1 2

3

4

5 6

7 8

9

10

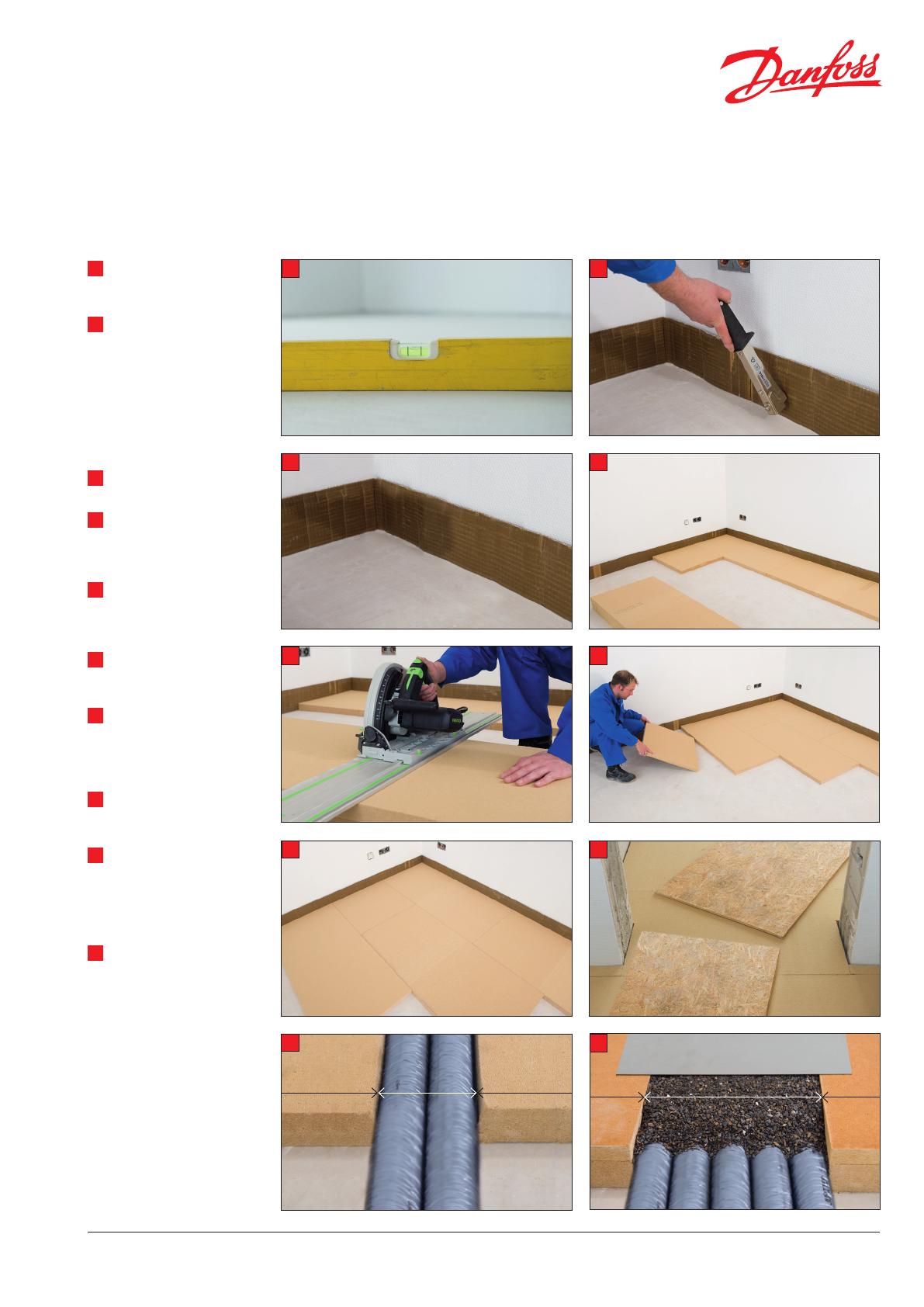

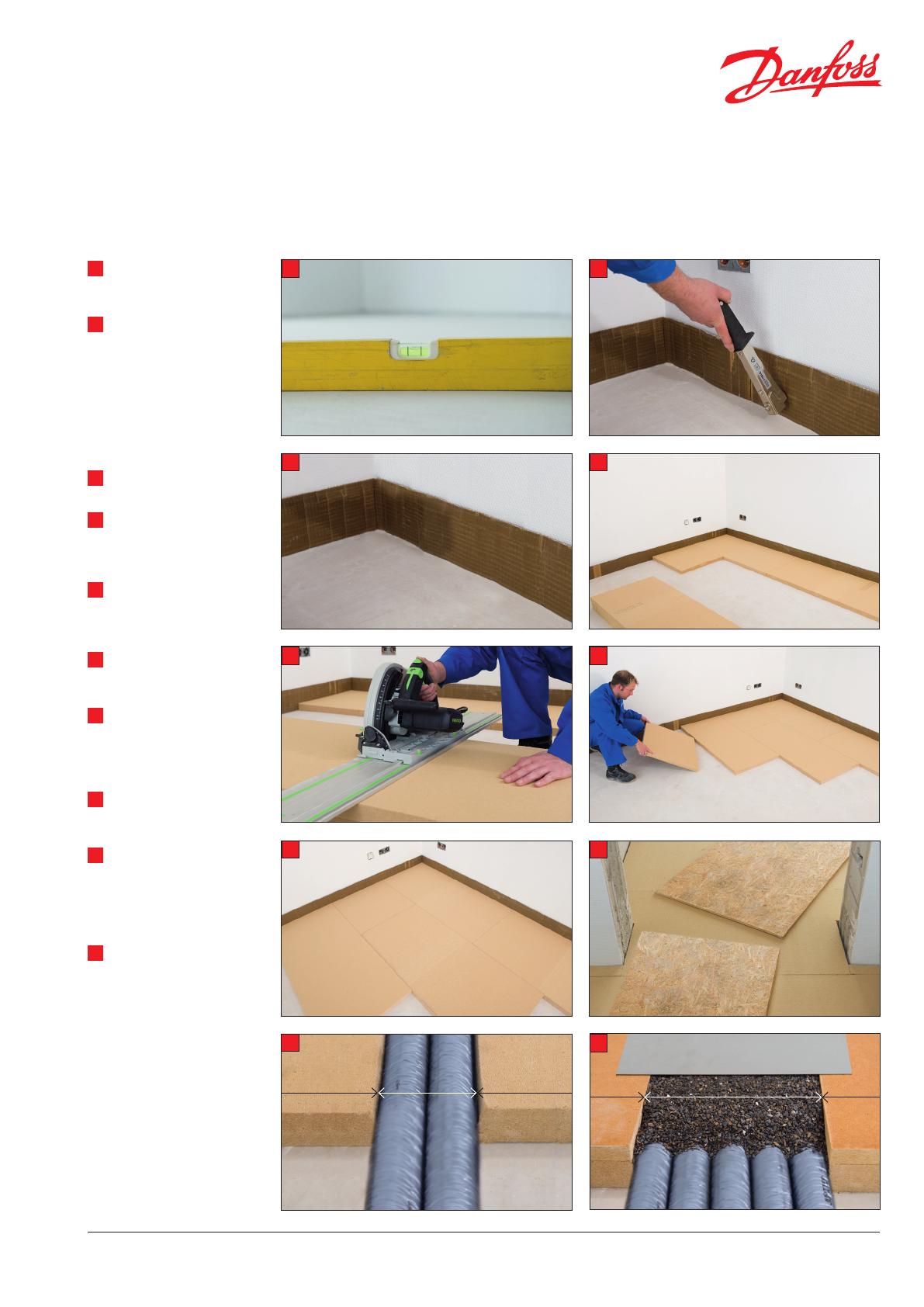

min. 20 cm min. 20 cmmax. 30 cm

min. 20 cm min. 20 cmmax. 30 cm

Instruction

Wood Fibre Insulation

for SpeedUp Eco

Installation of an additional wood fibre insulation

1

The floor base must be dry and

even and load bearing (tolerance

maximum 3 mm/m).

2

Attach SpeedUp Eco perim-

eter insulation on the wall. Avoid

overlapping the ends.

Note!

Additional insulation ≥ 5 cm is laid

without perimeter insulation but

position the perimeter insulation

afterwards on the additional

insulation.

3

Fold the corners of the perim-

eter insulation to fit in the corners.

4

Lay insulation panels in a stag-

gered pattern and cross-laid to the

eventual direction of the SpeedUp

Eco heat panels.

5

Use hand circular saw to cut to

correct size and begin the next row

with the cut off piece. In thresholds

use only whole panels.

6

Butt panels tightly to one an-

other while taking care the panels

are level.

7

Always cross-lay the second

layer of insulation panels to the

previous one. The final layer of

insulation must be cross-layed to

the SpeedUp heat panels above.

8

Important: Protect insulation

from frequent pedestrian traffic to

avoid damage.

9

Enclose pipe section with

panels (maximum width 30 cm

according to BEB/ZDB Information

leaflet) and fix and then fill up with

bonded compound up to level of

insulation.

10

Pipe sections with insulated

pipes and with width from 20 cm

must be covered with a 1 mm

aluminium plate and with 5 cm

overlap.

Note!

Where laminate/engineered tim-

ber or strongboard constructions

are laid straight on to the heat

panels pipe channels wider than

10 cm width must be covered with

a 1 mm thick metal panel. Pipe

channels wider than 15 cm require

a separate load bearing panel

(minimum 18 mm) on top of the

additional insulation.

Danfoss HES VI.CS.E1.02 © Danfoss 11/2008 1