Page is loading ...

CELL-DYN

®

3/35 Sample Loader TS Guide 9140234B-June 1997

Search

Book TOC

Go Back

28 Oct

1997 20:44

PROPRIETARY INFORMATION

i

PROPRIETARY INFORMATION

This CELL-DYN 3000/3500 Sample Loader Troubleshooting Guide was developed solely for use with

Abbott Laboratories equipment as specified in the operating instructions. The Guide is copyrighted by

Abbott. No part of this document may be reproduced, stored, or transmitted in any form or by any

means electronic, mechanical, photocopied, recorded, or otherwise without the prior written

permission of Abbott Laboratories.

This CELL-DYN 3000/3500 Sample Loader Troubleshooting Guide is published by Abbott Diagnostics

Division, Abbott Laboratories, Abbott Park, IL 60064-3500, U.S.A. Please direct all inquiries

concerning information in this guide to the foregoing address.

Vacutainer is a registered trademark of Becton-Dickinson and Company.

This troubleshooting guide was developed to be used, in the field, by trained Abbott Laboratories Field

Service Representatives and by in-house support personnel. The revision status of this guide is the

responsibility of the guide holder.

In no event shall Abbott Laboratories or its subsidiaries be liable for any injury, loss or damages

incurred in connection with or arising from the use of this guide by unauthorized personnel or persons

not fully trained by Abbott Laboratories.

© 1997 by Abbott Laboratories. All rights reserved.

END

CELL-DYN

®

3/35 Sample Loader TS Guide 9140234B-June 1997

Search

Book TOC

Go Back

28 Oct

1997 20:44

REVISION LOG

ii

REVISION LOG

The Revision Status of this guide is indicated below. Be sure that the guide contains the latest revision

number of all pages. Additional copies of this guide may be ordered using Catalog Number

8921133701.

END

REVISION DATE

PAGES

REVISED/ADDED

TSBs

INCORPORATED

ISAs

INCORPORATED

Original Issue 9/95 Not Applicable 95-001 through 95-053

97-001 through 97-012

95-001 through 95-029

97-001 through 97-006

Rev B 6/97 Add Chapter 3 Parts List 95-030 through 95-042

97-013 through 97-022 97-006 through 97-020

CELL-DYN

®

3/35 Sample Loader TS Guide 9140234B-June 1997

Search

Book TOC

Go Back

28 Oct

1997 20:44

HAZARDS

iii

HAZARDS

General Biosafety

WARNING: Potential Biohazard. Consider all clinical specimens and reagent controls that contain

human blood or serum (calibrators, etc.) and contaminated instruments as potentially infectious. Wear

gloves, lab coats, and safety glasses, and follow other biosafety practices as specified in the OSHA

Bloodborne Pathogen Rule (29 CFR Part 1910.1030) or other equivalent biosafety procedures.

Needles

Needles are sharp and potentially contaminated with infectious materials. Avoid any contact with

needles.

Handling spills

Consider all samples, reagents, calibrators, and controls that contain human blood or serum as

potentially infectious. Clean up spills of potentially infectious materials in accordance with established

biosafety practices. A generally accepted procedure for cleaning such spills is to absorb the spill with

toweling or other absorbent material, wipe the area with a detergent solution, and then wipe the area

with an appropriate tuberculocidal disinfectant such as 10% chlorine bleach solution.

Handling Waste and Waste Containers

Dispose of all clinical specimens, reagents, controls, calibrators, standards, cuvettes, and other

disposables that may be contaminated, in accordance with local, state, and federal regulations

governing the treatment of regulated medical waste. Sharps, such as contaminated probes, must be

placed in an appropriately marked, puncture-resistant container prior to treatment and disposal.

CELL-DYN

®

3/35 Sample Loader TS Guide 9140234B-June 1997

Search

Book TOC

Go Back

28 Oct

1997 20:44

HAZARDS

iv

Decontamination Procedures

The OSHA Bloodborne Pathogen Rule (20 CFR 1910.1030) requires the decontamination of

laboratory equipment prior to servicing or shipment. (Note: see Operations Manual, Section 9, Service

and Maintenance)

Needles

Flush the needles with a disinfectant solution, if possible, or a buffer or water solution used in the

assay system.

Fluid Pathway

Cycle the pathway with a disinfectant solution, if possible, or a buffer or water solution. If during

maintenance or repair the lines will be disconnected or changed, purge the waste reagents out of the

lines.

Instrument Surfaces

Wipe the surface of the instrument with a detergent solution to remove any soiling. Then wipe the unit

down with a hospital disinfectant such as 10% chlorine bleach solution.

Waste Container

Empty and rinse all waste containers with disinfectant or water prior to shipment.

Disposables

Remove all samples, reagents, controls and disposables from the unit prior to shipment.

CELL-DYN

®

3/35 Sample Loader TS Guide 9140234B-June 1997

Search

Book TOC

Go Back

28 Oct

1997 20:44

HAZARDS

v

Electrical Shock Hazard

WARNING: Electrical Shock Hazard. Basic electrical hazard awareness is essential to the safe

operation of any electrical device. Personnel must practice good habits of electrical safety such as the

following:

• Periodically inspect electrical cabling into and on the system for signs of wear or damage.

• Do not disconnect any electrical connection while the power is on.

• In the event of a blown fuse or thrown circuit breaker, determine and correct the cause before

attempting to resume operation of the equipment.

• Keep liquids away from all connectors of electrical or communication components.

• Keep the floor and countertop dry and clean under and around the system.

Laser Hazard

DANGER: Class 3B Laser System. Avoid direct exposure to beam. Wear approved laser eye

protection and observe procedural controls.

Electrostatic Discharge

Many of the electronic components on the CELL-DYN circuit boards are susceptible to electrostatic

discharge (ESD). To prevent ESD damage, follow these guidelines:

1. Place the static protective work mat on a solid surface close to the instrument. Allow the ground

strap to reach the instrument.

2. Attach the ground clip to the instrument chassis.

CELL-DYN

®

3/35 Sample Loader TS Guide 9140234B-June 1997

Search

Book TOC

Go Back

28 Oct

1997 20:44

HAZARDS

vi

3. Attach the other end of the ground clip cable and the connector from the wrist strap to the work

mat. (Exception: Some wrist strap cables provide a clip to connect to the same ground source as

the mat cable.)

4. Attach wrist strap to your wrist, make sure the metallic button on the inside of the wrist strap is in

direct contact with your skin.

5. Place PC Boards, removed from the instrument, on the work mat.

6. Replacement PC Boards should be placed on the work mat before removing from the protective

bag and remain on the mat until installation.

Defective PC Boards should be placed in the static-protective bag before removal from the work mat

area.

END

CELL-DYN

®

3/35 Sample Loader TS Guide 9140234B-June 1997

Search

Book TOC

Go Back

28 Oct

1997 20:44

How to Identify a CE MARK Loader

vii

How to Identify a CE MARK Loader

The previous version of the Guide (ISA 95-049 Attachment) used

[NEW]

and

[OLD]

references. These

have been replaced with

[CE MARK]

and

[NON-CE MARK]

.

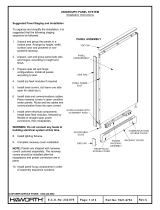

To determine if the Loader is CE MARK Certified, look for the CE Label affixed to the front cover near

the Power Input Panel (See ).

If the Loader is CE MARK Certified, follow the

[CE MARK]

instructions throughout the Guide. Follow

the

[NON-CE MARK]

instructions for all other configurations.

NOTE:The CE MARK Loader is also referred to as Sample Loader 96 in some ISA/TSB Documenta-

tion.

CELL-DYN

®

3/35 Sample Loader TS Guide 9140234B-June 1997

Search

Book TOC

Go Back

28 Oct

1997 20:44

How to Identify a CE MARK Loader

viii

Figure i - 1 CE MARK Label Location

END

Power Input

Panel

SL-276

CE MARK

Label

28 Oct

1997 20:45

CELL-DYN

®

3/35 Sample Loader TS Guide 9140234B-June 1997

TROUBLESHOOTING 1 - 1

1

Search

Book TOC

Go Back

CHAPTER 1 TABLE OF CONTENTS

1.1 OVERVIEW

1.2 ERROR MESSAGES

1.3 ISOLATION PROCEDURES

IP - 1 Blood Detected In Sample Line

IP - 2 Erratic Results

IP - 3 Mixin

g

Fault

IP - 4 Incomplete Aspiration

IP - 5 No Li

g

hts, Some Other Functions Work

IP - 6 Sample Loader Dead, No Li

g

hts, No

sounds

IP - 7 Alarm 4 (a) Needle Home & Limit Sensors

IP - 8 Alarm 4 (b) X-Axis Home And Limit

Sensors

IP - 9 Alarm 4 (c) Mixin

g

Home And Contact

Sensors

IP - 10 Alarm 4 (d) Mixin

g

Home And Limit

Sensors

IP - 11 Alarm 4 (e and j) Time-out Movin

g

X-Axis

IP - 12 Alarm 4 (f) Time-out Movin

g

Pusher

Y-Axis

IP - 13 Alarm 4 (

g

and k) Time-out Movin

g

Needles

IP - 14 Alarm 4 (h) Time-out Movin

g

Mixin

g

Paddle

IP - 15 Alarm 4 (i) Time-out Movin

g

X-Axis

IP - 16 Alarm 4 (l) Time-out Movin

g

Mixin

g

Paddle

IP - 17 Rack Fault or Alarm 4 (m, n, o, p, q, r)

Rack Sensors

IP - 18 Alarm 4 (s) Sample Tube Not Sensed

Properly

IP - 19 Covers Open or Alarm 4 (t) Safety Cover

Removed

IP - 20 Alarm 4 (u) Rack Number Misread

IP - 21 Alarm 1 (v, w, y, z) Communications

Problem

IP - 22 Alarm 2, Mixin

g

Failure

--- END ---

28 Oct

1997 20:45

CELL-DYN

®

3/35 Sample Loader TS Guide 9140234B-June 1997

TROUBLESHOOTING

1.1 OVERVIEW

1 - 2

1

Search

Book TOC

Go Back

1.1 OVERVIEW

This chapter contains the followin

g

information

for Type E, F, & G Sample Loaders:

• 1.2 Error Messa

g

es

• 1.3 Isolation Procedures (IPs)

Troubleshooting Approach

Troubleshootin

g

is required whenever an

Observed Error or a Displayed Error occurs.

Sample Loader Displayed Errors can be

viewed on the Bulletin Line of the Data Station

screen. (The Bulletin Line is down about 3/4

way on the screen.)

When a malfunction occurs, follow these

recommended procedures:

1. Decontaminate the Sample Loader and the

Analyzer accordin

g

to General Biosafety

Procedure.

2. Use this Troubleshootin

g

Guide as follows:

a. If possible, be

g

in by verifyin

g

the

reported error. Perform the exact pro-

cedure that produced the error condi-

tion.

b. When an error occurs, either observed

or displayed, look up the error in Sec-

tion 1.2, Error Messa

g

es table.

c. Perform the Corrective Action.

d. If directed to an IP, flip pa

g

es while look-

in

g

on ed

g

e of sheets for the desired IP

Number.

e. Turn to pa

g

e 1 of x, and be

g

in at the

START box.

f. Follow the directions in the IP.

g

. If directed to perform a Verification Pro-

cedure (VP), flip pa

g

es while lookin

g

on

ed

g

e of sheets for the desired VP Num-

ber.

h. If a part is adjusted or replaced,

g

o to

Section 3.2, Interrelationship Matrix.

i. Find part in left column.

j. Perform VPs in order

g

iven (i.e. 1, 2, 3,

4, etc.)

3. Perform Total Call.

--- END ---

28 Oct

1997 20:45

CELL-DYN

®

3/35 Sample Loader TS Guide 9140234B-June 1997

TROUBLESHOOTING

1.2 ERROR MESSAGES

1 - 3

1

Search

Book TOC

Go Back

1.2 ERROR MESSAGES

Table 1 - 1 Error Messages

MESSAGE

CORREC-

TIVE

ACTION

Alarms Fault Messa

g

eNone

Alarm 1 (v) Last messa

g

e sent to Analyzer was acknowled

g

ed ne

g

atively

(improper format or improper information.

IP - 21

Alarm 1 (w) Time-out - CELL-DYN did not Acknowled

g

e last messa

g

e from

Sample Loader.

IP - 21

Alarm 1 (x) Analyzer sent F command to Sample Loader, and Sample Loader

responded.

None

Alarm 1 (y) Time-out durin

g

aspiration. Sample Loader and Analyzer maybe

out of Sync.

IP - 21

Alarm 1 (z) Time-out durin

g

mixin

g

. Sample Loader and Analyzer maybe out of

Sync.

IP - 21

Alarm 2 Mixin

g

Failure IP - 22

Alarm 3 Not Used None

Alarm 4 (a) Z Ventin

g

/Samplin

g

Needle’s Ori

g

in and Limit Sensors BOTH ON

at Power-On.

IP - 7

28 Oct

1997 20:45

CELL-DYN

®

3/35 Sample Loader TS Guide 9140234B-June 1997

TROUBLESHOOTING

1.2 ERROR MESSAGES

1 - 4

1

Search

Book TOC

Go Back

Alarm 4 (b) X Ori

g

in and Limit Sensors BOTH ON at Power On. IP - 8

(X Transport Home and Limit Sensors both active durin

g

initialization of Sample Loader.)

Alarm 4 (c) Mixin

g

Paddle’s Ori

g

in and Position Sensors BOTH ON at Power

On.

IP - 9

Alarm 4 (d) Mixin

g

Paddle’s Ori

g

in and Limit Sensors BOTH ON at Power On. IP - 10

Alarm 4 (e) X Home Sensor Failure. IP - 11

Time-out in an attempt to drive X-axis mechanism to/from its ori

g

in.

A test performed durin

g

initialization and Run where the particular

mechanism is moved sli

g

htly past a particular sensor then back

and forth several times. The Sensor operation is verified each

time.

Alarm 4 (f) Y Home Sensor Failure. IP - 12

Time-out in an attempt to drive Y-axis mechanism to/from its ori

g

in.

A test performed durin

g

initialization and Run where the particular

mechanism is moved sli

g

htly past a particular sensor then back

and forth several times. The Sensor operation is verified each

time.

Table 1 - 1 Error Messages(continued)

MESSAGE

CORREC-

TIVE

ACTION

28 Oct

1997 20:45

CELL-DYN

®

3/35 Sample Loader TS Guide 9140234B-June 1997

TROUBLESHOOTING

1.2 ERROR MESSAGES

1 - 5

1

Search

Book TOC

Go Back

Alarm 4 (

g

) Time-out in an attempt to drive the Ventin

g

/Samplin

g

needle’s axis

mechanism to/from its ori

g

in.

IP - 13

Alarm 4 (h) Time-out in an attempt to drive the Mixin

g

Z2-axis mechanism

to/from its ori

g

in.

IP - 14

Alarm 4 (i) Time-out in an attempt to drive the X-axis mechanism to its

Slowdown Sensor.

IP - 15

Alarm 4 (j) X Limit Sensor Time-out in an attempt to drive the X-axis

mechanism to/from its limit sensor.

IP - 11

Alarm 4 (k) Z1 Limit Sensor Time-out in an attempt to drive the

Ventin

g

/Samplin

g

needle’s axis mechanism to/from its ori

g

in.

IP - 13

Alarm 4 (l) Time-out in an attempt to drive the Mixin

g

Paddle’s axis

mechanism to its Position Sensor.

IP - 16

Alarm 4 (m) Rack-B Sensor did not detect a Rack. IP - 17

Alarm 4 (n) At least 2 Rack Sensors A throu

g

h D not in correct state durin

g

phases of rack rotation.

IP - 17

Alarm 4 (o) Rack Sensor A not in correct state durin

g

rotation phase. IP - 17

Alarm 4 (p) Rack Sensor B not in correct state durin

g

rotation phase. IP - 17

Alarm 4 (q) Rack Sensor C not in correct state durin

g

rotation phase. IP - 17

Alarm 4 (r) Rack Sensor D not in correct state durin

g

rotation phase. IP - 17

Table 1 - 1 Error Messages(continued)

MESSAGE

CORREC-

TIVE

ACTION

28 Oct

1997 20:45

CELL-DYN

®

3/35 Sample Loader TS Guide 9140234B-June 1997

TROUBLESHOOTING

1.2 ERROR MESSAGES

1 - 6

1

Search

Book TOC

Go Back

Alarm 4 (s) Sample Tube not sensed correctly. IP - 18

Alarm 4 (t) Safety Cover removed durin

g

sample processin

g

. IP - 19

Alarm 4 (u) Rack Number Misread. Barcode reader did not properly read a

rack barcode.

IP - 20

Autosampler Command Ne

g

atively Acknowled

g

ed Reseat

RS232

Cable At

Both

Ends

And

Restart

Auto Stand-by Mode None

Blood Detected

in Sample Line

If system automatically rinses, and error does not recur. None

If "Blood Detected in Sample Line" error displays on bulletin line. IP - 1

If FATAL error displays on bulletin line. Cycle

Power,

then

IP - 1

Check Rack Alarm None

Cover Open IP - 19

Table 1 - 1 Error Messages(continued)

MESSAGE

CORREC-

TIVE

ACTION

28 Oct

1997 20:45

CELL-DYN

®

3/35 Sample Loader TS Guide 9140234B-June 1997

TROUBLESHOOTING

1.2 ERROR MESSAGES

1 - 7

1

Search

Book TOC

Go Back

Emer

g

ency STOP Switch Pressed None

End Ma

g

azine (Rack) Detected None

Erratic Results IP - 2

Incomplete Aspiration (or Samplin

g

Error) IP - 4

Laser OFF None

Laser ON None

Manual Mode None

Mixin

g

Fault for 1st pre-mixer on E-Loader, or F-Loader. Mixin

g

1 Overloaded. IP - 3

Mixin

g

Fault for 2nd pre-mixer on E-Loader. Mixin

g

2 Overloaded. IP - 3

Mixin

g

Faults IP - 3

No Li

g

hts on Control Panel - Other Functions Work IP - 5

Pause Executed None

Re-Mixin

g

Off None

Repeat Auto-Run None

Table 1 - 1 Error Messages(continued)

MESSAGE

CORREC-

TIVE

ACTION

28 Oct

1997 20:45

CELL-DYN

®

3/35 Sample Loader TS Guide 9140234B-June 1997

TROUBLESHOOTING

1.2 ERROR MESSAGES

1 - 8

1

Search

Book TOC

Go Back

--- END --

Request to Clean Ventin

g

Needle Clean

Ventin

g

Needle

Per

Operator

Manual

Reset Started None

Sample is at Mixin

g

Position None

Sample Loader Dead - No Li

g

hts -No Sound IP - 6

Samplin

g

Error (or Incomplete Aspiration) IP - 4

Start Key Pressed or Initialize started. None

Start: Send Barcode, CKSUM, RACK, Tube Numbers None

Vertical Barcode Number for Dia

g

nostics. DA=Ali

g

nment, DV=Verification None

Table 1 - 1 Error Messages(continued)

MESSAGE

CORREC-

TIVE

ACTION

28 Oct

1997 20:45

CELL-DYN

®

3/35 Sample Loader TS Guide 9140234B-June 1997

TROUBLESHOOTING

IP - 1 Blood Detected In Sample Line, 1 of 3

1 - 10

1

Search

Book TOC

Go Back

IP - 1 Blood Detected In Sample Line, 1 of 3

Blood in

Line

?

Check for Blood in

Sample Line Near

Blood In-Line

Sensor

1

No

START

From the Data Station Main Menu

- Go to Special Protocols and Press

CLEAN NEEDLE Key

- Check All Tubing, T-Connectors, and

Y-Fittings leading Through SOL #96

and #92 Ending at Waste Chamber

#2

- Check 12" (82.7 kPa) Vacuum Used

for Evacuating Leftover Sample

- Check Diluent Line leading Through

SOL #91 along With 4 PSI (27.6 kPa)

Used to Flush the Line

- Check Vacuum Connection from

Waste Chamber #2 to Sample

Loader Wash Block

YES

28 Oct

1997 20:45

CELL-DYN

®

3/35 Sample Loader TS Guide 9140234B-June 1997

TROUBLESHOOTING

IP - 1 Blood Detected In Sample Line, 2 of 3

1 - 11

1

Search

Book TOC

Go Back

IP - 1 Blood Detected In Sample Line, 2 of 3

Problem

Corrected

?

Perform Total

Call

Yes

1

- Turn OFF

Sample Loader

- Reseat CN5 on

CPU Main Bd

- Reseat

Connector on

Blood In-Line

Sensor Bd

- Perform Blood

In-Line Sensor

Check (VP-12.1)

Replace Sample

Line (PL-7.8)

Problem in

Line

?

Pull Sample Line Through

Sensor About 1/2 "

(1.27cm), and Inspect Line

For Dark Spots and Kinks

That Might Cause Error

Yes

No

No

2

Blood

In-Line

Sensor

SL-267

/