Page is loading ...

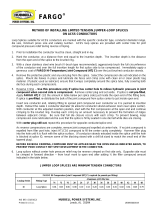

FARGO®

INSTALLATION INSTRUCTIONS

UNI-GRIP DEAD ENDS

AAC, AAAC & ACAR CONDUCTORS

The Uni-Grip compression dead end assembly for consists of a pre-filled aluminum body with pre-compressed eye or

clevis. Assembly may also include 15, pre-filled aluminum jumper terminals and terminal mounting hardware. The dead

end pad is angled at 15, which permits either a 30or straight jumper take-off. Each fitting is marked to show FARGO,

catalog number, conductor size stranding and type, and installation die size. Repair deadends have catalog number marks

that include suffix “XL” followed by and the damaged conductor cutout length in inches

1. Prior to installation the conductor must be clean, straight and in lay. Any bend in the conductor section inserted into

the deadend will tend to make the deadend body bow during compression.

2. Mark the conductor from the end at a distance equal to the insertion length. The insertion length is the distance from

the mouth of the dead end to the knurl.

3. With a clean stainless steel wire brush (V-brush type recommended), aggressively brush the aluminum conductor over

the entire crimp zone. Immediately apply a generous coat of FARGO Joint Compound Type UJC over the entire

compression length of the aluminum conductor.

4. Remove the protective plastic and the end plug from the dead end. Insert the conductor into the mouth of the dead to

the full insertion length marked in step 2

DO NOT REMOVE ANY FACTORY-FILLED JOINT COMPOUND FROM DEADEND TUBE

5. Select the die set as indicated on the dead end body. Mount die halves in press and lubricate die faces and the entire

compression zone of the deadend body with die lubricant stick, clean oil or clean plastic bag material (if plastic used as

lubricant, ensure that it wraps completely around the deadend tube, fully covering both die face during each

compression). Make the first compression at the knurled ring and continue crimping toward the tapered end. Ensure

die closure with each crimp and overlap crimps by an amount necessary to prevent the formation of ridges between

adjacent crimps. Continue crimping to the tapered end. To minimize bowing of the deadend, keep the compression

zone lubricated equally at both die faces and fully seat deadend body in one die half as dies close.

6. Remove excess joint compound. Remove flash from the dead end body and file or sand for smooth appearance.

7. If deadend supplied as a kit with jumper terminal, the required terminal hardware and instruction sheet is included. To

ensure corona-free operation at EHV, mount jumper terminal with bolt heads toward the span and bolt thread ends

toward the structure (inside the jumper loop). EHV installations without jumper loops will require bolt shields on

terminal pad connections.

DO NOT COMPRESS IN THE REVERSE DIRECTION

DO NOT APPLY TENSION TO THE CONDUCTOR PRIOR

TO COMPLETION OF ALL COMPRESSION.

INS 880 (05/26/09) HUBBELL POWER SYSTEMS, INC.

Printed in U.S.A. Leeds, AL 35094 1908800000

/