Page is loading ...

CIRRUS AIRPLANE MAINTENANCE MANUAL MODEL SR20

51-00

Page 1

All

EFFECTIVITY:

STANDARD PRACTICES: STRUCTURES

1. GENERAL

This Chapter contains standard practices for the maintenance and repair of composite structures for Cirrus

aircraft and components. The objective governing all recommendations in the following procedures is to

restore the composite structure to its original level of strength and durability.

The general procedure for using the Chapter 51 - Standard Practices: Structures is as follows:

The extent of damage is determined using the methods outlined in Section 10 - Investigation, which

contains guidance for identification of damage and associated classifications. (Refer to 51-10)

Processes and methods used in the repair of the aircraft are described in Section 20 - Processes.

(Refer to 51-20)

Approved materials and equipment necessary to perform standard repairs are contained in Section 30

- Materials. Prior to each repair process, a table listing all necessary tools, equipment, and supplies is

provided. (Refer to 51-30)

Section 70 - Standard Repairs contains specific composite repair procedures that are used with the

supporting processes outlined in Section 20. (Refer to 51-70)

Prior to each repair process, a table listing all necessary tools, equipment, and supplies is provided.

For information related to safety equipment refer to Section 00 - Standard Practices: Structures. (Refer

to 51-00)

A discussion on personnel qualifications, description of the primary structural components, Airframe Zone

Diagrams outlining the principal repair areas, and a definition of terms used in this Chapter are included

below.

15 Jun 2010

51-00

Page 2

All

EFFECTIVITY:

CIRRUS AIRPLANE MAINTENANCE MANUAL MODEL SR20

15 Jun 2010

A. Personnel Qualifications and Safety

Repair personnel must be fully qualified in the preparation and handling of repair materials and the

repair of composite laminate construction.

The capability of a repair to satisfactorily maintain its integrity for the remaining life of the aircraft is

dependent on the quality of the repair. Therefore, it is essential that the procedures outlined in this

Chapter be carefully followed and that all repairs be conducted with the highest possible degree of

workmanship.

Materials used for the manufacture and repair of laminates are potentially dangerous. Prior to perform-

ing any repair the following Health and Safety Information, Safety Equipment, and First Aid Procedures

should be reviewed:

WARNING:

The repair procedures described in this Chapter call for the use of processes and/

or substances that may be harmful to the health if adequate precautions are not

taken. Materials used for the manufacture of laminates are potentially dangerous

and may cause a number of health hazards.

(1) Health and Safety Information

(a) Materials used for the manufacture of laminates are potentially dangerous and prior to use

the material safety data sheets must be read.

(b) Damaged composite materials may cause a number of health hazards. Single fiber parti-

cles, with a diameter of 3 to 4 microns and a length of less than 0.1 mm pose the greatest

threat to the respiratory system. Respiratory protection is essential for those operations,

such as drilling and sanding where dust exists or is generated.

(c) Composite material dust is injurious to health. A respirator must be worn at all times when

drilling or sanding composite materials.

(d) Individual fiber filaments are very brittle and broken fiber may cause irritation to the skin.

Approved barrier creams should be used and protective clothing worn. If irritation is felt,

thorough washing and rinsing will remove loose filaments.

(e) Technicians should, before mixing and using the repair resin, apply liberal quantities of

approved barrier cream to their hands (particularly around the finger nails) and wrists.

(f) To keep resin from contacting the hands, rubber gloves must be used (in addition to the

barrier cream) when carrying out a repair.

(g) Resin deposits on the skin should be removed before they set hard by wiping with a clean

rag. Removal of obstinate deposits of resin and final cleaning of the hands after the repair

should be carried out by applying a quantity of white vinegar, thoroughly rubbing in, wiping

with a clean rag, and followed by washing in warm water. Resin that is allowed to set hard

on the skin cannot be removed.

(h) Acetone should not be used on the hands as it removes the natural oils from the skin and

may have other associated health hazards.

(2) Safety Equipment

(a) Respiratory Protection-Dust and Vapor Masks

Depending on the hazard presented by the material being used, appropriate masks must

be worn. When sanding, a dust mask must be worn. When masks are worn for protection

against gases or chemical vapors, ensure the correct type of mask is used. Full-face (neg-

ative pressure) masks are available and can be fitted with a wide range of filter canisters to

suit gases, solvents, or particulates against which protection is required. Always consult

the Material Safety Data Sheet for each hazard, and use the recommended protection.

(b) Eye and Ear Protection

Goggles giving all-round eye protection should be worn when drilling or sanding compos-

ite materials, and when chemicals are being used. Ear protection should be worn for noisy

processes such as grinding.

CIRRUS AIRPLANE MAINTENANCE MANUAL MODEL SR20

51-00

Page 3

All

EFFECTIVITY:

(c) Clothing

A resin proof apron should be worn when the situation demands that level of care. If mate-

rials being used are toxic by absorption through the skin, coveralls providing complete pro-

tection may be worn.

(d) Barrier Creams

An approved barrier cream should be rubbed into the hands before commencing work with

resins and adhesives. Moisturizing creams and barrier creams protect the skin but must

be regarded only as supplements. They should be used in conjunction with gloves rather

than as a replacement for gloves. Refer to Section 30 - Materials for approved barrier

creams. (Refer to 51-30)

(3) First Aid Procedures

Refer to the products material safety data sheet for additional first aid information.

(a) Skin Contact

Immediately remove liquids from the skin by wiping with disposable towels, then cleanse

the skin with white vinegar, followed by washing with warm soapy water. Do not use sol-

vents.

(b) Eye Contamination or Irritation

Immediately flush the affected eye with eyewash bottle or fountain - or with low-pressure

running water- for at least 15 minutes. Seek medical attention promptly.

(c) Inhalation

Operators affected by the inhalation of vapor, droplets, etc., should be taken immediately

into fresh air and made to rest while medical attention is called.

(d) Clothing

Remove and isolate contaminated overalls and clothing. Launder before re-use.

(e) Ingestion

Immediately rinse the mouth repeatedly with water. If swallowing has occurred, drink

plenty of water. Seek medical attention promptly.

15 Jun 2010

51-00

Page 4

All

EFFECTIVITY:

CIRRUS AIRPLANE MAINTENANCE MANUAL MODEL SR20

15 Jun 2010

B. Primary Structural Components

The airplane is constructed primarily of composite materials composed of fiberglass, carbon, epoxy

resin, and foam core. Each component uses a combination of construction methods, employing vary-

ing ply thicknesses to achieve the necessary strength for component sections with differing load

requirements. Primary structural components include: fuselage, wing, vertical stabilizer, and horizontal

stabilizer. For additional information pertaining to the structural components listed below, see the refer-

enced Chapter following each component description.

(1) Fuselage

The fuselage is a fiberglass/epoxy structure. The skins form a monocoque shell with the left and

right halves bonded together. The main section of the fuselage is reinforced by a rollcage struc-

ture that supports loads in case of a rollover. The rollover structure also contains side longerons

to support bending loads in the fuselage. In addition, the fuselage contains a floor structure and

floor longerons as well as bulkheads to add stability. Forward and aft spars as well as two ribs

support the empennage. (Refer to 53-00)

(2) Wing

The wing is a fiberglass/epoxy, bonded structure consisting of a main spar, aft shear webs, six-

teen main ribs, fourteen leading edge ribs, upper and lower skins, and two wing tips. (Refer to

57-00)

(3) Vertical Stabilizer

The vertical stabilizer consists of two C-channel spars fabricated from fiberglass/epoxy. Two ribs

are bonded to the spars and the right and left fuselage skins cover the ribs and spars to form a

two cell box beam structure that resists bending and torsion created by wind gust and aircraft

maneuvers. The vertical stabilizer is structurally bonded to the fuselage. (Refer to 55-30)

(4) Horizontal Stabilizer

The horizontal stabilizer is a fiberglass/epoxy composite assembly composed of sandwich skins

bonded to ribs and spars. The horizontal stabilizer is structurally bonded to the fuselage. (Refer

to 55-10)

CIRRUS AIRPLANE MAINTENANCE MANUAL MODEL SR20

51-00

Page 5

All

EFFECTIVITY:

C. Construction Methods

Construction methods used in primary structural components are described below:

(1) Secondary Bond

Composed of paste adhesive, secondary bonds are used most commonly at primary structural

joints to bond previously cured composite parts together. For example, the spar-to-ribs bond

forming the torque box is a secondary bond.

(2) Solid Laminate

Composed of fiberglass and/or carbon, and epoxy, solid laminates are used where thinner con-

struction is required at lightly loaded areas, such as aft shear webs and most ribs.

(3) Sandwich Construction

Composed of fiberglass and/or carbon, and epoxy composite layers encasing closed-cell foam

core, sandwich construction stabilizes both layers to prevent buckling in more heavily loaded

areas, such as wing skins, bulkheads, floors, longerons, and ribs.

D. Metal Components - Corrosion Control

Corrosion is the deterioration of metal by chemical or electrochemical attack. Water which is allowed to

remain on the aircraft and industrial pollution are the major causes of corrosion in aircraft. The two

general types of corrosion are Direct chemical attack. (i.e. spilled battery acid) and Electrochemical

attack which requires a medium. (usually water)

(1) Forms of Corrosion

Contact Cirrus Design for disposition. (Refer to AMM-Intro-)

(2) Conditions Affecting Corrosion

Contact Cirrus Design for disposition. (Refer to AMM-Intro-)

19 Sep 2017

51-00

Page 6

All

EFFECTIVITY:

CIRRUS AIRPLANE MAINTENANCE MANUAL MODEL SR20

15 Jun 2010

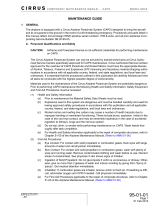

E. Airframe Zone Diagrams (See Figure 51-001), (See Figure 51-002)

To aid the repair technician in determining the structural criticality of each damage site, the following

zone diagrams identify original ply lay-up sections, composite repair zones, no-repair zones, and areas

with embedded expanded metal mesh (EMM) used in the electrical bonding of the aircraft.

CAUTION: Contact Cirrus Design before attempting to repair any composite structure within the

shaded no-repair zones. (Refer to AMM-Intro-)

CIRRUS AIRPLANE MAINTENANCE MANUAL MODEL SR20

51-00

Page 7

All

EFFECTIVITY:

Figure 51-001

Airframe Zone Diagrams Legend and Example Data

1:1 wet-lay repair plies are acceptable on engine cowling, main/nose landing gear fairings, wing tips, and wing root fairings.

NOTE

Repair plies are laid up alternately +45° and -45° from the 0° reference unless orientation is specifically defined in this section or as

a part of a Cirrus authorized field repair instruction.

The 0° reference line runs parallel to WL100 for the fuselage, perpendicular to WL100 for the wing skin, and the horizontal stabilizer

skin.

If no repair ply quantity is indicated, install twice as many plies as original lay-up.

Generally, the thickness of one ply is 0.008 - 0.010 inch (0.203 - 0.254 mm). To verify, or if no value is found in the ply lay-up tables,

determine ply count by dividing measured laminate thickness by 0.009 inch (0.229 mm).

EXTERIOR FINISH

CORE

MATERIAL

3RD INNER PLY (+45°)

2ND INNER PLY (-45°)

1ST INNER PLY (+45°)

3RD OUTER PLY (+45°)

2ND OUTER PLY (-45°)

1ST OUTER PLY (+45°)

SR20_MM51_1204E

2

TYPICAL SANDWICH CONSTRUCTION LAY-UP

PLY LAY-UP TABLE

EXTERIOR FINISH

6TH PLY (-45°)

5TH PLY (+45°)

4TH PLY (-45°)

3RD PLY (+45°)

2ND PLY (-45°)

1ST PLY (+45°)

TYPICAL SOLID LAMINATE LAY-UP

1

6

---

1

Ply Only

Quantity

Inner Ply

Quantity

Core Material

Thickness

inches (mm)

Outer Ply

Quantity

Reference

Number

-

3

0.375 (9.525)

32

Ply Only

Quantity

Inner Ply

Quantity

Core Material

Thickness

inches (mm)

Outer Ply

Quantity

Reference

Number

FS

100.0

WL 100.0

Lightning Protection

No Repair Area on

Lightning Protection

No Repair Area

LEGEND

Bond Line

It is not permissible to place repair laminations over Expanded Metal Mesh (EMM). EMM must be removed sufficiently to

accommodate the repair and replaced after the repair has been fully cured and inspected.

01 May 2012

51-00

Page 8

Serials 1005 thru 2015

EFFECTIVITY:

CIRRUS AIRPLANE MAINTENANCE MANUAL MODEL SR20

19 Sep 2010

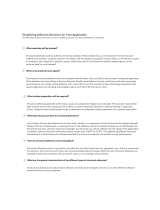

Figure 51-002

Airframe Zone Diagrams - Serials 1005 thru 2015 (1 of 29)

45°

0°

-45°

90°

45°

0°

-45°

90°

SR20_MM51_1906C

-

-

9

-

-

4

2

-

1

2

0.250 (6.350)

0.250 (6.350)

-

0.250 (6.350)

0.375 (9.525)

4

2

-

2

2

12

11

10

9

8

Ply Only

Quantity

Inner Ply

Quantity

Core Material

Thickness

inches (mm)

Outer Ply

Quantity

Reference

Number

10

8

-

-

4

6

-

-

3

1

-

-

-

-

0.375 (9.525)

0.375 (9.525)

-

-

-

-

3

2

-

-

6

5

4

3

2

1

Ply Only

Quantity

Inner Ply

Quantity

Core Material

Thickness

inches (mm)

Outer Ply

Quantity

Reference

Number

FS

226.0

FS

296.0

FS

260.0

FS

256.0

FS 340

FS 320

FS 300

FS 280

FS 260

FS 240

FS 220

FS 200

FS 180

FS 160

FS 140

FS 120

FS 100

12

4

5

1

11

2

11

2

6

12

11

8

5

11

11

5

11

6

5

13

14

1

FS

282.5

FS

191.0

FS

202.0

FS

100.0

FS

228.0

FS

281.0

FS

235.0

8

7

5

8

9

FS

186.0

FS

202.0

FS

100.0

4

1

8

1

2

9

2

11

6

4

10

3

1

4

5

8

8

Serials 1423 thru 2015.

RIGHT SIDE VIEW FUSELAGE

12

---

7

-

4

0.250 (6.350)

4

13

-

5

0.375 (9.525)

5

14

WL 140.0

WL 130.0

WL 120.0

WL 110.0

WL 100.0

WL 90.0

WL 80.0

WL 70.0

WL 150.0

WL 160.0

Serials 1005 thru 1422.

WL 140.0

WL 130.0

WL 120.0

WL 110.0

WL 100.0

WL 90.0

WL 80.0

WL 70.0

WL 150.0

WL 160.0

Lightning Protection

No Repair Area on

Lightning Protection

LEGEND

Bond Line

No Repair Area *

Fuselage flange repair allowed per

horizontal stabilizer removal, refer to 55-10.

NOTE

CIRRUS AIRPLANE MAINTENANCE MANUAL MODEL SR20

51-00

Page 9

Serials 2016 & subs

EFFECTIVITY:

Figure 51-002

Airframe Zone Diagrams - Serials 2016 & subs (2 of 29)

45°

0°

-45°

90°

SR20_MM51_3378

-

-

9

-

-

4

2

-

1

2

0.250 (6.350)

0.250 (6.350)

-

0.250 (6.350)

0.375 (9.525)

4

2

-

2

2

12

11

10

9

8

Ply Only

Quantity

Inner Ply

Quantity

Core Material

Thickness

inches (mm)

Outer Ply

Quantity

Reference

Number

10

8

-

-

4

6

-

-

3

1

-

-

-

-

0.375 (9.525)

0.375 (9.525)

-

-

-

-

3

2

-

-

6

5

4

3

2

1

Ply Only

Quantity

Inner Ply

Quantity

Core Material

Thickness

inches (mm)

Outer Ply

Quantity

Reference

Number

FS 340

FS 320

FS 300

FS 280

FS 260

FS 240

FS 220

FS 200

FS 180

FS 160

FS 140

FS 120

FS 100

FS

228.0

FS

281.0

FS

235.0

8

7

5

8

9

FS

186.0

FS

202.0

FS

100.0

4

1

8

1

2

9

2

11

6

4

10

3

1

4

5

8

8

Serials 2016 thru 2029.

RIGHT SIDE VIEW FUSELAGE

12

---

7

-

4

0.250 (6.350)

4

13

-

5

0.375 (9.525)

5

14

WL 140.0

WL 130.0

WL 120.0

WL 110.0

WL 100.0

WL 90.0

WL 80.0

WL 70.0

WL 150.0

WL 160.0

Lightning Protection

No Repair Area on

Lightning Protection

LEGEND

Bond Line

45°

0°

-45°

90°

FS

228.0

FS

281.0

FS

235.0

8

7

5

8

9

FS

186.0

FS

202.0

FS

100.0

4

1

8

1

2

9

2

11

6

4

10

3

1

4

5

8

8

Serials 2030 & subs.

WL 140.0

WL 130.0

WL 120.0

WL 110.0

WL 100.0

WL 90.0

WL 80.0

WL 70.0

WL 150.0

WL 160.0

No Repair Area

Fuselage flange repair allowed per

horizontal stabilizer removal, refer to 55-10.

NOTE

19 Sep 2010

51-00

Page 10

Serials 1005 thru 2015

EFFECTIVITY:

CIRRUS AIRPLANE MAINTENANCE MANUAL MODEL SR20

19 Sep 2010

Figure 51-002

Airframe Zone Diagrams - Serials 1005 thru 2015 (3 of 29)

SR20_MM51_1908C

FS

224.0

FS

193.0

FS

203.0

1

2

313

3

1

3

9

10

1

6

9

6

5

1

1

FS 100

FS 120

FS 140

FS 160

FS 180

FS 200

FS 220

FS 240

FS 260

FS 280

FS 300

FS 320

FS 340

4

8

7

4

FS

100.0

FS

282.5

FS

281.0

FS

230.5

FS

202.0

FS

100.0

FS

238.0

4

3

5

3

11

5

2

1

3

3

13

1

3

2

6

12

6

9

12

Lightning Protection

No Repair Area on

Lightning Protection

LEGEND

-

-

-

-

-

1

1

4

2

4

0.250 (6.350)

0.375 (9.525)

0.250 (6.350)

0.250 (6.350)

0.375 (9.525)

2

2

4

2

4

12

11

10

9

8

Ply Only

Quantity

Inner Ply

Quantity

Core Material

Thickness

inches (mm)

Outer Ply

Quantity

Reference

Number

4

-

6

-

10

8

-

3

-

2

-

-

-

0.375 (9.525)

-

0.375 (9.525)

-

-

-

3

-

2

-

-

6

5

4

3

2

1

Ply Only

Quantity

Inner Ply

Quantity

Core Material

Thickness

inches (mm)

Outer Ply

Quantity

Reference

Number

LEFT SIDE VIEW FUSELAGE

-

5

0.375 (9.525)

57

12

---

13

WL 140.0

WL 130.0

WL 120.0

WL 110.0

WL 100.0

WL 90.0

WL 80.0

WL 70.0

WL 150.0

WL 160.0

WL 140.0

WL 130.0

WL 120.0

WL 110.0

WL 100.0

WL 90.0

WL 80.0

WL 70.0

WL 150.0

WL 160.0

Bond Line

Serials 1423 thru 2015.

Serials 1005 thru 1422.

45°

0°

-45°

90°

45°

0°

-45°

90°

No Repair Area *

Fuselage flange repair allowed per

horizontal stabilizer removal, refer to 55-10.

*NOTE

CIRRUS AIRPLANE MAINTENANCE MANUAL MODEL SR20

51-00

Page 11

Serials 2016 & subs

EFFECTIVITY:

Figure 51-002

Airframe Zone Diagrams - Serials 2016 & subs (4 of 29)

45°

0°

-45°

90°

FS

281.0

FS

230.5

FS

202.0

FS

100.0

FS

238.0

SR20_MM51_3379

FS 100

FS 120

FS 140

FS 160

FS 180

FS 200

FS 220

FS 240

FS 260

FS 280

FS 300

FS 320

FS 340

FS

281.0

FS

230.5

FS

202.0

FS

100.0

FS

238.0

4

3

5

3

11

5

2

1

3

3

13

1

3

2

6

12

6

9

12

Lightning Protection

No Repair Area on

Lightning Protection

LEGEND

-

-

-

-

-

1

1

4

2

4

0.250 (6.350)

0.375 (9.525)

0.250 (6.350)

0.250 (6.350)

0.375 (9.525)

2

2

4

2

4

12

11

10

9

8

Ply Only

Quantity

Inner Ply

Quantity

Core Material

Thickness

inches (mm)

Outer Ply

Quantity

Reference

Number

4

-

6

-

10

8

-

3

-

2

-

-

-

0.375 (9.525)

-

0.375 (9.525)

-

-

-

3

-

2

-

-

6

5

4

3

2

1

Ply Only

Quantity

Inner Ply

Quantity

Core Material

Thickness

inches (mm)

Outer Ply

Quantity

Reference

Number

LEFT SIDE VIEW FUSELAGE

-

5

0.375 (9.525)

57

12

---

13

WL 140.0

WL 130.0

WL 120.0

WL 110.0

WL 100.0

WL 90.0

WL 80.0

WL 70.0

WL 150.0

WL 160.0

Bond Line

Serials 2030 & subs.

Serials 2016 thru 2029.

45°

0°

-45°

90°

WL 140.0

WL 130.0

WL 120.0

WL 110.0

WL 100.0

WL 90.0

WL 80.0

WL 70.0

WL 150.0

WL 160.0

No Repair Area

Fuselage flange repair allowed per

horizontal stabilizer removal, refer to 55-10.

NOTE

4

3

5

3

11

5

2

1

3

3

13

1

3

2

6

12

6

9

12

19 Sep 2010

51-00

Page 12

Serials 1005 thru 2015

EFFECTIVITY:

CIRRUS AIRPLANE MAINTENANCE MANUAL MODEL SR20

19 Sep 2010

Figure 51-002

Airframe Zone Diagrams - Serials 1005 thru 2015 (5 of 29)

SR20_MM51_1910C

Lightning Protection

No Repair Area on

Lightning Protection

No Repair Area

LEGEND

-

-

-

12

4

1

2

-

0.375 (9.525)

0.250 (6.350)

0.375 (9.525)

-

4

2

2

-

11

10

9

8

7

Ply Only

Quantity

Inner Ply

Quantity

Core Material

Thickness

inches (mm)

Outer Ply

Quantity

Reference

Number

8

-

-

4

6

-

3

1

-

-

-

0.375 (9.525)

0.375 (9.525)

-

-

-

3

2

-

-

5

4

3

2

1

Ply Only

Quantity

Inner Ply

Quantity

Core Material

Thickness

inches (mm)

Outer Ply

Quantity

Reference

Number

10

---

6

-

5

0.375 (9.525)

5

BL 0.0

BL 10

BL 20

BL 30

BL 10

BL 20

BL 30

BL 0.0

BL 10

BL 20

BL 30

BL 10

BL 20

BL 30

1

8

1

8

3

3

8

1

8

1

4

4

2

9

9

Serials 1423 thru 2015.

Serials 1005 thru 1422.

FS 100

FS 120

FS 140

FS 160

FS 180

FS 200

FS 220

FS 240

FS 260

FS 280

FS 300

FS 320

FS 340

TOP VIEW FUSELAGE

5

1

4

10

4

8

8

4

11

4

1

5

45°

0°

-45°

90°

45°

0°

-45°

90°

For fuselage flange repairs at horizontal

stabilizer, refer to 53-10.

NOTE

CIRRUS AIRPLANE MAINTENANCE MANUAL MODEL SR20

51-00

Page 13

Serials 2016 & subs

EFFECTIVITY:

Figure 51-002

Airframe Zone Diagrams - Serials 2016 & subs (6 of 29)

SR20_MM51_3380

Lightning Protection

No Repair Area on

Lightning Protection

No Repair Area

LEGEND

-

-

12

1

2

-

0.250 (6.350)

0.375 (9.525)

-

2

2

-

9

8

7

Ply Only

Quantity

Inner Ply

Quantity

Core Material

Thickness

inches (mm)

Outer Ply

Quantity

Reference

Number

8

-

-

4

6

-

3

1

-

-

-

0.375 (9.525)

0.375 (9.525)

-

-

-

3

2

-

-

5

4

3

2

1

Ply Only

Quantity

Inner Ply

Quantity

Core Material

Thickness

inches (mm)

Outer Ply

Quantity

Reference

Number

10

---

6

BL 0.0

BL 10

BL 20

BL 30

BL 10

BL 20

BL 30

1

8

1

8

3

3

8

1

8

1

4

4

2

9

9

Serials 2016 thru 2029.

FS 100

FS 120

FS 140

FS 160

FS 180

FS 200

FS 220

FS 240

FS 260

FS 280

FS 300

FS 320

FS 340

TOP VIEW FUSELAGE

45°

0°

-45°

90°

For fuselage flange repairs at horizontal

stabilizer, refer to 53-10.

NOTE

1

8

1

8

3

3

8

1

8

1

4

4

2

9

9

BL 0.0

BL 10

BL 20

BL 30

BL 10

BL 20

BL 30

Serials 2030 & subs.

45°

0°

-45°

90°

19 Sep 2010

51-00

Page 14

Serials 1005 thru 2015

EFFECTIVITY:

CIRRUS AIRPLANE MAINTENANCE MANUAL MODEL SR20

19 Sep 2010

Figure 51-002

Airframe Zone Diagrams - Serials 1005 thru 2015 (7 of 29)

8

5

8

5

8

8

11

11

8

10

8

10

8

5

8

5

8

8

1

9

3

1

8

2

6

4

4

3

8

5

5

5

4

7

7

Serials 1005 thru 1422.

SR20_MM51_1912B

FS 100

FS 120

FS 140

FS 160

FS 180

FS 200

FS 220

FS 240

FS 260

FS 280

FS 300

FS 320

FS 340

Lightning Protection

No Repair Area on

Lightning Protection

No Repair Area

LEGEND

-

-

-

12

2

5

2

-

0.250 (6.350)

0.375 (9.525)

0.375 (9.525)

-

2

5

2

-

11

10

9

8

7

Ply Only

Quantity

Inner Ply

Quantity

Core Material

Thickness

inches (mm)

Outer Ply

Quantity

Reference

Number

8

-

-

4

6

-

3

1

-

-

-

0.375 (9.525)

0.375 (9.525)

-

-

-

3

2

-

-

5

4

3

2

1

Ply Only

Quantity

Inner Ply

Quantity

Core Material

Thickness

inches (mm)

Outer Ply

Quantity

Reference

Number

BOTTOM VIEW FUSELAGE

10

---

6

-

4

0.375 (9.525)

4

BL 0.0

BL 10

BL 20

BL 30

BL 10

BL 20

BL 30

BL 0.0

BL 10

BL 20

BL 30

BL 10

BL 20

BL 30

Bond Line

Serials 1423 thru 2015.

45°

0°

-45°

90°

45°

0°

-45°

90°

CIRRUS AIRPLANE MAINTENANCE MANUAL MODEL SR20

51-00

Page 15

Serials 2016 & subs

EFFECTIVITY:

Figure 51-002

Airframe Zone Diagrams - Serials 2016 & subs (8 of 29)

8

8

3

3

8

8

8

8

1

3

1

8

2

6

4

4

3

8

5

4

7

7

SR20_MM51_3381

FS 100

FS 120

FS 140

FS 160

FS 180

FS 200

FS 220

FS 240

FS 260

FS 280

FS 300

FS 320

FS 340

Lightning Protection

No Repair Area on

Lightning Protection

No Repair Area

LEGEND

-

12

2

-

0.375 (9.525)

-

2

-

8

7

Ply Only

Quantity

Inner Ply

Quantity

Core Material

Thickness

inches (mm)

Outer Ply

Quantity

Reference

Number

8

-

-

4

6

-

3

1

-

- -

0.375 (9.525)

0.375 (9.525)

-

- -

3

2

-

-

5

4

3

2

1

Ply Only

Quantity

Inner Ply

Quantity

Core Material

Thickness

inches (mm)

Outer Ply

Quantity

Reference

Number

BOTTOM VIEW FUSELAGE

10

---

6

BL 0.0

BL 10

BL 20

BL 30

BL 10

BL 20

BL 30

Bond Line

Serials 2016 thru 2029.

45°

0°

-45°

90°

5

5

5

5

5

5

5

5

8

8

7

7

5

4

8

8

45°

0°

-45°

90°

1

BL 0.0

BL 10

BL 20

BL 30

BL 10

BL 20

BL 30

Serials 2030 & subs.

1

2

6

4

4

19 Sep 2010

51-00

Page 16

Serials 1005 thru 1885

EFFECTIVITY:

CIRRUS AIRPLANE MAINTENANCE MANUAL MODEL SR20

19 Sep 2010

Figure 51-002

Airframe Zone Diagrams - Serials 1005 thru 1885 (9 of 29)

Serials 1005 thru 1877, 1879 thru 1885.

SR20_MM51_2128B

9

10

2

7

4

6

---

1

Ply Only

Quantity

Inner Ply

Quantity

Core Material

Thickness

inches (mm)

Outer Ply

Quantity

Reference

Number

4

---

2

4

---

3

Repair Plies

To Original

Lay-Up

-

2

0.375 (9.525)

24

Ply Only

Quantity

Inner Ply

Quantity

Core Material

Thickness

inches (mm)

Outer Ply

Quantity

Reference

Number

5

Repair Plies

To Original

Lay-Up

9

---

1.5 to 1.0

1.5 to 1.0

2.0 to 1.0

2.0 to 1.0

2.5 to 1.0

LEFT WING TOP VIEW SHOWN

RIGHT WING TOP OPPOSITE

5

8

WS

20

WS

40

WS

60

WS

80

WS

100

WS

120

WS

140

WS

160

WS

180

WS

200

3

1

8

6

45°

0°

-45°

90°

Bond Line

LEFT WING CUFF TOP VIEW SHOWN

RIGHT WING CUFF TOP OPPOSITE

WS

200

WS

180

WS

160

WS

140

WS

120

45°

0°

-45°

90°

11

3

WING SKIN

(REF)

68

---

3.0 to 1.0

6

---

7

6

---

8

-

4

0.375 (9.525)

49

-

2

0.375 (9.525)

4

10

11

8

---

1.0 to 1.0

2.0 to 1.0

2.0 to 1.0

2.5 to 1.0

2.0 to 1.0

No Repair Area on

Lightning Protection

No Repair Area

Lightning Protection

LEGEND

CIRRUS AIRPLANE MAINTENANCE MANUAL MODEL SR20

51-00

Page 17

Serials 1005 thru 1885

EFFECTIVITY:

Figure 51-002

Airframe Zone Diagrams - Serials 1005 thru 1885 (10 of 29)

SR20_MM51_1209D

Ply Only

Quantity

Inner Ply

Quantity

Core Material

Thickness

inches (mm)

Outer Ply

Quantity

Reference

Number

4

---

1

4

---

2

-

2

0.375 (9.525)

23

-

3

0.375 (9.525)

24

Repair Plies

To Original

Lay-Up

-

2

0.375 (9.525)

2

8

7

Ply Only

Quantity

Inner Ply

Quantity

Core Material

Thickness

inches (mm)

Outer Ply

Quantity

Reference

Number

8

---

9

11

Repair Plies

To Original

Lay-Up

5

---

5

6

---

12

-

1

0.250 (6.350)

2

-

2

0.250 (6.350)

28

---

6

1.5 to 1.0

2.0 to 1.0

1.5 to 1.0

2.0 to 1.0

2.0 to 1.0

2.5 to 1.0

2.0 to 1.0

1.5 to 1.0

2.0 to 1.0

2.0 to 1.0

2.0 to 1.0

LEFT WING BOTTOM VIEW SHOWN

RIGHT WING BOTTOM OPPOSITE

WS

20

WS

40

WS

60

WS

80

WS

100

WS

120

WS

140

WS

160

WS

180

WS

200

3

4

6

7

5

2

8

1

Lightning Protection

Bond Line

LEGEND

WING SKIN

(REF)

12

11

10

2

9

90°

-45°

0°

45°

9

LEFT WING CUFF BOTTOM VIEW SHOWN

RIGHT WING CUFF BOTTOM OPPOSITE

45°

0°

-45°

90°

WS

200

WS

180

WS

160

WS

140

WS

120

10

8

---

2.0 to 1.0

5

7

2

Serials 1005 thru 1877, 1879 thru 1885.

19 Sep 2010

51-00

Page 18

Serials 1886 & subs

EFFECTIVITY:

CIRRUS AIRPLANE MAINTENANCE MANUAL MODEL SR20

19 Sep 2010

Figure 51-002

Airframe Zone Diagrams - Serials 1886 & subs (11 of 29)

-

3

1.5 to 1.0

8

0.375 (9.525)

4

14

2

1.5 to 1.0

---

-

4

2.0 to 1.0

4

0.375 (9.525)

4

-

5

2.0 to 1.0

6

0.335 (8.509)

6

76

1.5 to 1.0

---

-

7

2.0 to 1.0

2

0.375 (9.525)

4

-

8

1.5 to 1.0

1

0.375 (9.525)

4

3

---

10

1.5 to 1.0

-

1

0.375 (9.525)

2

11

2.0 to 1.0

-

2

0.375 (9.525)

2

12

2.0 to 1.0

4

---

13

2.0 to 1.0

6

---

14

2.0 to 1.0

8

---

15

2.0 to 1.0

-

1

0.125 (3.175)

2

16

1.5 to 1.0

-

3

0.375 (9.525)

2

17

1.5 to 1.0

6

17

10

12

11

12

11

13

15

13

6

13

16

12

11

4

9

8

3

10

15

10

11

7

15

1

2

15

14

4

5

LEFT WING TOP VIEW SHOWN

RIGHT WING TOP OPPOSITE

Lightning Protection

Bond Line

No Repair Area on

Lightning Protection

No Repair Area

LEGEND

SR20_MM51_2738A

Lightning Protection

Bond Line

No Repair Area on

Lightning Protection

No Repair Area

LEGEND

Serials 1878, 1886 & subs.

WS

20

WS

40

WS

60

WS

80

WS

120

WS

100

WS

140

WS

160

WS

180

WS

200

WS

220

12

1

Ply Only

Quantity

Inner Ply

Quantity

Core Material

Thickness

inches (mm)

Outer Ply

Quantity

Reference

Number

5

---

9

Repair Plies

To Original

Lay-Up

Ply Only

Quantity

Inner Ply

Quantity

Core Material

Thickness

inches (mm)

Outer Ply

Quantity

Reference

Number

Repair Plies

To Original

Lay-Up

1.5 to 1.0 1.5 to 1.0

---

45°

0°

-45°

90°

CIRRUS AIRPLANE MAINTENANCE MANUAL MODEL SR20

51-00

Page 19

Serials 1886 & subs

EFFECTIVITY:

Figure 51-002

Airframe Zone Diagrams - Serials 1886 & subs (12 of 29)

83

2.0 to 1.0

---

-

2

2.0 to 1.0

5

0.375 (9.525)

3

64

1.5 to 1.0

---

45

1.5 to 1.0

---

-

6

1.5 to 1.0

3

0.375 (9.525)

3

37

1.0 to 1.0

---

-

8

2.0 to 1.0

-

0.375 (9.525)

2

12

1

2.0 to 1.0

---

-

1

0.375 (9.525)

2

10

1.5 to 1.0

9

---

11

1.0 to 1.0

-

3

0.375 (9.525)

2

12

2.0 to 1.0

5

---

13

2.0 to 1.0

-

2

0.225 (5.715)

29

2.0 to 1.0

Ply Only

Quantity

Inner Ply

Quantity

Core Material

Thickness

inches (mm)

Outer Ply

Quantity

Reference

Number

Repair Plies

To Original

Lay-Up

Ply Only

Quantity

Inner Ply

Quantity

Core Material

Thickness

inches (mm)

Outer Ply

Quantity

Reference

Number

Repair Plies

To Original

Lay-Up

Lightning Protection

Bond Line

No Repair Area on

Lightning Protection

No Repair Area

LEGEND

Serials 1878, 1886 & subs.

3

9

8

8

8

7

9

4

3

5

8

5

13

3

8

5

4

3

8

3

7

10

8

5

4

11

3

4

5

6

5

13

1

4

2

1

3

7

6

3

6

12

WS

220

WS

200

WS

180

WS

160

WS

120

WS

140

WS

100

WS

80

WS

60

WS

40

WS

20

LEFT WING BOTTOM VIEW

SR20_MM51_2739

45°

0°

-45°

90°

19 Sep 2010

51-00

Page 20

Serials 1886 & subs

EFFECTIVITY:

CIRRUS AIRPLANE MAINTENANCE MANUAL MODEL SR20

19 Sep 2010

Figure 51-002

Airframe Zone Diagrams - Serials 1886 & subs (13 of 29)

83

2.0 to 1.0

---

-

2

2.0 to 1.0

5

0.375 (9.525)

3

64

1.5 to 1.0

---

45

1.5 to 1.0

---

-

6

1.5 to 1.0

3

0.375 (9.525)

3

37

1.0 to 1.0

---

-

8

2.0 to 1.0

2

0.375 (9.525)

2

12

1

2.0 to 1.0

---

-

1

0.375 (9.525)

2

10

1.5 to 1.0

9

---

11

1.0 to 1.0

-

3

0.375 (9.525)

2

12

2.0 to 1.0

5

---

13

2.0 to 1.0

-

2

0.225 (5.715)

29

2.0 to 1.0

Lightning Protection

Bond Line

No Repair Area on

Lightning Protection

No Repair Area

LEGEND

Lightning Protection

Bond Line

No Repair Area on

Lightning Protection

No Repair Area

LEGEND

Serials 1878, 1886 & subs.

Ply Only

Quantity

Inner Ply

Quantity

Core Material

Thickness

inches (mm)

Outer Ply

Quantity

Reference

Number

Repair Plies

To Original

Lay-Up

Ply Only

Quantity

Inner Ply

Quantity

Core Material

Thickness

inches (mm)

Outer Ply

Quantity

Reference

Number

Repair Plies

To Original

Lay-Up

3

7

8

9

8

7

8

3

5

4

9

5

8

4

5

8

3

3

5

10

8

8

4

11

3

1

4

4

5

6

13

5

8

2

1

3

7

6

13

3

12

63

RIGHT WING BOTTOM VIEW

SR20_MM51_2740A

45°

0°

-45°

90°

WS

20

WS

40

WS

60

WS

80

WS

120

WS

100

WS

140

WS

160

WS

180

WS

200

WS

220

/