Page is loading ...

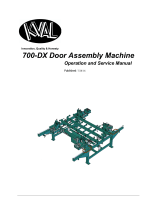

700-C QUICK START700-C QUICK START

Power-Down

Power-UP

Verify Area is safe, power and air are applied, E-Stops

are out and Fence Gates are closed.

1. At the Electrical Box, turn the Electrical Dis-

connect to the ON position.

2. Turn the Control Circuit Switch to the ON

position. (Approximately 3 minute boot-up)

Light Tower lights should all be green.

See reverse side for a Light Tower Description.

1. Turn the Control Circuit Switch to the OFF

position.

2. Turn the Electrical Disconnect to the OFF

position on the Electrical Cabinet.

Note: Some of these setings are options and may not be

located on your machine.

• Ensure the proper guns are enabled and staples are

loaded.

• Adjust the machine for the desired Door Width.

• Adjust the machine for Door Lenth.

• Adjust the machine for Jamb Width.

• Adjust the machine for Jamb Thickness.

Mechanical Setup

Before processing the door, set-up the following mechani-

cal adjustments.

Note: See the back of this Quick Stat for information on

these setings.

Main Panel Controls

Stage the door for framing.

1. Inset the Header Jamb

→Identiy the hand of the door. (See back

for hand location.)

→Patially pull the door into the 700-C.

→Place the header jamb into Head Jamb

Clamp.

2. Inset the Strike Jamb

→Place strike jamb into the machine and

pull the door in all the way in.

→Make sure the strike jamb aligns to the

header.

→Flip the hinge jamb down.

→Roughly align the hinge jamb to the

header jamb.

Power Controls

Reset.

• Brings 700- C to stating position.

Turn On or OFF Staple Guns

Select Jamb Type (Reg or Split)

Select the Staple Syle Se-

quence.

• Select A = 0-3.

• Select B= 4-7.

• Sequence REV and FWD .

• Rev= Step back Clear Hands

Control.

• FWD = Go foward from Rev Step.

Width Butons:

• Select Jamb Width-Butons

• Select Door Width-Black buton

control. Manually move fence to

door width position.

Stage the Door

Frame the Door

1. Bring in the Movable Heads and Header Clamps

→Press both Hands Free Butons simultaneously.

→The movable side staple guns and strike jamb clamps

move close to the door.

→The header and swing clamps extend.

→Staple guns and clamps are raised into position.

2. Drop Down the Door to Align

→Press both Hands Free Butons simultaneously.

→The infeed wheels lower to align the door to the header

and strike jambs.

3. Bring in the Fixed Heads

→Press both Hands Free Butons simultaneously.

→Fixed side staple guns move in.

4. Raise the Door and Frame into Stapling Position

→Press both Hands Free Butons simultaneously.

→Oufeed wheels raise the door into position.

→Botom jamb clamps rise, pushing the frame up from the

botom.

→End jamb clamps move in.

→Ensure that the door, header jamb, strike jamb are

clamped square.

5. Fire Staple Guns

→Press the let Hands Free Buton and the green Fire But-

ton simultaneously.

→Oufeed wheels move down and the swing clamps

retract.

→Staple guns ire to the programmed patern.

→Staple guns will ire when dropping down.

5a. Fire Nail Guns (Option)

→Press the right Hands Free Buton and the Yellow Fire

Buton simultaneously.

→Nail guns ire.

Note: The nail guns are an option and are not installed on all

700-C machines.

6. Unclamp the Door

→Press both Hands Free Butons simultaneously.

→All guns move away from the door.

→All clamps retract.

→Oufeed wheels move up.

→Manually move the door out of the 700-C.

7. Reset 700-C

→Press both Hands Free Butons simultaneously.

→700-C goes back to the initial stage.

→Last step before pulling in another door or shuting down

the machine.

Note: Pressing the Reset Buton on the Main Control Panel is

an alternate way to reset the 700-C.

Ater the door is pulled in and the hinge and strike jambs

are aligned, use the Hands Free controls to staple the

frame to the door.

If a step needs to be reversed, move the Main Control

panel Sequence switch to REV. Press the Hands Clear but-

tons to go back a step. Ater the issue is resolved, set the

Sequence switch to back to FWD and continue process-

ing the door.

Hands FreeHands Free

Hands FreeHands Free

Hands FreeHands Free

Hands FreeHands Free

Hands FreeHands Free

Hands FreeHands Free

Hands FreeHands Free

Hands FreeHands Free

Hands FreeHands Free

Green Fire ButtonGreen Fire Button

Yellow Fire ButtonYellow Fire Button

Hands FreeHands Free

AlignAlign

Staple Guns FiredStaple Guns Fired

1: Headers/Movable Fence In Close1: Headers/Movable Fence In Close

Nail Guns FiredNail Guns Fired

5a: Fire the Nail Guns5a: Fire the Nail Guns

7: Reset the 700-C7: Reset the 700-C

5: Fire the Staple Guns5: Fire the Staple Guns

6: Unclamp the Door and Frame6: Unclamp the Door and Frame

4:Raise the Door and Frame4:Raise the Door and Frame

3: Bring in the Fixed Head Side3: Bring in the Fixed Head Side

2: Align the Door2: Align the Door

Hands Free (X2)Hands Free (X2)

Download Manuals and Access Videos

htps://kvalinc.com/machine-suppot

At the web page, enter the 700-C serial

number in the search box. Access to the

manuals and videos will be available.

Hands Free (X2)Hands Free (X2)

Door Length Adjust

1. Pull out the pins located on the ends of the machine.

2. Move the 4 stops(2 per end) to the desired door lenth. (6’8”,7’0”, or

8’0”.)

3. Re-Inset pins to lock the stops in-place.

Mechanical Setup

High Voltage may cause injury or death. Trou-

bleshooting checks must be performed by a

Qualied Electrical Technician. (High voltage

contacts are located in the host machine)

Jamb Width Adjust

1. At the Main Control Panel, push the desired jamb width buton.

2. Ater the buton is pushed, the pneumatic suppot cylinders will

move to the select position.

3. The strike jamb is ready to load.

Door Width Adjust

1. Pull up the width adjust buton located on the main control panel or

the (optional) remote control panel. This will retract the pickle forks

freeing the movable fence for positioning.

2. Slide the movable fence until Pickle Fork is at the desired location on

the Collar Bar. The Pickle Forks have a 1.0” width equaling to 1.0” per

side for a total of 2.0”change in width.

3. Ater width is set, push the width adjust buton down to extend the

Pickle Fork.

Load Staple Guns

1. Open the Magazine Door: Press or slide the magazine release to open

the magazine. The release s located on the botom side of the maga-

zine. This will allow you to access the staple chamber.

2. Inset the Staples: Lit up the magazine cover. Slide a strip of staples

into the magazine with the legs of the staples facing downward.

Make sure the staples are aligned properly and it within the width

of the magazine.

3. Close the Magazine: Once the staples are inseted, close the mag-

azine by releasing the magazine release buton, lever, or latch. The

magazine should click or lock into place.

Pickle Fork

Jamb Thickness Adjustment

Step 1: Adjusting the Width

1. Locate the Width Adjust Shat.

2. Adjust the collars on the shat to accommodate the thick spacer:

3. Loosen the inner collar using the T-Handle to create space for the

thicker jambs.

4. Slide the outer collar against the collar bar bracket for a narrow

jamb or away from the bracket to allow space for the thick jamb

spacer.

5. Flip the thick jamb spacer into the created space.

6. Push the inner collar against the collar bar bracket and tighten it

using the T-handle.

Step 2: Spacer Adjustments at the Staple Heads

1. On all Staple Heads, lip the spacers in line with the carriage for

thick jambs.

Step 3: Stop Pin Adjustments

1. Locate the insetion point on the sides of both of the Fixed Side

Carriage Heads.

2. Remove the standard stop pin and inset it into the holder on

the frame next to the Carriage Head.

3. Replace with the designated thickness pin.

To revet to a thin jamb, reverse the above steps.

Flip SpacerFlip Spacer

Stop PinStop Pin

700-C_QS_MV101_Rev1

Light Position Categoy Descriptions

Machine Status

OFF (Clear): Machine not in operation.

White: Initializing

1 Flash: Waiting for all systems to initialize

Red: Machine Error

Solid: General Error

• 1 Flash: EtheCat Device not Ready to Run

• 3 Flashes: 24 VDC Power Error

Yellow: External Error

Solid: General Error

• 1 Flash: 3 Phase Voltage Error

Blue: Operator Status

Solid: Waiting for Operator

• 1 Flash: Reposition Door

Green: Machine is Operational

Control Power

O : No Control Power

ON (Green): 24 VDC Control Power ON

2

1

2 Light Tower Rev2

2

1

Both Lights Green- The Machine is Ready to Work

/