Page is loading ...

Service instructions

AMD.07.18.1410.3

50 Hz

3~

1 / 9

26.11.2003

GB

Contents

1. Type identification .......................................................................................................................2

1.1 Nameplate......................................................................................................................................................2

1.2 Type key ..........................................................................................................................................................2

2. Torques.......................................................................................................................................... 3

3. Service tools..................................................................................................................................4

3.1 Special tools ...................................................................................................................................................4

3.2 Standard tools ...............................................................................................................................................4

3.3 Torque tools ...................................................................................................................................................4

4. Dismantling and assembly .......................................................................................................... 5

4.1 Dismantling the mixer ................................................................................................................................6

4.2 Assembling the mixer .................................................................................................................................6

5. Service chart.................................................................................................................................. 7

5.1 Oil in shaft seal housing ............................................................................................................................. 7

6. Fault finding..................................................................................................................................8

6.1 Fault finding chart........................................................................................................................................8

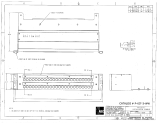

7. Drawing.........................................................................................................................................9

26.11.2003

GB

2 / 9

1. Type identification

1.1 Nameplate

1.2 Type key

TM02 8022 4503

Pos. Description Pos. Description

1 Type designation 9 Maximum installation depth

2 Product number 10 Power factor

3 Supply voltage and frequency 11 Net weight

4 Maximum current 12 Insulation class

5 Motor power input/output 13 Enclosure class

6 Version number 14 Production code

7 Rated speed 15 Place of production

8 Maximum liquid temperature

Example A M D .07 .18 .1410 .3

Type range

Version:

M = Mixer

Drive:

D = Direct

Shaft power output, P

2

[kW] x 10

Propeller diameter [cm]

Propeller speed [min

-1

]

Number of phases

1

3

4

5

6

2 9

10

11

12

13

8

14

7

15

-1

P.c:0000

Made in Denmark

I :1,9A n:1410min

P1/P2:1,0 /0,75kW

MAX

Vers: 1 : P 3

U: 3x400 V: 50Hz

Prod. No: 96113490

Type:AMD.07.18.1410.3

T : 40 C

Cos :0,78

:20m

MAX

10,50kg

Class: F

IP 68

26.11.2003

GB

3 / 9

2. Torques

Position numbers refer to 7. Drawing.

Pos. Designation Quantity Dimensions Torque [Nm]

1 Hub screw 1 M12 x 1 (left-hand thread) 10

2 Spring washer 1 M12 -

3 Lock washer 1 - -

4 Propeller 1 - -

5 Mounting clamp 1 - -

6 Mounting bracket 1 2" thread -

7Nut 1 M8 -

8Spring washer 1 M8 -

9Spring washer 2 M6 -

10 Nut 2 M6 -

11 Screw 2 M6 x 16 -

12 Screw 1 M8 x 20 -

13 Screw 2 M5 x 20 2

14 O-ring 2 5 x 1 -

15 Seal cover 1 - -

16 O-ring 2 4.8 x 2.5 -

105

17 O-ring 1 21 x 2 -

18 O-ring 1 21.8 x 3 -

19 O-ring 1 12 x 1 -

20 Rotating shaft seal part (SiC) 1 - -

21 Stationary shaft seal part (SiC) 1 - -

22 Spring for shaft seal 1 - -

23 Stationary seat 1 - -

24 Motor 1 - -

25 Cable with plug 1 - -

26.11.2003

GB

4 / 9

3. Service tools

3.1 Special tools

3.2 Standard tools

3.3 Torque tools

ABCD

EFG

Pos. Designation For pos. Description Part number

ASoft jaws 24 SV0412

B Puller 20 -

Pos. Designation For pos. Description Part number

C Bits kit 13 3 mm hexagon key SV2010

D Screwdriver 105 Straight slot -

ESocket 1 M43 -

Pos. Designation For pos. Description Part number

F Torque wrench 1, 13

1-6 Nm SV0438

4-20 Nm SV0292

G Ratchet insert tool F 9 x 12, ½" x ½" SV0295

26.11.2003

GB

5 / 9

4. Dismantling and assembly

The motor must only be replaced by Grundfos or an authorized service workshop. This also applies to the cable

entry.

Position numbers

Position numbers of parts (digits) refer to exploded views, sectional drawings and parts lists; position

numbers of tools (letters) refer to 3.

Service tools.

Before dismantling

• Disconnect the electricity supply to the mixer.

• Clean the mixer of injurious substances.

• Remove the electric cable in accordance with local regulations.

Before assembly

O-rings should always be replaced when the mixer is overhauled.

• Clean and check all parts.

• Order the necessary service kits.

• Replace defective parts by new parts.

During assembly

• Lubricate and tighten screws and nuts to the torque stated, see 2.

Torq ues .

26.11.2003

GB

6 / 9

4.1 Dismantling the mixer

4.1.1 Removing the propeller

1. Fit the mixer with the propeller upwards in a vice with soft jaws.

2. Remove the hub screw pos. 1 (left-hand thread).

3. Remove the spring washer pos. 2.

4. Pull the propeller pos. 4 including the lock washer pos. 3 off the shaft.

4.1.2 Removing the seal cover and draining of oil

1. Remove the propeller, see 4.1.1

Removing the propeller.

2. Slacken the screws pos. 13.

3. Remove the seal cover pos. 15 including the screws pos. 13 and the O-rings pos. 14 and 16.

4. Remove the mixer from the vice and pour the oil into a transparent container. Let the oil stand so that

water and oil separate. If the oil contains more than 30% water, the shaft seal must be replaced.

4.1.3 Removing the shaft seal

1. Remove the seal cover, see 4.1.2

Removing the seal cover and draining of oil.

2. Remove the rotation shaft seal part pos. 20 using the puller pos. B

.

3. Remove the stationary shaft seal part pos. 21 and the spring pos. 22.

4. Slacken the stationary seat pos. 23 including the O-rings pos. 17 and 18 using a small screwdriver.

5. Remove the seal ring.

6. Remove the O-ring pos. 17.

4.2 Assembling the mixer

4.2.1 Fitting the shaft seal

1. Fit the mixer with the shaft end upwards in a vice with soft jaws.

2. All O-rings should be lubricated with a little oil before being fitted.

3. Fit the O-ring pos. 19 on the shaft.

4. Fit the O-rings pos. 17 and 18 on the stationary seat pos. 23.

5. Place the seal ring pos. 23 with the thick O-ring downwards so that the tab points to one of the screw

holes.

6. Press the seal ring home in the motor.

7. Fit the spring pos. 22.

8. Fit the stationary shaft seal part pos. 21 with the seal face upwards and the tab aligned with the tab of the

seal ring. Take care of the seal face; it must not be exposed to blows or touched.

9. Fit the rotating shaft seal part pos. 20 loosely on the shaft with the seal face downwards. Take care of the

seal face; it must not be exposed to blows or touched.

10. Fit the propeller pos. 4 and the lock washer on the shaft and screw the hub screw (left-hand thread) on

the shaft, but do not tighten.

11. Check that the tab of the stationary shaft seal part is aligned with the tab of the seal ring.

12. Tighten the hub screw so that the rotating shaft seal part pos. 23 touches the recess of the shaft.

13. Check manually that the shaft can rotate freely.

14. Remove the hub screw, propeller and lock washer.

4.2.2 Filling of oil and fitting the seal cover

1. Fill oil through one of the threaded holes for the seal cover.

2. Fit the two thin O-rings pos. 13 on the screws pos. 13, and fit the screws in the seal cover pos. 15.

3. Fit the O-rings pos. 16.

4. Fit the seal cover pos. 15 and tighten the screws pos. 13 with 2 Nm.

4.2.3 Fitting the propeller

1. Fit the propeller pos. 4, lock washer pos. 3 and the spring washer pos. 2.

2. Fit the hub screw pos. 1 and tighten it with 10 Nm.

3. Check that the propeller rotates freely.

26.11.2003

GB

7 / 9

5. Service chart

5.1 Oil in shaft seal housing

Oil quality

Component Service instructions Lubrication Inspection

Motor

Keep the motor housing clean

(otherwise cooling is affected).

The motor housing cannot be

dismantled.

The motor is filled with dielectric oil. No

oil level check and oil change are required.

Supply cable

The supply cable must be checked twice a

year for surface damage, strain, kinks, etc.

If damaged, the cable must be replaced

by Grundfos.

Shaft seal housing

Change the oil every

5.000 operating

hours or minimum

every two years.

Propeller

Check the propeller blades regularly for

wear and tear. Remove any material

wound round the blades, such as ropes,

threads, etc. which may cause uneven

running and oscillation of the installa-

tion. In case of strong turbulence, clean-

ing is absolutely necessary.

If the propeller is damaged, it should be

replaced.

Pull and safety wire

Regular oiling or greasing

increases the life of the wire.

Check the lifting wire regularly and

always before using the winch. Replace

the wire, if required.

Screws

Check the fixing screws every

time the pit/tank is empty.

Ambient temperature 0 to +40°C

Type SHELL Ondina 917

Quantity 0.078 litre

26.11.2003

GB

8 / 9

6. Fault finding

6.1 Fault finding chart

Fault Cause Remedy

1. Mixer does not start.

a) No electricity supply or supply failure.

Check the electrical installation.

Call in an electrician.

b) Supply cable is faulty. Call in an electrician.

c) Control system is faulty. Call in an electrician.

d) Propeller not free to rotate.

Clean the propeller blades and

check manually that the propeller

can rotate freely.

e) Stator windings are faulty. Contact GRUNDFOS.

f) Motor cut out because of overheating.

Wait until the motor has cooled

and attempt to restart the mixer.

g) Different phase voltages. Call in an electrician.

h) Overload relay is set too low or is faulty.

Check the motor starter.

Set the starter to the rated

current.

i) Humidity in motor. Contact GRUNDFOS.

2. Mixer starts but stops

immediately.

a) Stator windings are faulty. Contact GRUNDFOS.

b) Different phase voltages. Call in an electrician.

c) Overload relay is set too low or is faulty.

Check the motor starter.

Set the starter to the rated

current.

d) Humidity in motor. Contact GRUNDFOS.

3. No or inadequate

circulation produced even

if the motor is running.

a) Propeller rotates in the wrong direction.

Interchange two phases of the

mains supply.

b) Mixer runs on two phases.

Replace faulty fuses.

Call in an electrician.

Check the electrical connections.

c) Internal parts are worn. Contact GRUNDFOS.

d) Propeller blades are dirty or damaged.

Clean the blades and inspect for

any wear.

4. Mixer runs unevenly and

is noisy.

a) Internal parts are worn. Contact GRUNDFOS.

b) Propeller blades are dirty or damaged.

Clean the blades and inspect for

any wear.

c) Oscillations caused by the installation (resonance). Check installation design.

5. High current and power

consumption.

a) Wrong voltage supply or supply failure.

Check the electrical installation.

Call in an electrician.

b) Supply cable is faulty. Call in an electrician.

c) Control system is faulty. Call in an electrician.

d) Propeller not free to rotate.

Clean the propeller blades and

check manually that the propeller

can rotate freely.

e) Stator windings are faulty. Contact GRUNDFOS.

f) Mixer runs on two phases.

Replace faulty fuses.

Call in an electrician.

Check the electrical connections.

g) Internal parts are worn. Contact GRUNDFOS.

26.11.2003

GB

9 / 9

7. Drawing

TM02 8013 4503

25

1

2

3

4

5

15

16

14

13

20

21

22

17

18

23

24

6

26

19

12

11

8 7 10 9

105

/