Page is loading ...

This manual must be available to the operator at all times. FTC-IOMM-2015-2

INSTALLATION, OPERATION AND MAINTENANCE MANUAL

FT-C

Fuel Fired Thermal Fluid Heater

FTC-IOMM-2015-2

Fulton Ltd

Page II

TABLE OF CONTENTS

SECTION 1 - INTRODUCTION

1.1 General 1

1.2 Technical Data 1

SECTION 2 - INSTALLATION

2.1 General 3

2.2 Transport 3

2.3 Siting 4

2.4 Gas Supply 5

2.5 Oil Supply 7

2.6 Minimum Clearance For Coil Removal 8

2.7 System Connections 8

2.7.1 Drain/Fill Connection 8

2.7.2 Heater Connections 8

2.7.3 Electrical Connections 9

2.7.3.1 Voltage and Frequency 9

2.8 Pipework Systems 9

2.9 Combination Expansion/Deaerator/Thermal Buffer Tank 10

2.9.1 Expansion Section 10

2.9.2 Deaerator Section 10

2.9.3 Thermal Buffer Section 10

2.9.4 Sizing the Tank for the System 11

2.9.5 Location 11

2.9.6 Pressurised Systems 12

2.9.7 Connections 13

2.10 Oil and Gas Circulating Pump 14

2.10.1 Location 14

2.10.2 Connections and Piping 14

2.10.3 Alignment 15

2.10.4 Lubrication 15

2.10.5 Seals 15

2.10.6 Air Cooling 15

2.10.7 Water Cooling 16

2.11 Catch Tank 16

2.12 Gauges 17

2.13 Valves 17

2.14 Piping 18

2.15 Gasket Installation Instructions 20

2.16 Testing 21

2.17 Insulation 21

2.18 Thermal Fluids 22

2.18.1 Thermal Fluids at Elevated Temperatures 22

2.18.2 Selecting a Thermal Fluid 22

2.18.3 Routine Analysis of Heat Transfer Fluid 24

2.18.4 Thermal Fluid Breakdown 24

2.19 Multi-Skid System 25

SECTION 3 - OPERATION

3.1 General 27

3.2 Start-Up Preparation and Installation Review 27

3.3 Filling the System 28

3.3.1 Filling Procedure 29

3.4 For Systems Equipped With Inert Blanket 30

3.5 Circulating Pump 30

3.5.1 Mechanical/Air Cooled Seal 31

3.6 Initial Start-up 32

3.6.1 Start-up Service 32

3.6.2 Cold Circulation 32

3.6.3 Filtering the System 33

3.6.4 System Boil-out 34

3.6.5 Procedure for First Shutdown 35

3.6.6 Sequence of Operation 36

3.6.7 Dual Fuel Burner - Changing Fuel 39

3.6.8 Gas Fired Modulating Burner 40

3.6.9 Setting Main Burner Ignition 41

3.6.10 Setting Main Run Ignition 42

3.6.11 Setting Low Fire 42

3.6.12 Setting the Complete Range 43

3.6.13 Changing Set Point on the AZL 44

3.6.14 For Manual Operation 44

3.7 Required Pressure Drop Across The Heater 44

3.8 Required Flow Through the Heater 44

3.9 Operating Control 45

3.9.1 Liquid Level Switch-When Combination Tank is Supplied 46

3.9.2 Air Safety Switch 46

3.9.3 Blower Motor Starter 47

3.9.4 Differential Pressure Switch 47

3.9.5 Pump Motor Starter 47

3.9.6 High and Low Fluid Pressure Switches 48

3.9.7 Gas Pressure Switch 48

3.9.8 Operating Temperature Control 49

3.9.9 High Limit Temperature Control 50

3.9.10 Pressure Gauges 50

3.9.11 Operating Limit Controller 50

3.9.12 On/Off Controls 51

3.9.13 Flow Proving Device 51

3.9.14 Test of Ignition Safety System Shut-off 51

3.9.15 Cycle Testing 51

3.10 Daily Start-up 52

3.11 Daily Shutdown 52

FTC-IOMM-2015-2

Fulton Ltd

Page III

TABLE OF CONTENTS

SECTION 4 - MAINTENANCE

4.1 Required Maintenance at First Shutdown 53

4.2 Maintenance Procedures 53

4.2.1 Lubrication 53

4.2.2 Soot Cleaning 54

4.3 Schedule of Operator Test and Checks 54

4.3.1 Daily 54

4.3.2 Weekly-in addition 55

4.3.3 Monthly-in addition 55

4.3.4 Six Monthly-in addition 56

4.3.5 Annually-in addition 56

4.4 Safety Check Procedures 56

4.4.1 Temperature Limit(s) 56

4.4.2 Air Switch 57

4.4.2.1 Air Filter Box Switch 57

4.4.3 Liquid Level Switch 57

4.4.4 Differential Pressure Switch 57

4.4.5 Low Inlet Pressure Switch 57

4.4.6 High Outlet Pressure Switch 57

4.4.7 High/Low Gas Pressure Switch 58

4.5 Troubleshooting: 59

4.5.1 Troubleshooting-Flow Circuit/Circulating Pump(s) 59

4.5.2 Troubleshooting-Tripped High Outlet Pressure Switch 62

4.5.3 Troubleshooting-Differential Pressure Switch Break 63

4.5.4 Troubleshooting-Call for Heat 64

4.5.5 Troubleshooting-Safety Interlock 65

4.13 Maintenance Log 66

APPENDIX A - TI SHEETS

FTC-IOMM-2015-2

Fulton Ltd

Page IV

WARNINGS

Prior to shipment, the following tests are made to assure

the customer the highest standards of manufacturing:

a) Material inspections

b) Manufacturing process inspections

c) ASME welding inspection

d) ASME hydrostatic test inspection

e) Electrical components inspection

f) Operating test

g) Final engineering inspection

h) Crating inspection

Rigging your heater into position should be handled

by a competent rigger experienced in handling heavy

equipment.

The customer should examine the heater for any

damage, especially the refractories.

It is the responsibility of the installer to ensure

all parts supplied with the heater are tted in a

correct and safe manner.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do not use any

phone in your building.

• Immediately call your gas supplier from a

neighbour's phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the re

department.

For your safety!

The following WARNINGS, CAUTIONS and NOTES appear in various sections of this manual.

• WARNINGS must be observed to prevent serious

injury or death to personnel.

• CAUTIONS must be observed to prevent damage

or destruction of equipment or loss of operating

effectiveness.

• Notes: must be observed for essential and

effective operating procedures, conditions and as

a statement to be highlighted.

It is the responsibility and duty of all personnel involved

in the operation and maintenance of this equipment

to fully understand the WARNINGS, CAUTIONS and

NOTES by which hazards are to be eliminated or

reduced.

Personnel must become familiar with all aspects

of safety and equipment prior to operation or

maintenance of the equipment.

CAUTION

In case of emergency

This heater has been designed and constructed to meet all of the essential requirements of the applicable

European Directives and subject to proper maintenance should not give occasion to any hazardous conditions.

If such a condition should occur during commissioning or during subsequent operation of this product,

whatever the cause, then the fuel supply to the boiler should be isolated immediately, until the fault has been

investigated by a competent person and rectied.

!

WARNING

Thermal Fluid Heaters are a potential hazard, possibly fatal if not properly maintained.

CAUTION

It is vitally important that the instructions given in this manual are strictly adhered to. Failure to carry

out the routine maintenance checks could result in a drastic reduction in the life expectancy of the

system and increase the possibility of re, explosion, property damage, personal injury or loss of life.

!

!

FTC-IOMM-2015-2

Fulton Ltd

Page V

WARNINGS

SAFETY

The instructions provided for the operation and maintenance

of the heater MUST be observed. Failure to do so could

result in damage to the heater and serious personal injury.

WARNING

Do not try to do repairs or any other maintenance work

you do not understand. Obtain a service manual from

Fulton Ltd or call a Fulton service engineer.

It is the responsibility of the installer to ensure all parts

supplied with the boiler are tted in a correct and safe

manner.

Understand the electrical circuit before connecting

or disconnecting an electrical component. A wrong

connection can cause injury and or damage.

A defective heater can injure you or others. Do not

operate

a heater which is defective or has missing parts. Make

sure that all maintenance procedures are completed

before using the heater.

LIFTING EQUIPMENT

Make sure that lifting equipment complies with all local

regulations and is suitable for the job. You can be injured

if you use faulty lifting equipment. Make sure the lifting

equipment is in good condition.

Operating the heater beyond its design limits can

damage the heater, it can also be dangerous.

Do not operate the boiler outside its limits.

Do not try to upgrade the heater performance by

unapproved modications.

Non-approved modications can cause injury and

damage. Contact your Fulton dealer before modifying

the boiler.

Only qualied persons should be allowed to operate and

maintain the heater and its equipment.

DANGER FROM HOT SURFACES

Thermal Fluid Heaters have high temperature surfaces,

that if touched may cause serious burns. Only competent

and qualied personnel should work on or in the locality

of a thermal uid heater and ancillary equipment. Always

ensure the working area and oor are clear of potential

hazards, work slowly and methodically.

Do not store or use gasoline or other ammable vapours

and liquids in the vicinity of this or any other appliances.

Note: Max. room temperature not to exceed 38 °C.

Note: In no case should any part of the drive side of the

pump be insulated.

Note: Max. operating temperature for air cooled pumps

varies by manufacturer. Consult instruction manual to

verify.

Note: If the tank is located outdoors nitrogen is required.

High temperature thermal uid, steam and combustible

vapours may be vented through the DA vent connection.

!

CAUTION

Obey all laws and local regulations which affect you and

your heater.

During operation, any leaks are usually detected by a

small amount of vapour. Leaks should be attended to as

soon as possible because under certain circumstances,

such as saturated insulation, thermal uid can ignite

when exposed to air and heat.

Note: Fulton Ltd cannot be held responsible in the

case of accident or damage resulting from the use of

inadequate uid.

Note: Unless specially ltered, compressed air will

introduce moisture into the system. Dry air or Nitrogen is

recommended.

Note: Some plastics can be dissolved by thermal uid.

Note: Do not use system circulating pump for system

lling. A pump that has been used for water or for

a different thermal uid should not be used prior to

extensive cleaning. Thermal uid can be damaged by

contact with moisture or other uids.

Use extreme caution opening plug when system

temperature is elevated.

Wear eye and hand protection.

Back the plug out slowly to the last two or three threads.

Allow any pressure under the plug to bleed slowly to

prevent a spray of hot oil.

Note: Flash steam may be generated at any point up to

the operating temperature. Watch for gauge uctuations.

Note: All of the above maintenance procedures should

be completed by trained personnel. Appropriate training

and instructions are available from the Fulton Service

Department.

!

WARNING

Once the system has been lled, any modication to the

tank or connected piping requires purging of the work

area to prevent ignition of potentially ammable vapours.

Consult factory prior to beginning work. Consult the

MSDS (material data safety sheet) for your thermal uid

for ammability limits.

Note: Unless the system is pressurised, the inlet to

the deaerator section of the combination tank must be

higher than or equal to the highest point in the system

to prevent pockets of air from collecting in the system

piping.

Pressurising a drum to force uid into the system is not

recommended. The drum can easily explode, creating a

hazard to personnel and equipment.

Note: Tanks are non-code as a standard. Non-code

tanks cannot be pressurised over 0.5 barg. Tanks built to

BS EN13445:2009 are available upon request.

Note: Do not run the pump before lling it with uid.

!

FTC-IOMM-2015-2

Fulton Ltd

Page VI

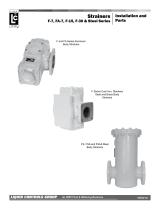

Figure. 1 - General Arrangement: Skid Mounted FT-C Thermal Fluids System

FT-C vertical

thermal uid

heater

Electrical panel

box containing all

operating safety

controls

FT-L combination

expansion/

dearaetor/thermal

buffer tank

Thermal uid

circulating pump

FTC-IOMM-2015-2

Fulton Ltd

Page 1

INTRODUCTION - 1

SECTION 1 - INTRODUCTION

1.1 GENERAL

The Fulton FT-C is a vertical thermal uid heater with a range of 11 models. The Fulton FT-C

Thermal Fluid Heater offers a compact fuel red 4-pass heater design capable of operating

temperatures up to 345 °C.

The heater is of a vertical, helical coil self venting design, and the pressure vessel coil

construction is carbon steel ASME SA106B, Schedule 40 or equal. The design pressure is 13.8

barg standard at 370 °C. The heater will be per ASME Code Section I stamped at 10.34 barg

maximum working pressure, trimmed at 6.9 barg unless otherwise specied. Test pressure will

be per ASME Code Section I. Minimal refractory lining will be supplied in the heater combustion

chamber to avoid thermal inertia and overheating of the thermal uid should a pump or power

failure occur.

The shell, coil and burner are encased in a pre-heater jacket. This jacket is a welded steel

construction with an integral oor plate and bolted top cover to facilitate coil removal, access

panels for air chamber inspection and has an aluminium inner air bafe. This pre-heater removes

the need for insulation of the heater and simultaneously boosts thermal efciency by preheating

incoming combustion air.

1.2 TECHNICAL DATA

For a full specication refer to Appendix A - TI-123-FT-C Dimensions & Specication.

FTC-IOMM-2015-2

Fulton Ltd

Page 2

Figure. 2 - FT-C Component View

Note: Thermal uid heater is of four-pass combustion design.

• First pass (radiant): combustion air enters burner fan and travels upward between inner and outer jacket

before it enters top-mounted burner.

• Second pass (convection): Gases travel back across the inner row of coils.

• Third pass (convection): Gases continue back down between inner and outer coil.

• Fourth pass: Upward between the outer coil and inner jacket to the ue outlet.

A - Fluid Outlet

B - Top Mounted Burner

C - Fluid Inlet

D - Control Panel

E - Fan Inlet

FTC-IOMM-2015-2

Fulton Ltd

Page 3

INSTALLATION - 2

2.1 GENERAL

The installation of a FT-C thermal uid heater should be carried out by competent personnel in

accordance with all relevant safety regulations. It is the responsibility of the installer to ensure that

these regulations are complied with.

a) All components exposed to thermal uid ow including pipe, valves, and screens must not

be made out of copper, copper alloys, aluminium, or cast iron. Cast iron is porous to thermal

uids, and copper and aluminium act as catalysts in the degradation of some thermal uids.

Carbon or stainless steel, or ductile iron are recommended.

b) For standard applications, all components must be rated to 350 °C unless otherwise specied.

c) All pipework, valves and user equipment must be suited to the maximum operating pressure

of the heater. The maximum pressure stamped on the heater nameplate is typically 10.34 barg

(150 psig).

d) If an isolating valve is completely closed, the pressure in the system will rise to the deadhead

pressure of the pump. Suitably sized pipe will enable the system to withstand the total head

generated by the circulating pump, should this occur. In applications where it is desirable

to design to pressures lower than 6.9 barg (100 psig), an alternative safeguard is to install

appropriately sized safety valves.

e) Where secondary circulating pumps are installed, the system must be suitable for the

aggregate head, against a closed valve, of both pumps.

f) During construction of the installation, ensure that no dirt, water, or residue from welding is left

in the system.

2.2 TRANSPORT

All Fulton Coil Design Heaters are shipped vertically and all units are crated for forklift transport.

Once unpacked, all units with the exception of free-standing Models FT-0080-C, FT-0120-C,

FT-0160-C, and FT-0240-C can be transported with a forklift.

These four models can only be lifted for unloading and moving by means of lifting lugs at the

top of the heaters. If means of lifting are not available then rollers should be placed beneath the

frame of the heater and it should be guided to the position of where it is to be installed. Under no

circumstances should weight be allowed to bear on the jacket, control panel or fan housing of any

Fulton Thermal Fluid Heater.

All stand alone heaters can be moved via a crane utilizing lifting lugs on top of the heater. The

FT-0320-C and larger stand alone heaters can also be moved using a fork lift. All skidded units

can be moved with forklifts.

SECTION 2 - INSTALLATION

FTC-IOMM-2015-2

Fulton Ltd

Page 4

INSTALLATION - 2

2.3 SITING

Reference should be made to Appendix A - TI-123-FT-C Dimensions & Specication to

ascertain the relevant dimensions and weights.

a) Authorities with jurisdiction over any national or local codes which might be applicable to

thermal uid applications should be consulted before installations are made.

b) The heater should be located as close as possible to the place where the heat will be used in

order to keep pipework costs to a minimum.

c) A level, hard, non-combustible surface is required as a suitable base for mounting the unit. It is

suggested that a 100 mm curb be installed completely around the unit. In the event of a large

spill, this will help contain the uid.

d) Approximations for the oor loading of each heater can be calculated using the weights given

in Appendix A - TI-123-FT-C Dimensions & Specication. Check building specications for

permissible oor loading.

e) The heater should be placed in a suitable heater house or well ventilated separate room

through which personnel do not normally pass. This is not essential, but the layout should

eliminate trafc in potentially hazardous areas. For instance, the service engineer or the

operator should not have to pass exposed and hot pipework to make adjustments to the

heater controls.

f) Ventilation must be sufcient to maintain a building temperature of 38 °C or less and the panel

box temperature must not exceed 52 °C. Natural ventilation should be provided by means of

grilles at oor and ceiling level.

g) To burn fuel properly, the burner must have an adequate supply of air.

See Technical Information sheet for the heater for minimum make up air required and the

recommended area of opening for each heater.

If positive forced ventilation is adopted, you must ensure that there will be no appreciable

pressure variation in the heater room.

FTC-IOMM-2015-2

Fulton Ltd

Page 5

INSTALLATION - 2

Adhere to the following for gas supply installation:

1. Install gas piping in accordance with all applicable codes.

2. Ensure pipe and ttings used are new and free of dirt or other deposits.

3. Ensure piping is of the proper size for adequate gas supply to the gas head assembly. Consult

your gas company for specic recommendations.

4. When making gas piping joints, use a sealing compound resistant to the action of liqueed

petroleum gases. Do not use Teon tape on gas line heads.

5. Ensure no piping stresses are transmitted to the equipment. The equipment shall not be used

as a pipe anchor.

6. Ensure all vent connections on diaphragms, gas valves, pressure regulators, and pressure

switches (gas-red units) are vented per local code.

7. During any pressure testing of the system at pressures in excess of 34 mbar (0.5psi),

disconnect the heater at the heater manual shut-off valve (located at the end of the supplied

gas train) from the gas supply piping system.

8. Ensure the supply pressure is regulated by a non-stacking, tight, shut-off regulator.

9. Arrange gas piping so that it does not interfere with any cover or burner, inhibit service or

maintenance, or prevent access between unit and walls or another unit. The burner assembly

and gas controls terminate at a manual stop valve to which the gas supply should be

connected. Piping must be sized for a gas ow consistent with the required kW input. Large

pressure drops must be avoided. Fulton recommends that the supply piping between the

pressure regulator and the inlet to the heater be kept to a minimum. The minimum required

gas pressure at the stop valve varies with the model of heater. The requirements for natural

gas-red coil design models are as follows:

• Models FT-0080-C to FT-0400-C 34 mbar (0.5 psi)

• Models FT-0600-C to FT-0800-C 149 mbar (2.2psi)

• Models FT-1000-C to FT-1400-C 299 mbar (4.3psi)

Note: Low emissions burners for all models require 345 mbar (5psi).

Note: Even when the unit is shut down, the gas supply pressure must never exceed these values.

Note: When operating, the supply pressure must not drop below these limits: Not less than 27 mbar where 34

mbar is required. Not less than 125 mbar where 149 mbar is required. Not less than 249 mbar where 299 mbar is

required.

10. After gas piping is completed and before wiring installation is started, carefully check all piping

connections (factory and eld) for gas leaks. Use a soap and water solution.

2.4 GAS SUPPLY

FTC-IOMM-2015-2

Fulton Ltd

Page 6

INSTALLATION - 2

Main gas valve

assembly

Main gas line

isolating valve

Pilot line

ball valve Pilot line

governor Pilot line

gas valves

Gas valve

Gas

governor

Gas

actuator

Figure. 3 - Gas Valve (non modulating burner)

Figure. 4 - Gas Valve (fully modulating burner)

FTC-IOMM-2015-2

Fulton Ltd

Page 7

INSTALLATION - 2

2.5 OIL SUPPLY

Burner is suitable for Class D fuel oil. If required to run on kerosene contact Fulton for

replacement components and commissioning

Adhere to the following for installation:

1. Fuel pipes must be of approved materials and of a diameter suitable for the quantity of oil

being delivered to the burner and the static head available.

Make fuel connection in accordance with the details on the enclosed fuel pump cut sheet.

2. Ensure fuel oil piping is in accordance with local/national requirements.

In addition, if a two pipe system is employed, a check valve must be tted into the return pipe.

Figure. 5 - Typical No.2 Oil Fired Fuel Train

FTC-IOMM-2015-2

Fulton Ltd

Page 8

INSTALLATION - 2

2.6 MINIMUM CLEARANCE FOR COIL REMOVAL

a) All heaters will also require a minimum clearance overhead for coil removal. In cases where

the available height is insufcient, a roof or ceiling trap might be considered.

b) Pipes should not be run within 250 mm of any control cabinets or combustible material.

c) Failure to provide suitable and safe access at the time of commissioning may cause delays, as

our service engineers are instructed not to commence commissioning if hazardous conditions

exist.

For more information see Appendix A - TI-123-FT-C Dimensions & Specication.

2.7 SYSTEM CONNECTIONS

If screwed connections have to be made, e.g. to items of control equipment, then a thread sealant

suitable for use with uids at elevated temperature must be used. Teon tape, standard pipe dope

or hemp and paste are not acceptable. Screw threads must be carefully and accurately cut. If

possible new tools should be used. Threaded connections larger than DN25 are not to be used. It

is recommended that class 8.8 or better tensile steel bolts be used for all anged joints.

2.7.1 DRAIN/FILL CONNECTION

The system is usually lled from the

lowest point, with the aid of a pump.

On skid mounted systems a drain and

ll connection is provided in the inlet

piping to the pump.

Note: The system pump is not to be used to ll the

system.

2.7.2 HEATER CONNECTIONS

a) The outlet of the pump should connect directly to the inlet of the heater via an isolating valve

and pump exible connector.

b) The heater outlet should be piped directly to the system, via an isolating valve.

c) A safety relief valve may be shipped in the parts box accompanying the electric heater, and

must be installed in the outlet manifold. On all units, the outlet of the safety relief valve must

be piped to a catch tank. The discharge ow must not be restricted, i.e. no valve should

be installed, there should be no reduction in pipe size, and the minimum number of bends

possible. The weight of the piping must be properly supported in order to prevent damage to

the safety valve. If the valve body becomes warped, leakage may result.

Figure. 6 - Drain and Fill Connection

FTC-IOMM-2015-2

Fulton Ltd

Page 9

INSTALLATION - 2

a) A wall mounted fused disconnect sized for the unit must be provided and tted by the

client/contractor if a disconnect is not supplied on the panel.

b) Fuses must be sized according to motor name plates and local electrical codes.

c) Heaters and single skid systems are shipped completely pre-wired. The liquid level switch on

the expansion tank, when supplied, will be shipped in the parts box and must be installed on

site. Multiple skid systems may require wiring between the skids.

d) If the unit is not skid-mounted at the factory, the client/contractor is required to wire the

circulating pump starter.

e) When using a SCR, a Shunt Trip Breaker is required to be installed by the customer. It will be

used to remove power to the panel in the event of an over temperature/pressure condition.

The Shunt Trip Coil needs to be wired to the boiler electrical panel as indicated on the

electrical drawing.

Note: If the circulating pump motor is not supplied by Fulton Ltd, the motor starter will not be supplied.

2.7.3 ELECTRICAL CONNECTIONS

Normal supply will be 400 volts, 3

phase, 50 Hz, AC unless otherwise

specied.

Make sure the information on the

electrical drawing corresponds to the

voltage and frequency specic to the

heater. Check the supply voltage and

make sure that there is no over or

under voltage exceeding 10% of the

nominal value.

2.7.3.1 VOLTAGE AND FREQUENCY

2.8 PIPEWORK SYSTEMS

Certain properties of thermal uid including low surface tension, make it necessary to pay

particular attention to contain the uid. Good pipework system design, welded construction,

proper anging, gaskets, and other appropriate means of eliminating potential leakage must be

employed.

Figure. 7 - Thermal Fluid Heater Nameplate

FTC-IOMM-2015-2

Fulton Ltd

Page 10

INSTALLATION - 2

2.9 COMBINATION EXPANSION/DEAERATOR/THERMAL BUFFER TANK

Figure. 8 - Combination Expansion/Deaerator/Thermal Buffer Tank

Please see Appendix A - FT-L Dimensions & Specication.

Fulton Ltd's efcient design combines the operation of the expansion, deaerator and thermal

buffer tanks. Installation is simplied by virtue of this arrangement.

The tank will be constructed of carbon steel. It is supplied with expansion section liquid level

switch and PN16 anged connections.

The tank may be built to BS EN 13445: 2009 upon request. Non-coded tanks should not be

pressurised above 0.5 barg.

The expansion section is vital to the thermal uid system. From ambient to operating temperature,

the thermal uid in the system will typically expand in the range of 25%-50%, and a vessel

capable of handling this expansion is mandatory. The customer should conrm the expansion rate

of the chosen uid and system volume.

At start up the primary purpose of the deaerator section is to remove all volatiles from the system

to avoid pump cavitation. The deaerator section also allows oxygen to be vented from the system

on a continuous basis during operation to avoid oxidation of the thermal uid, and removes other

volatile particles generated by the uid itself during system operation. This section of the tank

should be insulated.

2.9.1 EXPANSION SECTION

2.9.2 DEAERATOR SECTION

Expansion

Volume

Vent for piping

to Safe Catchment

Expansion

Tank

Hot Fluid

Medium Fluid

Cool Fluid

Gases (Steam)

Thermal

Buffer Section

Drain

Fluid Out

Liquid

Level

Switch

Fluid In

Dearator

Section

Section

FTC-IOMM-2015-2

Fulton Ltd

Page 11

INSTALLATION - 2

Combination tank capacity is the total volume of the tank. It is necessary to have some air space

available at the top of the tank to avoid spillage or overow. At initial ll (for system volume

calculations) the deaerator and thermal buffer sections must be lled completely and the

expansion section must be lled to a level of 100 mm to “make” the liquid level switch.

The volume between the initial ll level and the safe “full” level is the amount available for

expansion. That volume is used to decide which tank is suitable for the system expansion.

Sizing Example

A system contains 660 litres (including the heater, but not the tank). You select the FT-200-L, so

you add 95 litres to 660. You must look up the expansion rate for the thermal uid (assume it is

25%). 755 litres x 1.25 = 945 litres. 945-755 = 190 litres expansion. The FT-200-L has only 75

litres available for expansion, so the correct selection is the FT-500-L.

2.9.5 LOCATION

a) The combination tank must be installed in accordance with Fulton Ltd’s specications.

b) Unless the system is pressurised, the inlet to the deaerator section must be higher than or

equal to the highest point in the system to prevent pockets of air from collecting in system

piping.

c) The head required at the circulation pump suction inlet must also be taken into account

to avoid the possibility of pump cavitation. In systems operating close to maximum uid

temperature, the tank must be elevated if possible above the highest point in the system to

prevent pump cavitation by increasing the static head. An inert pressurising blanket may be

considered as an alternative. See Section 2.9.6 - Pressurised Systems.

d) Supports for tank mounting should be provided by the client/contractor. These should be

suited for supporting the tank by the side rails. The eyelets tted to the tank are for lifting only.

A system of interconnecting pipework in the thermal buffer tank section prevents the movement

of any oil that has not cooled sufciently into the expansion section. This avoids contact of very

high thermal uid temperature with oxygen contained in the atmosphere, which causes uid

breakdown. DO NOT insulate this section.

2.9.3 THERMAL BUFFER SECTION

2.9.4 SIZING THE TANK FOR THE SYSTEM

FTC-IOMM-2015-2

Fulton Ltd

Page 12

INSTALLATION - 2

Figure. 9 - Liquid Level Switch

Nitrogen pressurisation may be used to advantage where the total system content is very large or

in a system operating near or above the vapour pressure of the uid employed or if the inlet of the

DA tank is not the highest point in the piping system.

In conjunction with this system, an automatic venting device must be tted to the system

expansion tank. Consult Fulton Ltd for further details.

The location for the liquid level switch is a connection on the same end of the tank as the inlet.

The liquid level switch is supplied and shipped with the unit and must be installed by the customer

and then wired to the control panel.

Note: If the tank is located outdoors nitrogen pressurisation is required.

Liquid Level

Switch

2.9.6 PRESSURISED SYSTEMS

FTC-IOMM-2015-2

Fulton Ltd

Page 13

INSTALLATION - 2

2.9.7 CONNECTIONS

a) The vent connection must be made in a manner that will prevent penetration of water or

foreign bodies into the tank. This connection must always terminate in a safe, well ventilated

area and has to be free of obstruction, open to atmosphere and arranged in such a manner

that in the event of discharge from the system, thermal uid could drain into a catch tank

without danger to personnel or property.

Note: Non-code tanks cannot be pressurised over 0.5 barg.

WARNING

High temperature thermal uid, steam and combustible vapours may be vented through this connection.

!

b) The vent run should be the same size as the tank outlet. It should run pitch down from the

outlet of the tank to the catch tank.

c) If nitrogen is used on the system, the vent can be reduced to DN50 and should be piped with a

positive closing valve at the catch tank.

d) The connection between the tank outlet and the horizontal pump inlet run should be as close

to a vertical drop as possible. It should not contain an excessive number of bends of length of

pipe. These faults could encourage pump cavitation.

e) As noted, the inlet to the combination tank must be higher than or equal to the highest point in

the system or a pressurised system must be used.

f) The liquid level switch supplied and shipped with the unit must be installed and wired to the

control panel by the customer.

g) The high and low level test connections are DN15. The low level is situated lower than the

high level. The high level rises up from the bottom of the tank and ends 100 mm below the top;

the low level rises 50 mm from the bottom of the tank.

h) Both the high and low level connections should be piped to a safe catchment. Valves should

be installed in these lines at the catch tank.

Installation of the valves should be accomplished in such a manner that any ow will be visible

when the valves are open.

Flow from the high level test connection indicates when a tank is too full; no ow from the low

level test connection indicates too little uid in the tank.

i) There is a drain on the bottom of the thermal buffer section for the purpose of draining the tank

when necessary. This should be piped with a valve in the line to a safe catchment. The valve

specications outlined above apply to this valve as well.

j) An inspection opening is located at the highest point on the tank. Access to this port is

recommended but not required.

k) Refer to the maintenance schedule for recommendations on draining the thermal buffer

section. For positioning of all connections on the tank, see Figure. 8.

WARNING

Once the system has been lled, any modication to the tank or connected piping requires purging of the work

area to prevent ignition of potentially ammable vapours. Consult factory prior to beginning work. Consult the

MSDS for your thermal uid for ammability limits.

!

FTC-IOMM-2015-2

Fulton Ltd

Page 14

INSTALLATION - 2

2.10 OIL AND GAS CIRCULATING PUMP

Installing the pump in accordance

with the manufacturer’s specications

and these instructions will prolong

the life of the pump and contribute

signicantly to the successful operation

of your Fulton heater system. The

pump manufacturer’s installation and

operation instructions will be provided

with the pump (with skid-mounted

systems it will be provided within the

same folder as all OEM literature).

Figure. 10 - Oil and Gas Circulating Pump

2.10.1 LOCATION

The pump should be located adjacent to the heater. Its base must be rm, level (preferably

concrete) and free from vibration.

2.10.2 CONNECTIONS AND PIPING

a) The pump should be routed as per the manufacturer’s requirements. It should be equipped

with exible connections at the suction and discharge sides. The primary function of these

connections is to prevent stresses due to pipe expansion from being placed on the pump and

to isolate pump vibrations from the pipework and the heater. They also allow for expansion

and deection of the pipework. These connections should be rated for high temperature since

they are considered part of the piping system.

b) The suction pipework must be directly connected to the deaerator section of the combination

tank via a vertical run with as few elbows as possible and should contain the strainer and an

isolating valve. The discharge pipework must be connected directly to the heater inlet and

should contain an isolating valve. See that pipework connections match up accurately with

pump anges. Refer to the pump manufacturer’s recommendations for the specic pump inlet

piping requirements.

Typically these requirements are that:

i. It be a straight run of pipe.

ii. The straight run from the pump inlet to the rst tting, valve or ex connector be a minimum

of 6-10 pipe diameters in length.

iii. The pipe used should be the same size as the inlet of the pump.

c) The piping in the immediate vicinity of the pump must not be supported by the pump. The

pump is not designed to bear the weight of the piping and weight on any part of the pump will

throw it out of alignment.

/