Page is loading ...

1

Visit our website at http://watt-age.globalhobby.com for information on other Wattage products

The Wattage Cap 232 EP ARF is distributed

exclusively by Global Hobby Distributors 18480

Bandilier Circle, Fountain Valley, CA 92708

All contents copyright © 2002, Global Hobby

Distributors Version V3.0 June 2002

Kit Product Number 128407

Specifications:

●

Wing Span: 36 Inches

●

Wing Area: 220 Square Inches

●

Length: 32 Inches

●

Weight RTF: 26 - 30 Ounces

●

Functions: Ailerons, Elevator, Rudder and Throttle

●

Power: Cobalt 400 Direct Drive w/7 x 4 Propeller

●

Radio: 4 Channel Micro w/3 Micro Servos & 30 AMP ESC

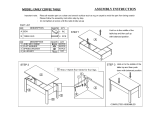

INSTRUCTIONS FOR FINAL ASSEMBLY

2

Need help or have any questions? Call us at 1-714-963-0329 or send us an email to service@globalhobby.net

TABLE OF CONTENTS

This R/C airplane is not a toy! If misused or abused, it can cause serious bodily injury and/or damage to property. Fly only

in open areas and preferably at a dedicated R/C flying site. We suggest having a qualified instructor carefully inspect your

airplane before its first flight. Please carefully read and follow all instructions included with this airplane, your radio control

system and any other components purchased separately.

SAFETY WARNING

OUR GUARANTEE

Wattage guarantees this kit to be free from defects in both material and workmanship, at the date of purchase. This does not cover any component

parts damaged by use, misuse or modification. In no case shall Wattage's liability exceed the original cost of the purchased kit.

In that Wattage has no control over the final assembly or material used for final assembly, no liability shall be assumed for any damage resulting from

the use by the user of the final user-assembled product. By the act of using the final user-assembled product, the user accepts all resulting liability.

FOR YOUR INFORMATION

To make your modeling experience totally enjoyable, we recommend that you get experienced, knowledgeable help with assembly and

during your first flights. Your local hobby shop has information about flying clubs in your area whose membership includes qualified

instructors. If there is no hobby shop in your area, we recommend that you contact the AMA at the address below. They will be able to

help you locate a flying field near you.

Academy of Model Aeronautics

5151 East Memorial Drive

Muncie IN 47302-9252

(800) 435-9262

www.modelaircraft.org

Safety Warning ...................................................................................... 2

Introduction ............................................................................................ 3

Section 1: Our Recommendations.......................................... 4

Section 2: Kit Contents ........................................................... 5

Section 3: Metric Conversion Chart ........................................ 5

Section 4: Tools and Supplies Required ................................ 6

Section 5: Replacement Parts ................................................ 6

Section 6: A Note About Covering .......................................... 7

Section 7: Becoming Familiar with Your Cobalt 400 Motor ..... 7

Section 8: Mounting the Wing ................................................. 9

Section 9: Horizontal Stabilizer ............................................. 10

Section 10: Vertical Stabilizer ............................................... 12

Section 11: Hinging the Control Surfaces ............................ 14

Section 12: Installing the Main Landing Gear ...................... 17

Section 13: Servo Installation ............................................... 19

Section 14: Pushrod Installation ........................................... 20

Section 15: Final Assembly ................................................... 27

Section 16: Balancing the Cap 232 EP ................................ 30

Section 17: Lateral Balancing the Cap 232 EP .................... 30

Section 18: Control Throws................................................... 31

Section 19: Preflight Check & Safety ................................... 31

Section 20: Flying the Cap 232 EP ...................................... 33

Section 21: Trim Chart .......................................................... 34

Product Evaluation Sheet ................................................................... 35

3

Visit our website at http://watt-age.globalhobby.com for information on other Wattage products

This instruction manual is designed to guide you through the entire final assembly process of your new airplane in the

least amount of time possible. Along the way you'll learn how to properly assemble your new airplane and also learn

tips that will help you in the future. We have listed some of our recommendations below. Please read through them

before beginning assembly.

●

Please read through each step before beginning

assembly. You should find the layout very complete

and straightforward. Our goal is to guide you through

assembly without any of the headaches and hassles

that you might expect.

●

There are check boxes next to each step. After

you complete a step, check off the box. This will help

prevent you from losing your place.

●

Cover your work table with brown paper or a soft

cloth, both to protect the table and to protect the parts.

●

Keep a couple of small bowls or jars handy to put

the small parts in after you open the accessory bags.

●

We're all excited to get a new airplane in the air, but

take your time. This will ensure you build a straight,

strong and great flying airplane.

●

If you come across this symbol

☞

, it means that

this is an important point or an assembly hint.

If you should find a part missing or damaged, or have any questions about assembly, please

contact us at the address below:

Global Services

18480 Bandilier Circle

Fountain Valley CA 92708

Phone: (714) 963-0329 Fax: (714) 964-6236 E-mail: service@globalhobby.net

INTRODUCTION

Thank you for purchasing the new Wattage Cap 232 EP. Before completing the final assembly of your new

airplane, please carefully read through this instruction manual in its entirety. Doing so will ensure your success

the first time around!

Wattage Cap 232 EP Features:

●

Compact, Lightweight Design for Small-Field Flying

●

Exciting Flight Characteristics

●

Hand-Built from Quality Balsa & Plywood

●

Covered with Real Iron-On Covering Material

●

Preinstalled Cobalt 400 Direct Drive Motor for More Power

●

Prepainted Cowling and Wheel Pants

●

Generous Hardware and Custom Decal Set Included

●

Fast & Easy Assembly - 50 High Resolution Digital Photos & Drawings Guide You

To serve your needs better, please include your email address with any correspondence you send to us. Your email

address will be added to our Customer Service Database so you will automatically receive free updates and tech

notices for your particular product. You will also receive repair status updates (if applicable) and other important

information about your product as it becomes available.

IMPORTANT INFORMATION ABOUT YOUR EMAIL ADDRESS

Global Hobby Distributors will not disclose the information it collects to outside parties. Global Hobby Distributors does not sell,

trade, or rent your personal information to others . Your privacy is important to us.

Website

http://globalservices.globalhobby.com

4

Need help or have any questions? Call us at 1-714-963-0329 or send us an email to service@globalhobby.net

This section describes the items you will need to purchase for your new Cap 232 EP. These suggestions are not set in

stone, but they should provide you with a good starting point.

SECTION 1: OUR RECOMMENDATIONS

Here's What We Used to Finish Our Cap 232 EP:

P/N 759118 Hitec 555 Micro Receiver

Hitec Dual Conversion FM RX Crystal

P/N 444045 Cirrus CS-09 Micro Servos (3)

P/N 128486 Wattage IC-30A Micro ESC

7 Cell CP1300SCR NiCD Flight Battery

P/N 130108 Wattage PF-12 AC/DC Peak Detection Charger

P/N 625085 Dean's Ultra-Plug Battery Connector

P/N 869020 Dubro Double-Sided Tape

What Servos Do I Use?

The servos you use should be the lightest available, yet still have an adequate amount of torque. We suggest using servos

that weigh no more than 0.34 ounces and have a torque rating of no less than 11.0 ounces per square inch.

What Receiver Do I Use?

The receiver should be as light as possible, preferably 1/2oz. or less. Most four channel micro receivers would be a good

choice. If you plan on using the Hitec 555 Micro receiver, we suggest removing the case to reduce the receiver's weight.

If you do remove the case from your receiver we strongly suggest wrapping the receiver with heat-shrink material to protect

the internal components.

What Electronic Speed Control Do I Use?

The ESC you choose should be capable of handling no less than 30 amps continuous current. Again, lighter is better. Your

ESC should weigh no more than 1 ounce including the wiring and switch.

What Flight Battery Do I Use?

Through much testing with this power system and airframe combination, we recommend using a Sanyo 7cell CP1300SCR

flight pack. The CP1300SCR pack is ideal because it will provide superior runtime without any significant weight penalty.

We do not suggest using NiMH battery packs. At this time they cannot handle the current draw of this power system.

IMPORTANT

When choosing accessories for your Cap 232, such as servos, ESC, and receiver, it's very important to take the

weight of these items into consideration. Remember, the lighter the overall weight of the finished airplane, the

better the airplane will fly.

IMPORTANT The part number listed for the Cirrus servos is compatible with all radio control systems. This servo uses a universal

connector. The part number listed for the Hitec 555 Micro receiver is compatible with Hitec radio control systems. This receiver is also

available for Futaba, JR and Airtronics radio control systems. The Wattage IC-30A Micro ESC is compatible with Futaba, JR, Hitec,

Airtronics-Z and others.

When you purchase the Hitec 555 Micro receiver, you must also purchase a Hitec brand crystal compatible with the receiver. The crystal

must also be on the same frequency as your transmitter. Note that the Hitec 555 Micro receiver uses a dual conversion FM

Hitec crystal.

Note: To minimize current loss, we suggest

soldering the motor wires directly to the ESC.

We also suggest replacing the stock Tamiya

connector that is likely preinstalled on your

ESC and flight battery with a more efficient

Dean's Ultra-Plug battery connector.

5

Visit our website at http://watt-age.globalhobby.com for information on other Wattage products

We have organized the parts as they come out of the box for easier identification during assembly. Before you begin

assembly, group the parts as we list them below. This will ensure that you have all of the parts before you begin assembly

and it will also help you become familiar with each part. If you find any parts missing or damaged, please contact us below:

AIRFRAME ASSEMBLIES

❑ (1) Fuselage w/Motor, Cowling & Canopy

❑ (1) Wing Assembly w/Ailerons & Hinges

❑ (1) Horizontal Stabilizer w/Elevator & Hinges

❑ (1) Vertical Stabilizer w/Rudder & Hinges

PUSHROD ASSEMBLIES

❑ (2) 1mm x 450mm Pushrod Wires

❑ (2) 1mm x 120mm Pushrod Wires

❑ (2) Plywood Control Horns

SECTION 2: KIT CONTENTS

Global Services

18480 Bandilier Circle

Fountain Valley CA 92708

Phone: (714) 963-0329 Fax: (714) 964-6236 E-mail: service@globalhobby.net

LANDING GEAR ASSEMBLY

❑ (2) Prebent Main Gear Wires

❑ (2) Main Gear Wheels

❑ (2) Nylon Landing Gear Straps

❑ (4) 2.5mm x 10mm Wood Screws

❑ (4) 3mm Wheel Spacers

❑ (2) Molded Wheel Pants

❑ (2) Aluminum Wheel Pant Mounts

❑ (4) 2mm x 5mm Flange-Head Wood Screws

❑ (1) Prebent Tail Wheel Wire

❑ (1) Tail Wheel

❑ (2) 1mm Nylon Wheel Retainers

SPINNER ASSEMBLY

❑ (1) Molded Spinner

❑ (1) Molded Shaft Adaptor Set

❑ (2) 2.5mm x 10mm Wood Screws

MISCELLANEOUS ITEMS

❑ (1) 3mm x 20mm Flange-Head Machine Screw

❑ (1) 7 x 4 Nylon Propeller

❑ (3) Velcro

®

Squares

❑ (1) Decal Set

To convert inches into millimeters: Inches x 25.4 = mm

To convert millimeters into inches: Millimeters / 25.4 = in

1/64" = .4mm

1/32" = .8mm

1/16" = 1.6mm

3/32" = 2.4mm

1/8" = 3.2mm

5/32" = 4.0mm

3/16" = 4.8mm

1/4" = 6.4mm

3/8" = 9.5mm

1/2" = 12.7mm

5/8" = 15.9mm

3/4" = 19.0mm

1" = 25.4mm

2" = 50.8mm

3" = 76.2mm

6" = 152.4mm

12" = 304.8mm

18" = 457.2mm

21" = 533.4mm

24" = 609.6mm

30" = 762.0mm

36" = 914.4mm

SECTION 3: METRIC CONVERSION CHART

6

Need help or have any questions? Call us at 1-714-963-0329 or send us an email to service@globalhobby.net

❑ Kwik Bond Thin C/A # 887500

❑ Kwik Bond Thick C/A # 887510

❑ Kwik Bond 5 Minute Epoxy # 887560

❑ Kwik Bond C/A Debonder # 887545

❑ # 0 Phillips Head Screwdriver

❑ # 1 Phillips Head Screwdriver

❑ 7/64" Hex Wrench

❑ Magnum Z-Bend Pliers # 237473

❑ Wire Cutters

❑ Needle Nose Pliers

❑ Excel Modeling Knife # 692801

❑ Scissors

❑ Electric Drill

❑ Assorted Drill Bits

❑ Ernst Airplane Stand # 223977

❑ Ruler

❑ Pencil

❑ Builder's Triangle

❑ 220 Grit Sandpaper w/Sanding Block

❑ Dubro T-Pins # 567677

❑ Masking Tape

❑ Scotch

®

Tape

❑ Waxed Paper

❑ Paper Towels

❑ Rubbing Alcohol

❑ NHP Epoxy Mixing Sticks # 864204

❑ NHP Epoxy Mixing Cups # 864205

SECTION 4: TOOLS AND SUPPLIES REQUIRED

Wattage stocks a complete line of replacement parts for your Cap 232 EP. Listed below are the replacement parts that are

available along with their respective part numbers for easy ordering convenience. We suggest ordering directly from your

local dealer. If your dealer does not stock Wattage products, you can order directly from us at the address shown below:

SECTION 5: REPLACEMENT PARTS

Global Services

18480 Bandilier Circle

Fountain Valley CA 92708

Phone: (714) 963-0329 Fax: (714) 964-6236

Wattage Cap 232 EP ARF - Complete ----------- 128407

Pushrod & Control Horn Set ------------------------ 145194

Prepainted Cowling ------------------------------------145215

Prepainted Wheel Pants ----------------------------- 145216

Spinner Assembly -------------------------------------- 145217

Clear Canopy -------------------------------------------- 145218

Landing Gear Wire ------------------------------------- 145219

Fuselage Set -------------------------------------------- 145220

Wing Set -------------------------------------------------- 145221

Stabilizer Set --------------------------------------------- 145222

Screw Set ------------------------------------------------- 145223

Decal Set -------------------------------------------------- 145224

Instruction Manual -------------------------------------- 145225

7 x 4 Nylon Propeller ----------------------------------- 608140

Motor Mounting Straps --------------------------------- 131346

Main Gear Wheels -------------------------------------- 131347

Propeller Adaptor for Cobalt 400 -------------------- 131476

Cobalt 400 Direct Drive Motor ----------------------- 131480

On the Web

http://globalservices.globalhobby.com

7

Visit our website at http://watt-age.globalhobby.com for information on other Wattage products

SECTION 7: BECOMING FAMILIAR WITH YOUR COBALT 400 MOTOR

The covering material used on your airplane is real iron-on heat shrink covering material, not cheap "shelf paper."

Because of this, it is possible with heat and humidity changes that the covering on your airplane may wrinkle or sag. This

trait is inherent in all types of heat shrink material. To remove any wrinkles that might be visible you will need to purchase,

or borrow from a fellow modeler, a heat iron. If you need to purchase one, the Global Heat Sealing Iron # 360900 is

recommended.

Follow this simple procedure to remove the wrinkles:

❑ Plug in and turn on the sealing iron to the medium-high temperature setting. Allow the iron to heat up for approximately

5 - 7 minutes.

❑ After the iron has reached temperature, lightly apply the iron to the wrinkled section of the covering. Move the iron

slowly over the wrinkled section until the covering tightens and the wrinkles disappear. You will notice that the color of the

covering will darken when it is heated. When the covering cools back down, it will return to its normal color.

☞

If the color layer smears from any of the seams the temperature of the iron is too hot. Turn the temperature dial down

and wait about 5 minutes for the iron to adjust to the lower temperature. You can remove any excess color streaks using

a paper towel soaked with a small quantity of Acetone.

SECTION 6: A NOTE ABOUT COVERING

WARNING

We do not suggest storing your airplane in an extremely hot environment (like the back of your car in direct

sunlight) for any length of time. The extreme heat could cause the covering material to wrinkle and possibly

damage the fragile components of the radio system, ESC or batteries.

Your Wattage Cap 232 EP is powered by the Wattage Super Cobalt 400 Direct Drive motor. This motor is a high-quality

alternative to lower power, closed end-bell motors, and more expensive specialty motors. The Super Cobalt 400 Direct

Drive motor features a 3.2mm (1/8") shaft and a bolt pattern that can match either 05 or 400 size mounting dimensions.

And at 3.7 ounces, this motor is light for its enormous power potential.

Please take a moment to familiarize yourself with the Wattage Super Cobalt 400 Direct Drive motor:

Nominal Voltage: 7V

Operating Voltage: 6V - 10V

No-Load Motor Speed: 19,500 RPM

RPM Per Volt: 2,395 RPM

Max Efficiency: 75%

Max Efficiency Current: 18A

Max Loading: 31A/20s

Stall Current: 55A

Shaft Diameter: 3.2mm (1/8")

Weight: 3.7 Ounces

Propeller Range: 5 x 5 to 8 x 6

The motor break-in procedure begins at the top of the next page.

Note: Continuous amps should not exceed more than 30A, so if you use propellers larger than 7 x 4, you will

need to reduce voltage accordingly.

8

Need help or have any questions? Call us at 1-714-963-0329 or send us an email to service@globalhobby.net

Step 1: Breaking In the Motor

Motor break-in is not absolutely necessary, but taking time to break in the motor now will result in increased motor

performance and longevity. You can either leave the motor secured to the fuselage during the break-in process or you can

remove the motor and secure it to a test stand. If you leave the motor in the fuselage, make sure to hold the fuselage

securely during the break-in process.

❑ Using a # 1 phillips head screwdriver, remove the four screws holding the cowling in place. Remove the cowling and

set it aside for now.

☞

If you leave the motor on the fuselage during the break-in process, the cowling should be removed so that the motor

receives adequate cooling.

❑ Install a smaller propeller onto the motor than the one included with the airplane. We suggest using a 5 x 5 or a 6 x 5

propeller to begin the break-in procedure. We don't suggest using the 7 x 4 propeller included for the break-in procedure

because it will put too much load on the motor before it's fully broken in.

❑ To start the break-in procedure, attach the motor wires directly to a fully charged 4 cell battery pack. A receiver battery

pack works great for this. Run the motor in 5 minute intervals for a total of 15 minutes runtime. This means run the motor

for 5 minutes, unplug the battery pack, let the motor cool for 5 minutes, and repeat this three times for a total of 15 minutes

runtime. This technique will begin to seat the motor brushes and prevent the motor from overheating.

❑ After you've completed the initial 15 minute break-in procedure, connect the motor to your ESC and the flight battery

you plan on using to fly the airplane. Run the motor in 1 to 2 minute intervals of varying throttle settings with increasingly

larger propellers until you reach the 7 x 4 propeller included with the airplane. During this process, let the motor cool

between runs and do not run the motor at full power for more than 15 seconds at a time.

IMPORTANT

To prevent current loss, we strongly suggest soldering the motor wires directly to the ESC. We also suggest using a Dean's

Ultra-Plug battery connector in place of the stock Tamiya connector likely preinstalled on your flight battery and ESC.

IMPORTANT INFORMATION ABOUT MOTOR COOLING

The Super Cobalt 400 Direct Drive motor must have airflow through and over the motor to prevent overheating. It's

important that the air-exit holes be larger than the air-intake holes. We also strongly suggest that the flight battery and

ESC receive maximum cooling, too.

IMPORTANT INFORMATION ABOUT MOTOR MAINTENANCE

We do not recommend using spray cleaners or liquid solvents to clean the motor. Any dust and debris should be

removed using compressed air, either from an air-compressor or from a can.

Regularly check the motor brushes and springs. If they look worn, replace them immediately. Worn motor brushes will

cause short motor life and poor performance. The part number for the replacement brushes and spring set is 131475.

9

Visit our website at http://watt-age.globalhobby.com for information on other Wattage products

❑ Kwik Bond Thin C/A

❑ # 1 Phillips Head Screwdriver

❑ Excel Modeling Knife

YOU'LL NEED THE FOLLOWING PARTS:

SECTION 8: MOUNTING THE WING

❑ (1) 3mm x 20mm Flange-Head Machine Screw

YOU'LL NEED THE FOLLOWING TOOLS AND SUPPLIES:

❑ Ernst Airplane Stand

❑ Ruler

Step 1: Mounting the Wing

❑ Using a modeling knife, cut away the covering material

from over the top and bottom of the predrilled hole in the

trailing edge of the wing.

❑ Carefully apply a couple of drops of thin C/A into the

threaded wing hold-down hole in the fuselage.

WARNING

Allow the C/A to dry completely before proceeding or you may

inadvertently glue the wing to the fuselage.

❑ Set the wing into the wing saddle and align it. The hardwood dowel in the leading edge of the wing should fully engage

the predrilled hole in the forward bulkhead and the predrilled hole in the back of the wing should line up with the hole in the

wing hold-down block inside the fuselage.

❑ (1) Fuselage w/Motor, Cowling & Canopy

❑ (1) Wing Assembly w/Ailerons & Hinges

10

Need help or have any questions? Call us at 1-714-963-0329 or send us an email to service@globalhobby.net

❑ Secure the wing into place using the 3mm x 20mm

flange-head machine screw.

☞

Don't overtighten the screw. You don't want to crush the

wing or distort the trailing edge.

❑ Kwik Bond 5 Minute Epoxy

❑ Ernst Airplane Stand

❑ Ruler

❑ Pencil

❑ 220 Grit Sandpaper w/Sanding Block

❑ Dubro T-pins

YOU'LL NEED THE FOLLOWING PARTS:

❑ (1) Horizontal Stabilizer w/Elevator & Hinges

SECTION 9: HORIZONTAL STABILIZER

YOU'LL NEED THE FOLLOWING TOOLS AND SUPPLIES:

❑ Masking Tape

❑ Paper Towels

❑ Rubbing Alcohol

❑ NHP Epoxy Mixing Sticks

❑ NHP Epoxy Mixing Cups

Step 1: Aligning the Horizontal Stabilizer

❑ Remove the elevator and hinges from the horizontal stabilizer and set them aside for now.

❑ Remove the ailerons and hinges from the wing and set them aside.

❑ Carefully remove the elevator joiner wire from the two

elevator halves. It has only been dry-fitted.

❑ Slide the joiner wire through the stabilizer mounting slot

in the back of the fuselage.

WARNING

The joiner wire must be placed in the mounting slot before

installing the stabilizer. If it's not, you won't be able to hinge

the elevator halves later.

11

Visit our website at http://watt-age.globalhobby.com for information on other Wattage products

❑ Using a ruler, measure the distance between the tips of

the stabilizer and the tips of the wing.

☞

If the measurements aren't equal, pivot the front of the

stabilizer until both measurements are equal.

❑ When you are satisfied that the stabilizer is aligned, use a pencil to draw a couple of marks on each side of the stabilizer

where it and the fuselage sides meet, then use a couple of pieces of masking tape to hold the stabilizer firmly in place.

B=B-1

❑ Using a ruler and a pencil, measure and draw a vertical

centerline mark on the top of the stabilizer at the trailing edge.

❑ Slide the stabilizer into the mounting slot in the fuselage

and push the stabilizer completely forward.

IMPORTANT

The elevator joiner wire should be behind the trailing edge of

the stabilizer.

❑ Install the wing onto the fuselage using the machine screw provided.

☞

The wing must be installed now so you can align the horizontal stabilizer properly.

❑ Looking through the vertical stabilizer mounting slot, line up the centerline mark you drew on the trailing edge of the

stabilizer with the center of the fuselage.

❑ Hold the stabilizer temporarily in place (only at the trailing edge) using a pin.

12

Need help or have any questions? Call us at 1-714-963-0329 or send us an email to service@globalhobby.net

Step 2: Mounting the Horizontal Stabilizer

❑ After you're satisfied with the alignment, remove the stabilizer.

❑ Mix a generous amount of 5 minute epoxy and apply a thin layer to only the top and bottom of the gluing surface on the

stabilizer.

☞

Because the stabilizer has to slide through the fuselage, applying epoxy only to the stabilizer will prevent the epoxy

from spreading over the entire length of one half of the stabilizer when you slide it into place.

❑ Slide the stabilizer into place and realign it, double-checking all of your measurements once more before the epoxy

sets up. Quickly remove the excess epoxy and hold the stabilizer in place until the epoxy sets up.

❑ With the stabilizer held firmly in place, look from the front

of the airplane at both the wing and the stabilizer. When

aligned properly, the stabilizer should be parallel to the wing.

IMPORTANT

If the stabilizer is out of alignment, remove it and use 220 grit sandpaper with a sanding block to sand down the higher side of

the stabilizer mounting platform, then reinstall the stabilizer and check the alignment once more. Repeat this procedure until

you are satisfied with the alignment.

WARNING

Before going on to the next step, double-check that your measurements are correct. If the stabilizer is not lined up with the

wing, the airplane will not fly straight.

C=C-1

❑ Kwik Bond 5 Minute Epoxy

❑ Excel Modeling Knife

❑ Ernst Airplane Stand

❑ Pencil

❑ Builder's Triangle

❑ 220 Grit Sandpaper w/Sanding Block

YOU'LL NEED THE FOLLOWING PARTS:

❑ (1) Vertical Stabilizer w/Rudder & Hinges

SECTION 10: VERTICAL STABILIZER

YOU'LL NEED THE FOLLOWING TOOLS AND SUPPLIES:

❑ Masking Tape

❑ Paper Towels

❑ Rubbing Alcohol

❑ NHP Epoxy Mixing Sticks

❑ NHP Epoxy Mixing Cups

Step 1: Aligning the Vertical Stabilizer

❑ Remove the rudder and hinges from the vertical stabilizer and set them aside for now.

13

Visit our website at http://watt-age.globalhobby.com for information on other Wattage products

❑ While holding the stabilizer firmly in place, use a pencil

to outline the base of it onto the top of the fuselage.

❑ Using a modeling knife, carefully cut away and remove

the covering from inside the outline you drew.

IMPORTANT

Glue does not stick well to covering material. For the stron-

gest joint, it's important to remove as much covering from the

gluing surfaces as possible.

❑ Push the vertical stabilizer back into place and realign it.

❑ Using a builder's triangle, check to make sure that the

vertical stabilizer is aligned 90º to the horizontal stabilizer.

Step 2: Mounting the Vertical Stabilizer

❑ Remove the stabilizer and mix a generous amount of 5 minute epoxy.

❑ Apply a thin layer of epoxy to the gluing surfaces of the stabilizer and the fuselage.

❑ Push the stabilizer into place and realign it, double-checking all of your measurements once more before the epoxy

sets up. Quickly remove any excess epoxy and hold the stabilizer in place until the epoxy has set up.

❑ Remove the stabilizer and set it aside.

❑ Push the vertical stabilizer into the mounting slot in the fuselage. When properly aligned, the stabilizer should be

pushed down firmly and the trailing edge should be even with the back edge of the fuselage.

14

Need help or have any questions? Call us at 1-714-963-0329 or send us an email to service@globalhobby.net

❑ Kwik Bond Thin C/A

❑ Kwik Bond 5 Minute Epoxy

❑ Kwik Bond C/A Debonder

❑ Excel Modeling Knife

❑ Electric Drill

❑ 1/16" Drill Bit

❑ Ernst Airplane Stand

❑ Ruler

YOU'LL NEED THE FOLLOWING PARTS:

❑ (1) Prebent Tail Wheel Wire

❑ (1) Tail Wheel

SECTION 11: HINGING THE CONTROL SURFACES

❑ (2) 1mm Nylon Wheel Retainers

YOU'LL NEED THE FOLLOWING TOOLS AND SUPPLIES:

❑ Pencil

❑ 220 Grit Sandpaper w/Sanding Block

❑ Waxed Paper

❑ Paper Towels

❑ Rubbing Alcohol

❑ NHP Epoxy Mixing Sticks

❑ NHP Epoxy Mixing Cups

Step 1: Hinging the Ailerons

❑ Slide one hinge into each hinge slot in one aileron.

❑ Center each hinge within its slot and double-check to

make sure the centerline of the hinges is flush with the leading

edge of the aileron.

❑ Glue each hinge into place using 5-6 drops of thin C/A.

Allow a few seconds between drops for the C/A to "wick" into

the hinges, then turn the aileron over and apply 5-6 drops on

the other side of each hinge. Let the C/A dry for about 10

minutes before proceeding.

☞

If any C/A gets onto the aileron, it can be removed promptly using a paper towel soaked with a small quantity of

C/A Debonder.

❑ Cut out a 2" square piece of waxed paper.

❑ Slide the waxed paper between the torque rod and the

trailing edge of the wing on one wing half.

☞

The waxed paper will prevent epoxy from gluing the torque

rod to the trailing edge.

❑ Mix a small quantity of 5 minute epoxy. Apply a thin layer to the end of the aileron torque rod and pack more into the

predrilled hole and the precut groove in the leading edge of the aileron.

15

Visit our website at http://watt-age.globalhobby.com for information on other Wattage products

❑ Slide the aileron and its hinges into the hinge slots in the trailing edge of the wing, making sure that the torque rod is

firmly seated in the leading edge of the aileron. Adjust the aileron so that the tip of the aileron is even with the wing tip.

❑ While holding the aileron tightly against the wing, pivot

the aileron down about 45º and apply 5-6 drops of thin C/A to

the exposed area of each hinge. Turn the wing over and

repeat for the other side of the hinges.

☞

Remove any C/A that may run down the hinge line using

C/A Debonder.

❑ After the C/A has dried completely - about 15 minutes-

pivot the aileron up and down to free up the hinges.

IMPORTANT

After the C/A and epoxy have fully cured, gently grasp the aileron and pull on it like you are trying to pull out the hinges. The

hinges should hold securely. If one or more hinges feels loose, apply more thin C/A to the hinge(s) and allow it to com-

pletely cure.

❑ Repeat the previous procedures to install the second aileron on the other half of the wing.

Step 2: Hinging the Elevator Halves

Before hinging the elevator halves, look carefully at the elevator half with the precut slot in it. This slot is in the bottom

of the elevator half, so make sure that you hinge it with the slot toward the bottom of the horizontal stabilizer.

❑ Hinge the elevator halves using the same methods as for the ailerons. Make sure that the ends of the elevator halves

are even with the ends of the stabilizer and make sure to put a piece of waxed paper behind the elevator joiner wire to

prevent epoxy from gluing the wire to the trailing edge of the stabilizer.

Step 3: Installing the Tail Wheel Wire

❑ Using a ruler and a pencil, measure up 9/16" from the bottom of the rudder (at the leading edge) and draw a mark.

❑ Using a drill with a 1/16" drill bit, carefully drill a shallow

hole into the leading edge of the rudder at the mark you drew.

☞

Make sure you drill the hole perpendicular to the leading

edge.

16

Need help or have any questions? Call us at 1-714-963-0329 or send us an email to service@globalhobby.net

❑ Using a modeling knife, carefully cut a shallow groove in

the leading edge from the base of the hole down to the bot-

tom of the rudder.

❑ Test-fit the tail wheel wire into the hole and groove. When

properly aligned, the wire should rest within the groove and

the outer surface of the wire should be flush with the leading

edge of the rudder.

❑ When satisfied with the fit, remove the tail wheel wire. Using 220 grit sandpaper, carefully roughen only the gluing

surface of the wire.

❑ Glue the tail wheel wire into place using 5 minute epoxy. Remove any excess epoxy using a paper towel and rubbing

alcohol and allow the epoxy to set up before proceeding.

Step 4: Hinging the Rudder

❑ Hinge the rudder using the same method as for the elevator halves. Make sure that the top edge of the rudder is even

with the top of the vertical stabilizer.

Step 5: Installing the Tail Wheel

❑ Carefully push one 1mm nylon wheel retainer onto the

tail wheel wire as far as it will go.

❑ Slide the tail wheel up against the nylon wheel retainer,

then install the second retainer to secure the wheel into place.

❑ Very carefully apply one drop of thin C/A to the outer wheel retainer to secure it into place.

17

Visit our website at http://watt-age.globalhobby.com for information on other Wattage products

❑ # 1 Phillips Head Screwdriver

❑ Needle Nose Pliers

❑ Electric Drill

YOU'LL NEED THE FOLLOWING PARTS:

❑ (2) Prebent Main Gear Wires

❑ (2) Main Gear Wheels

❑ (2) Nylon Landing Gear Straps

❑ (4) 2.5mm x 10mm Wood Screws

SECTION 12: INSTALLING THE MAIN LANDING GEAR

❑ (4) 3mm Wheel Spacers

❑ (2) Molded Wheel Pants

❑ (2) Aluminum Wheel Pant Mounts

❑ (4) 2.5mm x 5mm Flange-Head Wood Screws

YOU'LL NEED THE FOLLOWING TOOLS AND SUPPLIES:

❑ 1/16" Drill Bit

❑ Ernst Airplane Stand

❑ Pencil

Step 1: Installing the Landing Gear Wires

❑ Line up the short 90º bend in each landing gear wire with

the predrilled holes in the landing gear block.

❑ Firmly push the landing gear into the holes. When aligned

properly the wires should be flush with the bottom of the

fuselage.

❑ The wires are held in place using two nylon landing gear

straps. Position the straps equal distances from the end of

each wire.

❑ Use a pencil to mark the locations of the mounting screws.

☞

Make sure the straps do not hang over the edge of the

hatch cover.

❑ Remove the straps and drill 1/16" pilot holes into the fuselage at the locations you marked.

❑ Using a modeling knife, cut away the covering material from over the landing gear slot in the bottom of the fuselage.

The slot is 3/16" wide, 3-1/4" long and 3/8" behind the hatch cover.

18

Need help or have any questions? Call us at 1-714-963-0329 or send us an email to service@globalhobby.net

❑ Install the straps using four 2.5mm x 10mm wood screws.

Tighten the screws completely to secure the landing gear wires

into place.

Step 2: Installing the Wheels & Wheel Pants

❑ Slide one wheel pant partially onto one of the landing gear axles followed by one 3mm wheel spacer.

IMPORTANT

If you look inside the wheel pant you will see a piece of plywood glued to the side of the pant. When installing the wheel

pant, the side with the plywood should be toward the inside of the landing gear wire.

❑ Carefully slide one main gear wheel onto the axle, then a

second wheel spacer.

❑ Align the predrilled hole in the outside of the wheel pant

and push it over the end of the axle.

❑ Line up one aluminum wheel pant mount with the predrilled

holes in the side of the wheel pant.

❑ Secure the wheel pant and mount into place using two

2mm x 5mm flange-head wood screws.

☞

Be careful not to overtighten the screws.

❑ Rotate the wheel to double-check that it doesn't bind against the wheel pant.

❑ Repeat the previous procedures to install the second wheel and wheel pant assembly.

19

Visit our website at http://watt-age.globalhobby.com for information on other Wattage products

❑ # 1 Phillips Head Screwdriver

❑ Electric Drill

❑ 1/16" Drill Bit

SECTION 13: SERVO INSTALLATION

YOU'LL NEED THE FOLLOWING TOOLS AND SUPPLIES:

❑ Ernst Airplane Stand

❑ Pencil

Step 1: Installing the Servos

❑ Install the rubber grommets and brass collets onto your

elevator, aileron and rudder servos. Make sure to install the

collets with the flanges toward the bottom of the servos.

❑ Set the elevator and rudder servos into the servo tray

taking note of the positions of the servo output shafts.

IMPORTANT

Run the servo leads out toward the front of the airplane.

❑ While holding the servos in place, drill 1/16" pilot holes through the servo tray for the mounting screws.

❑ Install the servos using the wood screws provided with your radio system.

❑ Install the aileron servo into the aileron servo tray taking

note of the position of the output shaft. It should face the

leading edge of the wing.

☞

Run the servo lead out of the wing through the notch in

the side of the tray.

20

Need help or have any questions? Call us at 1-714-963-0329 or send us an email to service@globalhobby.net

❑ Kwik Bond Thick C/A

❑ # 0 Phillips Head Screwdriver

❑ Magnum Z-Bend Pliers

❑ Wire Cutters

❑ Needle Nose Pliers

YOU'LL NEED THE FOLLOWING PARTS:

❑ (2) 1mm x 450mm Pushrod Wires

❑ (2) 1mm x 120mm Pushrod Wires

SECTION 14: PUSHROD INSTALLATION

❑ (2) Plywood Control Horns

YOU'LL NEED THE FOLLOWING TOOLS AND SUPPLIES:

❑ Excel Modeling Knife

❑ Ernst Airplane Stand

❑ Ruler

❑ Pencil

❑ Masking Tape

Step 1: Installing the Elevator Pushrod Wire

❑ Using Magnum Z-Bend Pliers, make a Z-Bend in only

one end of one 1mm x 450mm pushrod wire.

❑ Use wire cutters to remove any excess wire, leaving about

3/16" of wire beyond the Z-Bend.

❑ Using a ruler and a pencil, measure forward 3/4" from the middle of the Z-Bend and draw a mark on the pushrod wire.

❑ Using a pair of needle nose pliers, carefully bend a "V"

shape in the wire. The middle of the "V" should be located at

the mark you drew.

IMPORTANT

When you bend the "V" shape, make sure it points toward

the Z-Bend as shown.

IMPORTANT

This "V" shape is necessary to allow adjustment of the pushrod wire. Do not omit this procedure.

/