Rockwell Automation Publication 2198-UM001I-EN-P - May 2019 13

Preface

You can view or download publications at

http://www.rockwellautomation.com/global/literature-library/overview.page

.

System Design for Control of Electrical Noise Reference Manual,

publication GMC-RM001

Information, examples, and techniques designed to minimize system failures

caused by electrical noise.

Kinetix Motion Control Selection Guide, publication KNX-SG001

Overview of Kinetix servo drives, motors, actuators, and motion accessories

designed to help make initial decisions for the motion control products best suited

for your system requirements.

Kinetix 5500 Drive Systems Design Guide, publication KNX-RM009

System design guide to select the required (drive specific) drive module, power

accessory, feedback connector kit, and motor cable catalog numbers for your

Kinetix 5500 drive and Kinetix VP motor motion control system.

Rockwell Automation Product Selection

website http://www.rockwellautomation.com/global/support/selection.page

Online product selection and system configuration tools, including AutoCAD (DXF)

drawings.

Motion Analyzer System Sizing and Selection Tool

website https://motionanalyzer.rockwellautomation.com/

Comprehensive motion application sizing tool used for analysis, optimization,

selection, and validation of your Kinetix Motion Control system.

Product Certifications website, rok.auto/certifications

Provides declarations of conformity, certificates, and other certification details.

Motor Nameplate Datasheet Entry for Custom Motor Applications Application Technique,

publication 2198-AT002

Provides information on the use of nameplate data entry for custom induction

motors and permanent-magnet motors that are used in applications with

Kinetix 5700 servo drives.

Vertical Load and Holding Brake Management Application Technique,

publication MOTION-AT003

Provides information on vertical loads and how the servo motor holding-brake

option can be used to help keep a load from falling.

Integrated Motion on the EtherNet/IP Network Reference Manual,

publication MOTION-RM003

Information on the AXIS_CIP_DRIVE attributes and the configuration software

control modes and methods.

Integrated Motion on the EtherNet/IP Network Configuration and Startup User Manual,

publication MOTION-UM003

Information on how to configure and troubleshoot your ControlLogix® and

CompactLogix™ EtherNet/IP network modules.

GuardLogix 5570 Controllers User Manual, publication 1756-UM022

Provides information on how to install, configure, program, and use ControlLogix

controllers and GuardLogix® controllers in Studio 5000 Logix Designer® projects.

GuardLogix 5580 Controllers User Manual, publication 1756-UM543

Compact GuardLogix 5370 Controllers User Manual, publication 1769-UM022

Provides information on how to install, configure, program, and use CompactLogix

and Compact GuardLogix controllers.

Compact GuardLogix 5380 Controllers User Manual, publication 5069-UM001

GuardLogix 5570 and Compact GuardLogix 5370 Controller Systems Safety Reference

Manual, publication 1756-RM099

Provides information on how to achieve and maintain Safety Integrity Level (SIL)

and Performance Level (PL) safety application requirements for GuardLogix and

Compact GuardLogix controllers.

GuardLogix 5580 and Compact GuardLogix 5380 Controller Systems Safety Reference

Manual, publication 1756-RM012

ControlFLASH Firmware Upgrade Kit User Manual, publication 1756-UM105

Provides information on how to upgrade your drive firmware by using

ControlFLASH™ software.

Rockwell Automation Industrial Automation Glossary, publication AG-7.1

A glossary of industrial automation terms and abbreviations.

Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

Provides general guidelines for installing a Rockwell Automation industrial system.

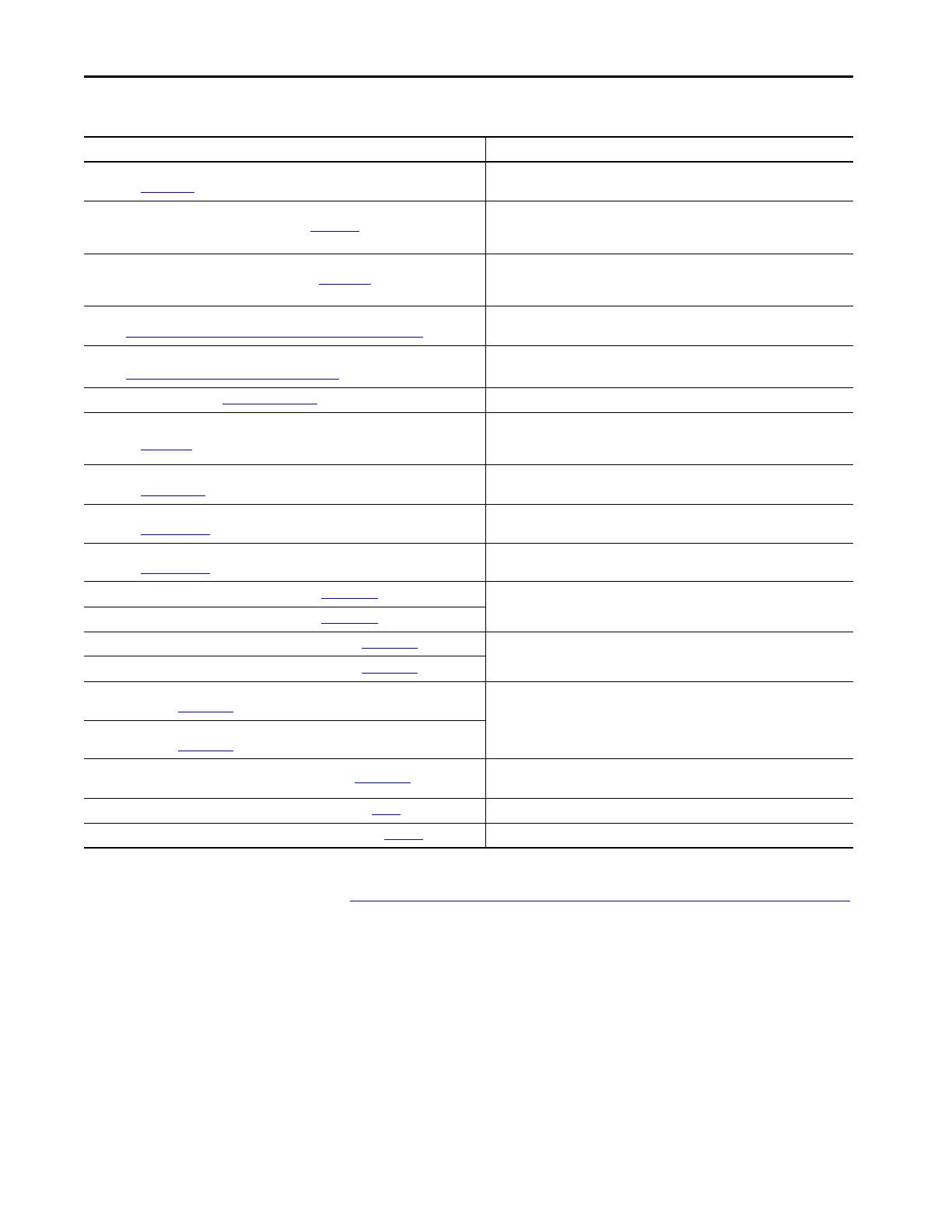

Table 1 - Additional Resources (continued)

Resource Description