Page is loading ...

©2019InvacareCorporation

Allrightsreserved.Republication,duplicationormodicationinwholeorinpartisprohibitedwithoutpriorwritten

permissionfromInvacare.Trademarksareidentiedby™and®.AlltrademarksareownedbyorlicensedtoInvacare

Corporationoritssubsidiariesunlessotherwisenoted.

Invacarereservestherighttoalterproductspecicationswithoutfurthernotice.

Contents

1General.........................................4

1.1Aboutthismanual..............................4

1.2GeneralInformation............................4

1.3NotesonShipping..............................4

1.4SymbolsinThisManual..........................4

1.5ImagesinThisManual..........................4

2Safety..........................................5

2.1SafetyandFittingInstructions.....................5

3Hygiene.........................................7

3.1HandlingofReturnedUsedProducts................7

4Setup...........................................8

4.1Adjustingseatingposition........................8

4.1.1AdjustingLowerLegLength....................8

4.1.2Adjustingseatdepth.........................8

4.1.3Adjustingcenterofgravityofseat...............8

4.2Moduliteseat.................................9

4.2.1Telescopicseatframe.........................9

4.2.2One-PieceSeatPlate.........................9

4.3Imperialtometricconversionchart.................9

5Testing..........................................11

5.1TestingMotor.................................11

5.2TestingMotorBrake............................11

5.3Raintest.....................................11

5.4FieldLoadT est................................12

5.5CheckingBatteryChargeLevel.....................12

6Service..........................................14

6.1GeneralWarningInformationonInstallationWork......14

6.2Tighteningtorques.............................14

6.3Troubleshooting...............................14

6.3.1OperationalFaults...........................14

6.3.2DriveFaultDiagnosis.........................14

6.3.3Chargingdevicefaultdiagnosis..................18

6.4ServicePlan(OnceaYear)........................19

6.5Overviewmobilitydevice.........................21

6.6Chassis......................................22

6.6.1OverviewofComponents......................22

6.6.2Stabilitylock...............................22

6.6.3TopWalkingBeam...........................24

6.6.4BottomWalkingBeam........................25

6.6.5Steeringheadfront..........................25

6.6.6Removingrearsprings.......................26

6.6.7Installingrearsprings.........................26

6.6.8Replacingbatterytray........................27

6.6.9Replacingbatterybox.........................27

6.6.10ReplacingRubberStopper....................28

6.6.11ReplacingTie-DownAdapter(Low-Rider)..........28

6.7DriveComponents..............................29

6.7.1OverviewMotor/GearboxUnit..................29

6.7.2ReplacingMotor/GearboxUnit..................29

6.7.3Replacingorrotatingmotor/gearboxunitsealing

ring.....................................30

6.7.4Replacingmotor/gearboxclutch.................30

6.7.5Replacingcarbonbrushes......................31

6.7.6RemovingRearSuspension.....................32

6.7.7Removingrearsuspension–alternativemethod.....32

6.7.8Rettingrearsuspension......................32

6.7.9Rettingrearsuspension–alternativemethod......33

6.7.10Replacingcasterfork........................33

6.7.11Adjustingcasterfork........................34

6.8Wheels......................................34

6.8.1RepairInstructions...........................34

6.8.2TyrePressure...............................35

6.8.3TyreTypes.................................35

6.8.4SpecicTighteningTorques....................35

6.8.5OverviewofPowerWheelchairModelsandWheel

Types....................................36

6.8.6Replacingriminsertsindrivewheels.............37

6.8.7ReplacingTyres.............................37

6.8.8ReplacingDriveWheel(5–ScrewInstallation).......38

6.8.9Replacingdrivewheelhub.....................39

6.8.10ReplacingCastorWheelonDouble-SidedFork.....39

6.8.11ReplacingCastorWheelsonSingle-SidedFork......41

6.9Shrouds.....................................41

6.9.1Removingfrontshroud........................41

6.9.2ReplacingRearShroud(WithoutOperatingHour

Counter)..................................41

6.9.3ReplacingRearShroud(WithOperatingHour

Counter)..................................41

6.9.4Removingtopshroud.........................42

6.9.5Replacingfender............................42

6.10Controls....................................42

6.10.1ReplacingPowerModule.....................42

6.10.2ReplacingTiltActuator(“FixedPivot”Tilt).........43

6.10.3ReplacingG-TracSensor......................43

6.10.4Replacingoperatinghourcounter/connecting

cable....................................44

6.10.5UpdatingSoftware..........................45

6.10.6ReplacingUSBcharger.......................45

6.10.7Checkingcable.............................45

6.10.8Cablerouting..............................45

6.11Batteries....................................46

6.11.1GeneralInstructionsonHandlingBatteries........46

6.11.2HandlingDamagedBatteriesCorrectly...........46

6.11.3MakingBatteriesAccessible...................46

6.11.4ReplacingBatteries(60Ah/73Ah).............47

6.11.5ReplacingBatteries(50Ah)....................48

6.11.6ReplacingBatteries/BatteryCables.............48

6.11.7Checkingandreplacingmainfuse...............49

6.12Lightingunit.................................49

6.12.1Replacingfrontbulb(conventionallighting

system)..................................49

6.12.2Replacingheadlightcomplete(conventional

lightingsystem)............................50

6.12.3Replacingheadlightcomplete(LEDlighting

system)..................................50

6.12.4Replacingfrontlampholder(conventionallighting

system)..................................50

6.12.5Replacingfrontlampholder-(conventional

lightingsystem)............................51

6.12.6Replacingfrontlampholder-(LEDlighting

system)..................................51

6.12.7Replacingrearbulb(conventionallighting

system)..................................51

6.12.8Replacingrearlightcomplete-(conventional

lightingsystem)............................51

6.12.9Replacingcompleterearlight-(LEDlighting

system)..................................52

6.12.10Replacingrearlampholder-(conventional

lightingsystem)............................52

6.13Seating.....................................52

6.14MountingDahlDockingSystem...................52

Invacare®TDX®SP2Series

1General

1.1Aboutthismanual

•ThismanualreferstocongurationswithModulite

seatsystem.Olderspecicationshavebeendescribed

inrevision11ofthisservicemanual.

•Forseatsystems,refertothecorrespondingmanual.

•ForShark,DX,DX2,refertorevision11ofthisservice

manual.

•ForLiNXcontrols,refertoLiNXServiceManual.

1.2GeneralInformation

Serviceandmaintenanceworkmustbecarriedouttaking

thisdocumentintoaccount.

Itisimperativethatyouobservesafetyinformation.

Informationaboutoperationoraboutgeneralmaintenance

andcareworkontheproductshouldbetakenfrom

servicemanual.

Assemblyofaccessoriesmightnotbedescribedinthis

document.Refertothemanualdeliveredwiththe

accessory.Additionalmanualscanbeorderedfrom

Invacare.Seeaddressesattheendofthisdocument.

Youcanndinformationaboutorderingsparepartsin

thesparepartscatalogue.

SparepartsmustmatchoriginalInvacareparts.Onlyuse

sparepartswhichhavebeenapprovedbyInvacare.

Theproductmayonlybemaintainedandoverhauledby

qualiedpersonnel.

Theminimumrequirementforservicetechniciansis

suitabletraining,suchasinthecycleororthopedic

mechanicselds,orsufcientlylong-termjobexperience.

Experienceintheuseofelectricalmeasuringequipment

(multimeters)isalsoarequirement.SpecialInvacare

trainingisrecommended.

Alterationstothemobilitydevicewhichoccurasaresult

ofincorrectlyorimproperlyexecutedmaintenanceor

overhaulworkleadtotheexclusionofallliabilityonthe

sideofInvacare.

Ifyouhaveanyproblemsorquestionscontactyour

provider .

1.3NotesonShipping

•Ifthemobilitydevicehastobeshippedbacktothe

manufacturerformajorrepairs,youshouldalways

usetheoriginalpackagingfortransport.

•Pleaseattachaprecisedescriptionofthefault.

1.4SymbolsinThisManual

Symbolsandsignalwordsareusedinthismanualand

applytohazardsorunsafepracticeswhichcouldresultin

personalinjuryorpropertydamage.Seetheinformation

belowfordenitionsofthesignalwords.

WARNING

Indicatesahazardoussituationthatcould

resultinseriousinjuryordeathifitisnot

avoided.

CAUTION

Indicatesahazardoussituationthatcould

resultinminororslightinjuryifitisnot

avoided.

IMPORTANT

Indicatesahazardoussituationthatcould

resultindamagetopropertyifitisnot

avoided.

Tips

Givesusefultips,recommendationsand

informationforefcient,trouble-freeuse.

Tools

Identiesrequiredtools,componentsand

itemswhichareneededtocarryoutcertain

work.

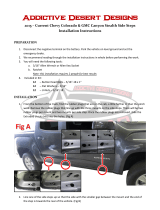

1.5ImagesinThisManual

Thedetailedimagesinthismanualaregivenmarksto

identifyvariouscomponents.Componentmarksintext

andoperationalinstructionsalwaysrelatetotheimage

directlyabove.

4

1532486-N

Safety

2Safety

2.1SafetyandFittingInstructions

Thesesafetyinstructionsareintendedtopreventaccidents

atwork,anditisimperativethattheyareobserved.

Beforeanyinspectionorrepairwork

•Readandobservethisrepairmanualandthe

associatedusermanual.

•Observetheminimumrequirementsforcarryingout

thework(see1.2GeneralInformation,page4).

PersonalSafetyEquipment

Safetyshoes

Themobilitydevice,andsomeofitscomponents,arevery

heavy.Thesepartscanresultininjuriestothefeetifthey

areallowedtodrop.

•Wearstandardizedsafetyshoesduringallwork.

Eyeprotection

Itispossiblethatbatteryacidcanbedischargedwhen

workingondefectivebatteriesorwhenhandlingbatteries

improperly.

•Alwaysweareyeprotectionwhenworkingonany

defectiveorpossiblydefectivebatteries.

Safetygloves

Itispossiblethatbatteryacidcanbedischargedwhen

workingondefectivebatteriesorwhenhandlingbatteries

improperly.

•Alwayswearacid-proofsafetygloveswhenworking

onanydefectiveorpossiblydefectivebatteries.

GeneralSafetyInformationandInformationAboutFitting

/Removal

DANGER!

RiskofDeath,SeriousInjury,orDamage

Lightedcigarettesdroppedontoanupholstered

seatingsystemcancauseareresultingin

death,seriousinjury,ordamage.Mobility

deviceoccupantsareatparticularriskofdeath

orseriousinjuryfromtheseresandresulting

fumesbecausetheymaynothavetheabilityto

moveawayfromthemobilitydevice.

–DONOTsmokewhileusingthismobility

device.

WARNING!

RiskofSeriousInjuryorDamage

Storingorusingthemobilitydevicenearopen

ameorcombustibleproductscanresultin

seriousinjuryordamage.

–Avoidstoringorusingthemobilitydevice

nearopenameorcombustibleproducts.

CAUTION!

Riskofcrushing

Variouscomponentssuchasthedriveunit,

batteries,seatetcareveryheavy.Thisresults

ininjuryhazardstoyourhands.

–Notethehighweightofsomecomponents.

Thisappliesespeciallytotheremovalofdrive

units,batteriesandtheseat.

CAUTION!

Injuryhazardifthemobilitydevicestarts

movingunintentionallyduringrepairwork

–Switchthepowersupplyoff(ON/OFFkey).

–Engagethedrive.

–Beforeliftingup,securethemobilitydevice

byusingchockstoblockthewheels.

CAUTION!

Fireandburnhazardduetoelectrical

short-circuit

–Themobilitydevicemustbecompletely

switchedoffbeforeremovalof

voltage-carryingcomponents!Todo

this,removethebatteries.

–Avoidshort-circuitingthecontacts

whencarryingoutmeasurementson

voltage-carryingcomponents.

CAUTION!

Riskofburnsfromhotsurfacesonthemotor

–Allowthemotorstocooldownbefore

commencingworkonthem.

CAUTION!

Injuryhazardandriskofdamagetomobility

deviceduetoimproperorincomplete

maintenancework

–Useonlyundamagedtoolsingoodcondition.

–Somemovingpartsaremountedinsockets

withPTFEcoating(Teon™).Nevergrease

thesesockets!

–Neveruse"normal"nutsinsteadof

self-lockingnuts.

–Alwaysusecorrectly-dimensionedwashers

andspacers.

–Whenreassembling,alwaysreplaceanycable

tieswhichwerecutduringdismantling.

–Aftercompletingyourwork/beforerenewed

start-upofthemobilitydevice,checkall

connectionsfortighttting.

–Aftercompletingyourwork/beforerenewed

start-upofthemobilitydevice,checkallparts

forcorrectlocking.

–Onlyoperatethemobilitydevicewiththe

approvedtyrepressures(seetechnicaldata).

–Checkallelectricalcomponentsforcorrect

function.Notethatincorrectpolaritycan

resultindamagetothecontrolsystem.

–Alwayscarryoutatrialrunattheendof

yourwork.

CAUTION!

Riskofinjuryanddamagetoproperty,ifthe

maximumspeedreductiononawheelchair

withalifterdoesnotfunctioncorrectly

Thewheelchair’scontrolunitmustreducethe

maximumpossiblespeedassoonasthelifter

israised.

–Testthemaximumspeedreductionfor

correctfunctionafteranymaintenancework

ormodicationstothewheelchair.

1532486-N5

Invacare®TDX®SP2Series

CAUTION!

Anychangestothedriveprogramcanaffect

thedrivingcharacteristicsandthetipping

stabilityofthemobilitydevice

–Changestothedriveprogrammayonlybe

carriedoutbytrainedInvacareproviders.

–Invacaresuppliesallmobilitydeviceswitha

standarddriveprogramex-works.Invacare

canonlygiveawarrantyforsafemobility

devicedrivingbehavior-especiallytipping

stability-forthisstandarddriveprogram.

Markallcurrentsettingsforthemobilitydevice

(seat,armrests,backrestetc.),andtheassociated

cableconnectingplugs,beforedismantling.This

makesreassemblyeasier.Allplugsarettedwith

mechanicallockswhichpreventreleaseofthe

connectingplugsduringoperation.Toreleasethe

connectingplugsthesafetylocksmustbepressed

in.Whenreassemblingensurethatthesesafety

locksarecorrectlyengaged.

61532486-N

Hygiene

3Hygiene

3.1HandlingofReturnedUsedProducts

Whenreconditioningorrepairingreturnedmobilitydevices:

•Takeprecautionsforyourselfandtheproduct.

•Useprotectionequipmentasspeciedlocally.

BeforeTransport(AccordingtoBiologicalAgentsOrdinance)

Treatproductaccordingtofollowingprocesssteps:

ProcessStepComponent

ApplicationConditioning

technique

WorkStation

ManualcleaningSurfaceofuseddeviceBeforerepairor

reconditioning

Usesaturatedtowel

toapplycleaning

detergentandremove

residuesafterimpact.

Cleaningand

disinfection

DisinfectionSurfaceofuseddeviceBeforerepairor

reconditioning

Usesaturated

disinfectantwipes

andclean*thedevice

surface.

Cleaningand

disinfection

*Invacareusesdetergent"Nücoseptspecial"1.5%inwaterml/ml

DisinfectionTools

•Disposablewipes(eece)

•Brushestocleanareasdifculttoaccess

FurtherInformation

FormoreinformationcontactyourInvacareservicedepartment.

1532486-N

7

Invacare®TDX®SP2Series

4Setup

4.1Adjustingseatingposition

Adjustingtheseatingpositioninordertoadaptthe

mobilitydeviceoptimallytotherequirementsoftheuser,

werecommendthatyouaskyourauthorisedInvacare®

dealertoadjustseatdepthindividually.Adaptingtheseat

totheuser'sseatingpositiondependsontheseatthathas

beentted,andshouldbecarriedoutinthefollowing

sequence.

1.Adjustingthelowerleglengthandseatdepth.See

chapter4.1.1AdjustingLowerLegLength,page8.

2.Adjustingthecenterofgravityoftheseatframe.See

chapter4.1.3Adjustingcenterofgravityofseat,page

8.

3.Checkingthattheswivelcastorscanmovefreely.

4.Repetitionofsteps2to4,ifnecessary.

WARNING!

Riskofinjuryaftertiltingofmobility

causedbyblockedsteeringwheels

–Alwayschecktheseatdepthsettingsfor

bothforwardandreversemovement.

Makesurethatsteeringwheelscan

rotatefreelyandhavenotcontacttoany

xedmobilitydevicecomponent.

CAUTION!

Riskoftippingover

Anychangeintheseatingpositioncan

negativelyinuencethestabilityofthe

mobilitydevice.

–Alwaysmakesurethatthemobility

deviceisstableandwillnottipover,

afteradjustingseatingposition.

WARNING!

Anychangestothedriveprogramcan

affectthedrivingcharacteristicsandthe

tippingstabilityofthemobilitydevice

–Changestothedriveprogrammayonly

becarriedoutbytrainedInvacare®

providers.

–Invacare®suppliesallmobilitydevices

withastandarddriveprogramex-works.

Invacare®canonlygiveawarrantyfor

safevehicledrivingbehavior-especially

thetippingstability-forthisstandard

driveprogram.

WARNING!

Riskofcrushing

Theseatisveryheavy.Riskofinjuryto

handsandfeet.

–Payattentiontothehandandfeet.

–Useproperliftingtechniques.

4.1.1AdjustingLowerLegLength

Invacareoffersarangeoflegrestswhichcanbeadjusted

individually.Seeusermanual.

4.1.2Adjustingseatdepth

A:Seatdepth

B:Centerofgravityoftheseat/seatposition

SeatdepthAcanbeadjustedbymovingbackrestin

relationtoseatsurface.

Moduliteseat

Theseatdepthisadjustedbyshiftingthepositionofthe

backrest.SeeUserManual.

Seatsystems

Fordetailson

•Standardseat

•Flexseat

•Contourseat

•Maxseat

refertorevision11ofthisservicemanual.

FordetailsonModuliteseatseebelow.

4.1.3Adjustingcenterofgravityofseat

Thecenterofgravityofseat(CoG)canbeadjustedby

mountingseatframefarthertowardsfrontortherearof

seat.

CAUTION!

Theseatingsystemofthemobilitydeviceis

deliveredexworkswithastandardadjustment

ofcenterofgravity(CoG),whichmeets80–90%

ofuserrequirements.CoGcanbeadjusted

individually.However,anychangeinthis

adjustmentsettingcannegativelyinuence

thestabilityofthepowerwheelchair.

–Youmustperformanindividualriskanalysis

everytimeyouchangethecenterofgravity

oftheseatingposition,inordertoensurethe

safetyandstabilityofthepowerwheelchair.

A:Seatdepth

B:Centerofgravityoftheseat/seatposition

81532486-N

Setup

Theuserweightandseatdepthhavestrong

inuencesonthechoiceofthecenterofgravity

(CoG).Iftheuserisheavyandtheseatdepthis

greater,thefocusshouldbethefartherback.For

bestpossibledrivingcharacteristicsofrear-wheel

drivewheelchairs,theweightshouldbedistributed:

30–40%frontand60-70%rear.Forcenter

wheeldrivestheweightshouldbedistributed25%

front,50%centerand25%rear.

CAUTION!

Riskofdamageduetocollisionsofthelegrests

withotherpartsofthemobilitydevice

–Setthelegreststothesmallestanglebefore

adjustingtheseatcenterofgravity.

–Payattentionwithadjustingseatcenterof

gravitythatlegrestsdonottouchanyother

partsofwheelchair.Thisensuresthatthe

legrestscannotcollidewithotherpartsof

wheelchair.

Seatsystems

Fordetailson

•Standardseat

•Flexseat

•Contourseat

•Maxseat

refertorevision11ofthisservicemanual.

FordetailsonModuliteseatseebelow.

4.2Moduliteseat

TheModuliteseatisavailableintwoversions:

•Telescopicseatframe(plateandstrap):Adjustmentof

centerofgravityviathelateralproles,asdescribed

belowin“Telescopicseatframe”.

•Onepieceseatplate:Adjustmentofcenterofgravity

viatheoblongholesoftheseatadapterasdescribed

belowinchapter“Onepieceseatplate”.

4.2.1Telescopicseatframe

•6mmAllenkey

1.Removeseatplateorslingseat(1),seechapter

“Adjustingseatwidth”inModuliteservicemanual.

2.LoosenAllenscrews(2)infrontandrear,leftandright

–DONOTremove.

3.Shiftpositionofseat.

4.Tightenscrews.

5.Installseatplateorslingseat.

4.2.2One-PieceSeatPlate

•6mmAllenkey

Fig.4-1Thispictureisanexample.

1.Removeseatplate.

2.Loosenscrews(2)leftandright–DONOTremove.

3.Shiftpositionofseatframe.

4.Tightenscrews.

5.Installseatplate.

4.3Imperialtometricconversionchart

Youcanusethischartasanorientationtondtheright

toolsize.

IMPERIALMETRIC

inch

mm

5/64

1.9844

3/32

2.3813

7/64

2.7781

1/8

3.1750

9/64

3.5719

1532486-N9

Invacare®TDX®SP2Series

IMPERIALMETRIC

inch

mm

5/32

3.9688

11/64

4.3656

3/16

4.7625

13/64

5.1594

7/32

5.5563

15/64

5.9531

1/4

6.3500

17/64

6.7469

9/32

7.1438

19/64

7.5406

5/16

7.9375

21/64

8.3344

11/32

8.7313

23/64

9.1281

3/8

9.5250

25/64

9.9219

13/32

10.3188

27/64

10.7156

7/16

11.1125

29/64

11.5094

15/32

11.9063

31/64

12.3031

1/2

12.7000

33/64

13.0969

IMPERIALMETRIC

inch

mm

17/32

13.4938

35/64

13.8906

9/16

14.2875

37/64

14.6844

19/32

15.0813

39/64

15.4781

5/8

15.8750

41/64

16.2719

21/32

16.6688

43/64

17.0656

11/16

17.4625

45/64

17.8594

23/32

18.2563

47/64

18.6531

3/4

19.0500

49/64

19.4469

25/32

19.8438

51/64

20.2406

13/16

20.6375

53/64

21.0344

27/32

21.4313

55/64

21.8281

7/8

22.2250

101532486-N

Testing

5Testing

5.1TestingMotor

•Phillipsscrewdriver,size2

•Digitalmultimeterwithresistancemeasurement

1.Removeshroudthatcoverspowermodule.See6.9

Shrouds,page41.

2.UnplugcableofmotorAfrompowermodule.

3.ConnectmultimeterBtomotorplugcontactsCandD

andmeasureresistancebetweencontacts.

Aresistanceofbetween0.5ohmsand5ohms

indicatesamotorreadyforoperation.A

resistanceofbetween15ohmsandinnity

indicatesadefectivemotor.Highresistancesare

normallycausedbybadconnectionsorworn

carbonbrushes.

Fig.5-1DuraWattmotorservesasanexample.

5.2TestingMotorBrake

Thistestshouldonlybecarriedoutonmobilitydevicewithconventionalmotor-gearboxunits.

CAUTION!

Riskofdamagetopowermoduleduetoshortsinmotorbrake

–NEVERconnectashortedmotorbraketoanintactpowermodule.

–Alwaysreplaceshortedbrakesimmediately.

Adefectivemotorcandamagethepowermodule,butadefectivepowermodulecannotdamagethemotor.

•Phillipsscrewdriver,size2

•Digitalmultimeterwithresistancemeasurement

1.Removeshroudthatcoverspowermodule.See6.9

Shrouds,page41

.

2.UnplugcableofmotorAfrompowermodule.

3.ConnectmultimeterBtomotorplugcontactsEandF

andmeasureresistancebetweencontacts.

Aresistanceofbetween40ohmsand80ohms

indicatesanintactbrake.Aresistanceof0ohms

oraveryhighresistance(mega-ohmsorinnity)

indicatesashort-circuit,abadconnectionora

defectivebrake.

4.Ifthereisadefect,replacemotorandsenditto

InvacareServiceforinspectionorrepair.

Fig.5-2DuraWattmotorservesasanexample.

5.3Raintest

•Checktoensurethattheblackbatteryterminalcapsaresecuredinplace,gaiterisnottornorcrackedwherewater

canenterandthatallelectricalconnectionsaresecureatalltimes.

•Donotusethemobilitydeviceifthegaiteristornorcracked.Ifthegaiterbecomestornorcracked,replace

immediately.

1532486-N

11

Invacare®TDX®SP2Series

5.4FieldLoadTest

Oldbatteriesloosetheirabilitytostoreandreleasepowerduetoincreasedinternalresistance.Inthisprocedure,batteries

aretestedunderloadusingadigitalvoltmetertocheckbatterychargelevelatthechargerconnector.Thechargerconnector

islocatedontheremote.Whenvoltageattheoutputdrops1.0voltsunderload(2.0voltsforapair),replacethebatteries.

Readtheseinstructionscarefullyandthemanufacturer’sinstructionsonthedigitalvoltmeterbeforeproceeding.

•Voltmeter

WARNING!

–Whenperformingthefollowingsteps,ensureyourfeetareclearfromcastersandwall,otherwiseinjury

mayresult.

1.SwitchelectronicsOFFonremote.

2.Makesurebatteryisfullycharged.Anextremely

dischargedbatterywillexhibitthesamesymptomsasa

badbattery.

3.Removefootboard/legrestsfrommobilitydevice.

4.ConnectvoltmeterleadstochargerconnectorAon

mobilitydevice.MostdigitalvoltmetersBarenot

affectedbypolarity.However,analogmeters(meters

withswingingneedles)canbeandshouldbeused

carefully.

Agoodmeterreadingshouldbe25.5VDCto

26.0VDCwiththechairinneutral.

5.SwitchelectronicsONonremote.

6.Ensuethatyourfeetareclearfromcastersandwall.

7.Runmobilitydeviceinneutralforatleast2minutes.

8.Sitinmobilitydeviceandplaceyourfeetagainstadoor

jam,workbenchorotherstationaryobject.

9.Carefullygiveforwardcommand,tryingtodrivethe

mobilitydevicethroughthestationaryobject.Theload

shoulddrawbetween30ampsto40ampsfromthe

batteriesfor0.3seconds.

Performingthisstepputsaheavyloadon

thebatteriesastheytrytopushthroughthe

stationaryobject.Ifthewheelsspin,havetwo

individuals(oneoneacharm)applyasmuch

downwardpressureaspossibleonthearmsof

themobilitydevice.

10.Readmeterwhilemotorsarestrainingtodetermine

voltageunderload.

Ifthevoltagedropsmorethan2.0voltsfrom

apairoffullychargedbatteriesduringthe0.3

seconds,theyshouldbereplacedregardlessof

theunloadedvoltages.

Fig.5-3

5.5CheckingBatteryChargeLevel

Thefollowing“Dos”and“Don’ts”areprovidedforyourconvenienceandsafety.

DON’TDO

Don’tperformanyinstallationormaintenancewithoutrst

readingthismanual.

Readandunderstandthismanualandanyservice

informationthataccompaniesabatteryandchargerbefore

operatingthepersonaltransporter .

Don’tperforminstallationormaintenanceofbatteriesin

anareathatcouldbedamagedbybatteryspills.

Movethepersonaltransportertoaworkareabefore

cleaningterminals,oropeningbatterybox.

Don’tmakeitahabittodischargebatteriestothelowest

level.

Rechargeasfrequentlyaspossibletomaintainahigh

chargelevelandextendbatterylife.

12

1532486-N

Testing

DON’TDO

Don’tusechargersorbatteriesthatarenotappropriate

forthechair.

Followrecommendationsinthismanualwhenselecting

abatteryorcharger .

Don’tputnewbatteriesintoservicebeforecharging.Fullychargeanewbatterybeforeusing.

Don’ttiportiltbatteries.Useacarryingstraptoremove,moveorinstallabattery.

Don’ttaponclampsandterminalswithtools.Pushbatteryclampsontheterminals.Spreadclampswider

ifnecessary.

1532486-N13

Invacare®TDX®SP2Series

6Service

6.1GeneralWarningInformationon

InstallationWork

CAUTION!

Riskofinjuryanddamagetoproperty,if

themaximumspeedreductiononamobility

devicewithalifterdoesnotfunctioncorrectly

Themobilitydevice’selectronicsmustreduce

themaximumpossiblespeedassoonasthe

lifterisraisedabove100mm.

–Testthemaximumspeedreductionfor

correctfunctionafteranymaintenancework

ormodicationstothemobilitydevice.

6.2Tighteningtorques

CAUTION!

Damagecanbecausedtothemobilitydevice

duetoimproperlytightenedscrews,nutsor

plasticconnections.

–Alwaystightenscrews,nutsetctothestated

tighteningtorque.

–Onlytightenscrewsornutswhicharenot

listedherengertight.

Thetighteningtorquesstatedinthefollowinglistare

basedonthethreaddiameterforthenutsandboltsfor

whichnospecicvalueshavebeendetermined.Allvalues

assumedryandde-greasedthreads.

ThreadTighteningtorquein

Nm±10%

M43Nm

M5

6Nm

M610Nm

M825Nm

M1049Nm

M1280Nm

M14120Nm

M16180Nm

UNCThreadTighteningtorquein

Nm±10%

1/4”-20

11–7Nm

5/16”-20

22–14Nm

3/8”-16

41–25Nm

7/16”-14

67–40Nm

1/2”-13

100–60Nm

9/16”-12

150–90Nm

5/8”-11

210–130Nm

3/4”-1

370–230Nm

7/6”-9

600–370Nm

1”-8

900–550Nm

6.3Troubleshooting

6.3.1OperationalFaults

Proceedasfollowsifyouhaveanyproblems:

1.Firstassessthepossiblecauseoftheproblemusing

thefollowingtable.

2.Checktheremotestatusdisplay.Evaluatetheash

errorcode.

3.Carryoutthenecessarychecksandrepairsas

recommendedinthefollowingtable.

Thevariouspowermodulescanbettedinconnection

withdifferentremotesinthemobilitydevice.Rectication

ofoperationalfaultsdependsonthepowermodule

tted.Thepowermodulesusedaredescribedinthe

correspondingcontrolsmanual.

Thetablesforrecticationofoperationalfaults

listedinthefollowingchaptersareonlyanexcerpt

fromtheoriginalmanufacturer'smanuals.Youcan

obtaintheoriginalmanualsfromInvacare.

6.3.2DriveFaultDiagnosis

ProblemOthersymptomsPossiblecauseSolution

Documentation

Mobilitydevicewill

notstart

Theremotestatus

displayilluminates

normallyandshows

anerrorcode.

Drivemotors

disengaged

Engagedrivemotors.Seeusermanual.

BatteriesdefectiveReplacebatteries.See6.11.4Replacing

Batteries(60Ah/

73Ah),page47

and6.11.6Replacing

Batteries/Battery

Cables,page48.

Remotestatusdisplay

doesnotilluminate

Completelydischarged

battery

Pre-chargebatteries.Seeusermanual.

14

1532486-N

Service

ProblemOthersymptomsPossiblecauseSolution

Documentation

Checkmainfuse.See6.11.7Checking

andreplacingmain

fuse,page49.

Powersupplyto

remoteinterrupted

Checkcablesbetween

modulesforloose

connectionsor

damage.

See6.10.7Checking

cable,page45

.

RemotedefectiveReplaceremote.See6.10.1Replacing

PowerModule,page

42.

Remotestatusdisplay

ashing

Variouscauses

Assesserrorcode.Seeremotemanual.

Batteriesdefective

(unstablevoltage)

Replacebatteries.See6.11.6Replacing

Batteries/Battery

Cables,page48

and6.11.4Replacing

Batteries(60Ah/

73Ah),page47.

Replacemotor(s).

See6.7.2Replacing

Motor/GearboxUnit,

page29.

Mobilitydevice

juddersindrivemode

None

Drivemotor(s)

defective

Replacecarbon

brushes.

See6.7.5Replacing

carbonbrushes,page

31

.

Mobilitydevicepulls

toleftorright

None

Drivemotorsrunning

asymmetrically

Changeprogramming

tosynchronisemotors.

Seeprogramming

manual.

TyrevisiblydentedNotenoughtyre

pressure

Checktyrepressure,

replaceinnertube

and/orvalveif

necessary.

Errormessagedoes

notdisappear

None

BadconnectionsCheckallconnecting

cables.

See6.10.7Checking

cable,page45.

MotorbrakedefectiveMeasureinternal

resistanceofbrakes,

replacemotorif

defective.

See5.2TestingMotor

Brake,page11

and6.7.2Replacing

Motor/GearboxUnit,

page29.

Motorsstopandstart

again

None

VoltagedeclineStopdrivingandallow

electronicstocool

down.

Motorrunsbutloses

power

None

Highmotorload

allowspowermodule

tolowervoltage

Stopdrivingandallow

electronicstocool

down.

Motorsstopanddo

notstartagain

None

Highmotorload

allowspowermodule

tolowervoltage

Leavemobilitydevice

switchedonand

letpowermodule

operate.Charge

batteriesovernight

withelectronics

turnedon.

None

FuseburntoutCheckcablingand

replacefuse.

See6.10.7Checking

cable,page45and

6.11.7Checkingand

replacingmainfuse,

page49.

1532486-N15

Invacare®TDX®SP2Series

ProblemOthersymptomsPossiblecauseSolution

Documentation

None

MotordefectiveCheckcarbonbrushes

andreplaceif

necessary.

See6.7.5Replacing

carbonbrushes,page

31.

Measureinternal

resistanceofmotor,

replacemotorif

defective.

See5.1Testing

Motor,page11

and6.7.2Replacing

Motor/GearboxUnit,

page29.

None

Powermodule

defective

Replacepower

module

See6.10.1Replacing

PowerModule,page

42.

Motorslosepower

whiledriving

None

BadconnectionsTurnoffelectronics,

wait10seconds,turn

onelectronics.Check

allcabling.

See6.10.7Checking

cable,page45

.

Motorjuddersorruns

irregularly,oronly

onemotorruns

None

Carbonbrushes

worn(onlyapplies

formotorswithout

lifetimebrushes)

Checkcarbonbrushes

andreplaceif

necessary(only

appliesformotors

withoutlifetime

brushes).

See6.7.5Replacing

carbonbrushes,page

31.

Clutch(es)defective

Replaceclutch.See6.7.2Replacing

Motor/GearboxUnit,

page29.

BearingdefectiveReplacemotor.See6.7.2Replacing

Motor/GearboxUnit,

page29.

CollectordefectiveMeasureinternal

resistanceofmotor,

replacemotorif

defective.

See5.1Testing

Motor,page11

and6.7.2Replacing

Motor/GearboxUnit,

page29.

Motorsdonotrun

None

BadconnectionsCheckallcabling.See6.10.7Checking

cable,page45.

FuseburntoutCheckcablingand

replacefuse.

See6.10.7Checking

cable,page45and

6.11.7Checkingand

replacingmainfuse,

page49.

BatteriesdefectiveReplacebatteries.See6.11.4Replacing

Batteries(60Ah/

73Ah),page47

and6.11.6Replacing

Batteries/Battery

Cables,page48.

Cablingtopower

moduleorremote

defective

Checkcabling.See6.10.7Checking

cable,page45.

Powermodule

defective

Replacepower

module.

See6.10.1Replacing

PowerModule,page

42

.

CorrodedcontactsContactsdefectiveCheckcabling,replace

ifnecessary.

See6.10.7Checking

cable,page45.

Motormakesclicking

noise

None

Clutch(es)defective

Replaceclutch.See6.7.2Replacing

Motor/GearboxUnit,

page29.

161532486-N

Service

ProblemOthersymptomsPossiblecauseSolution

Documentation

BearingdefectiveReplacemotor.See6.7.2Replacing

Motor/GearboxUnit,

page29.

CollectordefectiveMeasureinternal

resistanceofmotor,

replacemotorif

defective.

See5.1Testing

Motor,page11

and6.7.2Replacing

Motor/GearboxUnit,

page29

Scrapingnoiseor

motorblocked

None

Clutch(es)defective

Replaceclutch.See6.7.4Replacing

motor/gearboxclutch,

page30

.

BearingdefectiveReplacemotor.See6.7.2Replacing

Motor/Gearbox

Unit,page29and

6.7.4Replacing

motor/gearboxclutch,

page30.

GearboxdefectiveReplacegearbox.See6.7.2Replacing

Motor/Gearbox

Unit,page29

and6.7.4Replacing

motor/gearboxclutch,

page30.

Gearboxmakes

clickingnoise

None

GearboxdefectiveReplacegearbox.See6.7.2Replacing

Motor/Gearbox

Unit,page29

and

6.7.4Replacing

motor/gearboxclutch,

page30.

DrivewheellooseTightendrivewheel,

secureboltswith

threadlocking

adhesiveifnecessary.

See6.7.2Replacing

Motor/GearboxUnit,

page29.

Gearboxlosesoil

None

Sealingringondrive

shaftdefective

Replacegearboxif

sealingringdefective.

See6.7.2Replacing

Motor/Gearbox

Unit,page29and

6.7.4Replacing

motor/gearboxclutch,

page30.

Checkcarbonbrushes

foroilwetting,replace

motorifbrusheswet.

See6.7.2Replacing

Motor/Gearbox

Unit,page29and

6.7.4Replacing

motor/gearboxclutch,

page30and6.7.5

Replacingcarbon

brushes,page31.

Irregularrunning

None

Driveshaftmovable

orbent

Checkdriveshaft,

replacegearbox,if

defective.

See6.7.2Replacing

Motor/Gearbox

Unit,page29and

6.7.4Replacing

motor/gearboxclutch,

page30.

Batteriesnotbeing

charged

None

Fuseburntout,cable

defective

Checkcablingand

replacefuse.

See6.10.7Checking

cable,page45and

6.11.7Checkingand

replacingmainfuse,

page49.

1532486-N

17

Invacare®TDX®SP2Series

ProblemOthersymptomsPossiblecauseSolution

Documentation

BatteriesdefectiveReplacebatteries.6.11.6Replacing

Batteries/Battery

Cables,page48

and6.11.4Replacing

Batteries(60Ah/

73Ah),page47.

LEDsashingon

charger

ChargerdefectiveReplacecharger.Seechargeruser

manual.

Shortchargingperiod

None

Oneofthebatteries

couldbedefective

Replacebatteries.See6.11.6Replacing

Batteries/Battery

Cables,page48

and6.11.4Replacing

Batteries(60Ah/

73Ah),page47.

Mobilitydeviceruns

tooslowly

None

RemotedefectiveReplaceremote.See6.10.1Replacing

PowerModule,page

42.

BatteriesdefectiveReplacebatteries.See6.11.6Replacing

Batteries/Battery

Cables,page48

and6.11.4Replacing

Batteries(60Ah/

73Ah),page47

.

6.3.3Chargingdevicefaultdiagnosis

Symptom

PossiblecauseSolution

NoLEDsilluminatingonbatterychargerChargingdevicenotconnectedto

mainssupply.

Ensurethatthebatterychargerhas

beenpluggedin.

NomainssupplyCheckthemainssupplywitha

voltmeter .

Defectivemainssupplycable.Checkthemainssupplycable.Replace

damagedcablesorsendthebattery

chargertoInvacareServiceforrepair.

LEDsareburntoutSendthebatterychargertoInvacare

Serviceforrepair .

Aninternalfusemightbeburntout.SendthebatterychargertoInvacare

Serviceforrepair .

BatteriesdonotchargeFuseonmobilitydevicehasburntout.Checkmobilitydevicefuses.See“Main

fuse”.

Batterychargernotconnectedto

mobilitydevice.

Ensurethatthebatterychargerhas

beenconnectedtothemobilitydevice.

NomainssupplyCheckthemainssupplywitha

voltmeter .

Defectivemainssupplycable.Checkthemainssupplycable.Replace

damagedcablesorsendthebattery

chargertoInvacareServiceforrepair.

Batterychargercouldbedefective.Useabatterychargerwhichyouknow

isworkingproperlytochargethe

batteries.Sendthedefectivebattery

chargertoInvacareServiceforrepair.

Batteryvoltageistoolowtooperate

mobilitydevice.

Replacethebatteries.See“Removing

batteries”

181532486-N

Service

6.4ServicePlan(OnceaYear)

CAUTION!

Riskofinjuryanddamagetoproperty,ifmaximumspeedreductiononwheelchairwithlifterdoesnot

functioncorrectly

Thewheelchair’selectronicsmustreducethemaximumpossiblespeedassoonasthelifterisraised.

–Testthemaximumspeedreductionforcorrectfunctionafteranymaintenanceworkormodicationstothe

wheelchair.

Component

CheckRemedy

Notes

Damagetoposture

belt

Replacebeltif

damaged

SeeReplacingPostureBeltin

servicemanualofseatingsystem.

Posturebelt

BeltlockfunctionReplacebeltif

damaged

SeeReplacingPostureBeltin

servicemanualofseatingsystem.

Damagetoarmrests

Replacecoverif

damaged

Armrests

ArmrestxingsTightenscrews

Damagetoclothing

guard

Replaceclothing

guard,ifdamaged

Clothingguard

ClothingguardxingsTightenscrews

PoweredtiltTighttofSLretainer

clip

ReplaceSLretainer

clip,ifnecessary

Poweredrecline(if

tted)

Damagetobackrest

Seams

Fixing

Checkcable

Checkfunction

Replacepartsif

damaged

Tightenscrews

Replacecableor

motorifnecessary

Frames(chassis)/

batterymounting

Checkxings,welded

seamsandbattery

mounting

Tightenscrews

Replacecomponents

ifnecessary

StabilityLockCheckgascylinderRepairorreplaceif

damaged

Replacegascylinder

every2years!

See6.6.2Stabilitylock,page22

.

DahlDockingstationCheckscrewsTightenscrewsSee6.14MountingDahlDocking

System,page52.

Checkdrivewheelsfor

tighttandsideplay

Adjust,replacewheel

hubs

See6.8.8ReplacingDriveWheel

(5–ScrewInstallation),page38

and6.8.9Replacingdrivewheel

hub,page39

.

Checkcastorsfortight

t,oatandsideplay

Replacewheels,

castorforksorwheel

bearings

See6.8Wheels,page34.

Tyres

Repairorreplaceif

damaged

See6.8Wheels,page34

.

ChecksuspensionRepairorreplaceif

damaged

See6.8Wheels,page34.

Wheelsuspensionand

wheels

CheckstraightrunningReplacewheels,

castorforksorwheel

bearings

See6.8Wheels,page34

.

1532486-N19

Invacare®TDX®SP2Series

Component

CheckRemedy

Notes

MotorsTestmotors

See5.1TestingMotor,page11.

Driveunits,clutch

mechanism

Checkfunctionsin

driveandpushmodes

Checkclutch

mechanism

Checkcarbonbrushes,

replaceifnecessary

(notwithlifetime

brushes)

Replacemotorif

necessary

Tightenscrews/nuts,

adjustorreplaceif

necessary

See6.7DriveComponents,page

29

.

BrakesCheckmotorbrakeTestmotorbrake

See5.1TestingMotor,page11.

Legrests

Checkweldedseams,

interlocking,screws,

footplates

Tighten,replaceif

necessary

Powerlegrests(if

tted)

Checkcable

Checkcontacts

Checkfunctions

Replacecableif

necessary

Lighting(iftted)

Checkcable

Checkfunction

Replacelamporcable

ifnecessary

See6.12Lightingunit,page49.

Batterymounting

Checkbatterysupport

andmountingbelts

fordamage

Replaceifnecessary

Checkbatteriesfor

damage

Replacebatteriesif

necessary

See6.11.4ReplacingBatteries

(60Ah/73Ah),page47,6.11.6

ReplacingBatteries/Battery

Cables,page48and6.11.2

HandlingDamagedBatteries

Correctly,page46.

CheckbatteryvoltageChargebatteriesSeeusermanual.

Batteries

Checkcontactsand

terminals

Cleancontactsand

terminals

Seesafetyinformationin6.11.4

ReplacingBatteries(60Ah/

73Ah),page47,6.11.6Replacing

Batteries/BatteryCables,page

48and6.11.2HandlingDamaged

BatteriesCorrectly,page46.

Remote,statusLED

ashing

Evaluateerror/ash

code

See6.3Troubleshooting,page14

.

Fixings

Tightenxings,

replaceifnecessary

Cablesandconnecting

plugs

Replacedamaged

cablesandtighten

connectingplugs,if

necessary

Replacejoystickknob

ifnecessary

Joystickfunction

Replaceremoteif

necessary

Remote/power

module

PowersupplyReplacedamaged

cablesandtighten

connectingplugs,if

necessary

201532486-N

/