Contents

Safety.......................................................................4

GeneralSafety...................................................4

Engine-EmissionCertication.............................4

SafetyandInstructionalDecals..........................4

Setup.......................................................................11

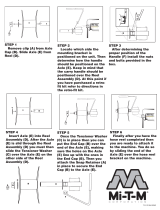

1AdjustingtheSupportRollers.........................12

2InstallingtheHoodLockforCE

Compliance...................................................12

3InstallingtheCuttingUnits..............................13

4AdjustingtheTurf-Compensation

Spring...........................................................17

5UsingtheCutting-UnitKickstand....................17

6GreasingtheMachine....................................18

7CheckingtheFluidLevels..............................19

8UsingtheGaugeBar......................................19

9ApplyingtheCEDecals.................................19

ProductOverview...................................................20

Controls...........................................................20

Specications..................................................27

TractionUnitSpecications..............................27

Attachments/Accessories.................................27

BeforeOperation.................................................27

BeforeOperationSafety...................................27

PerformingDailyMaintenance..........................28

FillingtheFuelTank..........................................28

DuringOperation.................................................29

DuringOperationSafety...................................29

StartingtheEngine...........................................30

ShuttingOfftheEngine.....................................31

EngineSpeedSwitch........................................31

CuttingGrasswiththeMachine........................31

DieselParticulateFilterRegeneration...............31

AdjustingtheLift-ArmCounterbalance.............43

AdjustingtheLift-ArmTurnaround

Position.........................................................44

FoldingtheRollBar..........................................44

CheckingtheInterlockSwitches.......................45

OperatingTips.................................................46

AfterOperation....................................................46

AfterOperationSafety......................................46

HaulingtheMachine.........................................46

IdentifyingtheTie-DownPoints........................46

LocatingtheJackingPoints..............................47

PushingorTowingtheMachine........................47

Maintenance...........................................................49

MaintenanceSafety..........................................49

RecommendedMaintenanceSchedule(s)...........49

DailyMaintenanceChecklist.............................51

Pre-MaintenanceProcedures..............................52

RemovingtheHood..........................................52

Lubrication..........................................................52

GreasingtheBearingsandBushings................52

EngineMaintenance...........................................54

EngineSafety...................................................54

ServicingtheAirCleaner..................................54

ServicingtheEngineOil....................................55

ServicingtheDiesel-OxidationCatalyst

(DOC)andtheSootFilter..............................57

FuelSystemMaintenance...................................57

DrainingtheFuelT ank......................................57

CheckingtheFuelLinesand

Connections..................................................57

ServicingtheWaterSeparator.........................58

ServicingtheFuelFilter....................................58

CleaningtheFuel-IntakeScreen.......................58

ElectricalSystemMaintenance...........................59

ElectricalSystemSafety...................................59

ChargingandConnectingtheBattery...............59

ServicingtheBattery.........................................60

CheckingtheFuses..........................................60

DriveSystemMaintenance..................................61

CheckingtheTirePressure...............................61

CheckingtheT orqueoftheWheel

Nuts..............................................................61

CheckingforEnd-PlayinthePlanetary

Drives............................................................61

CheckingthePlanetaryGear-Drive

Lubricant.......................................................61

ChangingthePlanetary-Gear-Drive

Oil.................................................................62

CheckingtheOilLeveloftheRear

Axle...............................................................63

ChangingtheOilintheRearAxle......................64

CheckingtheLubricantintheGearBoxof

theRearAxle................................................64

AdjustingtheTractionDriveforNeutral.............64

CheckingtheRear-WheelToe-In......................65

CoolingSystemMaintenance..............................66

CoolingSystemSafety.....................................66

CheckingtheCoolingSystem...........................66

ServicingtheEngineCoolingSystem...............66

BrakeMaintenance.............................................68

AdjustingtheServiceBrakes............................68

BeltMaintenance................................................68

ServicingtheAlternatorBelt.............................68

HydraulicSystemMaintenance...........................69

HydraulicSystemSafety...................................69

CheckingtheHydraulicLinesand

Hoses............................................................69

CheckingtheLeveloftheHydraulic

Fluid..............................................................69

HydraulicFluidSpecications...........................69

HydraulicFluidCapacity...................................70

ChangingtheHydraulicFluid............................70

ReplacingtheHydraulicFilters.........................70

CuttingUnitMaintenance.....................................72

BladeSafety.....................................................72

BacklappingtheCuttingUnits...........................72

Cleaning..............................................................73

WashingtheMachine.......................................73

Storage...................................................................74

StorageSafety..................................................74

PreparingtheTractionUnit...............................74

PreparingtheEngine........................................74

3