Page is loading ...

Short Guide

for

modification kit 08064164001 for cobas p 471

modification kit 08064237001 for cobas p 671

Retrofitting of Barcode Reader

for cobas p 471 (SN 43xxxxx) centrifuge unit

and cobas p 671 (SN 48xxxxx) centrifuge unit

Roche PVT GmbH

Maybachstrasse 30

D-71332 Waiblingen

Germany

Short guide

Retrofitting Barcode Reader (English)

2/21

Document History

Version

Date

Author

Section

Changes

1.0

02/2017

Hem

Added Modi Kit IDs

Added a Safety Notice

1

Added parts list

2

Added overview of installation procedure

4

Additional picture

4

Changed sequence of procedural steps 14 and 15

4

Specified jumper; added reference to Service manual

5

6

Added references to Service manual

Additional picture

Safety Notice

Only trained service technicians may perform installation and service tasks on systems related to this

document. Always adhere to safety instructions in service manual of related system.

Non-compliance can lead to system damage and operator injury.

Disclaimer

This manual is a product of Roche PVT GmbH.

All rights are reserved. No part of this manual may be reproduced in any form (print, photocopy,

microfilm or another procedure) or processed using electronic systems, copied or distributed without

the written permission of Roche PVT GmbH. Roche PVT GmbH assumes no liability for any errors,

omissions or damages resulting from the use of the information contained in this manual.

Neither Roche PVT GmbH nor its subsidiaries assume any liability to the purchaser of this product or

any third parties for damages, losses, costs or expenses incurred by the purchaser or third parties due

to accident, misuse of the product or unapproved modifications, repairs or improvements to the

instrument.

Roche PVT GmbH assumes no liability for damages or disruptions resulting from the use of options or

accessories that are not original PVT-products or that do not have express approval from Roche PVT

GmbH.

Note: All of the product names contained in this manual are trademarks of the respective companies. If

the trademark symbols © or ® are not included, it can not be assumed that the name is an

unregistered product name.

The content of this manual is subject to change without any communicative obligations by Roche PVT

GmbH. Copyright by Roche PVT GmbH.

Roche PVT GmbH, Waiblingen 2016

Short guide

Retrofitting Barcode Reader (English)

3/21

1 Contents of retrofitting kits

Contents of modification kits

Position

Part description

Quantity

1

angle cobas p671

3

2

screw DIN912 M4x8 VA

6

3

washer DIN125 A4.3 VA

6

4

hinge, hood

2

5

control unit, swivel mounted

1

6

screw DIN912 M6x14 zinc plated

8

7

cable clip d=28 mm

3

8

screw DIN912 M4x10 zinc plated

2

9

washer DIN125 A4.3 VA

6

10

cbox_two V1.0 (SCOI) control module complete

1

11

nut DIN934 M4 zinc plated

8

12

valve terminal cap recognition

1

13

washer DIN9021 A4.3 zinc plated

4

14

cable clip d= 8-13

1

15

nut DIN934 M3 zinc plated

1

16

washer DIN125 A3.2 zinc plated

1

17

printed circuit board DMS, 24V/ 7W

1

18

19" box for cobas p 471/ 671 including bus board and

cable

1

19

screw DIN965 M4x16 zinc plated

2

20

spacer 10 5.2 03

2

21

rear panel top (control unit)

1

22

cover for control unit, swivel mounted cobas p 471/ 671

1

23

screw DIN7380 M4x8 zinc plated (circled black below)

10

24

screw DIN7380 M4x12 zinc plated (circled gray below)

4

25

analytical unit cap recognition (with bc-reading unit)

1

26

Short Guide for Retrofitting Barcode Reader

available on GRIPS

Table 1: Contents of modification kits

Short guide

Retrofitting Barcode Reader (English)

4/21

2 Overview of installation procedure

Steps

Action

Preparation

check software version

prepare housing

Installation

mount and align angles

mark position of angles on strut

detach strut

tap M4 treads

re-install camera

re-install strut

mount hinges to control unit

fasten control unit with screws

prepare and fasten cable clips

attach cable clips to control unit

connect valve terminal

fasten valve terminal to wall

mount valve terminal

mount cbox_two

set jumper positions

set motor addresses

mount control board

fix 19” box

connect barcode scanner

connect PDM

convert maintenance unit

mount panels

Configuration

set barcode reader

activate barcode reader and barcode types in software

initialize cbox_two

set camera system

set RTC positions

Table 2: Steps of installation procedure

Short guide

Retrofitting Barcode Reader (English)

5/21

3 Preconditions

Please Note: After the system has been retrofitted with a barcode reader, it is mandatory to use

software version 1.3.0 or higher!

The system housings must be prepared with drill holes to be able to mount the barcode reader unit. On

older systems, it may be necessary to bore those holes (see Section 6, 'Appendix') prior to installation

of the barcode reader unit!

As necessary, refer to Service manual for installation.

4 Installing the barcode reader unit

Overview

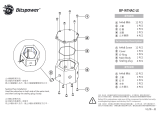

Figure 1: Rear side – barcode reader (circled)

Short guide

Retrofitting Barcode Reader (English)

6/21

1. Using the screws and washers, mount the 3 angles to the housing for the control units and cover,

respectively (1). Align the angles.

angle cobas p 671 (3 pcs.)

screw DIN912 M4x8 VA (6 pcs.)

washer DIN125 A4.3 VA (6 pcs.)

Figure 2: Angles (circled)

2. Mark the positions of the angles on the strut.

3. Detach the strut.

4. Tap M4 threads.

Figure 3: Strut with angles (circled)

Short guide

Retrofitting Barcode Reader (English)

7/21

NOTICE

Prior to installation, route the scanner cables sideways past the camera to the cbox_two.

5. Re-install the camera. Do not yet tighten the fastening screws.

6. Re-install the strut.

Figure 4: Camera installed

NOTICE

Make sure the cables (motor, rotary and lifting unit) are laid between the left side panel of the

system and the TTI housing. Secure the cables with cable clips.

hinge, hood (2 pcs.)

control unit, swivel mounted (1 pc.)

screw DIN912 M6x14 zinc plated (8 pcs.)

cable clip d=28 mm (2 pcs.)

screw DIN912 M4x10 zinc plated (2 pcs.)

washer DIN125 A4.3 zinc plated (2 pcs.)

7. Mount the hinges to the control unit with two screws each.

8. Fasten the control unit with two screws each.

9. Drill a hole with diameter 4.2 mm in the cable clips.

10. Fasten them with a screw and washer each.

Short guide

Retrofitting Barcode Reader (English)

8/21

Figure 5: Hinges and cable clips

Short guide

Retrofitting Barcode Reader (English)

9/21

11. Attach the cable clip to the control unit (to the right of the 19"-box) by using an instant adhesive.

Keep a distance of 15 mm from the edge.

cable clip d=28 mm (1 pc.)

Figure 6: Location of cable clip at control unit (circled)

Figure 7: Cable clip at the control unit

12. Connect the valve terminal. Make sure the connections are correct.

13. Fasten the valve terminal to the wall.

Short guide

Retrofitting Barcode Reader (English)

10/21

Figure 8: Cabling valve terminal

14. Mount the valve terminal (1) using the nuts and washers.

valve terminal cap recognition (1 pc.)

nut DIN934 M4 zinc plated (4 pcs.)

washer DIN9021 A4.3 zinc plated (4 pcs.)

cable clip d= 8-13 (1 pcs.)

nut DIN934 M3 zinc plated (1 pcs.)

washer DIN125 A3.2 zinc plated (1 pcs.)

15. Mount the cbox_two (2) using the nuts and washers.

cbox_two V1.0 (SCOI) control module, complete (1 pc.)

nut DIN934 M4 zinc plated (4 pcs.)

washer DIN125 A4.3 zinc plated (4 pcs.)

2.0

2.1

Short guide

Retrofitting Barcode Reader (English)

11/21

16. Fasten the cable clip (3).

Figure 9: cbox_two and valve terminal

17. Set jumper 7 to position 1 and 2 on the board.

printed circuit board DMS, 24V/ 7W, Rotary (1 pc.)

Figure 10: Jumper setting

18. Set the motor addresses in accordance with Service manual, chapter Electronics -> Top View

DMS:

Lift = 66 W control board address 0

Rotary = 7 W control board address 1

2

1

3

Short guide

Retrofitting Barcode Reader (English)

12/21

19. Mount the control board.

Figure 11: control boards

Short guide

Retrofitting Barcode Reader (English)

13/21

20. Untighten the two lower screws fixing the 19" box.

21. Fasten the 19" box with the screws and spacers, which must be placed between the box and the

control unit.

19" box for cobas p 471/ 671 including bus board and cable (1 pc.)

screw DIN965 M4x16 zinc plated (2 pcs.)

spacer 10 5.2 03 (2 pcs.)

Figure 12: 19"box

Figure 13: Spacers (circled red)

Short guide

Retrofitting Barcode Reader (English)

14/21

22. Secure the cabling of the barcode scanner.

Figure 14: Cabling

23. Connect the barcode scanner.

24. Fasten the cables of the scanner with cable ties to the cables of the y-axis leading downwards.

Figure 15: Plug socket connection barcode scanner/ cable ties

Short guide

Retrofitting Barcode Reader (English)

15/21

25. Connect the PDM.

Figure 16: PDM

Short guide

Retrofitting Barcode Reader (English)

16/21

26. Check the cable assignment marked below.

Figure 17: Connector Block X1 (DC-Voltages)

Short guide

Retrofitting Barcode Reader (English)

17/21

27. Lay the cable of the PDM inside.

Figure 18: cable laying PDM inside

28. Convert the maintenance unit for connecting the barcode scanner.

Figure 19: Maintenance unit – scanner connection

Short guide

Retrofitting Barcode Reader (English)

18/21

29. Mount the panelings to the system.

rear panel top (control unit) (1 pc.)

cover for control unit, swivel mounted cobas p 471/ 671 (1 pc.)

screw DIN7380 M4x8 zinc plated (circled black below) (10 pcs.)

screw DIN7380 M4x12 zinc plated (circled gray below) (4 pcs.)

Figure 20: Screws fixing the covers

Short guide

Retrofitting Barcode Reader (English)

19/21

5 Software adaptation

Please note: Software adaption on site is not possible! Please ask Roche PVT support for assistance.

30. Set barcode reader in accordance with Service manual, chapter Electronics -> Barcode Scanner.

31. Set barcode parameters in accordance with Service manual, chapters Software Description ->

Barcode Types.

32. Initialize cbox_two in accordance with Service manual, chapter Software -> Module Utilities.

33. Set camera parameters in accordance with Service manual, chapters Software Description ->

Camera parameters and the following.

34. Set RTC positions in accordance with Service manual, chapters Mechanics -> Camera rack

transport RTC.

Please note: When setting the work position of the lifting rotary gripper of the cobas p 671, make

sure the tube is not lifted completely out of the rack.

Short guide

Retrofitting Barcode Reader (English)

20/21

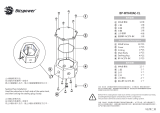

6 Appendix

Figure 21: Positions for drill holes (exemplary)

Item

Description

A

M6 thread

B

M4 thread

C

Drill hole; diameter 28 mm

A

A

B

B

C

/