Reference

Modification no.

- 0 -

Page

6

Date

1997 02 01

Main

914 F

01476

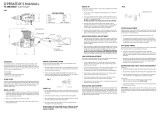

13.2) Lubricating system ................................................................................................. 142

13.2.1) Oil pump ................................................................................................... 142

13.2.1.1) Oil pump removal (main- and suction oil pump) ...................... 142

13.2.1.2) Oil pump disassembly ............................................................ 143

13.2.1.3) Oil pump checking .................................................................. 144

13.2.1.4) Oil pump re-assembly............................................................. 145

13.2.2) Check valve (Turbo) ................................................................................. 146

13.2.3) Oil sump container (Turbo) ....................................................................... 146

13.2.4) Magnetic screw ........................................................................................ 147

13.2.5) Drain screw .............................................................................................. 147

13.2.6) Oil tank ..................................................................................................... 148

13.2.7) Oil tubes (steel tubes) .............................................................................. 149

13.2.8) Oil tubes ................................................................................................... 150

13.2.9) Oil cooler .................................................................................................. 150

13.2.10) Venting of lubrication system ................................................................... 150

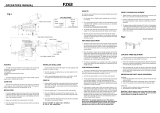

13.3) Cooling system ...................................................................................................... 152

13.3.1) Water pump removal ................................................................................ 152

13.3.2) Water pump housing - disassembly and check ....................................... 153

13.3.3) Magneto hub ............................................................................................. 154

13.3.4) Ignition housing - removal and check ...................................................... 154

13.3.5) Water pump shaft - removal ..................................................................... 157

13.3.6) Rotary seal - removal ............................................................................... 158

13.3.6) Rotary seal - refitting ............................................................................... 158

13.3.8) Section through water pump .................................................................... 159

13.3.9) Fitting of ignition housing .......................................................................... 160

13.3.10) Water pump housing — reassembly ........................................................ 161

13.3.11) Expansion tank ........................................................................................ 162

13.3.12) Overflow bottle ......................................................................................... 162

13.3.13) Radiator .................................................................................................... 162

13.3.14) Radiator hoses ......................................................................................... 162

13.3.15) Hose clamps ............................................................................................ 162

13.3.16) Cooling air baffle....................................................................................... 162

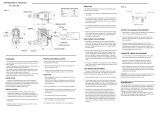

13.4) Ignition system ....................................................................................................... 164

13.4.1) Checking of ignition unit, trouble shooting ................................................ 164

13.4.2) Spark plugs, ignition cables, spark plug connectors, cables ................... 164

13.4.3) Electronic module, trigger set ................................................................... 165

13.4.4) Charging coil ............................................................................................ 166

13.4.5) Generator coil .......................................................................................... 166

13.4.6) Double ignition coil ................................................................................... 167

13.4.7) Cut-in speed of ignition ............................................................................. 167

13.4.8) Ignition timing control ................................................................................ 168

13.4.9) Check of ignition circuits (magneto check) .............................................. 169

13.4.10) Wiring diagrams ....................................................................................... 170

13.4.10.1) Engine, internal ....................................................................... 170

13.4.10.2) Engine, external .................................................................................... 172

13.4.11) Removal of ignition electric set ................................................................ 176

13.4.12) Dismantling of ignition electric set ............................................................ 177

13.4.13) Re-assembly of ignition electric set ......................................................... 178

13.4.14) Re-fitting of ignition electric set ................................................................ 179

13.4.16) Exchange of external trigger coils ............................................................ 180

13.4.16) Stator removal and re-fitting ..................................................................... 181

13.4.17)Flywheel ass'y .......................................................................................... 182