Page is loading ...

FARGO®

INS 886S (01/03/06) HUBBELL POWER SYSTEMS, INC.

Printed in U.S.A. Leeds, AL 35094 190886S000

METHOD OF APPLYING CONVENTIONAL

TUBULAR COMPRESSION DEAD ENDS (FILLER SLEEVE STYLE)

ON ACSR CONDUCTOR

The compression dead end assembly consists of an aluminum body with or without terminal pads and a steel eye or clevis dead end forging.

Assemblies supplied with terminal pads may also include jumper terminals. If included, jumper terminals include mounting hardware. The

standard aluminum dead end terminal pad is angled at 15°, as is the pad on the jumper terminal. This permits either a 30° or straight jumper

loop take-off, depending on how the fittings are bolted together. Fittings are stamped with conductor size, stranding and type, die size and

catalog number.

1. Prior to installation the conductor must be clean, straight and in lay.

2. Remove the protective plastic and end caps. Be sure the bores of the aluminum and steel components are clear of foreign matter. Do not

remove any of the grit coating inside the steel barrel.

3. Slide aluminum filler sleeve and aluminum dead end body, tapered end first, over the conductor – leaving room to work the conductor

end and crimp the steel eye.

4. Cut-mark the aluminum strands at a distance, from conductor end, equal to the depth of the bore in the forged steel fitting plus 1/2-3/4”

to allow for elongation of the steel dead end barrel during compression. Tape the aluminum strands at _" beyond the cut mark. Expose

the steel core by removing the aluminum strands to the cut mark. Do not nick the steel strands while cutting away the aluminum

strands.

5. Select die specified on steel deadend barrel. Mount die halves in press and lubricate die faces with clean oil. Fully insert the steel core

into the steel barrel, and make the first compression on the smooth portion of the steel barrel, adjacent the ribbed section. Continue

compression to the end of the steel barrel. Overlap each crimp by an amount necessary to prevent the formation of ridges between

adjacent crimps, and ensure complete die closure with each crimp.

6. Remove tape from the conductor end and apply a generous coat of FARGO Joint Compound (type UJC or HTJC) over the entire

compression length of the aluminum conductor. Thoroughly clean the strands through the compound with a wire brush over the entire

compression length. Leave compound coating on conductor to prevent aluminum oxide from re-forming on the brushed strands.

7. Slide the aluminum deadend body over the steel dead end, until snugly against the felt washer and forging collar. Slide aluminum filler

sleeve into the aluminum deadend body until filler sleeve and deadend body tubes ends are flush.

8. With a caulking gun, inject Fargo Universal Joint Compound (UJC), through the filler hole, until compound begins to flow out between

the aluminum body and the felt washer. Hammer the aluminum plug / pin into the filler hole. If pin style plug, clip or cut off excess

length of pin and peen end flush with aluminum barrel.

9. Select AH die specified on splice body. Mount die halves in press and lubricate die faces with clean oil. Rotate the aluminum body to

get the required jumper pad position with respect to the steel eye. With deadend body firmly seated in one die half, make the first

compression at the knurl nearest the felt washer and continue compressions to the second knurl mark. Overlap each crimp by an amount

necessary to prevent the formation of ridges between adjacent crimps. Ensure that full die closure occurs with each crimp.

10. Re-apply lubricating oil to die faces and then to deadend barrel crimp zone beginning at third knurl mark (Plastic wrap packaging, or

plastic shrink wrap, is an effective lubricant if it is clean and debris-free). Continue crimping from third knurl marks to the tapered end

of the deadend body. Overlap each crimp by an amount necessary to prevent the formation of ridges between adjacent crimps. Ensure full

die closure with each crimp. To minimize bowing, keep both die faces and splice crimp zone equally lubricated during crimp operation,

and keep the splice body firmly seated in one die half while dies are closing.

11. Remove excess joint compound. Remove any flash from deadend body and file or sand for a smooth appearance.

12. If deadend supplied as a kit with jumper terminal, the required terminal hardware and instruction sheet is included. To ensure corona-

free operation at EHV, mount jumper terminal with bolt heads toward the span and bolt thread ends toward the structure (inside the

jumper loop). EHV installations without jumper loops will require bolt shields on terminal pad connections.

NOTE: DO NOT COMPRESS IN THE REVERSE DIRECTION

DO NOT APPLY TENSION TO THE CONDUCTOR PRIOR TO COMPLETION OF ALL COMPRESSION

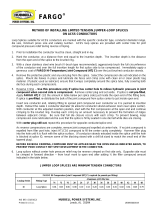

74 75 76 20 24 27 30 34 36 38 40 42 44 48

12 / 15

Sgl./Dbl. DE body 0.03 0.05 0.08 0.15 0.24 0.34 0.50 0.56 0.62 0.82 0.90 1.10 1.20 0.90

FARGO Universal Joint Compound (UJC) required (in pounds per fitting)

Catalog Series

Fitting Type

Aluminum (AH) Die Size

/