Page is loading ...

CREWSERIES

RACKCONVEYORDISHMACHINES

TECHNICALMANUAL

INSTALLATIONMANUALFOREXPORTUNITS

SERVICEMANUALFORDOMESTICUNITS

ELECTRICALLYHEATEDMODELS:

CREW44

July27,2010

P/N07610‐003‐78‐18(RevisionA)

JacksonMSC,LLC

P.O.Box1060,Hwy25E

Barbourville,KYUSA

1.606.523.9795

www.jacksonmsc.com

Revision

Letter

Revision

Date

MadeBy ApplicableECNs Details

A 07-27-10 CW/JC N/A Initial release of manual

TABLEOFCONTENTS

Specifications

OperatingParameters Page6

NotesRegardingElectricalRequirements Page7

ElectricalRequirements Page8

Instructions

InstallationInstructions Page10

CurtainInstallationInstructions Page15

OperatingInstructions Page16

DelimingInstructions Page18

Maintenance

Troubleshooting Page19

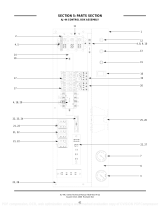

PartsSection

ControlBoxAssembly Page20

Overloads Page22

MiscellaneousElectricalComponents Page23

WashHeaterandHeaterShroudAssemblies Page24

WashHeaters Page25

DoorAssembly Page26

WashDoorSpringAssembly Page28

PlumbingAssembly,MainWaterInlet Page29

WashTankFillAssembly Page30

WashManifoldandArmAssembly Page31

RinseAssembly Page33

Crew44PawlBarAssembly Page35

PawlBarBracketAssembly Page36

PawlBarGutterAssembly Page37

RackPaddleAssembly Page38

RinsePaddleAssembly,L‐R Page39

DrainAssemblyParts Page40

Covers,GuardsandPanels Page41

Brackets Page42

TABLEOFCONTENTS(CONTINUED)

PartsSection

DriveAssembly Page45

BoosterHeaterOption Page47

MiscellaneousParts Page43

VentilationCowlParts Page44

ElectricalDiagramsandSchematics

BoosterHeaterSchematic(3Phase) Page48

BoosterHeaterSchematic(1Phase,12KW) Page49

BoosterHeaterSchematic(1Phase,18KW) Page50

TemperatureBoard Page51

Schematic,CREW44(208‐230‐460/60/3Phase) Page52

Schematic,CREW44(208‐230/60/1Phase) Page53

6

PageCreated:05‐04‐2010

Revised:N/A

CREWTechnicalManual(07610‐003‐78‐18)

OperatingParameters

ModelDesignation:CREW44

OperatingCapacity:

RacksperHour218

DishesperHour 3488

GlassesperHour 7848

TankCapacity(gallons):

WashTank35.6

ElectricalLoads(asapplicable):

WashMotorHP3.0

DriveMotorHP0.25

WashHeaterKW15or18

NOTE:Always refer to the machine data

plate

for specific electrical and water requirements.

The material provided on this page is for refer‐

ence only and is subject to change without no‐

tice.

HOTWATERSANITIZING

WaterTemperatures(Fahrenheit):

MinimumWashTemperature 160

MinimumRinseTemperature 180

IncomingWaterTemperature

12KWBooster 140

18KWBooster 110

CHEMICAL

SANITIZING

WaterTemperatures(Fahrenheit):

MinimumWashTemperature 120

MinimumRinseTemperature 120

IncomingWaterTemperature

12KWBooster80

18KWBooster 50

OtherWaterRequirements:

WaterFlowPressure(PSI) 15

FlowRateMinimum(GPM)1.18

WaterLineSize(NPT)1/2”

DrainLineSize(NPT)1‐1/2”

7

PageCreated:05‐04‐2010

Revised:N/A

CREWTechnicalManual(07610‐003‐78‐18)

NotesRegardingElectricalRequirements

Allelectricalratingsprovidedinthismanualareforreferenceonly.Alwaysrefertothemachinedataplate

togettheexactelectricalinformationforyourmachine.Allelectricalworkperformedonmachinesshould

bedoneinaccordancewithapplicablelocal,state,territorialandnationalcodes.Workshouldonlybeper‐

formedbyqualifiedelectriciansandauthorizedserviceagents.AlistofJacksonAuthorizedServiceAgencies

islocatedinthebackofthismanual.

NotethatallelectricalwiringusedintheCREWseriesofmachinesmustberated,ataminimum,for100C

(212F).Furthermore,usecopperconductorsonly.

Whereapplicable,heatingelementamperagedrawshavebeenadjustedfortheassumedinputvoltage.Jack‐

sonassumesincomingvoltageswillbeeither208,230or460volts.Someoftheheatingelementsusedin

ourmachinesareactuallyratedforothervoltages,suchas240 or480 volts.Always verify the amperage

drawofthemachineinoperationwhensizingcircuitprotection.

Ifyourmachineisequippedwiththeoptionalrinseheater,notetherinseheaterhasitsownelectricalcon‐

nectionandthereforerequiresaseparateservice.Amperageloadsformotorsandheatersarecalledouton

themachinedataplatefortheinstallation/servicetechnician.

TheelectricalconfigurationsoftheCREWseriesofmachinesareasfollows:

AvailableElectricalCharacteristics:

208volt,60Hz,singlephase

230volt,60Hz,singlephase

208volt,60Hz,threephase

230volt,60Hz,threephase

460volt,60Hz,threephase

AvailableWashTankHeaters:

15KW(standard)

18KW(optional)

AvailableRinseHeaters(“BoosterHeaters”):

None(standard)

12KW(40Friseintemperature)

18KW(70Friseintemperature)

8

PageCreated:05‐04‐2010

Revised:N/A

CREWTechnicalManual(07610‐003‐78‐18)

ElectricalRequirementsforCREW44

Volts Ph Freq

Wash

Motor

Amps

Drive

Motor

Amps

Wash

Heater

Amps

FLA MCA MOP

208 1 60 10.0A 1.8A 72.1A 83.9A 86.4A 96.4A

230 1 60 10.0A 1.8A 59.9A 71.7A 74.2A 84.2A

208 3 60 8.6A 1.1A 41.6A 51.3A 53.5A 62.1A

230 3 60 8.4A 1.1A 34.6A 44.1A 46.2A 54.6A

460 3 60 4.2A 0.6A 17.3A 22.1A 23.2A 27.4A

CREW44,15KWWashHeater

Volts Ph Freq

Wash

Motor

Amps

Drive

Motor

Amps

Wash

Heater

Amps

FLA MCA MOP

208 1 60 10.0A 1.8A 86.5A 98.3A 100.8A 110.8A

230 1 60 10.0A 1.8A 78.3A 90.1A 92.6A 102.6A

208 3 60 8.6A 1.1A 50.0A 59.7A 61.9A 70.5A

230 3 60 8.4A 1.1A 45.2A 54.7A 56.8A 65.2A

460 3 60 4.2A 0.6A 22.6A 23.2A 23.7A 27.9A

CREW44,18KWWashHeater

Volts Ph Freq

Wash

Motor

Amps

Drive

Motor

Amps

FLA MCA MOP

208 1 60 10.0 1.8A 11.8A 14.3A 24.3A

230 1 60 10.0 1.8A 11.8A 14.3A 24.3A

208 3 60 8.6 1.1 9.7A 11.9A 20.5A

230 3 60 8.4 1.1 9.5A 11.6A 20.0A

460 3 60 4.2 0.6 4.8A 5.9A 10.1A

CREW44S

Note:0nthe208voltmachines,therinseheaterisactuallyratedat17.2KW

9

PageCreated:05‐04‐2010

Revised:N/A

CREWTechnicalManual(07610‐003‐78‐18)

ElectricalRequirementsforBoosterTanks

Volts Ph Freq

Rinse

Heater

Amps

FLA

208 1 60 57.7A 57.7A

230 1 60 47.9A 47.9A

208 3 60 33.3A 33.3A

230 3 60 27.7A 27.7A

460 3 60 13.8A 13.8A

40°FRise‐12KWBooster

Volts Ph Freq

Rinse

Heater

Amps

FLA

208 1 60 82.7A 82.7A

230 1 60 71.9A 71.9A

208 3 60 47.7A 47.7A

230 3 60 41.5A 41.5A

460 3 60 20.7A 20.7A

Note:0nthe208voltmachines,therinseheaterisactuallyratedat17.2KW

70°FRise‐18KWBooster

10

PageCreated:05‐04‐2010

Revised:N/A

CREWTechnicalManual(07610‐003‐78‐18)

INSTALLATIONINSTRUCTIONS

VISUAL INSPECTION:Beforeinstallingtheunit,checkthecontainerandthemachinefordamage.A

damagedcontainermaybeanindicationthereispossibledamagetotheproduct.Ifthereisanytypeofdam‐

agetoboththecontainerandtheunit,DONOTTHROWAWAYTHECONTAINER. The dish‐machine has

beenpreviouslyinspectedatthefactoryandisexpectedtoarrive to you in new, undamaged condition.

However,roughhandlingbycarriersorothersmayresultindamagetotheunitwhileitisintransit.Ifsuch

asituationoccurs,DONOTRETURNTHEUNITTOJACKSON.Instead,contactthecarrierandaskthemto

sendarepresentativetothesitetoinspectthedamage.Youshouldrequestthataninspectionreportbe

completed.Youmustcontactthecarrierwithin48hoursofreceivingthemachineinordertoreportpossi‐

blefreightdamage.Youarealsoencouragedtocontactthedealerthroughwhichyoupurchasedtheunit.

UNPACKING THEMACHINE:Themachineshouldbeunboxedandremovedfromthepalletprior to

installing. Also remove the wooden lift beams and their associatedbracketsaftertheunithasbeenposi‐

tioned.Openthefrontdoorandremoveallofthematerialsfromtheinside.Onceunpacked,verifythereare

nomissingpartstothebestofyourability.Ifyoudiscoverapartismissing,contactJacksonimmediately.

LEVELTHEDISHMACHINE:Thedish‐machineisdesignedtooperatewhilelevel.Thisisimportantto

preventanydamagetothemachineduringoperationandtoensurethebestresultspossible.Theunitcomes

equippedwithadjustablebulletfeet,whichcanbeturnedusingapairofpliers.Verifytheunitislevelfrom

fronttobackandsidetosidepriortomakinganyelectricalorplumbingconnections.

PLUMBINGTHEMACHINE:Allplumbingconnectionsmustbemadetoadheretolocal,state,territorial

andnationalcodes.Theinstallingplumberisresponsibleforensuringtheincomingwaterlinesareflushed

ofdebrispriortoconnectingtothemachine.Notethatchipsandmaterialsfromcuttingprocessescanbe‐

comelodgedinthesolenoidvalvesandpreventthemfromopeningorclosing.Anyvalvesthatarefoundto

befouledordefectivebecauseofforeignmatterleftinthewaterline,andanysubsequentwaterdamage,are

nottheresponsibilityofthemanufacturer.

Waterhardnessshouldbeamaximumof6grainspergallon.Hardwatershouldbetreatedpriortobe

usedbythemachine.Ironinthewaterlinecancausestaining.Afilterdesignedtoremoveironfromthewa‐

tersupplyishighlyrecommendedforsuppliesinexcessof0.1ppm.

Yourdish‐machinecomeswithaWaterPressureRegulatingValve.TheCREWincorporatesaflowpres‐

sureof15PSIfortheincomingwaterline.Donotconfusestaticpressurewithflowpressure.Staticpressure

isthepressurewhenthereisnoflowandthevalvesareclosed;flowpressureiswhenthewaterisrunning

intothemachine.TheWPRVshouldbeadjustedtotheproperflowpressureataminimum.

Thewatersupplylineshallbe1/2”NPTminimumandmustbeabletoprovidewaterattheminimum

temperatureindicatedonthemachinedataplate.

Itisrecommendedashut‐offvalvebeinstalledtoallowisolatingthedish‐machinefromthewatersys‐

temintheeventmaintenanceorotheractivitiesrequireit.Also,itissuggestedthatashockabsorberbein‐

stalledontheincomingwaterline.Thispreventswaterhammer(hydraulicshock),inducedbythesolenoid

valveasitoperates,fromcausingdamagetotheequipment.

11

PageCreated:05‐04‐2010

Revised:N/A

CREWTechnicalManual(07610‐003‐78‐18)

INSTALLATIONINSTRUCTIONS(CONTINUED)

CONNECTINGTHEDRAINLINE:ThedrainfortheCREWisagravitydischargedrain.Allpipingtothe

machinedrainmustbeaminimum1‐1/2”NPTANDSHALLNOTBEREDUCED.Theremustalsobeanair

gapbetweenthemachinedrainlineandthefloorsinkordrain.Ifagreasetrapisrequiredbycode,itshould

haveaflowcapacityof30gallons.

STEAMLINECONNECTIONS:Somemachinescoveredinthismanualaredesignedtouselowpressure

steamasasourceofheatforthewashtank.Thosemachinescomewithlinesbywhichanoutsidesourceof

steam(i.e steam booster) isconnected.Connectall steam linesfromtheboostertothemachineinaccor‐

dance with the booster manufacturer’s instructions. Ensure thatallapplicablecodesandregulationsare

adheredto.Seethemachinedataplateforinformationrelatedtosteamflowrequirements.

ELECTRICALPOWERCONNECTIONS:Allelectricalconnectionsaretobemadeinaccordancewithap‐

plicableportionsoflocal,state,territorialandnationalcodes.

DISCONNECTELECTRICALPOWERSUPPLIESANDTAGOUTINACCORDANCEWITHAPPROPRIATE

PROCEDURESANDCODESATTHEDISCONNECTSWITCHTOINDICATEYOUAREWORKINGONTHATCIR‐

CUIT.

Thismanualprovidesreferenceinformationregardingelectricalrequirementsandloads,butthatinfor‐

mationmaychangewithoutnotice.Alwaysrefertothemachinedataplate for voltage requirements, ma‐

chinevoltage,totalamperageloadandserialnumber.Ifyoucannotreadyourdataplatebecauseithasbeen

damaged,youshouldcontactJackson.

Themainpowerterminalblocks(forthedish‐machineandfortherinseboosterheater,ifapplicable)

are located atthe top ofthe machine. Youwill have toremove the top cover toaccesstheseconnections.

Routeincomingpowerlineswithinconduitthatwillconnectviafittingstothepre‐punchedholesinthe

backoftheunit.Installpowerandgroundwirestolugsasindicatedbytheappropriatedecalsinthecontrol

box.Usecopperconductorsonly.Useofaanti‐oxidationagentis permissible on the power connections.

Tightenallconnections.

Verifytheincomingvoltagematchesthevoltageindicatedonthedecalnexttotheincomingpowerpre‐

punchedhole.

Pleasenotethedish‐machinehasaseparatepowerconnectionfromtherinseboosterheaterandthe

circuit protection requirements are different for each. Referto the machine data plate for information on

minimumcircuitprotection.

DISHMACHINEVENTILATION:Thedish‐machineshouldbelocatedwithprovisionsforventingintoan

adequateexhausthoodorventilationsystem.Thisisessentialtopermitefficientremovalofthecondensa‐

tionexhaust.Ensuretheexhaustsystemisacceptableinaccordancewithapplicablecodesandstandards.

Note: any damage that iscaused bysteam and/or moisturedue to improper ventilationis NOT

coveredunderthewarranty.

12

PageCreated:05‐04‐2010

Revised:N/A

CREWTechnicalManual(07610‐003‐78‐18)

INSTALLATIONINSTRUCTIONS(CONTINUED)

TheCREWhasthefollowingventilationrequirements:

LoadEnd:200CFM

UnloadEnd:200CFM

Theexhaustsystemmustbesizedtohandlethisvolumeforthedish‐machinetooperateinthemanner

itwasdesignedto.

THERMOSTATS:ThethermostatsonyourCREWunithavebeensetatthefactoryforthewashtank.

Theyshouldonlybeadjustedbyanauthorizedserviceagent.

CHEMICAL FEEDER EQUIPMENT:YourCREWdish‐machineDOESNOTCOMEWITHANINTEGRAL

CHEMICALSUPPLY/FEEDERSYSTEM.YoumustconnecttheCREWtoathirdpartychemicaldispenserthat

meetstherequirementsofNSFStandard29forthemachinetooperatecorrectly.

Youshouldcontactyourchemicalsupplieraboutconnectingadispensertoyourdish‐machine.Chemi‐

caldispensersmustbesetforthetypeandconcentrationofchemicalsbeingusedandthereareseveralfac‐

torsthathavetobetakenintoaccount.

Detergentusageandwaterhardnessaretwofactorsthatcontributegreatlytohowefficientlyyourdish‐

machinewilloperate.Usingtheproperamountofdetergentcanbecome,intime,asourceofsubstantialsav‐

ings.Aqualifiedwatertreatmentspecialistcanexplainindetailtoyouwhatisneededtogainthemaximum

efficiencyfromyourdetergent.

TheCREW dish‐machine is ableto operate ineither hot watersanitizingmodeorchemicalsanitizing

mode.Yourunitshouldbeclearlymarkedastothemodeitisin.Ifyoucannotdeterminethis,contactJack‐

sonimmediatelyforassistance.

Itisimportanttorememberthatifyoudecidetooperatetheunitinchemicalsanitizingmode,youmust

ensureanappropriatechlorine‐basedsanitizerisusedinthefinalrinseline.

13

PageCreated:05‐04‐2010

Revised:N/A

CREWTechnicalManual(07610‐003‐78‐18)

INSTALLATIONINSTRUCTIONS(CONTINUED)

DETERGENT INJECTION POINT.

ANOTHER BULKHEAD PLUG

IS PROVIDED ON THE LEFT SIDE

OF THE UNIT

1-1/2" NPTF DRAIN CONNECTION

ADJUSTABLE BULLET FEET

BULKHEAD OPENING FOR

CONDUCTIVITY PROBE

CHEMICAL TUBE

INSERTION POINT

875"

INLET WATER FITTING

1/2" NPTF

MAIN ELECTRICAL

CONNECTION OPENING

1.375"

BOOSTER HEATER

ELECTRICAL CONNECTION

OPENING

1.375"

SHOWN FROM REAR OF LEFT TO RIGHT UNIT.

RIGHT TO LEFT UNIT IS MIRRORED

14

PageCreated:05‐04‐2010

Revised:N/A

CREWTechnicalManual(07610‐003‐78‐18)

INSTALLATIONINSTRUCTIONS(CONTINUED)

REMOVE THIS JUMPER

WIRE TO ALLOW FOR

TABLE LIMIT SWITCH

CONNECTIONS

CONNECTION POINT

FOR VENT FAN SIGNAL

CONNECTION FOR

DETERGENT

DISPENSER

RINSE AID & SANITIZER

CONNECTION SIGNALS

FROM DOOR SWITCH

TO PLC

TABLE LIMIT

SWITCH

CONNECTION

ELECTRICALCONNECTIONPOINTSFORTABLELIMITSWITCH,

VENTILATIONFANSIGNAL&CHEMICALDISPENSINGSYSTEMS

SIGNALBOARDISLOCATEDINTHEMAINCONTROL

BOXBEHINDTHELOWERDRESSPANEL

CHEMICALDISSPENSERTUBECONNECTIONPOINTSTORINSEINJECTOR

P:PRESSURESWITCH(1/4”NPT)

S:SANITIZER(1/8”NPT)

R:RINSEAID(1/8”NPT)

15

PageCreated:05‐04‐2010

Revised:N/A

CREWTechnicalManual(07610‐003‐78‐18)

CURTAININSTALLATIONINSTRUCTIONS

DETERMINING CONVEYOR DIRECTION: Your CREW machine will be configured for

eitherLefttoRightorRighttoLeftoperation.DirectionisalwaysfromtheLoadEndto

theUnloadEnd,asshownintheexamples.

LefttoRightOperation

LoadEnd UnloadEnd

IMPORTANCEOFPROPERCURTAINPLACEMENT:ThecurtainsinsidetheCREWmachinearerequired

tobeinstalledinaparticularfashion.Notetheapproximatelocationsforeachtypeofcurtainintheabove

illustrations. S=Short, L=Long &XL=Extra Long. See the chartbelow for actual curtain lengths and part

numbers.

Legend Length PartNumber QTY

S 12” 08415‐131‐73‐44 1

L 19” 08415‐002‐14‐41 2

XL 24.25” 08415‐002‐47‐37 2

CurtainRod 20.50” 05700‐003‐77‐52 5

OntheCREW44models,thereare5locationsfortheplacementofcurtainsinsidethe

machine,startingfromtheloadendandgoingallthewaytotheunloadend.Thetableto

theleftindicateswhatsizecurtaingoesonwhichcurtainhook.Ifyouaremissinganyof

thecurtaincomponents,itis very importantyouobtainreplacementpartsinorderto

makesureyourunitrunscorrectly.Curtainsareusedtocontroltheaircurrentsinside

yourunitandtheygreatlyassistinmaintainingtheheatnecessarytokeepenergycosts

down.

RighttoLeftOperation

UnloadEnd LoadEnd

XLSLLXL XLLLSXL

16

PageCreated:05‐04‐2010

Revised:N/A

CREWTechnicalManual(07610‐003‐78‐18)

OPERATIONINSTRUCTIONS

PREPARATION:Beforeproceedingwiththestart‐upoftheunit,verifythefollowing:

Thedrainstopperisinstalled;

Thestrainersareinstalled;

Thepawlbarisinstalledandsecure;

Theactuatorswitchesmovewithrelativefreedomanddonotbind;

Thecurtainsareinstalledcorrectly

POWERUP:Toplacetheunitinstandby,presstheStartButtononthefrontofthemachine.

Theunitwillautomaticallydetermineifthereis aproperwater levelinthewashtank.Ifnot,the

unitwillbegintofilluntiltheappropriatelevelisreached.

Ifthewashtanktemperatureisnotattheminimumlevelforthe mode of operation, the wash

heater will energize. Refer to the machine data plate for a better understanding of the minimum

temperaturesneededtooperatetheunitcorrectly.Itmaytakeseveralminutesforthewashtankto

heatup,dependingontheinitialtemperatureofthewater.

Ifyourmachineisequippedwitharinseboosteroption,notetheboostershall turn on whenthe

unitturnson.

Ifyourmachineisheatedwithasteambooster,thenyouwillneedtoturnonthesteamboosterin

accordancewiththemanufacturer’sinstructions.

Itisimportantthatyoudonotattempttostarttheunituntil:

Theunitstopsfilling;

Theunithasreachedtheappropriatewashtanktemperature.

FIRSTRACK:Thefirstrackofwarethatyouplaceintotheunitusuallyhastheeffect ofveryquickly

reducingthetemperatureofthewashtank.Thisisbecauseyouareintroducingcoldmaterialsintothedish‐

machineenvironmentandtheunithastocirculatewatertogettheheatingcyclegoing.Youmayhavetorun

thefirstrackthroughtheunitagain.Anytimetheunithasnotbeenoperatedforanextendedperiodoftime

thisispossible,butunlikely.Thisisusuallydependentonthetypeofwareyouareusing,itstemperature

andtheambienttemperatureofthekitchenarea.Alwaysobservethetemperaturesofthewashandrinse

whenfirststartingtheunittoensureproperoperation.

WAREPREPARATION:Properpreparationofwareisessentialforthesmooth,efficient operation of

yourdish‐machine.Ifdoneproperly,youcanexpecttohavefew

erre‐washesandusesubstantiallylessde‐

tergent.Anywareplacedinsidethemachineshouldhaveallsolidfoodwasteandscrapsremoved.Itisrec‐

ommendedthatwarealsobesprayeddownpriortoentryintothedish‐machine.

Placecupsandglassesupsidedowninrackssotheydonotholdwaterduringthecycle.Presoakflat‐

wareinwarmwatertoassistingettingstuck‐onmaterialoff.Loadplatesandsaucersinthesamedirection

(withthesurfacefoodisplacedonfacingtowardstheunloadendofthemachine).

WASHINGARACKOFWARE:TheCREWmachineisdesignedtowashwareplacedinarack.Underno

circumstanceshouldanymaterialsbeplacedinsidetheCREWmachinethathavenotbeenproperlysecured

17

PageCreated:05‐04‐2010

Revised:N/A

CREWTechnicalManual(07610‐003‐78‐18)

OPERATIONINSTRUCTIONS(CONTINUED)

intoadishrack.

Tostartthecycle,gentlypushtherackintotheunitontheloadend.Oncethewashactuatorhasmoved

sufficiently,theunitwillautomaticallybegintoconveythedishrackthroughtheunit.Theentirecycleis

automatic.

OPERATIONAL INSPECTIONS: It is recommended that operators periodically review the following

itemswhilethemachineisoperating.Alloftheseitemsareimportanttooperatingthemachineinaneffi‐

cientmanner.

Review wash and rinse temperatures and compare to the minimums required by the data plate.

Lowtemperaturescanbeanindicationofafaultythermostat,athermostatthatneedsadjustment

orsomeotherconditionthatneedstobeaddressed.

Verifythepanstrainersarenotbecomingclogged.Keepingthesefreeofsoilanddebrisallowsfor

muchbetterflowofwaterthroughthemachineandpreventsanysortofredepositissues.

Waterpressure.TheCREWisdesignedtorunataminimumof15PSI;anylowerthanthatandyou

won’thaveenoughrinsewatertoproperlyremovedetergentfromyourware.

Washandrinsearmnozzlesshouldbefreeofdebris.Opennozzlesareessentialtotheoperationof

thedish‐machine.

SHUTDOWN:Toshuttheunitdown,presstheStartSwitchonthefrontofthemachine.Todrainthe

machine,openthefrontdoorandpulluponthedrainreleaseinsidetheunit.Ifyouhaveasteamboosterfor

heatingthedish‐machine,shutitdowninaccordancewithitsmanufacturer’sinstructions.

CLEANING:Itisrecommendedtheunitbecleanedatleastonceevery24hoursorattheendoftheday.

Cleaningassistsinmaintainedtheefficientoperationoftheunitbyremovingsoilanddebristhatmightoth‐

erwisebecometrappedinnozzlesorgetdepositedontoware.

Curtains:shouldbe removedandscrubbedwith milddetergent/soapandabrushandallowed to

airdry.

Strainers:shouldberemovedandhavedebrisscoopedout.Neverhitstrainerstoremovedebris;

thiscancausethemtowarpandnotseatcorrectly.Rinseunderwatershouldremovetherestofany

debristrappedinthepart.

WashArms:thewasharmscanberemovedusinga7/16”driver;however,theCREWisdesignedso

thewasharmsareliterallyself‐cleaning.Operatorshavetheabilitytoflushthearmsbyremoving

theplasticendcapsand running a rackthroughthe unit. This shouldonlybedoneasacleaning

functionwithanemptyrackandatubthatisfilledwithwater.

InternalChamber:Milddetergent/soapandadishragshouldbeallthatisneededtocleantheinside

ofthemachine.Strainersandthepawlbarshouldberemovedto

provideasmuchroomaspossible.

External Areas: The outside of the unit should be cleaned with a standard countertop or general

cleaner.Neverattempttocleaninsideanycompartments,boxesorchambersthataresecuredwith

acover.Thesenormallycontainliveelectricalcomponents.

DONOTCLEANTHEUNITWITHANYTYPEOFMETALLICSCRUBBINGSPONGE!

18

PageCreated:05‐04‐2010

Revised:N/A

CREWTechnicalManual(07610‐003‐78‐18)

DELIMINGINSTRUCTIONS

Toproceedwiththedelimingoperation,fillthedish‐machineandthecorrectamountofdelimingsolu‐

tionasrecommendedbythemanufacturerofthechemicals.Thetankcapacitiesofthemachinecanbefound

onthespecificationspageofthismanual.

Afterthechemicalsareadded,performthefollowingsteps:

1. FliptheNORMAL/DELIMESwitchtoDELIME.

2. Disconnectorturnoffchemicalfeederpumps.

3. Closealldoors.

4. PresstheStartSwitchandrunthemachineforthelengthoftimerequiredbythechemicalsolution

manufacturer.

5. PresstheStartSwitchtoshuttheunitoff.

6. Openthedoorandstepawayfor5minutes.

7. Inspecttheinsideoftheunittodetermineifyourexpectationshavebeenmet.Ifnot,youmayneed

torunthedelimingsolutionthroughtheunitformoretime.

8. Onceclean,drainthemachinecompletely.

9. Closethedoor.

10. Refilltheunit.

11. PresstheStartSwitchandruntheunitinManualfor10minutes.

12. PresstheStartSwitchtoturnofftheunit.

13. Openthefrontdoor.

14. Draintheunit.

15. FliptheNORMAL/DELIMESwitchtoNORMAL.

16. Yourmachineisreadytouse.

Thisequipmentisnotrecommendedforusewithdeionizedwaterorotheraggressivefluids.Useof

deionizedwaterorotheraggressivefluidswillresultin

corrosionandfailureofmaterialsandcom‐

ponents.Useofdeionizedwaterorotheraggressivefluidswillvoidthemanufacturer’swarranty.

19

PageCreated:05‐04‐2010

Revised:N/A

CREW Technical Manual (07610-003-78-18)

TROUBLESHOOTING

Green LED lights are illuminated on the PLC when in opera-

tion. The POWER, OK & RUN lights indicate that 24VDC

power is available to the PLC and that is functioning properly.

If the RUN light is out, the operational program of the PLC

may have been corrupted or lost. Temporary power surges may

have occurred. Secure all power to the machine , wait for 30

seconds and restore power. Verify that the Green light is illumi-

nated to the 24vdc power supply immediately to the left of the

PLC. If the RUN light is still off, replace the PLC.

Refer to the illustration below for the designation of each LED.

Inputs correspond to the connections behind the top flip up

panel of the PLC and are marked I1 thru I8. Outputs correspond

to the connections behind the bottom flip up panel of the PLC

and are marked Q1 thru Q8.

Note: All outputs are fused. Q1 & Q2 outputs utilize 1.0 Amp

fuses and Q3-Q8 utilize .75 Amp fuses.

UTILIZE THESE SCREWS

FOR PLC REPLACEMENT

UTILIZE THESE SCREWS

FOR PLC REPLACEMENT

STATUS

INDICATING

LIGHTS

INPUTS

OUTPUTS

Alloperationalrelays

utilizegreenLEDindicat‐

inglightstoverifyproper

operation.Theserelays

aremountedimmediately

totherightofthePLC.

Pleaserefertotheillustra‐

tiontotherightforthe

relaysdesignation&tothe

appropriateschematicsfor

troubleshooting.

20

PageCreated:05‐04‐2010

Revised:N/A

CREW Technical Manual (07610-003-78-18)

PARTS SECTION: CONTROL BOX ASSEMBLY

1

10

9

21

21

6

8

7

11

4

15

2

3

14

5

18

18

13

19

19

22

19

25

20

20

23

20

17

17

24

12

16

7

7

8

8

8

8

DETAILOFFUSELOCATIONSFORPARTNUMBER05920‐002‐42‐13

/