.6mm

30" = 762.0mm

36" = 914.4mm

SECTION 4: METRIC CONVERSION CHART

IMPORTANT

The soldering iron and solder listed above are optional. Depending on the ESC and flight battery you have chosen to use,

they may not have plugs that are compatible with the plug that comes preinstalled on the motor. If this is the case you will

need to solder a compatible plug onto the motor or, better yet, solder the ESC leads directly to the motor.

WARNING

The Tubby Cubby EP is constructed of EPS and Closed Cell Foam. It is very important that you use no solvents,

Cyanoacrylate (C/A) glue, or paint that can damage foam. If any of these chemicals comes in contact with the

foam parts, the parts will be destroyed and will not be covered under warranty. Use only epoxy where glue is

required. If you decide to add painted details to the airplane, use acrylic-based paints and always test the paint

on a scrap piece first.

WARNING

We do not suggest storing your airplane in an extremely hot environment (like the back of your car in direct

sunlight) for any length of time. The extreme heat could cause the foam to melt and possibly damage the fragile

components of the radio system, ESC or batteries.

7

Visit our website at http://watt-age.globalhobby.com for information on other Wattage products

Wattage stocks a complete line of replacement parts for your Tubby Cubby EP. Listed below are the replacement parts

that are available along with their respective part numbers for easy ordering convenience. We suggest ordering directly

from your local dealer. If your dealer does not stock Wattage products, you can order directly from us at the address

shown below:

SECTION 5: REPLACEMENT PARTS

Global Hobby Distributors

18480 Bandilier Circle

Fountain Valley CA 92728

Phone: (714) 963-0329 Fax: (714) 964-6236

❑ Kwik Bond 5 Minute Epoxy

❑ Excel Modeling Knife

❑ 1/8" Drill Bit

❑ Paper Towels

YOU'LL NEED THE FOLLOWING PARTS:

❑ (1) Fuselage

❑ (1) Fuselage Reinforcement Board - 2 Parts

❑ (1) 100mm Wooden Dowel

SECTION 6: FUSELAGE ASSEMBLY

❑ (1) 70mm Wooden Dowel

❑ (1) 12mm Square Plywood Plate

YOU'LL NEED THE FOLLOWING SUPPLIES:

❑ Rubbing Alcohol

❑ NHP Epoxy Mixing Sticks

❑ NHP Epoxy Mixing Cups

Step 1: Applying the Fuselage Reinforcement Board

❑ Using the tip of your modeling knife, carefully remove

the die-cut circles out of the ends of both pieces of fuselage

reinforcement board.

Instruction Manual - 145368

Wing Set - 145369

Fuselage Set - 145370

Stabilizer Set - 145371

Cowling - 145372

Decal Sheet - 145373

Landing Gear Set - 145336

Pushrod & Clevis/Horn Set - 145335

Motor, Gearbox & Propeller - 145346

370 Size Motor - 131350

7.5 x 5 Propeller - 131381

Gear Box Assembly - No Motor - 131371

Gears Only for Gear Box - 131376

8

Need help or have any questions? Call us at 1-714-963-0329 or send us an email to service@globalhobby.net

☞

Look carefully at the ends of the reinforcement board.

You will notice one end is cut straight and one end is cut at an

angle. The angled end goes toward the front of the fuselage.

❑ Carefully adhere the reinforcement board to the fuselage.

To align it properly, the angled end should be lined up with

the back edge of the motor plate and the top edge should be

even with the top of the fuselage.

❑ Remove one piece of reinforcement board from its protective backing.

Step 2: Installing the Wooden Dowels

❑ Repeat the procedures above to apply the second piece of reinforcement board to the other side of the fuselage.

❑ Using a 1/8" drill bit, drill four holes through the fuselage

sides using the die-cut holes in the reinforcement board as a

guide.

☞

To prevent tearing up the foam, don't drill the holes

using an electric drill. It is better to use your fingers to

slowly twist the drill bit.

❑ Test-fit the two wooden dowels into the fuselage. The

100mm long dowel is installed through the forward holes

and the 70mm long dowel is installed through the rear

holes. Adjust both dowels so that they are centered in the

fuselage.

❑ Remove both dowels and mix a small quantity of 5 minute epoxy. Apply a thin layer of epoxy inside each of the

four holes.

❑ Slide the dowels back into place and realign them. Remove any excess epoxy using a paper towel and rubbing

alcohol, and set the fuselage aside until the epoxy sets up.

9

Visit our website at http://watt-age.globalhobby.com for information on other Wattage products

Step 3: Installing the Plywood Plate

❑ Test-fit the plywood plate to the top of the motor plate.

To align it properly, the plate should be centered from side to

side and the back edge of the plate should be even with the

back edge of the motor plate.

☞

For added strength, make sure the wood grain in the plate

is running front to back.

❑ When satisfied with the alignment, glue the plate into place using a thin layer of 5 minute epoxy. Remove any excess

epoxy using a paper towel and rubbing alcohol, and hold the plate in place until the epoxy sets up.

❑ Kwik Bond 5 Minute Epoxy

❑ Excel Modeling Knife

❑ Ruler

❑ Pencil

❑ Builder's Triangle

YOU'LL NEED THE FOLLOWING PARTS:

❑ (1) Horizontal Stabilizer w/Elevator

❑ (1) Vertical Stabilizer w/Rudder

SECTION 7: STABILIZER INSTALLATION

❑ (1) Decal Sheet

YOU'LL NEED THE FOLLOWING SUPPLIES:

❑ 220 Grit Sandpaper w/Sanding Block

❑ Paper Towels

❑ Rubbing Alcohol

❑ NHP Epoxy Mixing Sticks

❑ NHP Epoxy Mixing Cups

Step 1: Hinging the Elevator

❑ Carefully remove the die-cut horizontal stabilizer and elevator from the foam sheet.

❑ Using 220 grit sandpaper with a sanding block, carefully sand the edges of the stabilizer and elevator smooth and

straight.

❑ Using a ruler and a modeling knife, carefully cut out the clear elevator hinge from the decal sheet.

IMPORTANT

The elevator hinge is the 13" long strip with the guide marks on each end. For a more appealing look when the hinge is

applied to the stabilizer and elevator, cut out the hinge inside the black outline.

10

Need help or have any questions? Call us at 1-714-963-0329 or send us an email to service@globalhobby.net

❑ Using 220 grit sandpaper with a sanding block, lightly sand the edges of the stabilizer and elevator even with each other.

Step 2: Mounting the Horizontal Stabilizer Assembly

❑ Using a ruler and a pencil, draw a centerline across

the top of the horizontal stabilizer.

☞

The line should be perpendicular to the hinge line as

shown.

❑ Using a ruler and a pencil, draw a centerline mark on

the bottom, back edge of the stabilizer as shown.

❑ Hinge the elevator to the horizontal stabilizer using the

clear decal. Apply the decal to the top of the parts, making

sure there is a 1/16" gap between them to allow for the up

and down movement of the elevator.

☞

Use the guide marks on the ends of the decal to help you

set the correct hinge gap.

❑ Set the stabilizer assembly on top of the fuselage, making

sure the top of the stabilizer is facing up toward you.

❑ To align the stabilizer properly, the trailing edge of the

stabilizer (not the elevator) should be even with the back edge

of the fuselage and the centerline you drew on top of the

stabilizer should be centered over the middle of the fuselage.

☞

Use the mark you drew on the bottom of the stabilizer to

help you align it at the back of the fuselage.

11

Visit our website at http://watt-age.globalhobby.com for information on other Wattage products

❑ When satisfied with the alignment, hold the stabilizer in

place and use a pencil to draw two lines on the bottom of the

stabilizer (one on each side) where it meets the fuselage sides.

☞

Be careful that the stabilizer assembly does not move

when you draw the lines.

❑ Mix a small quantity of 5 minute epoxy and apply a thin layer to only the bottom of the stabilizer between the two

lines you drew.

❑ Set the stabilizer back into place and realign it. Remove any excess epoxy using a paper towel and rubbing alcohol,

and hold the stabilizer firmly in place until the epoxy sets up.

Step 3: Hinging the Rudder

❑ Carefully remove the die-cut vertical stabilizer and rudder from the foam sheet.

❑ Using 220 grit sandpaper with a sanding block, carefully sand the edges of the stabilizer and rudder smooth and

straight.

❑ Using a ruler and a modeling knife, carefully cut out the clear rudder hinge from the decal sheet.

❑ Using 220 grit sandpaper with a sanding block, lightly sand the edges of the stabilizer and rudder even with each other.

❑ Hinge the rudder to the vertical stabilizer using the clear

decal, making sure there is a 1/16" gap between them to

allow for movement of the rudder.

☞

Use the guide marks on the ends of the decal to help you

set the proper hinge gap.

Step 4: Mounting the Vertical Stabilizer Assembly

❑ Test-fit the vertical stabilizer to the top of the horizontal

stabilizer.

❑ To align the stabilizer properly, the base of the stabilizer

should be lined up over the centerline you drew on top of the

horizontal stabilizer and the trailing edge of the stabilizer

should be even with the trailing edge of the horizontal

stabilizer.

12

Need help or have any questions? Call us at 1-714-963-0329 or send us an email to service@globalhobby.net

❑ While holding the vertical stabilizer in place, use a

builder's triangle to check to ensure that it is aligned 90º to

the horizontal stabilizer.

❑ When satisfied with the alignment, remove the vertical stabilizer. Mix a small quantity of 5 minute epoxy and apply

a thin layer to only the bottom edge of the vertical stabilizer.

❑ Set the stabilizer back into place and realign it, double-checking that it is 90º to the horizontal stabilizer. Remove any

excess epoxy using a paper towel and rubbing alcohol, and hold the stabilizer in place until the epoxy sets up.

❑ # 1 Phillips Head Screwdriver

❑ Needle Nose Pliers

❑ Excel Modeling Knife

❑ Electric Drill

YOU'LL NEED THE FOLLOWING PARTS:

❑ (1) Prebent Main Gear Wire

❑ (2) Nylon Main Gear Wheels

❑ (2) Nylon Wheel Retainers

SECTION 8: GEAR BOX & LANDING GEAR INSTALLATION

❑ (1) 370 Motor w/Gear Box

❑ (3) 3mm x 12mm Wood Screws

YOU'LL NEED THE FOLLOWING SUPPLIES:

❑ 1/16" Drill Bit

❑ Ruler

❑ Pencil

Step 1: Installing the Gear Box Assembly

❑ Using a modeling knife, cut a 1/2" square hole in the top

of the fuselage, 3/8" behind the back edge of the plywood

motor plate.

☞

The motor wires will come out through this hole for easy

access when connecting them to your ESC.

13

Visit our website at http://watt-age.globalhobby.com for information on other Wattage products

❑ Using a ruler and a pencil, measure down 1/8" from the

top of the motor plate and draw a mark.

☞

Draw the mark in the center of the motor plate to make it

easier to align the gear box assembly.

❑ Carefully press the landing gear wire into the molded

groove in the back of the gear box assembly.

IMPORTANT

To make it easier to line up the gear box assembly properly in the next few procedures, we suggest using a ruler and a

pencil to draw a vertical centerline on the plywood motor plate.

❑ Slide the motor wires into the precut hole in the motor plate and out through the hole you cut in the top of the fuselage.

❑ Push the gear box assembly up against the motor plate.

❑ To align the gear box assembly properly, the gear box

should be centered from side to side on the motor plate and

the top of the gear box should be even with the mark you

drew (1/8" below the top of the motor plate.)

❑ When satisfied with the alignment, use a pencil to mark

the locations of the three mounting holes onto the motor plate.

❑ Remove the gear box assembly and set it aside. Using a drill with a 1/16" drill bit, drill pilot holes through the motor

plate at each of the three marks you drew.

14

Need help or have any questions? Call us at 1-714-963-0329 or send us an email to service@globalhobby.net

❑ Set the gear box assembly back into place and realign it.

❑ Install and tighten the three 3mm x 12mm wood screws to hold the gear box assembly securely to the fuselage.

☞

Be careful not to overtighten the screws or you might strip the plywood motor plate.

Step 2: Installing the Main Gear Wheels

☞

Double-check that the wheel spins without binding. If the wheel does bind, carefully pull the nylon wheel retainer

just far enough away from the wheel to prevent the binding.

❑ Repeat the procedure above to install the second wheel and wheel retainer.

❑ Slide one wheel onto one of the axles.

❑ Using needle nose pliers, carefully squeeze one nylon

wheel retainer onto the axle to secure the wheel into place.

If you would like to use a more to-scale lightweight foam wheel, we recommend using the 2-1/4" Dave Brown Treaded

Lectra-Lite Wheels P/N 218547. The axle hole in the wheels will have a larger diameter than the axles, but you can use

a piece of KNS aluminum or brass tubing as a bushing. Hold the wheels in place using either small wheel collars or by

simply bending the end of the bushings up at an angle.

❑ # 0 Phillips Head Screwdriver

❑ Adjustable Wrench

❑ Excel Modeling Knife

YOU'LL NEED THE FOLLOWING PARTS:

❑ (1) Plastic Cowling

❑ (3) 1.5mm x 4mm Wood Screws

❑ (1) 7.5 x 5 Propeller

SECTION 9: COWLING & PROPELLER INSTALLATION

❑ (1) 3mm Flat Washer

❑ (2) 3mm Hex Nuts

YOU'LL NEED THE FOLLOWING SUPPLIES:

❑ Scissors

❑ 220 Grit Sandpaper w/Sanding Block

Step 1: Cutting Out the Cowling

❑ Using 220 grit sandpaper with a sanding block, carefully sand the back edge of the cowling smooth and straight.

15

Visit our website at http://watt-age.globalhobby.com for information on other Wattage products

❑ Using a modeling knife, cut out the small molded circle

and the molded air-intake in the front of the cowling.

❑ Using a pair of scissors, cut out the back edge of the

cowling to allow clearance for the landing gear wires.

☞

If you look carefully at each side of the cowling you will

notice scribe lines showing you where you need to cut out

for the landing gear wires.

Step 2: Installing the Cowling

❑ Slide the cowling over the gear box assembly and onto the fuselage.

❑ Thread one 3mm hex nut onto the propeller shaft and tighten it until it will not thread on any further.

❑ Slide the propeller onto the propeller shaft, making sure

that the back of the propeller slides firmly over the hex nut.

☞

The back of the propeller is molded to fit over the hex

nut.

❑ Slide the 3mm flat washer into place, then install and

tighten the second 3mm hex nut using an adjustable wrench.

❑ Carefully adjust the cowling so that it is centered around the end of the gear box and make sure the back edge of the

cowling overlaps (or is even with) the back edge of the plywood motor plate.

IMPORTANT

The top of the cowling will be pushed above the top of the fuselage by the plywood plate. This is normal. It is done to

make a space for hot air to exit the cowling so the motor and gear box do not overheat.

16

Need help or have any questions? Call us at 1-714-963-0329 or send us an email to service@globalhobby.net

❑ When satisfied with the alignment of the cowling, install

and tighten the three 1.5mm x 4mm wood screws to hold the

cowling securely in place.

☞

To make it easier to install the screws, use the tip of your

modeling knife to make small pilot holes in the cowling.

IMPORTANT

The cowling is held in place using three wood screws. One screw should be located on top of the cowling and thread into

the plywood plate and two screws (one on each side) should be located just below the landing gear wire cutout and thread

into the edge of the plywood motor plate.

❑ # 0 Phillips Head Screwdriver

❑ Magnum Z-Bend Pliers

❑ Wire Cutters

❑ Needle Nose Pliers

YOU'LL NEED THE FOLLOWING PARTS:

❑ (2) 1.5mm x 400 Threaded Wires

❑ (2) Nylon Control Horns w/Backplates

SECTION 10: ELEVATOR & RUDDER CONTROL SYSTEM INSTALLATION

❑ (2) Nylon Clevises

❑ (1) Servo Mounting Board - 2 Parts

YOU'LL NEED THE FOLLOWING SUPPLIES:

❑ Excel Modeling Knife

❑ Electric Drill

❑ 1/16" Drill Bit

❑ Pencil

Step 1: Applying the Servo Mounting Board

❑ Using the tip of your modeling knife, remove the die-cut

piece from inside each piece of servo mounting board.

❑ Remove one piece of servo mounting board from the

protective backing and stick the board to the side of the

fuselage. The back and top edges of the servo mounting

board should be even with the fuselage reinforcement board

as shown.

❑ Repeat the procedure above to apply the second piece of servo mounting board to the other side of the fuselage.

17

Visit our website at http://watt-age.globalhobby.com for information on other Wattage products

❑ Using a modeling knife, cut away and remove the foam from within the cutout in each piece of servo mounting board.

❑ Using a modeling knife, cut a 1/2" square hole in the top

of the fuselage, 3/4" in front of the rear wing hold-down

dowel.

☞

The servo wires will come out through this hole for easy

access when connecting them to your receiver.

Step 2: Installing the Nylon Control Horns

❑ Using the tip of your modeling knife, carefully remove the small die-cut pieces from the elevator and the rudder.

❑ Push one control horn through each die-cut hole in the rudder and the elevator. The tip of the elevator control horn

should face the bottom of the elevator and the tip of the rudder control horn should face the opposite side of the rudder.

❑ Making sure that the flat portion of the backplates face

away from the control surfaces, push the backplates over the

ends of the control horns until you hear them "click" firmly

into place.

Step 3: Installing the Elevator and Rudder Servos

❑ Test-fit one servo into each side of the fuselage. If the

servos are too large to fit, use a modeling knife to enlarge the

holes to accommodate the servos.

☞

Both of the servos' output shafts should face toward the

front of the fuselage.

❑ Install the rubber grommets and brass collets onto each of the servo mounting lugs.

❑ Mount the servos using the servo mounting screws provided with your servos. To make it easier to install the screws,

use the tip of your modeling knife to make small pilot holes in the servo mounting board.

18

Need help or have any questions? Call us at 1-714-963-0329 or send us an email to service@globalhobby.net

Step 4: Installing the Elevator and Rudder Pushrods

❑ Plug the elevator and rudder servo leads into their proper slots in the receiver. Plug the ESC lead into the receiver and

plug the flight battery into the ESC . Turn on the radio system and center both of the servos using the elevator and rudder

trim levers on the transmitter.

❑ Thread one nylon clevis onto each of the two 1.5mm x 400mm threaded pushrod wires. Thread the clevises on far

enough to leave room for adjustments later.

❑ Working with one pushrod wire for now, carefully snap

the clevis into the elevator control horn.

❑ Place a "single arm" servo horn onto the elevator servo (on the same side as the elevator control horn), making sure

that the servo horn is centered and points up toward the top of the fuselage. The arm should have at least two holes in it.

❑ Using Magnum Z-Bend Pliers, make a Z-Bend in the pushrod wire at the mark you drew and use wire cutters to

remove the excess wire.

❑ Remove the servo horn. Using a 1/16" drill bit, enlarge the hole in the servo arm that is 1/4" out from the center of the

servo horn.

❑ With both the servo horn and the elevator centered, use a

pencil to draw a mark on the pushrod wire where it crosses

the hole that is 1/4" out from the center of the servo horn.

☞

If you're using Cirrus CS-10 servos this will be the first

hole in the servo arm.

❑ Attach the servo horn to the Z-Bend, then attach the

servo horn to the servo, making sure it's centered.

❑ Install and tighten the servo horn retaining screw, provided

with your servo, to secure the servo horn into place.

19

Visit our website at http://watt-age.globalhobby.com for information on other Wattage products

❑ Install the rudder pushrod wire using the same technique as with the elevator pushrod wire. The Z-Bend should be

installed into the hole that is 1/4" out from the center of the servo horn as well.

❑ Double-check that the elevator and rudder are still centered. If they are out of adjustment, remove the clevises and

readjust them until you are satisfied with the alignment. Unplug and turn off your radio system.

❑ Kwik Bond 5 Minute Epoxy

❑ Scissors

❑ Ruler

❑ Masking Tape

❑ 220 Grit Sandpaper w/Sanding Block

YOU'LL NEED THE FOLLOWING PARTS:

❑ (1) Left Wing Panel

❑ (1) Right Wing Panel

❑ (1) Decal Sheet

❑ (1) Prebent Aluminum Tube

❑ (2) Fiberglass Dowels

SECTION 11: WING ASSEMBLY & INSTALLATION

❑ (2) Double-Sided Tape - Strips

❑ (1) Plastic Wing Mount

❑ (1) Plastic Wing Brace

❑ (4) Rubber Bands

YOU'LL NEED THE FOLLOWING SUPPLIES:

❑ Paper Towels

❑ Rubbing Alcohol

❑ NHP Epoxy Mixing Sticks

❑ NHP Epoxy Mixing Cups

Step 1: Trimming the Plastic Parts

❑ Using a pair of scissors, carefully cut out around the base

of the plastic wing mount leaving about 3/16" of material

beyond the molded radius.

❑ Test-fit the wing mount onto the fuselage. To align it properly, the front edge of the wing mount should be pushed up

against the back edge of the cowling and the wing mount should be centered over the fuselage. If the edges of the wing

mount hang past the fuselage sides, trim the edges using a pair of scissors so that they are even with the fuselage sides.

❑ When satisfied with the fit, use 220 grit sandpaper with a sanding block to carefully sand the edges of the wing mount

smooth and straight.

20

Need help or have any questions? Call us at 1-714-963-0329 or send us an email to service@globalhobby.net

❑ Using a pair of scissors, carefully cut out the plastic wing

brace along the molded upper edges.

☞

When cutting out the wing brace, make sure not to leave

any molded radius around the edges.

❑ Using 220 grit sandpaper with a sanding block, sand the edges of the wing brace smooth and straight.

Step 2: Joining the Wing Panels

❑ Remove the protective backing from only one side of

each strip of double-sided tape.

❑ Carefully apply one strip of tape to the top of each side of

the plastic wing mount as shown.

❑ Use a pair of scissors to cut one 1/2" wide by 6-3/8" long strip out of each piece of double-sided tape.

IMPORTANT

Before applying any pieces of double-sided tape to either the plastic parts or the foam wing panels, it's important to clean

the area first using a paper towel and rubbing alcohol. This will remove any traces of oil on the parts and result in a

stronger bond. Before applying the tape make sure any traces of rubbing alcohol have completely dried from the surfaces

to be joined.

❑ Using the remaining double-sided tape, apply the pieces

over the entire surface of the bottom of the plastic wing brace.

IMPORTANT

For maximum wing strength, it's important to cover the

entire surface of the wing brace with double-sided tape.

☞

You should have leftover double-sided tape after these procedures. Save the extra because it will be used later.

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

/