English (GB)

2

English (GB) Service instructions

Original service instructions

CONTENTS

Page

1. Symbols used in this document

2. Identification

The nameplate is fitted to the top cover of the pump. Fix the extra

nameplate supplied with the pump at the installation site or keep

it in the cover of this booklet.

2.1 Nameplate

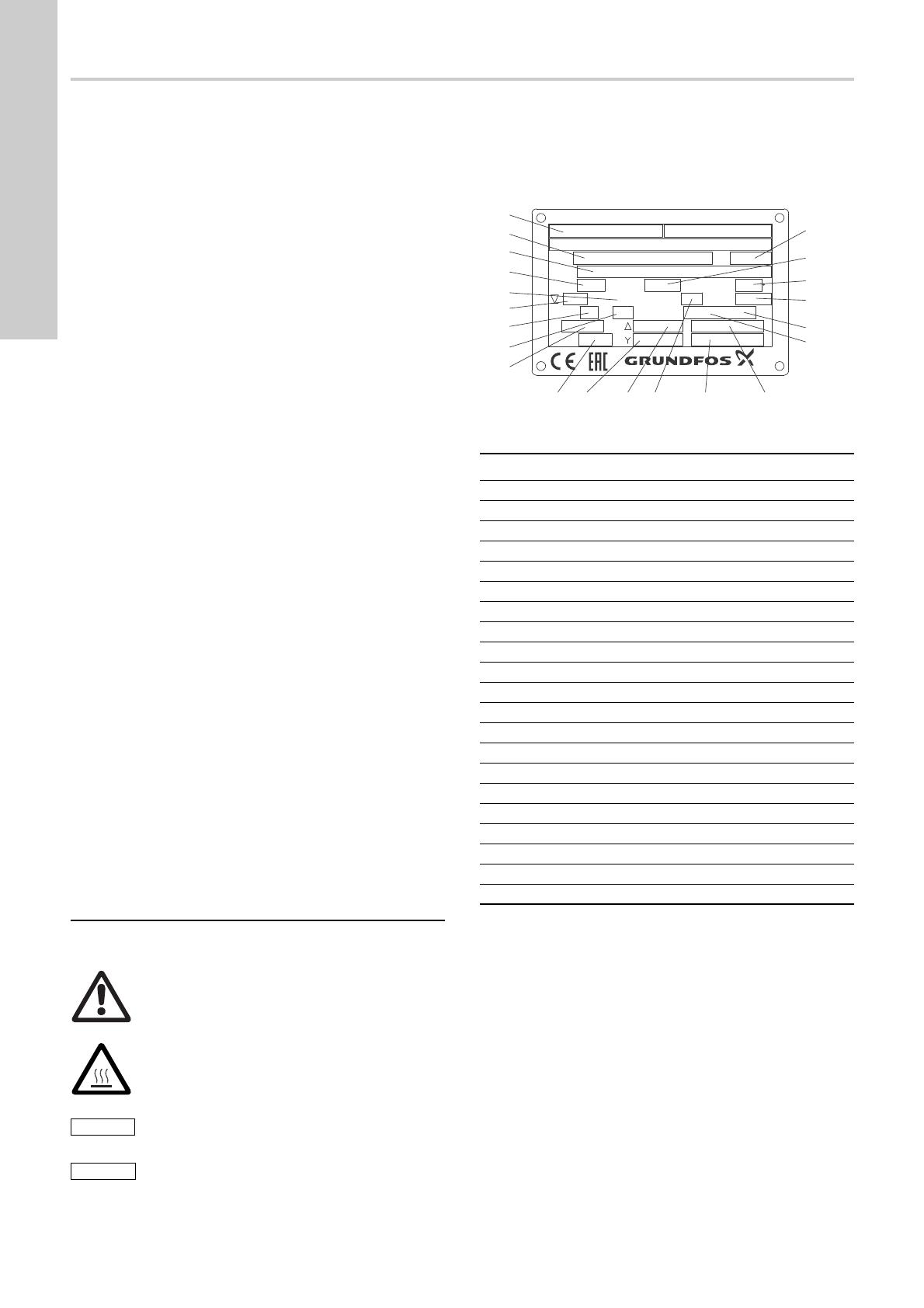

Fig. 1 Nameplate

1. Symbols used in this document

2

2. Identification

2

2.1 Nameplate

2

2.2 Type key, DWK

3

2.3 Type key, DPK

3

3. Tightening torques

4

4. Service tools

5

4.1 Standard tools

5

4.2 Torque tools

5

5. Dismantling

6

5.1 General information

6

5.2 Oil change

6

5.3 Removing impeller and pump housing

7

5.4 Removing shaft seals

8

5.5 Removing bearings

8

5.6 Removing cable

9

5.7 Removing stator

9

6. Assembly

10

6.1 Fitting stator

10

6.2 Fitting cable

10

6.3 Fitting bearings

12

6.4 Fitting shaft seals

12

6.5 Fitting impeller and pump housing

13

7. Fault finding

14

8. Components and material specification

15

8.1 DWK.O.6.50.075, DWK.O.6.50.15 and DWK.O.6.50.22

16

8.2 DWK.O.6.80.15, DWK.O.6.80.22, DWK.O.10.80.37

and DWK.O.10.100.37

17

8.3 DWK.O.13.80.55, DWK.O.13.100.55,

DWK.O.13.100.75, DWK.O.13.100.110,

DWK.O.13.100.150 and DWK.O.13.150.150

18

8.4 DWK.E.10.100.220, DWK.E.10.150.220,

DWK.E.10.150.300, DWK.E.10.200.300

19

8.5 DWK.E.10.150.370, DWK.E.10.150.450,

DWK.E.10.200.370, DWK.E.10.200.450,

DWK.E.10.150.550, DWK.E.10.200.550

20

8.6 DWK.E.10.200.750, DWK.E.10.200.900

21

8.7 DPK.10.50.075, DPK.10.50.15 and DPK.10.80.22

22

8.8 DPK.15.80.37, DPK.15.80.55, DPK.15.100.75,

DPK.20.100.110 and DPK.20.100.150

23

8.9 DPK.20.150.190 and DPK.20.150.220

24

8.10 DPK.V.65.80.15.2 and DPK.V.65.80.22.2

25

8.11 DPK.V.80.80.37.2

26

8.12 DPK.V.80.80.55.2 and DPK.V.80.80.75.2

27

8.13 DPK.V.65.80.15.4 and DPK.V.65.80.22.4

28

8.14 DPK.V.80.80.37.4, DPK.V.80.80.55.4 and

DPK.V.80.80.75.4

29

Warning

If these safety instructions are not observed, it may

result in personal injury.

Warning

The surface of the product may be so hot that it may

cause burns or personal injury.

If these safety instructions are not observed, it may

result in malfunction or damage to the equipment.

Notes or instructions that make the job easier and

ensure safe operation.

TM04 4093 1016

Pos. Description

1 Notified body

2 Type designation

3 Product number and serial number

4 Maximum head [m]

5 Enclosure class

6 Maximum installation depth [m]

7 Number of phases

8 Frequency [Hz]

9 Speed [min

-1

]

10 Weight

11 Rated voltage [V] Star

12 Rated voltage [V] Delta

13 Insulation class

14 Rated current [A] Star

15 Rated current [A] Delta

16 Motor input power P1 [kW]

17 Motor output power P2 [kW]

18 Power factor

19 Maximum liquid temperature [°C]

20 Maximum flow [l/s]

21 Production code (year/week)

1

2

3

4

5

6

7

8

9

10

11

12 13 14 15

16

17

18

19

20

21

DK-8850 Bjerringbro Denmark

Type

Model

Hmax Qmax Tmax. :

P.c.

m l/s c

P,3,QVXOFODVV&RVĭ

96883812

Made in China

Motor ~ Hz P1/P2 kW

n min

-1

Weight kg A

A

V

V