6.Aligntheholesinthecoverwiththeholesinthe

frame.Adherethecovertothehookandloop

fastenerstrips.

7.Securethebottomofthecoverusingthebottom

bracket,2bolts(3/8inchx1-1/4inch),and2

nuts(1/4inch)asshowninFigure11.

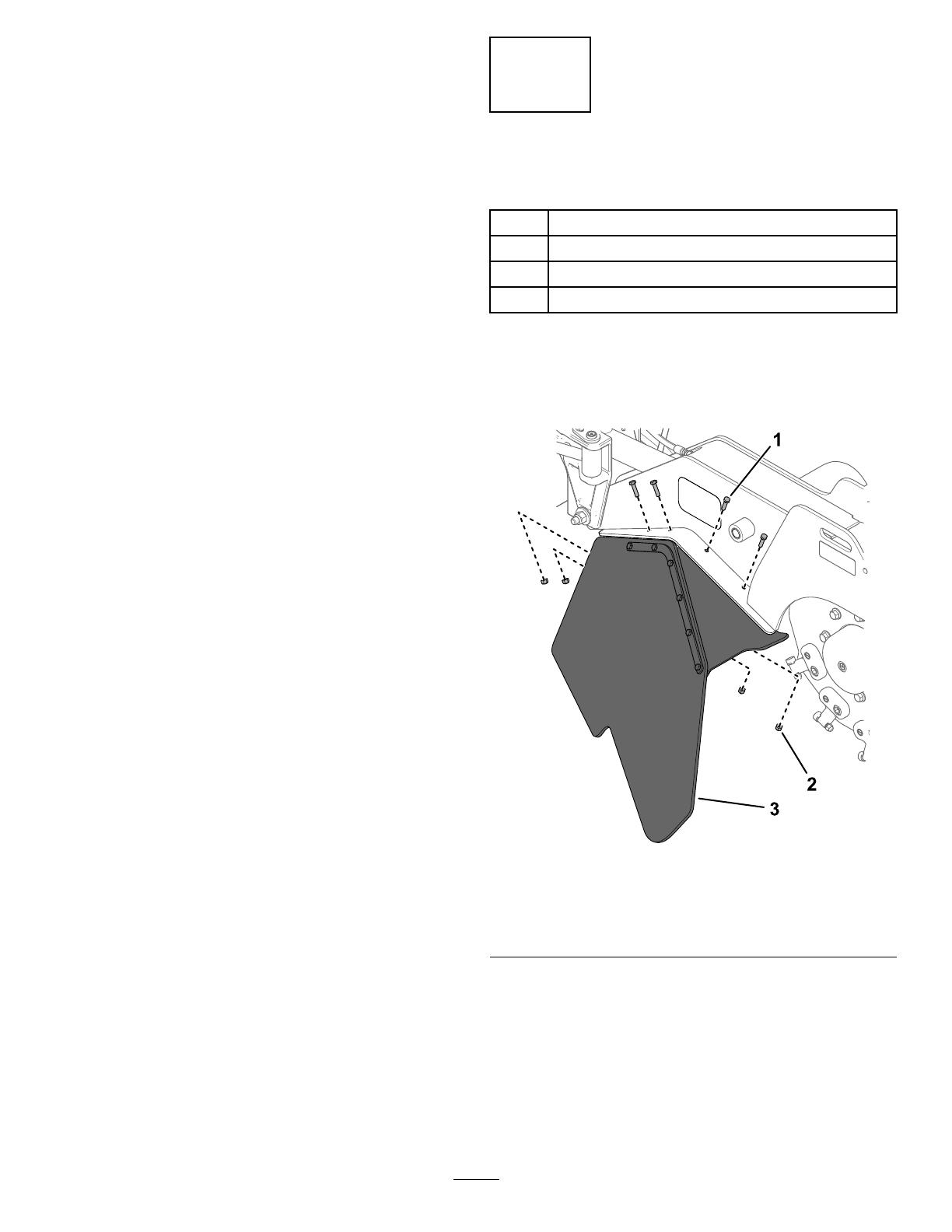

8.Placethehydrauliccoverontheframe,and

securethetopofthecylindercoverusingthe

topbracket,2bolts(5/16x1-1/4inch,previously

removed,and1/4inchx1-1/4inch)and1nut

(1/4inch)asshowninFigure11.

Note:Positionthetabonthehydrauliccover

overthetopbracket.

9.Securethehydrauliccoverusing1bolt(5/16x

1-1/4inch,previouslyremoved).

10.Adherethehosecovertothehookandloop

fastenerstriponthehydrauliccover.

5

ReplacingtheGuardMount

Partsneededforthisprocedure:

1

Guardmount

2

Clampplate

2

Bolt(5/16x1-1/4inches)

2

Locknut(5/16inch)

Procedure

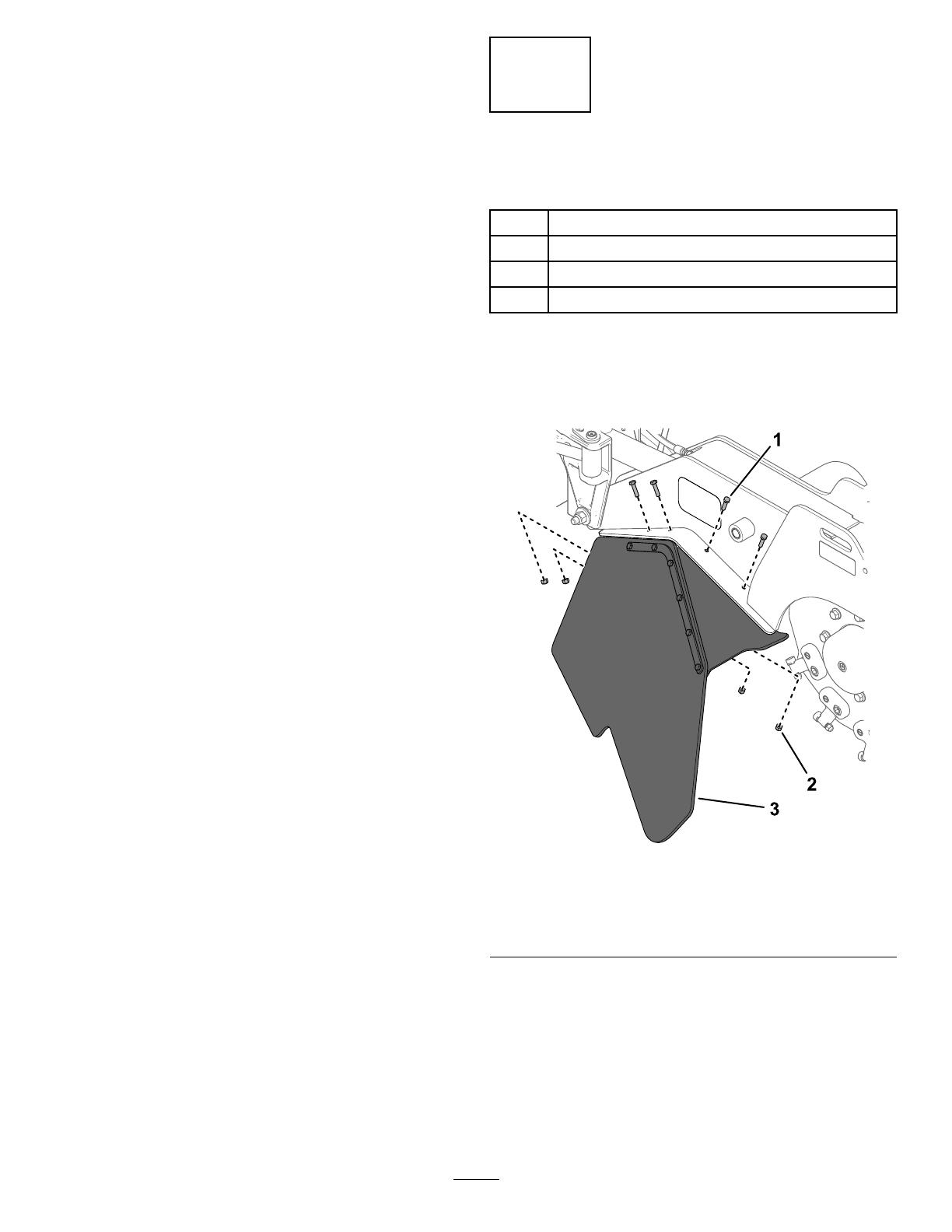

1.Removetheshieldassemblyfromthegrinder

head(Figure12).Retainthefasteners.

g309639

Figure12

1.Bolt—5/16x1-1/4inches

(8)

3.Shieldassembly

2.Locknut—5/16inch(8)

2.Removebothshieldsandclampplatesfromthe

guardmount(Figure13).Retainthefasteners

andshields.

6