Page is loading ...

CREWSERIES

RACKCONVEYORDISHMACHINES

With

WISR

TM

TECHNICALMANUAL

INSTALLATIONMANUALFOREXPORTUNITS

SERVICEMANUALFORDOMESTICUNITS

ELECTRICALLYHEATEDMODELS:

CREW44

CREW66

STEAMHEATEDMODELS

CREW44S

CREW66S

Feb.25,2011

P/N07610‐003‐78‐18(RevisionD)

JacksonWWS,Inc.

P.O.Box1060,Hwy25E

Barbourville,KYUSA

1.606.523.9795

www.jacksonwws.com

Revision

Letter

Revision

Date

MadeBy ApplicableECNs Details

A 07-27-10 CW/JC N/A Initial release of manual

B 02-25-11 JC 8183

8186

8187

8177

Transformer change for 208 Volt units.

Drain handle operation & alignment change.

Door splash shield addition.

Rinse paddle switch operation.

Initial release of 66” units, 44” Steam units &

66” Steam units

C 06-30-11 JC N/A Initial release of 23” & 30” unhooded side-

loaders

D 03-28-13 JC Changed Jackson Logo

TABLEOFCONTENTS

Speciications

MachineDimensions Page6

OperatingParameters Page12

NotesRegardingElectricalRequirements Page13

ElectricalRequirements Page14

SideLoaderDimensions Page10

SteamBoosterHeaterDimensions Page11

Instructions

InstallationInstructions Page17

CurtainInstallationInstructions Page22

OperatingInstructions Page23

DelimeInstructions Page25

Maintenance

Troubleshooting Page26

PartsSection

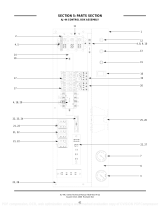

ControlBoxComponents Page27

Overloads Page29

MiscellaneousElectricalComponents Page30

WashHeaterandHeaterShroudAssemblies Page31

PumpSuctionAssembly Page32

WashHeaters Page33

DoorAssembly Page34

Pre‐WashDoorAssembly Page35

WashDoorSpringAssembly Page36

PlumbingAssembly,MainWaterInlet Page37

WashTankFillAssembly Page38

Pre‐WashTankFillAssemblies Page39

WashManifoldandArmAssembly Page40

Pre‐WashManifoldandArmAssemblies Page42

RinseAssembly Page44

PawlBarAssembly Page46

PawlBarBracketAssembly Page47

PawlBarGutterAssembly Page48

TABLEOFCONTENTS(CONTINUED)

PartsSection(Continued)

MiscellaneousParts Page54

VentilationCowlParts Page55

VentilationCowlforUnhoodedSide‐Loader Page56

DriveAssembly Page57

Side‐Loaders Page59

Side‐LoaderDriveLinkage Page62

SteamHeatingCoilAssembly Page63

BoosterHeaterOption(Electric) Page64

BoosterHeaterOption(Steam) Page65

RackPaddleAssembly Page49

Brackets Page53

Covers,GuardsandPanels Page52

RinsePaddleAssemblies Page50

DrainAssemblyParts Page51

ElectricalDiagramsandSchematics

BoosterHeaterSchematic(3Phase) Page67

BoosterHeaterSchematic(1Phase,12KW) Page68

BoosterHeaterSchematic(1Phase,18KW) Page69

TemperatureBoard Page71

Schematic,44”(208‐230‐460/60/3Phase) Page73

Schematic,44”(208‐230/60/1Phase) Page74

Schematic,Photo‐CellTableLimitSwitch Page72

Schematic,44”Steam(208‐230‐460/60/3Phase) Page75

Schematic,44”Steam(208‐230/60/1Phase) Page76

Schematic,66”(208‐230‐460/60/3Phase) Page77

Schematic,66”(208‐230/60/1Phase) Page78

Schematic,66”Steam(208‐230‐460/60/3Phase) Page79

Schematic,66”Steam(208‐230/60/1Phase) Page80

SteamBoosterHeaterSchematic Page70

Maintenance&RepairCentersPage81

6

PageCreated:06‐30‐2011

Revised:N/A

TechnicalManual(07610‐003‐78‐18)

MACHINEDIMENSIONS(44”LefttoRight)

E1 MAINELECTRICALCONNECTION(1.375”DIAHOLE)

E2 BOOSTERHEATERELECT.CONNECTION(1.375”DIA)

W MAININLETWATERCONNECTION(1/2NPT‐F)

D DRAINCONNECTION(1‐1/2”NPT‐F)

DET DETERGENTBULKHEADACCESS(.875”DIAHOLE)

SAN** SANITIZERINLETTORINSE(1/8”NPT‐F)

RA RINSEAIDCONNECTIONTORINSE(1/8”NPT‐F)

CP CONDUCTIVITYPROBEACCESS(.875”DIAHOLE)

S* STEAMTOWASHTUBHEATINGCOIL(3/4”NPT‐F)

C* CONDENSATERETURN(3/4”NPT‐F)

V1 VENTILATIONDUCTCONN.(LOADEND)4”x16”ID

V2 VENTILATIONDUCTCONN.(UNLOADEND)4”x16”ID

34 in

67

1

2

in

71

5

8

in

51

1

2

in MIN

(NOTE 2)

11 in

21 in

23.50

14

1

2

in

6

1

8

in

10

1

8

in (NOTE 3)

3

8

in

8

3

4

in

61

1

8

in

63

5

8

in

64

1

2

in

TABLE to TABLE

44 in

63

3

8

in

93 in MAX

(NOTE 1)

34 in

20 in

20

5

8

in

14 in

16

1

2

in

30

1

2

in

E1

E2

W

V2

V1

S*

C*

D

CP

DET

CP

4 in

7

3

8

in

RA

SAN

E2

E1

W

23

3

4

in

23

3

4

in

23

3

4

in

3

3

4

in

17

1

8

in

DET

DET

S*

W

E2

E1

C*

SAN

2

1

4

in

RA

26

5

8

in

D

7

7

8

in

19

1

8

in

11

1

2

in

11

1

2

in

44

1

8

in

NOTE 2:

VENTILATION DUCT ADAPTERS ARE

ADJUSTABLE FROM 51-1/2" TO 54".

NOTE 1:

THE MAXIMUM DOOR HEIGHT MAY BE

REDUCED BY THE ADDITION OF OPTIONAL

DOOR BRACKETS. MAXIMUM HEIGHTS OF

91", 89" & 87" ARE AVAILABLE.

NOTE 3:

THE DRIVE ASSEMBLY AND GUARD

MAY BE INSTALLED ON EITHER END

OF THE UNIT. INSTALLATION ON THE

UNLOAD END IS STANDARD. IF

INSTALLED ON THE LOAD END,

PLEASE ENSURE ANY SCRAP SINKS

IN THE TABLING ARE AT AN ADEQUATE

DISTANCE TO PROVIDE FOR CLEARANCE

OF THE DRIVE ASSEMBLY.

15

1

4

in

21

1

2

in

14

7

8

in

NOTE 4:

ALL VERTICAL DIMENSIONS MAY

VARY DUE TO THE ADJUSTABLE

FEET.

(NOTE 4)

(NOTE 4)

(NOTE 4)

(NOTE 4)

4

3

8

in

* APPLIES TO STEAM HEATED UNITS

** CHEMICAL SANITIZING UNITS ONLY

7

PageCreated:06‐30‐2011

Revised:N/A

TechnicalManual(07610‐003‐78‐18)

MACHINEDIMENSIONS(44”RighttoLeft)

63

5

8

in

64

1

2

in

61

1

8

in

71

5

8

in

67

1

2

in

15

1

4

in

9 in

8

3

4

in

11

1

2

in

11

1

2

in

6

1

8

in

14

1

2

in

21

1

8

in

23

5

8

in

11

1

8

in

4

1

4

in

7

3

8

in

23

3

4

in

23

3

4

in

51

5

8

in

(NOTE 2)

4

3

8

in

RA

3

8

in

2

1

4

in

7

7

8

in

19

1

8

in

14

7

8

in

21

1

2

in

26

5

8

in

4

3

8

in

TABLE to TABLE

44 in

63

3

8

in

93 in MAX

(NOTE 1)

34 in

23

3

4

in

3

3

4

in

17

1

8

in

20 in

20

5

8

in

14 in

30

1

2

in

16

1

2

in

W

E1

E2

DET

CP

S*

W

E2

E1

SAN

D

C*

S*

E1

E2

W

RA

SAN

DET

DET

S*

C*

D

CP

(NOTE 3) 10

1

8

in

(NOTE 4)

(NOTE 4)

(NOTE 4)

(NOTE 4)

NOTE 1:

THE MAXIMUM DOOR HEIGHT MAY BE

REDUCED BY THE ADDITION OF OPTIONAL

DOOR BRACKETS. MAXIMUM HEIGHTS OF

91", 89" & 87" ARE AVAILABLE.

NOTE 2:

VENTILATION DUCT ADAPTERS ARE

ADJUSTABLE FROM 51-1/2" TO 54".

NOTE 3:

THE DRIVE ASSEMBLY AND GUARD

MAY BE INSTALLED ON EITHER END

OF THE UNIT. INSTALLATION ON THE

UNLOAD END IS STANDARD. IF

INSTALLED ON THE LOAD END,

PLEASE ENSURE ANY SCRAP SINKS

IN THE TABLING ARE AT AN ADEQUATE

DISTANCE TO PROVIDE FOR CLEARANCE

OF THE DRIVE ASSEMBLY.

NOTE 4:

ALL VERTICAL DIMENSIONS MAY

VARY DUE TO THE ADJUSTABLE

FEET.

16 in

4 in

44

1

8

in

V2

V1

E1 MAINELECTRICALCONNECTION(1.375”DIAHOLE)

E2 BOOSTERHEATERELECT.CONNECTION(1.375”DIA)

W MAININLETWATERCONNECTION(1/2NPT‐F)

D DRAINCONNECTION(1‐1/2”NPT‐F)

DET DETERGENTBULKHEADACCESS(.875”DIAHOLE)

SAN** SANITIZERINLETTORINSE(1/8”NPT‐F)

RA RINSEAIDCONNECTIONTORINSE(1/8”NPT‐F)

CP CONDUCTIVITYPROBEACCESS(.875”DIAHOLE)

S* STEAMTOWASHTUBHEATINGCOIL(3/4”NPT‐F)

C* CONDENSATERETURN(3/4”NPT‐F)

V1 VENTILATIONDUCTCONN.(LOADEND)4”x16”ID

V2 VENTILATIONDUCTCONN.(UNLOADEND)4”x16”ID

* APPLIES TO STEAM HEATED UNITS

** CHEMICAL SANITIZING UNITS ONLY

8

PageCreated:06‐30‐2011

Revised:N/A

TechnicalManual(07610‐003‐78‐18)

MACHINEDIMENSION(66”LefttoRight)

15

1

4

in

67

1

2

in

63

5

8

in

64

1

2

in

7

3

8

in

61

1

8

in

23

1

2

in

21 in

11

1

8

in

4

1

4

in

73

1

2

in MIN

(NOTE 2)

63

1

2

in

61 in

10

7

8

in

34 in

11

1

2

in

23

3

4

in

3

3

4

in

17

1

8

in

33

1

2

in

7

5

8

in

14

1

2

in

6

1

8

in

9 in

8

3

4

in

8

3

4

in

20

5

8

in

20 in

93 in MAX

(NOTE 1)

3

8

in

9 in

2

1

4

in

14

7

8

in

21

1

2

in

26

5

8

in

30

5

8

in

TABLE to TABLE

66 in

85

1

2

in

14 in

16

5

8

in

20

3

8

in

14

7

8

in

W2

W3***

W1

SAN**

D1

C*

S*

RA

D2

E1

E2

W3***

W2

E1

E2

W1

RA

SAN**

V1

V2

S*

DET

D1

C*

CP

D2

E1

E2

W1

CP

66

1

8

in

DET

16 in

4 in

71

5

8

in

10

1

8

in (NOTE 3)

NOTE 1:

THE MAXIMUM DOOR HEIGHT MAY BE

REDUCED BY THE ADDITION OF OPTIONAL

DOOR BRACKETS. MAXIMUM HEIGHTS OF

91", 89" & 87" ARE AVAILABLE.

NOTE 2:

VENTILATION DUCT ADAPTERS ARE

ADJUSTABLE FROM 73-1/2" TO 76".

NOTE 3:

THE DRIVE ASSEMBLY AND GUARD

MAY BE INSTALLED ON EITHER END

OF THE UNIT. INSTALLATION ON THE

UNLOAD END IS STANDARD. IF

INSTALLED ON THE LOAD END,

PLEASE ENSURE ANY SCRAP SINKS

IN THE TABLING ARE AT AN ADEQUATE

DISTANCE TO PROVIDE FOR CLEARANCE

OF THE DRIVE ASSEMBLY.

NOTE 4:

ALL VERTICAL DIMENSIONS MAY

VARY DUE TO THE ADJUSTABLE

FEET.

(NOTE 4)

(NOTE 4)

(NOTE 4)

E1 MAINELECTRICALCONNECTION(1.375”DIAHOLE)

E2 BOOSTERHEATERELECT.CONNECTION(1.375”DIA)

W1 MAININLETWATERCONNECTION(1/2NPT‐F)

W2 PRE‐WASHINLETWATERCONN.(1/2NPT‐F)

W3*** PRE‐WASHCOLDWATERCONN.(1/2NPT‐F)

D1 DRAINCONNECTION,WASH(1‐1/2”NPT‐F)

D2 DRAINCONNECTION,PRE‐WASH(1‐1/2”NPT‐F)

DET DETERGENTBULKHEADACCESS(.875”DIAHOLE)

RA RINSEAIDCONNECTIONTORINSE(1/8”NPT‐F)

CP CONDUCTIVITYPROBEACCESS(.875”DIAHOLE)

S* STEAMTOWASHTUBHEATINGCOIL(3/4”NPT‐F)

C* CONDENSATERETURN(3/4”NPT‐F)

V1 VENTILATIONDUCTCONN.(LOADEND)4”x16”ID

V2 VENTILATIONDUCTCONN.(UNLOADEND)4”x16”ID

SAN** SANITIZERINLETTORINSE(1/8”NPT‐F)

* APPLIES TO STEAM HEATED UNITS

** CHEMICAL SANITIZING UNITS ONLY

*** PRE-WASH COLD WATER THERMOSTAT OPTION ONLY

9

PageCreated:06‐30‐2011

Revised:N/A

TechnicalManual(07610‐003‐78‐18)

MACHINEDIMENSION(66”RighttoLeft)

E1 MAINELECTRICALCONNECTION(1.375”DIAHOLE)

E2 BOOSTERHEATERELECT.CONNECTION(1.375”DIA)

W1 MAININLETWATERCONNECTION(1/2NPT‐F)

W2 PRE‐WASHINLETWATERCONN.(1/2NPT‐F)

W3*** PRE‐WASHCOLDWATERCONN.(1/2NPT‐F)

D1 DRAINCONNECTION,WASH(1‐1/2”NPT‐F)

D2 DRAINCONNECTION,PRE‐WASH(1‐1/2”NPT‐F)

DET DETERGENTBULKHEADACCESS(.875”DIAHOLE)

RA RINSEAIDCONNECTIONTORINSE(1/8”NPT‐F)

CP CONDUCTIVITYPROBEACCESS(.875”DIAHOLE)

S* STEAMTOWASHTUBHEATINGCOIL(3/4”NPT‐F)

C* CONDENSATERETURN(3/4”NPT‐F)

V1 VENTILATIONDUCTCONN.(LOADEND)4”x16”ID

V2 VENTILATIONDUCTCONN.(UNLOADEND)4”x16”ID

SAN** SANITIZERINLETTORINSE(1/8”NPT‐F)

* APPLIES TO STEAM HEATED UNITS

** CHEMICAL SANITIZING UNITS ONLY

*** PRE-WASH COLD WATER THERMOSTAT OPTION ONLY

15

1

4

in

73

1

2

in

(NOTE 2)

10

1

8

in (NOTE 3)

71

5

8

in

67

1

2

in

9 in

11

1

2

in

63

5

8

in

64

1

2

in

61

1

8

in

7

3

8

in

4

1

4

in

11

1

8

in

21 in

23

1

2

in

10

7

8

in

61 in

63

1

2

in

8

3

4

in

7

5

8

in

29

1

2

in

93 in MAX

(NOTE 1)

3

3

4

in

17

1

8

in

23

3

4

in

3

8

in

2

1

4

in

7

3

4

in

19

1

8

in

14

7

8

in

26

5

8

in

TABLE to TABLE

66 in

85

1

2

in

21

1

2

in

14 in

30

5

8

in

16

5

8

in

66

1

8

in

4

3

8

in

4 in

16 in

E2

E1

SAN**

RA W1

W2

W3***

D1

D2

S*

C*

SAN**

RA

W1

E2

E1

W2

W3***

S*

DET

C*

CP

D2

D1

CP

DET

W1

E1

E2

V2

V1

6

1

8

in

11

5

8

in

34 in

(NOTE 4)

(NOTE 4) (NOTE 4)

(NOTE 4)

NOTE 3:

THE DRIVE ASSEMBLY AND GUARD

MAY BE INSTALLED ON EITHER END

OF THE UNIT. INSTALLATION ON THE

UNLOAD END IS STANDARD. IF

INSTALLED ON THE LOAD END,

PLEASE ENSURE ANY SCRAP SINKS

IN THE TABLING ARE AT AN ADEQUATE

DISTANCE TO PROVIDE FOR CLEARANCE

OF THE DRIVE ASSEMBLY.

NOTE 2:

VENTILATION DUCT ADAPTERS ARE

ADJUSTABLE FROM 73-1/2" TO 76".

NOTE 1:

THE MAXIMUM DOOR HEIGHT MAY BE

REDUCED BY THE ADDITION OF OPTIONAL

DOOR BRACKETS. MAXIMUM HEIGHTS OF

91", 89" & 87" ARE AVAILABLE.

NOTE 4:

ALL VERTICAL DIMENSIONS MAY

VARY DUE TO THE ADJUSTABLE

FEET.

10

PageCreated:06‐30‐2011

Revised:N/A

Technical Manual (07610-003-78-18)

SIDE LOADER DIMENSIONS

23.00

29.00

30.32

23.00

29.00

30.32

16.35 16.35

10.00

34.00

+1.00

-1.00

10.00

34.00

+1.00

-1.00

22.00 22.00

ADJUSTABLE VENTILATION

DUCT ADAPTER

ADJUSTABLE VENTILATION

DUCT ADAPTER

SIDE-LOADER

DRAIN HOSE

SIDE-LOADER

DRAIN HOSE

23" L-R UNHOODED

SIDE-LOADER

23" R-L UNHOODED

SIDE-LOADER

VENTILATION SCOOP

VENTILATION SCOOP

VENTILATION COWL

WITH CUTOUT FOR

R-L UNITS

VENTILATION COWL

WITH CUTOUT FOR

L-R UNITS

DIMENSION IS 30.00" FOR THE

30" UNHOODED SIDE-LOADER

DIMENSION IS 30.00" FOR THE

30" UNHOODED SIDE-LOADER

ELECTRICAL

CONDUIT

ELECTRICAL

CONDUIT

11

PageCreated:06‐30‐2011

Revised:N/A

Technical Manual (07610-003-78-18)

STEAM BOOSTER HEATER DIMENSIONS

E MAINELECTRICALCONNECTION(7/8”DIAHOLE)

W1 MAININLETWATERCONNECTION(3/4NPT‐F)

W2 WATEROUTLETCONNECTION(3/4NPT‐F)

PW WATERPRESSURERELIEFOUTLET(3/4NPT‐F)

PS STEAMPRESSURERELIEFOUTLET(1”NPT‐F)

S STEAMSUPPLYTOBOOSTER(1”NPT‐F)

C STEAMCONDENSATECONNECTION(3/4NPT‐F)

20

3

4

in

2

7

8

in

17

1

2

in

24 in

14

5

8

in

33

1

8

in

8

7

8

in

8

5

8

in

S

PS

PW

C

S

W1

W2

C

10

1

8

in

PW

1

3

4

in

PS

W2

11

1

8

in

22 in

3

3

8

in

19

3

8

in

20

1

8

in

28

5

8

in

20

1

4

in

W1

S

W2

PS

PW

33.69

11

3

8

in

22 in

7

1

2

in

E

E

E

SteamConsumption

(lbm/hr)

30 37 45 52 59

TemperatureRise

(DegreesFahrenheit)

40 50 60 70 80

Based upon a Steam Inlet Pressure of 15-25psig

BOOSTER HEATER STEAM CONSUMPTION

12

PageCreated:05‐04‐2010

Revised:02‐25‐2011

TechnicalManual(07610‐003‐78‐18)

OperatingParameters

ModelDesignation:44”66”44”Steam66”Steam

OperatingCapacity:

RacksperHour218218218218

DishesperHour 3488348834883488

GlassesperHour 7848784878487848

TankCapacity(gallons):

WashTank 35.635.635.635.6

Pre‐WashTankN/A15.8N/A15.8

ElectricalLoads(asapplicable):

WashMotorHP 3.03.03.03.0

DriveMotorHP0.250.250.250.25

Pre‐WashMotorHPN/A2.0N/A2.0

WashHeaterKW15or1818N/AN/A

NOTE:Always refer to the machine data plate for speciic electrical and water requirements. The

materialprovidedonthispageisforreferenceonlyandissubjecttochangewithoutnotice.

HOTWATERSANITIZING

Water

Temperatures(Fahrenheit):

Pre‐WashTemperature(Recommended)N/A110‐140N/A110‐140

MinimumWashTemperature 160160160160

MinimumRinseTemperature 180180180180

IncomingWaterTemperature

12KWBooster 140140N/AN/A

18KWBooster 110110N/AN/A

NoBooster180180180180

CHEMICALSANITIZING

WaterTemperatures(Fahrenheit):

Pre‐WashTemperature(Recommended)N/A110‐120N/A

110‐120

MinimumWashTemperature 120120120120

MinimumRinseTemperature 120120120120

IncomingWaterTemperature

12KWBooster 8080N/AN/A

18KWBooster5050N/AN/A

NoBooster120120120120

OtherWaterRequirements:

WaterFlowPressure(PSIG) 15151515

FlowRateMinimum(GPM)1.181.181.181.18

WaterLineSize(NPT) 1/2”1/2”1/2”1/2”

DrainLineSize(NPT) 1‐1/2”1‐1/2”1‐1/2”1‐1/2”

SteamRequirements

SteamLineforWashTank(NPT)N/AN/A3/4”3/4”

SteamFlowPressure(PSIG)N/AN/A10‐2010‐20

Consumption@15PSIG(lbm/hr)N/AN/A6060

13

PageCreated:05‐04‐2010

Revised:02‐25‐2011

TechnicalManual(07610‐003‐78‐18)

NotesRegardingElectricalRequirements

Allelectricalratingsprovidedinthismanualareforreferenceonly.Alwaysrefertothemachinedataplate

togettheexactelectricalinformationforyourmachine.All electrical work performed on machines

shouldbedoneinaccordancewithapplicablelocal,state,territorialandnationalcodes.Workshould

onlybeperformedbyqualiiedelectriciansandauthorizedserviceagents.AlistofauthorizedServiceAgen‐

ciesislocatedinthebackofthismanual.

Note that all electrical wiring used in the dish‐machine must be rated, at a minimum, for 100C (212F).

Furthermore,usecopperconductorsonly.

Whereapplicable,heatingelementamperagedrawshavebeenadjustedfortheassumedinputvoltage.Jack‐

sonassumesincomingvoltageswillbeeither208,230or460volts.Someoftheheatingelementsusedin

ourmachinesareactuallyratedforothervoltages,suchas240 or 480volts. Alwaysverify the amperage

drawofthemachineinoperationwhensizingcircuitprotection.

Ifyourmachineisequippedwiththeoptionalrinseheater,notetherinseheaterhasitsownelectricalcon‐

nectionandthereforerequiresaseparateservice.Amperageloadsformotorsandheatersarecalledouton

themachinedataplatefortheinstallation/servicetechnician.

Theelectricalconigurationsofthemachinesareasfollows:

AvailableElectricalCharacteristics:

208volt,60Hz,singlephase

230volt,60Hz,singlephase

208volt,60Hz,threephase

230volt,60Hz,threephase

460volt,60Hz,threephase

AvailableWashTankHeaters:

15KW(standardforCREW44)

18KW(optionalforCREW44,standardforCREW66)

AvailableRinseHeaters(“BoosterHeaters”):

None(standard)

12KW(40Friseintemperature)

18KW(70Friseintemperature)

14

PageCreated:05‐04‐2010

Revised:02‐25‐2011

TechnicalManual(07610‐003‐78‐18)

ElectricalRequirementsfor44”Units

Volts Phase Freq

Wash

Motor

Amps

Drive

Motor

Amps

Wash

Heater

Amps

FLA MCA MOP

208 1 60 10.0A 1.8A 72.1A 83.9A 86.4A 96.4A

230 1 60 10.0A 1.8A *59.9A 71.7A 74.2A 84.2A

208 3 60 8.6A 1.1A 41.6A 51.3A 53.5A 62.1A

230 3 60 8.4A 1.1A *34.6A 44.1A 46.2A 54.6A

460 3 60 4.2A 0.6A **17.3A 22.1A 23.2A 27.4A

240 1 60 10.0A 1.8A 62.5A 74.3A 76.8A 86.8A

480 3 60 4.2A 0.6A 18.1A 22.9A 24.0A 28.2A

240 3 60 8.4A 1.1A 36.1A 45.6A 47.7A 56.1A

44”with15kWWashHeater

Volts Phase Freq

Wash

Motor

Amps

Drive

Motor

Amps

Wash

Heater

Amps

FLA MCA MOP

208 1 60 10.0A 1.8A 86.5A 98.3A 100.8A 110.8A

230 1 60 10.0A 1.8A *71.9A 83.7A 86.2A 96.2A

208 3 60 8.6A 1.1A 50.0A 59.7A 61.9A 70.5A

230 3 60 8.4A 1.1A *41.5A 51.0A 53.1A 61.5A

460 3 60 4.2A 0.6A **20.8A 25.6A 26.7A 30.9A

480 3 60 4.2A 0.6A 21.7A 26.5A 27.6A 31.8A

240 3 60 8.4A 1.1A 43.4A 52.9A 55.0A 63.4A

240 1 60 10.0A 1.8A 75.0A 86.8A 89.3A 99.3A

44”with18kWWashHeater

Volts Phase Freq

Wash

Motor

Amps

Drive

Motor

Amps

FLA MCA MOP

208 1 60 10.0A 1.8A 11.8A 14.3A 24.3A

230 1 60 10.0A 1.8A 11.8A 14.3A 24.3A

208 3 60 8.6A 1.1A 9.7A 11.9A 20.5A

230 3 60 8.4A 1.1A 9.5A 11.6A 20.0A

460 3 60 4.2A 0.6A 4.8A 5.9A 10.1A

44”Steam

*Denotes240Voltheatingelementsthathavebeendown‐ratedwhen230Voltsisapplied.

**Denotes480Voltheatingelementsthathavebeendown‐ratedwhen460Voltsisapplied.

15

PageCreated:02‐25‐2011

Revised:N/A

TechnicalManual(07610‐003‐78‐18)

ElectricalRequirementsfor66”Units

Volts Phase Freq

Wash

Motor

Amps

Drive

Motor

Amps

Wash

Heater

Amps

FLA MCA MOP

208 1 60 10.0A 1.8A 86.5A 108.5A

111.1A 121.3A

230 1 60 10.0A 1.8A *71.9A 93.1A

95.6A 105.6A

208 3 60 8.6A 1.1A 50.0A 66.5A

68.7A 77.3A

230 3 60 8.4A 1.1A *41.5A 57.4A 59.5A 67.9A

460 3 60 4.2A 0.6A **20.8A 28.8A

29.9A 34.1A

Pre‐Wash

Motor

Amps

10.2A

9.4A

6.8A

6.4A

3.2A

240 1 60

9.4A 10.0A 1.8A 75.0A 96.2A 98.7A 108.7A

240 3 60

6.4A 8.4A 1.1A 43.4A 59.3A 61.4A 69.8A

480 3 60

3.2A 4.2A 0.6A 21.7A 29.7A 30.8A 35.0A

66”with18kWWashHeater

Volts Phase Freq

Wash

Motor

Amps

Drive

Motor

Amps

FLA MCA MOP

208 1 60 10.0A 1.8A 22.0A

24.6A 34.8A

230 1 60 10.0A 1.8A 21.2A

23.7A 33.7A

208 3 60 8.6A 1.1A 16.5A

18.7A 27.3A

230 3 60 8.4A 1.1A 15.9A

18.0A 26.4A

460 3 60 4.2A 0.6A 8.0A

9.1A 13.3A

Pre‐Wash

Motor

Amps

10.2A

9.4A

6.8A

6.4A

3.2A

66”Steam

*Denotes240Voltheatingelementsthathavebeendown‐ratedwhen230Voltsisapplied.

**Denotes480Voltheatingelementsthathavebeendown‐ratedwhen460Voltsisapplied.

16

PageCreated:05‐04‐2010

Revised:N/A

TechnicalManual(07610‐003‐78‐18)

ElectricalRequirementsforBoosterTanks

Volts Phase Freq

Rinse

Heater

Amps

FLA

208 1 60 57.7A 57.7A

230 1 60 47.9A 47.9A

208 3 60 33.3A 33.3A

230 3 60 27.7A 27.7A

460 3 60 13.8A 13.8A

40°FRise‐12KWBooster

Volts Phase Freq

Rinse

Heater

Amps

FLA

208 1 60 82.7A 82.7A

230 1 60 71.9A 71.9A

208 3 60 47.7A 47.7A

230 3 60 41.5A 41.5A

460 3 60 20.7A 20.7A

Note:0nthe208voltmachines,therinseheaterisactuallyratedat17.2KW

70°FRise‐18KWBooster

17

PageCreated:05‐04‐2010

Revised:N/A

TechnicalManual(07610‐003‐78‐18)

INSTALLATIONINSTRUCTIONS

VISUAL INSPECTION: Beforeinstallingtheunit,checkthecontainerandthemachinefordamage.A

damagedcontainermaybeanindicationthereispossibledamagetotheproduct.Ifthereisanytypeofdam‐

agetoboththecontainerandtheunit,DONOTTHROWAWAYTHECONTAINER. The dish‐machine has

beenpreviouslyinspectedatthefactoryandisexpectedtoarrive to you in new, undamaged condition.

However,roughhandlingbycarriersorothersmayresultindamagetotheunitwhileitisintransit.Ifsuch

asituationoccurs,DONOTRETURNTHEUNITTOTHEMANUFACTURER.Instead,contactthecarrierand

askthemtosendarepresentativetothesitetoinspectthedamage.Youshouldrequestthataninspection

reportbecompleted.Youmustcontactthecarrierwithin48hoursofreceivingthemachineinordertore‐

portpossiblefreightdamage.Youarealsoencouragedtocontactthedealerthroughwhichyoupurchased

theunit.

UNPACKING THE MACHINE:Themachineshouldbeunboxedandremovedfromthepalletprior to

installing. Also remove the wooden lift beams and their associatedbracketsaftertheunithasbeenposi‐

tioned.Openthefrontdoorandremoveallofthematerialsfromtheinside.Onceunpacked,verifythereare

nomissingpartstothebestofyourability.Ifyoudiscoverapartismissing,contactthemanufacturerimme‐

diately.

LEVELTHEDISHMACHINE:Thedish‐machineisdesignedtooperatewhilelevel.Thisisimportantto

preventanydamagetothemachineduringoperationandtoensurethebestresultspossible.Theunitcomes

equippedwithadjustablebulletfeet,whichcanbeturnedusingapairofpliers.Verifytheunitislevelfrom

fronttobackandsidetosidepriortomakinganyelectricalorplumbingconnections.

PLUMBINGTHEMACHINE:Allplumbingconnectionsmustbemadetoadheretolocal,state,territorial

andnationalcodes.Theinstallingplumberisresponsibleforensuringtheincomingwaterlinesarelushed

ofdebrispriortoconnectingtothemachine.Notethatchipsandmaterialsfromcuttingprocessescanbe‐

comelodgedinthesolenoidvalvesandpreventthemfromopeningorclosing.Anyvalvesthatarefoundto

befouledordefectivebecauseofforeignmatterleftinthewaterline,andanysubsequentwaterdamage,are

nottheresponsibilityofthemanufacturer.

Waterhardnessshouldbeamaximumof6grainspergallon.Hardwatershouldbetreatedpriortobe

usedbythemachine.Ironinthewaterlinecancausestaining.Ailterdesignedtoremoveironfromthewa‐

tersupplyishighlyrecommendedforsuppliesinexcessof0.1ppm.

Yourdish‐machinecomeswithaWaterPressureRegulatingValve.Theunitutilizesalowpressureof

15PSIfortheincomingwaterline.Donotconfusestaticpressurewithlowpressure.Staticpressureisthe

pressurewhenthereisnolowandthevalvesareclosed;lowpressureiswhenthewaterisrunninginto

themachine.TheWPRVshouldbeadjustedtotheproperlowpressureataminimum.

Thewatersupplylineshallbe1/2”NPTminimumandmustbeabletoprovidewaterattheminimum

temperatureindicatedonthemachinedataplate.

Itisrecommendedashut‐offvalvebeinstalledtoallowisolatingthedish‐machinefromthewatersys‐

temintheeventmaintenanceorotheractivitiesrequireit.Also,itissuggestedthatashockabsorberbein‐

18

PageCreated:05‐04‐2010

Revised:N/A

TechnicalManual(07610‐003‐78‐18)

INSTALLATIONINSTRUCTIONS(CONTINUED)

stalledontheincomingwaterline.Thispreventswaterhammer(hydraulicshock),inducedbythesolenoid

valveasitoperates,fromcausingdamagetotheequipment.

CONNECTINGTHE DRAINLINE: The drainfor the unit isa gravity discharge drain. Allpipingtothe

machinedrainmustbeaminimum1‐1/2”NPTANDSHALLNOTBEREDUCED.Theremustalsobeanair

gapbetweenthemachinedrainlineandtheloorsinkordrain.Ifagreasetrapisrequiredbycode,itshould

havealowcapacityof30gallons.44”unitshaveonedrainconnectionpoint.66”unitshavetwopoints.

STEAMLINECONNECTIONS:Somemachinescoveredinthismanualaredesignedtouselowpressure

steamasasourceofheatforthewashtank.Thosemachinescomewithlinesbywhichanoutsidesourceof

steam(i.e.steambooster)isconnected.Connectallsteamlinesfromtheboostertothemachineinaccord‐

ancewiththeboostermanufacturer’sinstructions.Ensurethatallapplicablecodesandregulationsaread‐

heredto.Seethemachinedataplateforinformationrelatedtosteamlowrequirements.

ELECTRICALPOWERCONNECTIONS:Allelectricalconnectionsaretobemadeinaccordancewithap‐

plicableportionsoflocal,state,territorialandnationalcodes.

DISCONNECTELECTRICALPOWERSUPPLIESANDTAGOUTINACCORDANCEWITHAPPROPRIATE

PROCEDURESANDCODESATTHEDISCONNECTSWITCHTOINDICATEYOUAREWORKINGONTHATCIR-

CUIT.

Thismanualprovidesreferenceinformationregardingelectricalrequirementsandloads,butthatinfor‐

mationmay changewithoutnotice. Alwaysreferto themachinedata platefor voltage requirements, ma‐

chinevoltage,totalamperageloadandserialnumber.Ifyoucannotreadyourdataplatebecauseithasbeen

damaged,youshouldcontactthemanufacturer.

Themainpowerterminalblocks(forthedish‐machineandfortherinseboosterheater,ifapplicable)

are locatedat the topof the machine.You will haveto remove thetopcover toaccessthese connections.

Routeincomingpowerlineswithinconduitthatwillconnectviaittingstothepre‐punchedholesinthe

backoftheunit.Installpowerandgroundwirestolugsasindicatedbytheappropriatedecalsinthecontrol

box.Usecopperconductorsonly.Useofaanti‐oxidationagentis permissible on the power connections.

Tightenallconnections.

Verifytheincomingvoltagematchesthevoltageindicatedonthedecalnexttotheincomingpowerpre‐

punchedhole.

Pleasenote thedish‐machinehasaseparatepower connectionfromtherinseboosterheaterandthe

circuit protection requirementsare different for each.Refertothemachine data plate forinformation on

minimumcircuitprotection.

DISHMACHINEVENTILATION:Thedish‐machineshouldbelocatedwithprovisionsforventingintoan

adequateexhausthoodorventilationsystem.Thisisessentialtopermiteficientremovalofthecondensa‐

tionexhaust.Ensuretheexhaustsystemisacceptableinaccordancewithapplicablecodesandstandards.

19

PageCreated:05‐04‐2010

Revised:N/A

TechnicalManual(07610‐003‐78‐18)

INSTALLATIONINSTRUCTIONS(CONTINUED)

Note:any damage that is caused by steam and/or moisturedue toimproper ventilationis NOT

coveredunderthewarranty.

Thedish‐machinehasthefollowingventilationrequirements:

LoadEnd:200CFM

UnloadEnd:200CFM

Theexhaustsystemmustbesizedtohandlethisvolumeforthedish‐machinetooperateinthemanner

itwasdesignedto.

THERMOSTATS:Thethermostatsonyourunithavebeensetatthefactoryforthe wash tank. They

shouldonlybeadjustedbyanauthorizedserviceagent.

CHEMICALFEEDEREQUIPMENT:Yourdish‐machineDOESNOTCOMEWITHANINTEGRALCHEMI‐

CALSUPPLY/FEEDERSYSTEM.Youmustconnecttheunittoathirdpartychemicaldispenserthatmeetsthe

requirementsofNSFStandard29forthemachinetooperatecorrectly.

Youshouldcontactyourchemicalsupplieraboutconnectingadispensertoyourdish‐machine.Chemi‐

caldispensersmustbesetforthetypeandconcentrationofchemicalsbeingusedandthereareseveralfac‐

torsthathavetobetakenintoaccount.

Detergentusageandwaterhardnessaretwofactorsthatcontributegreatlytohoweficientlyyourdish

machinewilloperate.Usingtheproperamountofdetergentcanbecome,intime,asourceofsubstantialsav‐

ings.Aqualiiedwatertreatmentspecialistcanexplainindetailtoyouwhatisneededtogainthemaximum

eficiencyfromyourdetergent.

Thedish‐machineis able tooperatein eitherhotwater sanitizingmodeor chemicalsanitizing mode.

Yourunitshouldbeclearlymarkedabovethedataplateastothemodeitisin.Ifyoucannotdeterminethis,

contactthemanufacturerimmediatelyforassistance.

Itisimportanttorememberthatifyoudecidetooperatetheunitinchemicalsanitizingmode,youmust

ensureanappropriatechlorine‐basedsanitizerisusedintheinalrinseline.

20

PageCreated:05‐04‐2010

Revised:N/A

TechnicalManual(07610‐003‐78‐18)

INSTALLATIONINSTRUCTIONS(CONTINUED)

DETERGENT INJECTION POINT.

ANOTHER BULKHEAD PLUG

IS PROVIDED ON THE LEFT SIDE

OF THE UNIT

1-1/2" NPTF DRAIN CONNECTION

ADJUSTABLE BULLET FEET

BULKHEAD OPENING FOR

CONDUCTIVITY PROBE

CHEMICAL TUBE

INSERTION POINT

875"

INLET WATER FITTING

1/2" NPTF

MAIN ELECTRICAL

CONNECTION OPENING

1.375"

BOOSTER HEATER

ELECTRICAL CONNECTION

OPENING

1.375"

SHOWN FROM REAR OF LEFT TO RIGHT UNIT.

RIGHT TO LEFT UNIT IS MIRRORED

/