Page is loading ...

FARGO

INS 890 (03/19/12) HUBBELL POWER SYSTEMS, INC. Page 2 of 2

Printed in U.S.A. Leeds, AL 35094 1908900000

INSTALLATION INSTRUCTIONS

LIMITED TENSION JUMPER TERMINALS

FOR ACSS CONDUCTORS

Terminals are marked with conductor type and diameter range appropriate for that conductor type.

Markings also include die required, minimum press size, terminal body part number and date code.

Aluminum (standard) or Stainless Steel (optional) pad bolting hardware is included. Terminals

supplied pre-filled (optional) with joint compound will have catalog number suffix “PC”

1. Prior to installation the conductor must be clean, straight and in-lay.

2. Mount the die set specified on the jumper terminal tube in press.

3. Mark the conductor end at a distance equal to the insertion depth of the terminal. The insertion

depth is the distance from the open end of the terminal to the knurled ring.

4. With a clean stainless steel wire brush (V-brush type recommended), aggressively brush the

conductor circumference over the full insertion length marked in step 3. Immediately apply a

generous coat of FARGO Hi-Temperature Joint Compound (HTJC) over the just-brushed

conductor area. Carefully remove any tape wrap used to keep conductor strand ends in lay.

Brush clean and coat with HTJC compound this remaining conductor area.

5. Remove protective plastic from terminal and separate the bagged terminal pad bolting

hardware for use later.

6. Apply, or re-distribute if pre-filled, HTJC joint compound to just inside the open end of

the fitting bore. (Required amount of compound is indicated in the table on page 2). Slide

terminal onto conductor, rotating it to spread joint compound inside terminal bore as it is pushed

onto the conductor.

7. Lubricate die faces and terminal crimp zone with clean oil or clean plastic bag material. (If

plastic used as lubricant, ensure that it wraps completely around the splice tube, fully covering

both die face during each compression).

(Skip to step 9. if Forward Crimp procedure is to be used)

8. Reverse Crimp - Retract the conductor approximately 1 inch from full insertion in the terminal.

This will allow the ACSS strands room to extrude inside the terminal as it is reverse-crimped

without pressing against the closed end. With the conductor at the adjusted insertion depth,

start with the first compression at the open end and continue crimping to the knurled ring.

Overlap each crimp by an amount necessary to prevent the formation of ridges between

adjacent crimps. Be sure that full die closure occurs with each crimp. Maintain lubrication on

compression zone of terminal, and be sure that the terminal is firmly seated in one die half while

dies are closing.

NOTE: Reverse crimp (back press) procedure requires that the joint compound be

applied and distributed as indicated above to prevent poor contact and hot spot

development in the connector barrel. Terminals with 90 welded pads can be reverse

crimped IF equipped with pressure relief port near pad end.

INS 890 (03/19/12) HUBBELL POWER SYSTEMS, INC. Page 1 of 2

Printed in U.S.A. Leeds, AL 35094 1908900000

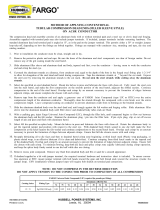

9. Forward Crimp – With conductor at full insertion depth in terminal, lubricate the compression

zone and make first compression at the knurl mark. Continue compressions to the open end.

Overlap each crimp by an amount necessary to prevent the formation of ridges between

adjacent crimps. Be sure that full die closure occurs with each crimp. Maintain lubrication on

compression zone of terminal, and be sure that the terminal is firmly seated in one die half while

dies are closing.

10. Once crimp operations are completed, wipe away expelled joint compound and remove any die

flash - File or sand terminal as needed for a smooth appearance.

11. Bolted pad connection. With a clean stainless steel wire brush (V-brush type recommended),

aggressively brush both mating pad surfaces and immediately apply a generous coat of

FARGO Hi-Temperature Joint Compound (HTJC) over the just-brushed pad surfaces. Remove

any compound from bolt holes (to keep bolt threads at the nut end free of compound) and bolt

pad joint together.

12. Make sure all washers are properly positioned and nuts are securely started. Alternately tighten

½ inch aluminum bolts to 25 ft-lb. If optional stainless steel hardware is used, install the

Belleville washer between nut and one of the stainless flat washers. Tighten the ½” stainless

steel nuts to 40 ft-lb or until Belleville washer is nearly flat.

13. To ensure corona-free operation at EHV, mount jumper terminal with bolt heads toward the

span and bolt threaded end toward the insulator connection (inside the jumper loop). EHV

installations without jumper loops will require terminal hardware shields.

NOTE: JUMPER TERMINALS ARE LIMITED TENSION CONNECTORS

APPLY NO TENSION UNTIL ALL COMPRESSION IS COMPLETE

76AH 20AH 24AH 27AH 30AH 34AH 36AH 38AH 40AH 42AH 44AH

Jumper Terminal 30/33/36/37 0.03 0.04 0.06 0.07 0.10 0.14 0.16 0.18 0.22 0.25 0.30

FARGO type HTJC-16 Joint Compound required (cartridges per fitting)

Die Size

Catalog

Series

Fitting Type

/