Page is loading ...

WORLD HEADQUARTERS & MANUFACTURING OPERATIONS

Highway 25E, P.O. Box

1060

Barbourville, KY

40906

888/800-JMSC

Fax: 606-523-9196

June 16, 1998 P/N 7610-011-44-01 Rev A

SECTION PAGE

WARRANTY POLICY INSIDE FRONT COVER

TABLE OF CONTENTS i

GENERAL

Machine Nomenclature

Important Safety Instructions

Nationwide Maintenance and Repair Centers

1

PARTS IDENTIFICATION AND FUNCTION

Diagram of Assembled Machine

2

INSTALLATION REQUIREMENTS

Electrical Requirements

Drain Hose Connection

Hot Water Supply Connection

Dishwasher Electrical Data Decal

Chemical Dispensing Equipment

6

DISHWASHER OPERATING INSTRUCTIONS

To Fill Dishwasher

To Drain the Machine

Manual Wash

8

TROUBLESHOOTING GUIDE 9

SERVICE PROCEDURES 14

ILLUSTRATED PARTS LIST 36

WIRING DIAGRAMS 60

NATIONWIDE MAINTENANCE AND REPAIR CENTERS (M&RC) INSIDE BACK COVER

i

Hot-water sanitizing Models JP-24/F and JP-24B/BF must have a minimum 180 Degree F. rinse water

temperature at a flow pressure of 20 PSI (+/-) 5 PSI to assure proper sanitization of ware.

The JP-24 series dishwasher is not supplied with chemical dispenser pumps for dispensing detergent,

rinse additive or sanitizer (JP-24LT/F). Consult your local detergent representative for information about a

chemical dispenser.

Low-temperature chemical sanitizing Model JP-24LT/LTF requires a minimum of 50 PPM of 5.25 %

sodium hypochlorite (liquid bleach) be injected in the final rinse line during the rinse. Do not operate

dishwasher as a low-temperature chemical sanitizing machine without a properly installed, N.S.F.

recognized chemical dispenser.

The "B" designation in the model number indicates the unit has a built-in hot water booster tank, requiring

a 140 Degree F. hot water supply. Units without the "B" require a 180 Degree F. hot water supply. The

"LT" designation indicates a low-temperature model requiring a minimum 120 Degree F. and 140 Degree

F. maximum hot water supply.

Free standing units not installed under a counter top will require a top and side panels, indicated by a "F"

designation in the model number.

IMPORTANT SAFETY INSTRUCTIONS

Please read all instructions before using this dishwasher. Safety precautions in this manual are preceded

by the words "DANGER", "WARNING", "CAUTION", or "NOTE" and are very important. DANGER is used

to indicate the presence of a hazard which will cause severe personal injury, death or substantial property

damage if the statement is ignored. WARNING is used to indicate the presence of a hazard which can

cause severe personal injury, death or substantial property damage if the statement is ignored. CAUTION

is used to indicate the presence of a hazard which will or can cause minor personal injury or property

damage if the statement is ignored. NOTE is used to notify personnel of installation, operations, or

maintenance information which is important, but not hazard related.

NATIONWIDE MAINTENANCE AND REPAIR CENTERS

If repairs or replacement parts are required, please call one of the Jackson Authorized Maintenance & Repair

Centers from the list provided on the rear cover of this manual. An illustrated list of replacement parts are included in

this manual to assist in identification and ordering of parts. BE SURE THAT ALL REPLACEMENT PARTS

PURCHASED AND USED IN YOUR DISHWASHER ARE GENUINE ORIGINAL PARTS, DISTRIBUTED BY A

JACKSON MAINTENANCE & REPAIR CENTER LISTED IN THE REAR COVER OF THIS MANUAL.

UNAUTHORIZED SUBSTITUTIONS MAY RESULT IN FIRE, ELECTRIC SHOCK OR OTHER HAZARDS.

1

PARTS IDENTIFICATION AND FUNCTION

ITEM

DESCRIPTION FUNCTION

1. Top Enclosure Panel Encloses Top - Freestanding Units

2. Right Side Panel Encloses Right Side of Machine

3.

Door Switch (Not Shown)

Starts Dishwashing Cycle

4.

Door Frame Panel

Access Pane

l to Door Switch/Spring

5.

Electrical Data Decal

Dishwasher Electrical Requirements/Serial No.

6. Electrical Control Panel Gauges/Switches for Operation

7.

Kick Panel

Encloses Electrical Panel Area

8. Dishwasher Door Encloses Dishwashing Area

9. Operating Instruction Decal Operating Procedures

10.

Left Side Panel Not Shown)

Encloses Left Side of Machine

11.

Door Handle

Used to Open and Close Door

12. Upper Rinse Arm & Feed Pipe Sprays Rinse Water Over Ware

13.

Right Rack Slide

Holds Rack Above

Spray Arms

14. Right Frame Leg Supports Right Side of Machine

15.

Leveling Foot

Used to Level Machine

16.

Lower Rinse Arm

&

Feed Pipe

Sprays Rinse Water Over Ware

17. Wash Spray Arm Sprays Wash Tank Water Over Ware

18.

Line Strainer

-

(1/2")

Filters

Debris From Water Supply Line

19. Pet Cock Valve Tap for Checking Rinse PSI/Temp.

20. Fill Solenoid Valve Allows Water in During Rinse/Fill

21.

Rinse Booster Tank (JP

-

24B/BF)

Holds Rinse Water For Heating

22.

Booster Tank Heater

(JP

-

24B/BF)

Heats Boo

ster Water For Rinse

•23.

Basket Strainer

Catches Food Soil in Wash Water

24. Left Rack Slide Holds Rack above Spray Arm

25.

Vacuum Breaker

(1/2")

Prevents Backflow into Water Supply

26. Rinse Injection Manifold Rinse Chemical/Sanitizer (JP-24LT/LTF) Injected

27.

Rinse Thermometer Bulb

Reads Final Rinse Temperature When Rinsing

28.

Vacuum Breaker Feed Pipe

Final Rinse Water Supplied Via Pipe

29. Detergent Injection Plug Injection Point for Detergent

30.

Rinse Thermometer Capillary

Senses Tempera

ture in Rinse Line

31, Rinse Booster Tank (JP-24B/BF) Heats Water for Final Rinse

32.

Drain Valve

(1

10V or 220V)

A

llows Waste Water to Drain Out

33. Hose, Pump to Drain Valve Carries Waste Water to Drain Valve

34.

Pump

&

Motor Assembly

Recirculates W

ash Water

35. Fill Line to Dishwasher Supplies Water to Dishwasher

36.

Fill Solenoid Valve

(1

10V or 220V)

Opens Water Supply Line

37. Petcock Valve Used to Check Pressure/Temp.

38.

Fill Line Strainer

(1/2")

Filters Water Supply Line

39.

Drain Hose

Fee

ds Waste Water to Drain System

40.

Rinse Manifold

Feeds Water From Booster to Rinse Arms

41. Hose, Rinse to Injection Feeds Rinse Water to Manifold

2

PARTS ID & FUNCTION

3

PARTS ID & FUNCTION

4

PARTS ID & FUNCTION

5

INSTALLATION REQUIREMENTS

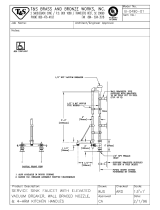

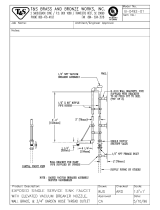

MODEL JP.24B/BF-ELECTRICAL REQUIREMENTS - SEE FIGURE - 1

IMPORTANT - PLEASE READ CAREFULLY - THE RINSE HEATER RELAY HAS BEEN TEMPORARILY

DISABLED SO THAT THE MACHINE'S INTERNAL BOOSTER TANK CAN FILL WITH WATER BEFORE

TURNING ON THE HEATING ELEMENT. A QUALIFIED SERVICEMAN MUST RECONNECT THE WIRE

(ORANGE/WHITE) TO THE RINSE HEATER RELAY COIL (TAGGED) AFTER THREE CYCLES OF OPERATION

AND THE WASH TANK IS FULL OF WATER. THE CIRCUIT BREAKER FEEDING THE UNIT SHOULD BE

TURNED OFF BEFORE DOING THIS.

DRAIN HOSE CONNECTION

Dishwasher has a pumped (pressure) drain capable of pumping waste water to a height of 24 inches from

floor to the kitchen's drain system. The dishwasher is supplied with a 8-foot long drain hose that extends

from the right rear side of machine. Drain hose must be installed indirect to kitchen's drain system with air

gap. It protects the dishwasher against water backing up in it if a drain clogs.

6

INSTALLATION REQUIREMENTS continued

HOT WATER SUPPLY CONNECTION

Install the water supply line (1/2" pipe size minimum) to the dishwasher line strainer using a soft copper

tube, flexible tube or hose to allow machine to be moved for servicing.

DISHWASHER ELECTRICAL DATA DECAL

DISHWASHER ELECTRICAL DATA DECAL is located on the right-side of unit at front. Refer to the

electrical data decal for machine operating requirements, machine voltage/total amperage load, and serial

number.

CHEMICAL DISPENSING EQUIPMENT

The JP-24 series dishwasher is not supplied with dispenser pumps for detergent, rinse additive or sanitizer

(JP-24LT/F). An injection hole is provided in the back wall of machine for dispensing detergent into

dishwasher wash tank. An injection manifold is provided in the final rinse line for injecting rinse additive and

sanitizer (Model JP-24LT/F requires a minimum of 50 PPM of 5.25% sodium hypochlorite (liquid bleach) be

injected in the final rinse line during the rinse).

Electrical power and signal source for detergent, rinse additive and sanitizer (JP-24LT/F) dispensing

equipment are available as follows:

DETERGENT SIGNAL - White/Red wire, "L1" signal (line voltage) for detergent dispensing. Detergent

dispenses during rinse cycle.

DISPENSER POWER - Red wire, "L2" return (line voltage). DISPENSER MAXIMUM AMPERAGE LOAD:

FUSE-TYPE 3AG "SLO-BLO", 2.5 MAXIMUM.

DISPENSER POWER - Green/White wire, "L1" power (line voltage) during dishwashing cycle. RINSE

AGENT/SANITIZER - Blue wire, "L1" signal (line voltage) (parallel with rinse/fill solenoid).

7

DISHWASHER OPERATING

INSTRUCTIONS

DISHWASHING CYCLE: Once the machine is initially filled, the dishwashing cycle consists of: the

machine washes a rack of dishes, drains the wash water, and then rinses with fresh water which remains

in the machine to wash the next rack of dishes. During the rinse, detergent, rinse additive, and sanitizer

(JP-24LT/LTF) should be injected.

TO FILL THE DISHWASHER

1. Close door and depress Power Switch to On/Fill position and place Cycle Switch to Auto position.

Red power indicator light will light to indicate machine has power turned on and the green light

will come to indicate that machine is automatically filling with water. Proper water level will be

achieved when water touches the bottom of pan strainer.

NOTE: CYCLE SWITCH MUST BE IN THE AUTO POSITION TO FILL MACHINE. MACHINE WILL NOT FILL

IN THE MANUAL POSITION AND WOULD CAUSE PUMP MOTOR TO RUN WITHOUT WATER

WHICH CAN DAMAGE PUMP SEAL.

2. After the wash tank is full of water, the green fill light will go out. Open the door, the amber cycle light

will go out to indicate that the machine is reset for another dishwashing cycle.

3. Placing the Cycle Switch to the center "off" position will allow the door to be opened and closed

without starting an automatic cycle.

4. If door is opened during a dishwashing cycle, machine will stop the cycle until door is closed. When

door is closed, cycle will resume where it was stopped.

TO DRAIN THE MACHINE AT END OF DAY/MEALTIME

5. The dishwasher cycle switch must be in the Auto position in order to drain machine. Machine will not

drain in the Manual mode.

6. Close the door and start a dishwashing cycle without a rack in the machine.

7. Once the cycle has started and the amber cycle light is on, push the Power Switch from the On/Fill

position to the Off/Drain position. The machine will finish the wash cycle and then drain.

MANUAL WASH

8. Place Cycle Switch in the Manual Wash position. In this position, machine will wash indefinitely until

switch in placed in center Off or Auto Cycle position.

8

TROUBLESHOOTING GUIDE

The following Troubleshooting Guide contains a list of possible problems/faults/symptoms which can be

used as a quick-reference to solving problems. Refer to appropriate section identify the equipment

malfunction.

WARNING: INSPECTION, TESTING AND REPAIR OR ELECTRICAL EQUIPMENT SHOULD BE PERFORMED

ONLY BY QUALIFIED SERVICE PERSONNEL. CERTAIN PROCEDURES IN THIS MANUAL REQUIRE ELEC-

TRICAL TESTS OR MEASUREMENTS WHILE POWER IS APPLIED TO THE DISHWASHER. EXERCISE

EXTREME CAUTION AT ALL TIMES. IF TEST POINTS ARE NOT EASILY ACCESSIBLE. DISCONNECT POWER

AND ATTACH TEST EQUIPMENT AND REAPPLY POWER TO TEST. DISCONNECT THE ELECTRICAL POWER

TO THE DISHWASHER AT THE MAIN CIRCUIT BREAKER BOX WHEN SERVICING. PLACE A TAG ON THE

CIRCUIT BOX INDICATING THE CIRCUIT IS BEING REPAIRED.

ITEM

PROBLEM

1. NOTHING ON MACHINE OPERATES (POWER SWITCH ON)

2. WILL NOT FILL AUTOMATICALLY (POWER SWITCH ON)

3. MACHINE WILL NOT RUN IN AUTO (POWER SWITCH ON)

4. MACHINE RUNS IN AUTOMATIC BUT MANUAL FUNCTION DOES NOT WORK

5. WASH TEMPERATURE LOWER THAN REQUIRED 150 DEG. F.

6. RINSE TEMPERATURE LOWER THAN REQUIRED 180 DEG. F.

7. FILLS SLOWLY AND/OR RINSE IS WEAK

8. RINSE WATER RUNS CONTINUOUSLY (POWER IS ON)

9. RINSE WATER RUNS CONTINUOUSLY (POWER IS OFF)

10. WASH TANK WATER LEVEL IS LOW

11. WASH TANK WATER LEVEL IS HIGH

12. DISHES ARE NOT COMING CLEAN

13. GLASSES AND SILVERWARE ARE SPOTTING

14. DOOR DROPS HARD AND WON'T STAY CLOSED

15. DOOR DOESN'T ACTIVATE CYCLE

16. WASH PUMP LEAKS

17. WON'T RINSE DURING CYCLE

18. VERY HIGH RINSE TEMPERATURE

19. VERY HIGH WASH TEMPERATURE

20. VACUUM BREAKER LEAKS

21. WATER FLOODING FROM DISHWASHER

22. WATER COMING OUT FROM BOTTOM OR SIDES OF DOOR WHEN CLOSED

9

TROUBLESHOOTING GUIDE continued

ITEM PROBLEM

1. NOTHING ON MACHINE OPERATES "POWER SWITCH ON - POWER LIGHT OFF"

1. Dishwasher circuit breaker turned off.

2. Defective circuit breaker - have electrician test.

3. Circuit breaker tripped - overload in circuit. a. Have electrician check amperage on

circuit.

2. WILL NOT FILL AUTOMATICALLY "POWER SWITCH ON - POWER LIGHT ON- RINSE/FILL

LIGHT OFF"

1. Close door completely and try again.

2. Faulty On/Fill - Off/Drain Switch.

3. Faulty Timer Cam Switch C-5.

4. Faulty Timer Cam Switch C-2.

5. Faulty Timer Motor.

6. Loose terminal connection or broken wire in circuit.

3. WILL NOT FILL AUTOMATICALLY "POWER SWITCH ON - POWER LIGHT ON -RINSE/FILL

LIGHT ON"

1. Low water supply pressure (requires 15-25 PSI flow) to machine

2. Faulty rinse/fill solenoid.

4. MACHINE WILL NOT RUN WASH/DRAIN/RINSE CYCLE IN AUTO CYCLE MODE BUT WILL

RUN WASH CYCLE IN MANUAL CYCLE - POWER SWITCH "ON" - POWER LIGHT "ON" -

CYCLE LIGHT-ON" IN AUTO

1. Faulty timer motor or bad connection.

2. Faulty timer motor cam switches C-3, C-4, C-5.

5. MACHINE WILL NOT RUN WASH/DRAIN/RINSE CYCLE IN AUTO CYCLE MODE BUT WILL

RUN WASH CYCLE IN MANUAL CYCLE - POWER SWITCH "ON" - POWER LIGHT "ON" -

CYCLE LIGHT "OFF" IN AUTO

1. Faulty timer motor or bad connection.

2. Faulty auto/manual switch.

3. Faulty timer cam switch C-3.

4. Faulty power switch S-1.

5. Faulty timer cam C-1.

6. Open circuit between door switch S-2 normally closed (N.C.) contacts

(Black/White wire) output and timer cam switch C-1 normally closed

(N.C.) contacts.

6. MACHINE RUNS DISHWASHING CYCLE IN AUTOMATIC BUT MANUAL WASH FUNCTION

DOES NOT WORK - POWER SWITCH "ON" - POWER LIGHT "ON" - CYCLE SWITCH IN

"MANUAL WASH".

1. Faulty cycle switch.

10

TROUBLESHOOTING GUIDE continued

ITEM PROBLEM

7. WASH TEMPERATURE LOWER THAN REQUIRED 150 DEG. F.

1. Faulty temperature gauge.

2. Rinse temperature below 180 cleg. F. minimum.

See RINSE TEMPERATURE LOWER THAN REQUIRED 180 DEG. F.

8. RINSE TEMPERATURE LOWER THAN REQUIRED 180 DEG. F.

1. Faulty temperature gauge.

2. Faulty rinse booster tank thermostat or adjustment.

3. Incoming water supply pressure not 15-25 PSI flow pressure.

4. Incoming water supply temperature below 140 deg. F. min.

5. Faulty power switch.

6. Faulty rinse booster tank heater element.

7. Rinse booster tank heater element scaled by hard water.

8. Faulty rinse booster heater contactor.

9. FILLS SLOWLY AND/OR RINSE IS WEAK

1. Low water pressure to dishwasher.

2. Rinse spray arms clogged or limed up.

10. RINSE WATER RUNS CONSTANTLY - "POWER IS ON" - "RINSE/FILL LIGHT ON" - RINSE STOPS

& LIGHT GOES OUT WHEN POWER IS TURNED OFF

1. Faulty timer switch cam C-5.

11. RINSE WATER RUNS CONSTANTLY - "POWER IS OFF" - "RINSE FILL LIGHT OFF

1. Check for excessive pressure to machine. Operating pressure is 15 -

25 PSI flow pressure.

2. Faulty rinse/fill solenoid.

12. WASH TANK WATER LEVEL IS LOW

1. Check for proper flow pressure to machine.

2 Check for minimum 1/2 pipe water supply line.

3. Check for clogged rinse spray arms.

4 Faulty timer cam switch C-5 for rinse/fill. Cycle not long enough

5. Faulty timer cam switch C-4 for draining. Cycle too long- may need calibration.

6. Leaking drain valve seal - see service procedures for replacement.

13. WASH TANK WATER LEVEL IS HIGH

1. Check for proper flow pressure to machine.

2. Faulty timer cam switch C-5 for rinse/fill. Cycle too long - may need calibration.

3. Faulty timer cam switch C-4 for draining. Cycle not long enough - may need calibration.

4. Faulty drain valve.

11

TROUBLESHOOTING GUIDE continued

ITEM PROBLEM

14. DISHES ARE NOT COMING CLEAN

1. Check water flow pressure to dishwasher.

2. Wash/rinse arms not rotating properly/clogged.

3 No detergent or improper concentration.

4. Dishwashing cycle times, wash, drain and rinse not correct.

5. Not pre-rinsing and pre-scrapping ware.

6. Wash and rinse water temperatures not correct.

7. Leaking drain valve seal.

15. GLASSES AND SILVERWARE ARE SPOTTING

1. Hard water condition.

2. Not using wetting agent.

3. Check water flow pressure to dishwasher.

4. Rinse spray arms not rotating properly/clogged.

5. Detergent concentration very high.

16. DOOR DROPS HARD AND WON'T STAY CLOSED

1. Broken door spring.

2. Bent hinges.

17. DOOR DOESN'T ACTIVATE CYCLE

1. Door switch needs and adjustment.

2. Defective door switch.

3. Timer not reset.

4. Faulty timer motor.

5. Faulty Cycle switch.

6. Faulty time cam switch C-1.

18. WASH PUMP LEAKS

1. Petcock valve open on pump.

2. Pump shaft seal defective.

3. Defective hose.

4. Defective pump gasket.

19. WONT RINSE DURING CYCLE

1. Power Switch depressed to Off/Drain position

2. Water supply turned off.

3. Defective timer cam switch C-5.

4. Defective fill solenoid.

12

TROUBLESHOOTING GUIDE continued

ITEM PROBLEM

20. VERY HIGH WASH OR RINSE TEMPERATURE

1. Faulty thermostat.

2. Rinse heater relay contacts sticking.

21. VACUUM BREAKER LEAKS

1. Very low water supply pressure.

2. Rinse arms clogged.

3. Vacuum breaker internal parts defective.

22. WATER FLOODING FROM DISHWASHER

1. Blocked drain line.

2. Defective drain valve.

3. High water supply pressure.

4. Defective water solenoid.

5. Faulty timer cam C-4.

13

SERVICE PROCEDURES

WARNING: INSPECTION, TESTING AND REPAIR OF ELECTRICAL EQUIPMENT SHOULD BE PERFORMED

ONLY BY QUALIFIED SERVICE PERSONNEL. CERTAIN PROCEDURES IN THIS MANUAL REQUIRE

ELECTRICAL TESTS OR MEASUREMENTS WHILE POWER IS APPLIED TO THE DISHWASHER. EXERCISE

EXTREME CAUTION AT ALL TIMES. IF TEST POINTS ARE NOT EASILY ACCESSIBLE, DISCONNECT POWER

AND ATTACH TEST EQUIPMENT AND REAPPLY POWER TO TEST. DISCONNECT THE ELECTRICAL POWER

TO THE DISHWASHER AT THE MAIN CIRCUIT BREAKER BOX WHEN SERVICING. PLACE A TAG ON THE

CIRCUIT BOX INDICATING THE CIRCUIT IS BEING REPAIRED.

The following is a list of service procedures included in this manual:

1. To replace Drain Valve assembly, Valve Motor

Valve Seal, Hoses and to check for leaking drain valve

Page 15

2. To replace rinse/fill solenoid valve coil or internal parts Page 17

3. To replace Pump Motor Assy., Pump Seal, Capacitor, Impeller Page 18

4. Timer adjustment, replacing; Timer, Cam Switch, Motor Page 20

5. To replace Door Switch, adjustment/check Page 23

6. To replace or check Power & Off Drain Switch Page 24

7. To replace or check Cycle Switch Page 25

8. To replace or test Booster Tank Heater Page 25

9. To replace or adjust Booster Heater Thermostat Page 25

10. To replace Booster Tank - Model JP-24B/BF Page 27

11. To install Vacuum Breaker repair kit Page 29

12. To replace the Wash or Rinse temperature gauges Page 30

13. To replace Rinse Spray Arm feed pipe or internal parts Page 32

14. To replace Wash Spray Arm internal parts Page 32

15. To adjust Rack Slides or replace broken mounting stud Page 33

16. To check Water Supply Pressure to Dishwasher Page 33

17. To check Water Supply Temperature Page 34

18 To clean Water Line Strainer Page 34

19. To replace the Door Springs Page 34

20. To replace Door Latch Assembly Page 35

14

SERVICE PROCEDURES continued

1. To replace Drain Valve, Valve Seal, Hoses.

The motor operated drain valve is electrically operated by the timer during the drain cycle. It is also activated

when the machine is placed in the off-drain position. The motor operated drain valve diverts the main pump

water flow through valve and out drain hose to kitchen's waste system. It is a spring-loaded normally closed

valve. There are two valves available, 240V and 110V, (JP-24LT/LTF) each have identical parts except

motor. See illustrated parts list for correct valve. —

A. To remove the drain valve or drain valve hoses for servicing:

(1) Turn off the water supply to the dishwasher.

(2) Move machine away from wall for servicing.

(3) Remove lower enclosure panel at rear of machine.

(4) Drain the dishwasher. Siphon out water or remove inlet hose to drain valve and drain into pan.

Machine may be drained by opening petcock on pump housing or by removing wash thermometer

bulb from lower wash tank fitting.

B. To replace feed hose to drain valve from pump.

(5) Loosen hose clamps and remove inlet hose. Reverse procedures to install new hose.

15

SERVICE PROCEDURES continued

C. To replace drain valve.

(6) Disconnect the lead wires and ground to drain valve. Remove discharge hose from valve.

(7) Remove drain valve from mounting place.

(8) Reverse procedures to install new valve. INSURE GROUND WIRE LEAD IS CONNECTED

PROPERLY TO TERMINAL ON MOTOR.

D. To check for leaking drain valve.

(1) Open door and verify water level in wash tank is up to basket strainer screen.

(2) Close door and start dishwashing cycle.

(3) Wait (30) seconds and open door (slowly).

(4) Check water level in wash tank if it is lower than before - the drain valve seal is leaking. See

service procedures to replace valve seal.

E. To replace drain valve seal.

(1) Follow procedures (1-8) above except don't remove inlet or discharge hoses.

(2) Remove cover plate from end of valve which is secured by (4) screws. Be careful not to damage

gasket.

(3) Remove stainless steel hinge with seal attached. See Illustrated Replacement Parts for exploded

view of parts.

(4) Install replacement hinge with seal and reassemble valve in reverse order.

F. To replace drain valve motor.

(1) Follow procedures (1-8) above.

(2) Remove motor from drain valve assembly which is secured by (4) screws. Note: Make note of

orientation of coil spring for proper reassembling of valve. See illustrated parts for exploded

view.

(3) Install replacement motor and reassemble valve in reverse order.

(4) Reinstall drain valve to machine in reverse order of above.

16

SERVICE PROCEDURES continued

2. To replace rinse/fill solenoid valve coil or internal parts.

The rinse/fill solenoid valve is electrically operated by the cam timer at the initial fill (at start of day/meal)

and then during the rinse cycle. Most problems are coil failures or water deposit buildup on diaphragm. See

illustrated parts list for repair parts.

A. To replace solenoid valve coil.

(1) Disconnect power to machine.

(2) Disconnect wire leads to coil.

(3) Remove screw holding coil in place and

remove coil.

(4) Install new coil in reverse order.

B. To replace Solenoid Valve internal parts.

(1) Shut off water supply to machine.

(2) Take valve apart as shown by unscrewing

the bonnet from valve body. Carefully lift off

the bonnet. The "o" ring seal and

diaphragm can now be lifted out. Don't drop

the plunger.

(3) Most problems are with a clogged

diaphragm pilot port. Clear pilot port in

diaphragm.

(4) To reassemble valve place the diaphragm

cartridge in the body with the pilot port

extension UP.

Hold the plunger with the synthetic seat

against the pilot port. Make sure the "o" ring

is in place, then lower the bonnet and

enclosing assembly over the plunger. Screw

the bonnet assembly firmly down on the

body.

(5) Turn on water supply to machine.

17

SERVICE PROCEDURES continued

3. To replace the pump motor assembly, pump seal, capacitor or impeller

Capacitor Start, Built-in Overload Protection. Marathon Jet Pump Assembly, 3450 RPM, 3/4 HP, 60 HZ, 1 PH,

115V/230V, FLA 8.8/4.4 AMPS, SPA 10.6/5.3 AMPS, ROTATION - CLOCKWISE. Mechanical Shaft Seal -

Standard Self-adjusting Shaft Seal (EPT Mechanical Seal) White Ceramic Seat and Carbon Seal Face.

Permanently Lubricated Ball Bearings. Direction o rotation should match the molded arrow on the pump

housing.

Motor has a capacitor start circuit controlled by a centrifugal switch. Once the start windings in the motor

have rotated the rotor to the proper running speed/rpm, the centrifugal switch opens and drops out the

capacitor. The main windings will then keep the motor running at run rpm.

Most problems can be found in either the capacitor or centrifugal switch.

A. To check the capacitor with an ohmmeter or substitute with good capacitor. WARNING:

Discharge capacitor before testing with ohmmeter.

Steps:

(1) Disconnect power to dishwasher and unplug wire leads from capacitor. Use appropriate range

on ohmmeter.

(2) If the capacitor is good, the meter should go to the right and then decrease slowly.

(3) If the capacitor is shorted, the meter should go to the right and stay there.

(4) If the capacitor is open, the meter should not read anything.

B. To replace the pump motor assembly.

/