Page is loading ...

FARGO

INS 899 (07/19/12) HUBBELL POWER SYSTEMS, INC.

Printed in U.S.A. Leeds, AL 35094 1908990000

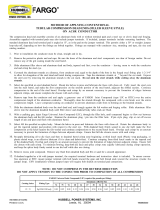

METHOD OF APPLYING COMPRESSION

REPAIR SLEEVES

ON ACSS CONDUCTORS

Repair sleeves for ACSS will restore conductor damage where the damaged section is no longer

than 20% of the repair sleeve length before crimping; and at least 50% of the aluminum strand and

100% of the steel core are undamaged.

Repair sleeves are marked with conductor diameter range, die type and size, minimum press size,

FARGO catalog number and date. Catalog # series sleeves with SSAC or ACSS suffix have

diameter ranges suitable for round-wire stranded ACSS conductors, and those with STW suffix

have diameter ranges suitable for ACSS/TW conductors.

1. With a clean stainless steel wire brush (V-brush type recommended), aggressively brush the

conductor over the full section that the repair sleeve will cover when installed. Immediately

apply a generous coat of FARGO Joint Compound Type HTJC over the just brushed conductor.

2. Remove the protective plastic from the sleeve, taking care not to drop either half as the sleeve

will separate at its interlocking side joints as plastic is removed. Wire brush the I.D. of both

sleeve halves and immediately coat brushed surfaces with FARGO HTJC compound.

3. Install the sleeve halves over the damaged conductor area so that the seams between sleeve

halves will be inside the die cavities during compression:

a. Position one of the brush-cleaned & compound-coated sleeve halves centered over the

damaged conductor section and slide the interlocking opposite half into place until ends

are flush.

b. Tape wrap near sleeve center, to prevent tube halves from separating at the slide joints

until set by crimping.

4. Select compression dies indicated on sleeve. Mount die halves in press and lubricate both die

faces and the sleeve compression zone with clean oil or clean plastic material (if plastic used as

lubricant, ensure that it wraps completely around the split tube, fully covering both die face

during each compression).

5. Move tool to position dies near sleeve center, and compress toward sleeve end. Overlap each

crimp by an amount necessary to prevent the formation of ridges between adjacent crimps. Be

sure that full die closure occurs with each crimp. To prevent bowing, keep compression zone

well lubricated and firmly seat sleeve in one die half while dies are closing. Remove temporary

tape wrap and repeat crimp operation on opposite sleeve end.

6. One-Way crimp procedure where damage is close to a deadend, splice or suspension clamp:

Press from short span side to center, remove center tape and press opposite sleeve side from

center to longer span end.

7. Once crimp operations are complete, remove any flash and file or sand for a smooth

appearance.

NOTE: REPAIR SLEEVES ARE MINUMUM TENSION CONNECTORS

/