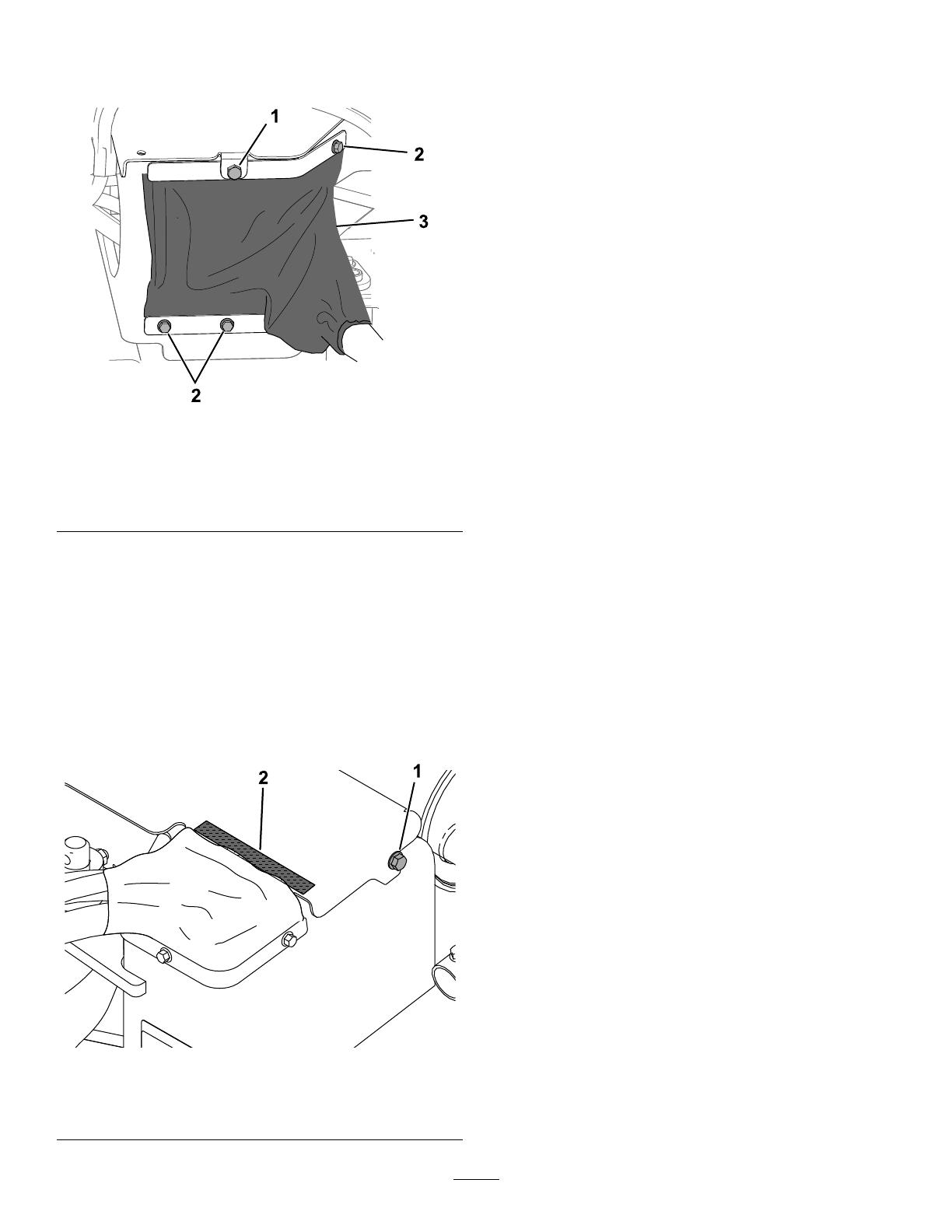

7.Securethebottomofthecoverusingthebottom

bracket,2bolts(3/8inchx1-1/4inch),and2

nuts(1/4inch)asshowninFigure13.

g309895

Figure13

1.Existingbolt(3/8inchx

1-1/4inch)

3.Cylindercover

2.Bolt(1/4x1inch)andnut

(1/4inch)

8.Placethehydrauliccoverontheframe,and

securethetopofthecylindercoverusingthe

topbracket,2bolts(5/16x1-1/4inch,previously

removed,and1/4inchx1-1/4inch)and1nut

(1/4inch)asshowninFigure13.

Note:Positionthetabonthehydrauliccover

overthetopbracket.

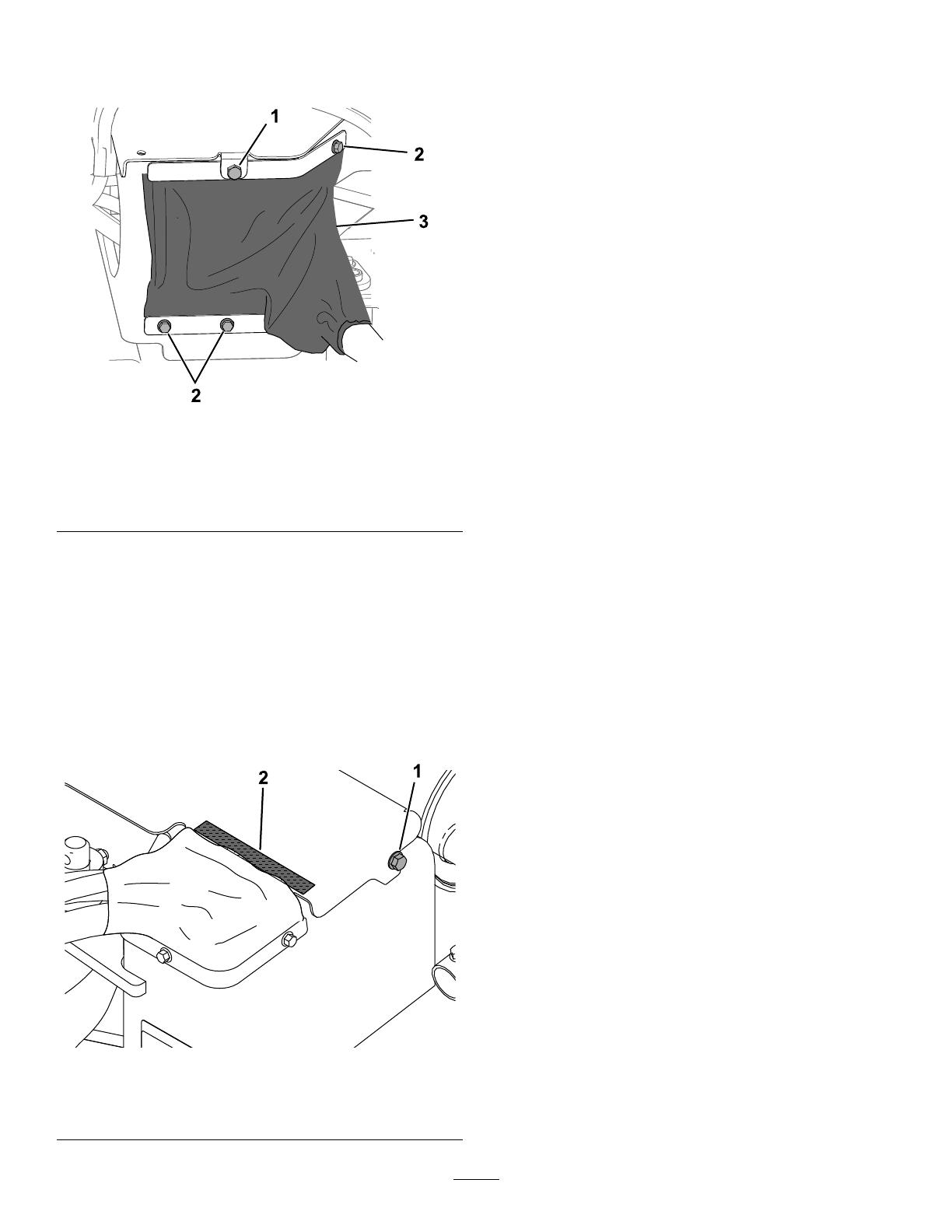

9.Securethehydrauliccoverusing1bolt(5/16

x1-1/4inch,previouslyremoved)asshownin

Figure14.

g323291

Figure14

1.Bolt(5/16x1-1/4inch)2.15.6cm(6-1/8inch)

fastenerstrip

10.Cleanthesurfaceofthehydrauliccoverwhere

youareadheringthefastenerstrip(Figure14).

11.Removethebackingfromtheremaininghook

andloopfastenerstripandadhereitonthe

hydrauliccover(Figure14).

12.Adherethehosecovertothefastenerstrip.

6