Page is loading ...

Electrical connection

The fan motor must always be controlled by a frequen-

cy converter, which permits the possibility of regula-

tion and soft starting.

N.B. The fan must not be started directly.

From the rating plate, determine the MAXIMUM

frequency to which the fan motor may be regulated.

Under no circumstances must the fan motor be

supplied at a higher frequency.

Electrical connection must be performed by a quali-

fied electrician.

The cable between the terminal box of the motor and

the frequency changer must be screened. A safety cut-

out switch must be installed between the electricity

mains supply and the frequency changer.

The safety cut-out switch is fitted close to the fan

inspection door.

Before working on the fan, the fan must be switched

off with the safety cut-out switch.

Fläkt Woods 8201 GB 2012.11 1 Specifications are subject to alteration without notice

EU Air Handling Unit INSTALLATION

Installation alternatives

Connection of outlet duct

Connection of the duct to the outlet from the fan unit

must take place in accordance with one of the examples

in Fig. 2.

Important!

The unit must not be allowed to support the weight of

the duct.

The duct may be connected in accordance with the

following alternatives:

A. Via a transition piece fixed to the casing with self-

tapping screws. The duct connection is then made

with a PG joint or a flanged union. Fig. 2a.

B. Via a flexible sleeve coupling fixed to the casing with

self-tapping screws. The duct connection is then

made with a PG joint or a flanged union. Fig. 2b.

C. Via a direct edge-mounted duct provided with sheet

metal angles at the corners. Fig. 2c.

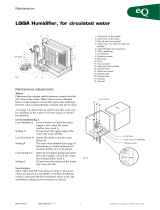

Fan EULK

Fig. 1

Protective net

EULZ-35

Counterflange

EULZ-34

Flexible sleeve

coupling EULZ-32

Transition piece

EULZ-33

Connection

accessories for

outlet:

Internal contact protec-

tion, outlet EULZ-36

Internal contact

protection,

inlet EULZ-37

Protective net for

door EULZ-38

Fig. 2a Fig. 2b Fig. 2c

EUL(B,F) 4A

EUL(B,F) 4B

EUL(B,F) 4C

Transition piece Flexible sleeve Counterflange Duct

EULZ-33 coupling EULZ-34

EULZ-32

xxx xxxx xxxxxx xxx

xxxx xxxxxxxx xx

xxx xxxx xxxxx

MAX frequency

Fig. 3

Electrical connection, continued.

Drill a hole for the cable conduit entry into the unit

casing at a suitable point in the fixed panel. Fig. 4 and

Fig. 5.

The cable must not be routed through the inspection

door. The screwed fitting for the cable can be executed

as shown in Fig. 6.

EULK can be supplied with an external, factory-

installed frequency converter connected to the termi-

nal box of the motor with a screened cable; accessory

STRZ-54. A safety isolator with cabling to the frequen-

cy converter is also available as an accessory; STRZ-65.

NOTE. STRZ-65 can only be ordered as a complete

assembly with STRZ-54.

EULK can also be supplied with a factory-installed

screened cable for an external screened terminal box;

accessory STRZ-66.

Fan EULK

Fläkt Woods 8201 GB 2012.11 2 Specifications are subject to alteration without notice

EU Air Handling Unit INSTALLATION

EUL(B,F) 6

EUL(B,F) 7

Fig. 5 Fig. 6

Testing before commissioning

– Check for compliance with the EU Machinery

Directive in respect of contact protection. Wherever

the fan unit is accessible from a duct or other func-

tional component, the fan unit must be fitted with

contact protection EULZ-36 and/or EULZ-37. Door

protective net EULZ-38 can be used as contact protec-

tion for the fan unit inspection door. See Fig. 1.

– Check that a qualified electrician has issued an

approval certificate prior to commissioning.

– Check that the impeller wheel rotates freely and that

no foreign objects are present which may be sucked in

and cause damage to the fan.

– If the fan is fitted with spring isolators, the transport

brackets must be removed before starting.

Airflow measurement

= Fixed panel

Fig. 4

Important!

If the fans are not operated for more than 3 months

before or after installation, the fans must be rotated

by hand at regular intervals. If not, the ball bearing

may suffer the following damage; see the illustration.

Belastningsskador

Load-induced damage

EULK is available with equipment for air flow meas-

urement, “d” = 1 or 3 in the EULK code. The air flow, q,

can be calculated from the following formula using a

measurement pressure of Δp(Pa), and a constant k:

The measurement pressure, Δp, which is the differ-

ence between the pressure in the empty part of the

fan inlet and the pressure inside the inlet cone, can be

read with a manometer (pressure range up to 6000 Pa)

connected to 2 externally located nipples. The value of

the constant k is shown in the table below.

A flow indicator with a built-in pressure transducer,

STYZ-78, is available as an accessory. STYZ-78, which

is connected via hoses to the external nipples, converts

the measurement pressure into a flow (m3/s) which

is indicated on a display and gives an output signal of

0-10 V in a linear relationship with the flow.

(See instruction for STYZ-78).

Fan EULK

Fläkt Woods 8201 GB 2012.11 3 Specifications are subject to alteration without notice

EU Air Handling Unit INSTALLATION

Size EULK, aa-b k- factor

20-2 42,55 1 fan

20-3 37,34 1 fan

21-2 29,95 1 fan

21-3, 22-2, 30-2 22,73 1 fan

30-3, 31-1 18,77 1 fan

31-2, 32-1 15,34 1 fan

31-3, 32-2, 33-2, 40-2 12,18 1 fan

40-3, 41-2, 42-1 9,49 1 fan

41-3, 42-2, 44-2, 51-1 7,5 1 fan

44-3, 50-3,51-2, 52-1, 60-1, 62-1 6,02 1 fan

51-3, 52-2, 53-2, 60-2, 62-2 4,6 1 fan

52-3, 53-3, 60-3, 64-1, 71-1, 73-1, 80-1 3,8 1 fan

62-3, 64-2, 71-2, 73-2, 80-2, 82-1 3,75 2 fans

64-3, 73-3, 82-2, 84-1 3,01 2 fans

64-4, 73-4, 82-3, 84-2 2,3 2 fans

84-3 1,9 2 fans

Where the fan section includes two fans the k-factor is valid for

the total air flow rate.

+–

�p

Fig. 7

q = √ Δp (m3/s)

1

kx

Temperature correction

The flow scale on the display instrument and the above

flow formula are applicable to air at a temperature of

+20°C. At other air temperatures, the flow must be

corrected using the formula:

where q = the actual flow through the fan, q20 = the

flow value reading and t = the prevailing temperature

in °C.

q = q20

(273 + t)

293 , m3/s

√

Frequency converter

Connection of the screening conductor shall be

made via an EMC approved union in the frequency

converter’s casing or by using a clamp intended for this

purpose. The screen conductor must not be connected

to an earth bolt.

Connection of the screen conductor

In those cases the screen conductor must be connected

to an earth bolt in the motor or frequency converter,

this should be done so that the impedance is as low

as possible, in these cases, this conductor is limited

in length to 5 times its width. For example, when the

screen conductor is 1 cm wide it must not be longer

than 5 cm.

Diverse

Besides this, the following should be observed:

– type of mains supply.

– local regulations and provisions.

– the manufacturer’s installation instructions for the

frequency converter.

Outputs over 22 kW

In the event of outputs over 22 kW, a symmetrical

screened cable with concentric or in some other way

symmetrically designed protective earth conductor

should be used, please refer to the installation instruc-

tions for the frequency converter for recommendations

concerning these installations.

Fan EULK

Fläkt Woods 8201 GB 2012.11 4 Specifications are subject to alteration without notice

EU Air Handling Unit INSTALLATION

Installation of the frequency converter

Warning: Incorrect installation of the frequency

converter can damage the bearings in the motor.

It is Fläkt Woods’ policy to only except claims

when the motor and frequency converter have been

supplied and installed by us.

Damage to the motor will not be accepted when the

motor has been connected to the frequency convert-

er by an installation engineer not provided by Fläkt

Woods.

The frequency converter and the motor must be

installed by a qualified electrician with good knowl-

edge of speed regulated, drive system installations

(frequency converters) and EMC-safety.

The following recommendations should be seen

as a supplement to the manufacturer’s installation

instructions. In those cases where there are differenc-

es, the manufacturer’s instructions shall take prec-

edence over the following; this is due to the warranty

undertaking from the manufacturer.

General

The installation between the motor and the

frequency converter should be carried out using

screened, unbroken 4-wire cable intended for

EMC-installations for motor operations, the screen

shall have at least 80% optical density, for example,

Nexan’s NCY or Ölflex Classic. The screen shall have

360° contact with the casing both in the motor and in

the frequency converter to give the maximum contact

surface. Safety switches or connection boxes fitted

between the frequency converter and motor are not

recommended.

Motor

The cable gland in the motor’s outlet box should

consist of an EMC approved cable gland, for exam-

ple, Miltronic SKINTOP MS-SC. The screen conduc-

tor may only be connected via EMC unions, not to

earth bolts.

The screen

should have

360° contact

with the casing

Screen Insulating tape

Insulating tape

The screen

should have

360° contact

with the

casing

Screen

Casing

Fig. 8

Fig. 9

Fig. 10

/