INSTRUCTIONS FOR INSTALLATION, OPERATION AND MAINTENANCE

Fire Damper

ETPR

FläktGroup DC_9938GB 20210830_R3 Specifications are subject to alteration without notice.

Fire Damper ETPR - Instructions for Installation, Operation and Maintenance

3

Maintenance Check List:

Installation

Fire damper ETPR must be installed according to this in-

stallation manual, see pages 4-9.

General instructions for using hangers

The fire damper must be supported so that the ductwork

connected to the damper does not impose any load on the

damper body.

In practice, a good way to fit the product centrally in the

installation opening is to hang the ductwork prior to sealing.

If the subsequent sealing is done using grouting concrete,

also other types of support can be used during installation

until the concrete has dried.

It is essential that no stress is imposed on the fire damper

or the duct. The hanging and fixing solution must be ade-

quate in the event of fire. The hanger must be located either

at the fire damper or immediately after the duct connection.

Designing the use of hangers is the responsibility of a

structural engineer.

Operation and function testing

According to CE marking, a fire damper must always be

equipped with a tripping mechanism based on temperature.

Fire dampers can be delivered equipped with either a fuse

mechanism or an actuator.

ETPR motorized fire dampers may additionally be linked to

a smoke detection based tripping mechanism. A tripping

system based on smoke detection is easy to install using

FläktGroup FICO control and monitoring system. The FICO

system can also be used for automatic function tests of fire

dampers.

The function testing for the motorized damper can be per-

formed by cutting off the power supply by using the switch

of the thermal trip connected to the motor. The spring will

then close the damper. The function testing can also be

done by means of the control and monitoring system FICO,

either manually or automatically. The recommended auto-

matic function testing interval for the motorized damper is

48 hours.

The operation of the fuse mechanism is tested by pushing

the red test button – the spring will close the blade. Beware

of the reset handle as it will rotate rapidly during test op-

eration. To reset the mechanism, turn the handle until the

mechanism clicks.

Maintenance

The function testing interval is always determined separate-

ly for each building, but testing must be carried out at least

twice a year according to product standard EN 15650:2010

(see example of check list beside).

WARNING! Never put your hands inside the damper while

it is closing.

Clean the fire damper by means of a vacuum cleaner. Avoid

chemical cleaning agents.

Fire damper reference

Date of inspection

Check actuator wiring for damage (where applicable)

Check end-switch wiring for damage (where applicable)

Check fire damper cleanliness and clean where necessary

Check the condition of blades and seals, rectify and report where

necessary

Confirm the safety closure operation of the fire damper according

to the manufacturer’s instructions

Confirm operation of damper to OPEN and CLOSE by use of the

control system and physical observation of the fire damper, rectify

and report where necessary

Confirm operation of OPEN and CLOSED end-switches, rectify and

report where necessary

Confirm that the fire damper fullfills its function as a part of the

control system (where applicable)

Confirm that the fire damper is left in its normal working position

NOTE! A fire damper is usually part of a system. As this is the

case, the whole system should be checked as governed by the

operation and maintenance requirements for the system.

Spare parts

Actuator: see type specification on the actuator.

Fuse part ETFF-99-01

Fuse part replacement, see page 11.

FläktGroup DC_9938GB 20210830_R3 Specifications are subject to alteration without notice.

Fire Damper ETPR - Instructions for Installation, Operation and Maintenance

4

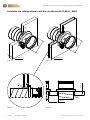

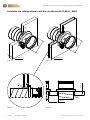

Installation into building elements with fire classification EI 60 (Ø100 - Ø630)

Figure 1 Figure 2

Figure 4Figure 3

ØD

≥100 mm

M

≥110 mm

≥ 200 mm

M

≥116 mm

ØD

S

S

FläktGroup DC_9938GB 20210830_R3 Specifications are subject to alteration without notice.

Fire Damper ETPR - Instructions for Installation, Operation and Maintenance

5

Size ØD (mm) Installation opening Ø (mm)

100

125

150

160

200

250

300

315

400

500

630

175 – 195

175 – 195

200 – 220

210 – 230

250 – 270

300 – 320

350 – 370

365 – 385

450 – 470

550 – 570

680 – 700

Size ØD (mm) Installation opening Ø (mm)

100

125

150

160

200

250

300

315

400

500

630

135 – 137

135 – 137

160 – 162

170 – 172

210 – 212

260 – 262

310 – 312

325 – 327

410 – 412

510 – 512

640 – 642

Installation of fire damper into rigid

building elements (walls and intermediate

floors) with fire classification EI 60 and

into floors with fire classification EI 90

(Fig. 1 and Fig. 4)

Installation of fire damper into flexible

building elements (gypsum board walls

or similar) with fire classification EI 60

(Fig. 2 and Fig. 3)

2. The fire damper blade must be closed during installa-

tion.

3. Place the circular duct centrally in the opening.

4. Place the fire damper in the duct so, that the damper

flange rests against the building element and connect

the damper to duct. Use screws of sufficient length (e.g.

M6 x 40 mm), which are suited for rigid construction, to

fasten the damper to the building element through the

bendable brackets on the flange. The damper must be

fastened at 4 brackets at the minimum. The blade shaft

can be placed in any position.

5. Completely fill the gap M between the duct and the

building element using incombustible, rock based, fine-

grained gypsum or concrete cast. Protect the damper

whilst infilling.

2. The fire damper blade must be closed during installa-

tion.

3. Place the circular duct in the opening.

4. Fill the gap S between duct and wall opening on both

sides by using fire-resistant mass.

5. Place the fire damper in the circular duct so, that the

damper flange rests against building element and

connect the damper to duct. Use screws or anchors

suited for gypsum board walls to fasten the damper to

the building element through the bendable brackets on

the flange. The damper must be fastened at 4 brackets

at the minimum. The blade shaft can be placed in any

position.

6. Check the functioning of the fire damper and proper

movement of the blade. Clean the damper, if necessary.

Place plastic covers on the openings and keep them

covered, until ducts are connected to the damper.

7. To reset the fuse mechanism: Turn the handle towards

the OPEN position until the mechanism clicks and the

blade locks into position.

8. Manual function testing of the motorized fire damper

can be performed with the tool delivered with the

actuator. When connected to a power supply, function

testing is done by using the switch of the thermal trip.

NOTE! If you open the damper blade manually with the

tool, be sure to release the damper back to the closed

position before switching on power.

9. Connect ducts to the damper according to the instruc-

tions provided by the designer and the manufacturer.

Use rivets of sufficient length (e.g. DIN 7337 4x10 or

shorter) to lock fire damper to the duct. Note! Always

check that damper blade can rotate freely and rivets/

screws are out of the way. Access panel should be

placed next to the fire damper to enable necessary

cleaning and inspection. Suspend the ducts according

to instructions from the manufacturer and ensure that

the ductwork does not cause any load on the damper

installation.

10. If the fire damper is used as an air transfer or air

terminal device, it must be equipped with a protective

grille. The distance between the grille and the damper

blade in the open position must be at least 30 mm. In

case of large fire dampers, an extension piece must

be installed between the grille and the damper blade.

A circular duct of suitable length can be used as an

extension piece.

11. When dampers are to be mounted next to one another,

the distance between the dampers should be ≥200mm

(Figure 4).

1. Installation opening in the rigid wall or intermediate

floor must comply with the dimensions given in the

table below.

1. Installation opening in the flexible wall must comply

with the dimensions given in the table below.

FläktGroup DC_9938GB 20210830_R3 Specifications are subject to alteration without notice.

Fire Damper ETPR - Instructions for Installation, Operation and Maintenance

6

Figure 5

Figure 6

Figure 7

Installation outside building elements with fire classification EI 60 (Ø100 - Ø630)

ØD

M

≥100 mm

1

≥116 mm

ØD

1

S

M

2

2

FläktGroup DC_9938GB 20210830_R3 Specifications are subject to alteration without notice.

Fire Damper ETPR - Instructions for Installation, Operation and Maintenance

7

Installation of fire damper outside building elements with fire classification EI 60

(Fig. 5-7)

1. Install the duct in the usual manner so that it pene-

trates the building element, and seal the openings (M or

S) using an approved method.

2. Connect damper to duct according to the instructions

provided by the designer or manufacturer. Use rivets of

sufficient length (e.g. DIN 7337 4x10 or shorter) to lock

fire damper to the duct. Note! Always check that damp-

er blade can rotate freely and rivets/screws are out of

the way. Access panel should be installed next to the

damper to enable necessary cleaning and inspection.

3. Support the duct installation so that there is no extra

load on the fire damper. In horizontal installation (Fig-

ures 5-6) the dimensioning of threaded rod hangers (1)

can be done based on the following table. In vertical

installation (Figure 7) use shaft hangers (2) or other

approved methods to stabilize the damper according to

instructions from structural engineer.

4. Insulate the duct between wall and fire damper flange

as shown in figures 5-7, so that the fire classification EI

60 is met.

Threaded rod Max load (kg)

t ≤ EI 60

M8

M10

M12

33,6

53,2

77,3

5. Check the functioning of the fire damper and proper

moving of the blade. Clean the damper, if necessary.

Place plastic covers on the openings and keep them

covered, until ducts are connected to the damper.

6. To reset the fuse mechanism: Turn the handle towards

the OPEN position until the mechanism clicks and the

blade locks into position.

7. Manual function testing of the motorized fire damper

can be performed with the tool delivered with the

actuator. When connected to a power supply, function

testing is done by using the switch of the thermal trip.

NOTE! If you open the damper blade manually with the

tool, be sure to release the damper back to the closed

position before switching on power.

8. The fixings used to secure the fire damper and ventila-

tion duct must have a fire resisting capacity that is at

least as high as the fire classification of the penetrated

building element (the fire resistance rating of a class EI

60 element is R 60, etc.).

9. If the fire damper is used as an air transfer or air

terminal device, it must be equipped with a protective

grille. The distance between the grille and the damper

blade in the open position must be at least 30 mm. In

case of large fire dampers, an extension piece must be

installed between the grille and the damper blade.

FläktGroup DC_9938GB 20210830_R3 Specifications are subject to alteration without notice.

Fire Damper ETPR - Instructions for Installation, Operation and Maintenance

8

Installation of fire damper into sandwich-type* building elements with fire

classification EI60

Figure 8

Figure 9

Figure 11Figure 10

*E.g. Paroc Panels AST S+ 100mm

ØD1

A

A

1

3

3

2

B B

A

1

4

ØD

ØD

FläktGroup DC_9938GB 20210830_R3 Specifications are subject to alteration without notice.

Fire Damper ETPR - Instructions for Installation, Operation and Maintenance

9

Size ØD

(mm)

Installation opening Insulation

height B

ØD1 (mm) A x A (mm)

100

125

160

200

250

315

400

500

630

110

135

170

210

260

325

410

510

640

325 x 325

325 x 325

360 x 360

400 x 400

450 x 450

515 x 515

600 x 600

700 x 700

830 x 830

162,5

162,5

180,0

200,0

225,0

257,5

300,0

350,0

415,0

Installation of fire damper into sandwich-type* building elements with fire

classification EI60 (Fig. 8-11)

Make a circular opening on the side where the fire

damper will be installed and a square opening on the

opposite side. Note! For a successful installation, it is

important that the openings are aligned.

2. Prepare the installation opening by cutting it completely

clear of wool from the square side so that only the

facing of the element is visible. Use fire-rated acrylic

sealant to seal the corners of the square opening as

well as any element joints at the installation opening

(see red markings in Fig. 8).

3. Install mounting rails (4 pcs) of L30x30x2, e.g. Wurth

0862001905, (see No. 1 in Fig. 8) on all edges of the

square opening. Use sharp-point screws, e.g. Wronic

4.2x38mm, at intervals of approximately 80mm. To

reinforce the corners of the opening, drill a 6 mm hole

at each corner through the opening in the mounting rail

and all the way through the element. Provide the holes

with through bolts of M6 x 120mm or M6 threaded

rods (4 pcs) and tighten them into place using washers

and nuts (see No. 2 in Fig. 8).

9. Check the functioning of the fire damper and proper

movement of the blade. Clean the damper, if necessary.

Place plastic covers on the openings and keep them

covered, until ducts are connected to the damper.

10. To reset the fuse mechanism: Turn the handle towards

the OPEN position until the mechanism clicks and the

blade locks into position.

11. Manual function testing of the motorized fire damper

can be performed with the tool delivered with the

actuator. When connected to a power supply, function

testing is done by using the switch of the thermal trip.

Note! If you open the damper blade manually with the

tool, be sure to release the damper back to the closed

position before switching on power.

12. Connect ducts to the damper according to the instruc-

tions provided by the designer and the manufacturer.

Use rivets of sufficient length (e.g. DIN 7337 4x10 or

shorter) to lock fire damper to the duct. Note! Always

check that the damper blade can rotate freely and

rivets/screws are out of the way. Access panel should

be placed next to the fire damper to enable necessary

cleaning and inspection. Suspend the ducts according

to instructions from the manufacturer and ensure that

the ductwork does not cause any load on the damper

installation.

13. If the fire damper is used as an air transfer or air

terminal device, it must be equipped with a protective

grille. The distance between the grille and the damper

blade in the open position must be at least 30 mm. In

case of large fire dampers, an extension piece must

be installed between the grille and the damper blade.

A circular duct of suitable length can be used as an

extension piece.

1. Installation openings in the element must comply with

Figure 8 and the dimensions given in the table below.

4. If there are any element joints at the installation open-

ing or within 800mm of any of its edges, seal these

joints on both sides with fire-rated acrylic sealant and

secure them with sharp-point screws, e.g. Wronic

4.2x38mm, at intervals of 100mm

(see No. 3 in Fig. 8)

.

5. Install the product and the duct. The fire damper blade

must be closed during installation. Insert the duct

through the square opening and all the way through

the wall, and connect the fire damper to the duct (see

Fig. 9).

6. Seal the surface of the calcium silicate flange around

the fire damper with fire-rated acrylic sealant where

it will be attached to the element (see Fig. 10). Place

the duct centrally in the opening. Press the fire damper

against the element, and fix it to the element surface at

the foldable brackets (4 to 6 pcs) using blind rivets (e.g.

steel rivets of 4.8x14mm (see Fig. 11).

7. Seal the edge of the calcium silicate ring against the

element surface with fire-rated acrylic sealant (see Fig.

11 and detail in Fig 10, the red markings).

8. Insulate the square installation opening with two layers

of Paroc HVAC Fire Slab EI 120 with a thickness of

60mm, the total insulation thickness being 120mm

(see No. 4 in Fig. 9). Cut the wool layers according to

Figure 9 and the table in step 1 above. Seal all joints

and edges in both insulation layers with fire-rated

acrylic sealant (see red markings in Fig. 9). Any insu-

lation slab surfaces that remain visible can be treated

with, for example, a fire-resistant paint if necessary.

FläktGroup DC_9938GB 20210830_R3 Specifications are subject to alteration without notice.

Fire Damper ETPR - Instructions for Installation, Operation and Maintenance

10

Tf Tf LE D

S1 S2 S3 S4 S5 S6

<5° <80°

21

–+

T

~

Status data of limit switches

Thermal trip

Power supply

Electrical wiring for motorized fire

damper

Only a trained electrician is allowed to perform the elec-

trical wiring according to separate drawings and wiring

diagrams. Wiring diagram for fire damper actuator is

shown below.

Microswitch wiring for fuse mechanism

operated fire damper

The microswitch does not affect fire damper triggering, it

just indicates the position of the fire damper blade. The fire

damper closes when the thermal trip activates.

Status data from the microswitch can be provided from two

microswitches (open/close).

Proper functioning of the microswitch must be checked and

proper indication verified.

Electric specification:

Operating temperature -25 °C ... +70 °C

Imax = 0,1 A

Umax = 30 V (AC/DC)

1 Test button

2 Cover

3 Cable clamp

4 Microswitches

(under cover)

5 Handle

Wiring diagram for microswitch

Wiring digram shows the situation where damper blade is

in closed position and microswitch (0°) is activated.

Figure 12. Figure 13.

2

5

4

3

1

123456

2

1 2

0° 90°

3 4 5 6

AC 230 V

AC 24 V

DC 24 V

FläktGroup DC_9938GB 20210830_R3 Specifications are subject to alteration without notice.

Fire Damper ETPR - Instructions for Installation, Operation and Maintenance

11

Replacing fuse part ETFF-99-01

NOTE! Safety gloves should be used when replacing the

fuse part.

1. Release the mechanism with the test button (1) – close

the fire damper. Figure 14.

2. Remove the fuse part mounting screw (6). Figure 15.

3. Holding the test button, pull out the complete fuse part

(7). Figure 16.

4. Correctly install the new fuse part and fasten it with the

screw (6).

5. Test the function of the product and reset the fire damp-

er. Turn the handle towards the OPEN position until

the mechanism clicks and the blade locks into OPEN

position. To test the operation of the fuse mechanism,

push the red test button (1) – the spring should close the

blade. Beware of the turning reset handle!

Figure 14.

Figure 15.

Figure 16.

1

6

6

7

6

WWW.FLAKTGROUP.COM ETPR 9938

» Learn more on www.flaktgroup.com

or contact one of our offices

FG_DC_9938GB_ETPR_IN-MA_20210830_R3 © Copyright 2021 FläktGroup

FläktGroup is the European market leader for smart and energy efficient Indoor Air

and Critical Air solutions to support every application area. We offer our customers

innovative technologies, high quality and outstanding performance supported by more

than a century of accumulated industry experience. The widest product range in

the market, and strong market presence in 65 countries worldwide, guarantee

that we are always by your side, ready to deliver Excellence in Solutions.

PRODUCT FUNCTIONS BY FLÄKTGROUP

Air Treatment | Air Movement | Air Diffusion | Air Distribution | Air Filtration

Air Management & ATD’s | Air Conditioning & Heating | Controls | Service

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

FläktGroup ETCE/ETCS Installation guide

-

FläktGroup Recycling Installation guide

-

FläktGroup Optivent Ultra ULSA, ULDA Installation guide

-

FläktGroup ETPS-E Installation guide

-

FläktGroup eCO TOP Installation and Maintenance Manual

-

FläktGroup FICO-MINI (FCMB-4) Installation guide

-

FläktGroup eCO TOP Installation and Maintenance Manual

-

FläktGroup DENCO - OFFICECool LECU Operating instructions

-

FläktGroup COM4plus Installation guide

-

FläktGroup vQ Stream Controls Installation guide

Other documents

-

Ortech FIRE DAMPER-ODC User manual

-

Trox FKRS-EU Installation guide

-

SystemAir FDR-3G-200-H0-OF User manual

SystemAir FDR-3G-200-H0-OF User manual

-

Trox FKRS-EU Installation guide

-

Trox FK2-EU Installation guide

-

Greenheck Fan OFD-XXX User manual

-

Trox EK2-EU Installation guide

-

Greenheck 461335 Corridor Ceiling Dampers Operating instructions

-

Trox FKT-EU Installation guide

-

Greenheck 472477 Grille Access Combination Fire Smoke Dampers Operating instructions