Page is loading ...

Form No. 3354-736 Rev C

CE Kit

For Dingo® 320-D Compact Utility Loaders with

260000001 and Higher Serial Numbers

Model No. 22365

Installation Instructions

Loose Parts

Use the chart below to verify that all parts have been shipped.

Step

Description

Qty.

Use

1

No parts required

–

Prepare the traction unit.

2

No parts required

–

Remove the rear wheel hubs.

Brake bar

2

Brake bar bracket

2

Flange-head bolt

2

Brake bracket

2

Parking brake cable

1

Locking collar with set screw

2

3

Large spring

1

Assemble the parking brake locking

mechanism.

Convoluted cable tube

1

Bolt (5/16 x 1 inch)

4

4

Locknut (5/16 inch)

4

Install the parking brake locking

mechanism.

Parking brake lever assembly

1

Clevis pin (3/4 inch)

1

5

Cotter pin

3/4 inch

Install the parking brake lever.

Wheel hub assembly

2

6

Hub locknut

2

Install the rear wheel hubs.

7

No parts required

–

Adjust the parking brake.

Loader valve lock assembly

1

Self-tapping screws (1/4 x 5/8 inch)

2

Bolt (1/4 x 2 inches)

1

8

Spacer

1

Install the loader valve lock.

© 2006—The Toro® Company

8111 Lyndale Avenue South

Bloomington, MN 55420

Register at www.Toro.com. Original Instructions (EN)

Printed in the USA.

All Rights Reserved

Step

Description

Qty.

Use

Auxiliary hydraulics lever gate

1

Spacer 2

Lever mount block

1

Thick washer

1

Lock washer (5/16 inch)

1

Flange-head bolt (8 x 20 mm)

1

Auxiliary hydraulics lever

1

Carriage bolt (1/4 x 2 inches)

2

Locknut (1/4 inch)

2

Torsion spring

1

Self-tapping screw (1/4 x 1-3/8

inches)

1

Lock washer (1/4 inch)

1

9

Nut (1/4 inch)

1

Install the auxiliary hydraulics lever

gate.

10

No parts required

–

Adjust the high-speed throttle

setting to 3200 rpm.

11

Self-tapping screw (5/16 x 3/4 inch)

1

Secure the rear access cover.

CE information decal, 108-9738

1

European noise decal, 108-4725

1

Danger decal, 100-1701

1

Caution decal, 100-1702

1

Speed limiter decal, 100-1703

1

Control panel decal, 108-9733

1

Pinch decal, 100-8821

4

No rider decal, 100-8822

2

Hydraulic oil decal, 93-6686

1

12

Radiator cap decal, 106-5976

1

Install the CE compliant decals.

13

Delaration of Conformity

1

Obtain an Operator’s Manual.

Step

1

Preparing the Traction Unit

No Parts Required

Procedure

1. Stop the engine , lo w er the loader ar ms , and

remo v e the k ey .

2. Hoist the rear of the traction unit off of the

g round and secure it with jac k stands under the

frame so that y ou can safely w ork under it and

remo v e the rear wheels .

Step

2

Removing the Rear Wheel

Hubs

No Parts Required

Procedure

1. R emo v e the rear wheels .

2. R emo v e and discard the loc kn uts securing the

rear wheel hubs .

3. Using a hub puller (Ow atonna T ool Company

(OTC) par t n umber TOR4096), remo v e the

rear wheel hubs ( Figure 1 ).

2

Note: Y ou can contact OTC at

www .OTCtools .com .

Figure 1

1. Hub 2. Hub puller

4. Sa v e the k ey from eac h shaft.

Step

3

Assembling the Parking

Brake Locking Mechanism

Parts needed for this step:

2

Brake bar

2

Brake bar bracket

2

Flange-head bolt

2

Brake bracket

1

Parking brake cable

2

Locking collar with set screw

1

Large spring

Procedure

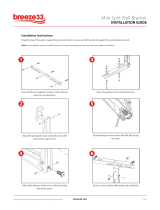

1. F asten the brak e bar brac k ets to the brak e bars

using 2 flang e-head bolts ( Figure 2 ).

Figure 2

1. Brake bar 3. Flange-head bolt

2. Brake bar bracket

2. Ar rang e the brak e brac k ets on a table as sho wn

in Figure 3 .

Figure 3

1. Brake brackets 2. Brake cable

3. Inser t the cable through the right brak e brac k et

as sho wn in Figure 3 .

4. Slide the bars through the openings in the

brak e brac k ets as sho wn in Figure 4 .

Figure 4

5. Set the cable into the right brak e bar brac k et,

and secure it fir mly in place with a loc king

collar and set screw assembly ( Figure 5 ). T he

cable m ust be securely held in the brac k et with

no mo v ement at all.

3

Figure 5

1. Locking collar

2. Set screw

6. P osition the larg e spring o v er the cable ( Figure

6 ).

Figure 6

1. Large spring

7. Set the cable into the left brak e bar brac k et,

and secure it fir mly in place with a loc king

collar and set screw assembly ( Figure 7 ). T he

cable m ust be securely held in the brac k et with

no mo v ement at all.

Figure 7

1. Locking collar

2. Set screw

Step

4

Installing the Parking Brake

Locking Mechanism

Parts needed for this step:

1

Convoluted cable tube

4

Bolt (5/16 x 1 inch)

4

Locknut (5/16 inch)

Procedure

1. Slide the con v oluted tube o v er the brak e cable

( Figure 8 ).

2. F rom under the mac hine , route the end of

the cable through the frame in the lo w er left

cor ner of the frame ( Figure 8 ). Ensure that the

con v oluted tube protr udes at least 4 to 6 in.

(10 to 15 cm) through the hole .

Figure 8

1. Parking brake cable with the convoluted tube

3. P osition the brak e assembly under the traction

unit ag ainst the bac k w all of the frame with

the brak e bars through the rectangular holes in

the sides of the frame , located in front of the

wheel motors ( Figure 9 ).

4

Figure 9

1. Rear wheel motors

2. Bolts (5/16 x 1 inch)

and locknuts (5/16 inch)

(fourth bolt and locknut

not visible)

4. Secure the brak e assembly to the frame with

4 bolts (5/16 x 1 in.) and loc kn uts (5/16

in.) ( Figure 9 ). T he bolts should be pushed

through the frame and brak e brac k ets from the

rear of the mac hine .

Step

5

Installing the Parking Brake

Lever

Parts needed for this step:

1

Parking brake lever assembly

1

Clevis pin (3/4 inch)

3/4

inch

Cotter pin

Procedure

1. R oute the cable across the parking brak e lev er

assembly ( Figure 10 ).

Figure 10

1. Parking brake cable 2. Parking brake lever

assembly

2. Secure the cable to the lev er with a clevis pin

and cotter pin (3/4 in.) ( Figure 11 ).

Figure 11

1. Parking brake lever 3. Parking brake cable

2. Clevis pin and cotter pin

3. Lightly tighten the n uts on the adjustment

collar around the brac k et on the lev er plate

( Figure 12 ).

5

Figure 12

1. Cable with adjustment nuts 2. Bracket on the parking

brake lever assembly

4. Loosen the n uts securing the air cleaner to the

frame ( Figure 13 ).

Figure 13

1. Air cleaner bolts and nuts 2. Air cleaner

5. Slide the slots in the lev er assembly o v er the

air cleaner bolts , betw een the frame and the

air cleaner mounting brac k et ( Figure 14 and

Figure 15 ).

Figure 14

1. Lever assembly 2. Slots

Figure 15

1. Air cleaner bolts 3. Lever assembly

2. Air cleaner mounting

bracket

6. With the slots in the plate positioned all the

w a y o v er the air cleaner bolts , tighten the air

cleaner n uts .

6

Step

6

Installing the Rear Wheel

Hubs

Parts needed for this step:

2

Wheel hub assembly

2

Hub locknut

Procedure

1. T horoughly clean the rear dri v e shafts and the

inside of the tapered bore of the wheel hubs

with alcohol or deg reaser ( Figure 16 ).

Figure 16

1. Rear drive shaft (left side)

2. Diseng ag e the parking brak e lev er .

3. Place the k eys remo v ed previously into the

slots in the dri v e shafts .

4. Place the new wheel hubs with the lugs

pointing out o v er the dri v e shafts ( Figure 17 ).

Figure 17

1. Wheel hub (left side)

5. Secure the hubs with the hub loc kn uts .

6. T or que the n uts to 300 to 350 ft-lb (406 to 474

N ⋅ m).

7. Install the rear wheels .

8. T or que the wheel lug n uts to 50 ft-lb (68 N ⋅ m).

Step

7

Adjusting the Parking Brake

No Parts Required

Procedure

1. Push the parking brak e lev er all the w a y up and

forw ard to diseng ag e it.

2. Chec k the brak e bars protr uding from either

side of the traction unit. T he bars should be

about 1/8 in. (0.3 cm) from the wheel hub and

neither bar should be able to mo v e side to side .

3. Pull the parking brak e lev er do wn to eng ag e

it. T he bars should slide all the w a y into the

notc hes in the wheel hub .

4. If the brak e bars mo v e , are too close to

the wheel hub when diseng ag ed, or do not

fully eng ag e the slots in the wheel hub when

eng ag ed, cor rect it b y adjusting the tw o jam

n uts on the cable ( Figure 18 ).

7

Figure 18

1. Cable with adjustment nuts 2. Bracket on the parking

brake lever assembly

Step

8

Installing the Loader Valve

Lock

Parts needed for this step:

1

Loader valve lock assembly

2

Self-tapping screws (1/4 x 5/8 inch)

1

Bolt (1/4 x 2 inches)

1

Spacer

Procedure

1. Using 2 self-tapping screws (1/4 x 5/8 inc h),

loosely install the loader v alv e loc k behind the

control lev ers ( Figure 19 ). T he loader v alv e

loc k should be able to slide forw ard and bac k

in the slots .

Figure 19

1. Loader valve lock

2. Self-tapping screws (1/4 x

5/8 inch)

2. R emo v e the bolt securing the left lev er and

re place it with the bolt (1/4 x 2 inc hes) and

spacer ( Figure 20 )

Figure 20

1. Bolt (1/4 x 2 inches)

2. Spacer

3. R otate the loader v alv e loc k rearw ard as sho wn

in Figure 21 .

8

Figure 21

4. Slide the loader v alv e loc k rearw ard until it

contacts the loader ar m and attac hment tilt

lev ers . Hold it tightly ag ainst the lev ers .

5. Tighten the screws to secure the loader v alv e

loc k.

6. Push forw ard on the loader ar m and

attac hment tilt lev ers . T hey should not mo v e

forw ard at all. If they do , loosen the screws

and re peat ste ps 4 through 6 .

Note: Y ou will need to mo v e the lev ers

rearw ard to eng ag e or diseng ag e the v alv e loc k.

T he loc k m ust touc h the lev ers when it is all

the w a y do wn and the lev ers are released.

Step

9

Installing the Auxiliary

Hydraulics Lever Gate

Parts needed for this step:

1

Auxiliary hydraulics lever gate

2 Spacer

1

Lever mount block

1

Thick washer

1

Lock washer (5/16 inch)

1

Flange-head bolt (8 x 20 mm)

1

Auxiliary hydraulics lever

2

Carriage bolt (1/4 x 2 inches)

2

Locknut (1/4 inch)

1

Torsion spring

1

Self-tapping screw (1/4 x 1-3/8 inches)

1

Lock washer (1/4 inch)

1

Nut (1/4 inch)

Procedure

1. R emo v e and discard decal n umber 98-4677

( Figure 22 ) from the frame near the auxiliar y

h y draulics lev er .

Figure 22

2. R emo v e the 2 bolts , loc kn uts , and spacers

securing the auxiliar y h y draulics v alv e to the

frame ( Figure 23 ). Discard the spacers .

9

Figure 23

1. Auxiliary hydraulics valve 9. Thick washer

2. Auxiliary hydraulics valve

lever gate

10. Carriage bolt (1/4 x 2

inches)

3. Bolt 11. Auxiliary hydraulics lever

4. Spacer

12. Locknut (1/4 inch)

5. Locknut

13. Lever spring

6. Lever mount block

14. Self-tapping screw (1/4 x

1-3/8 inches)

7. Flange-head bolt (8 x 20

mm)

15. Lock washer and nut (1/4

inch)

8. Lock washer (5/16 inch)

3. R emo v e and discard the auxiliar y h y draulics

lev er from the v alv e .

4. Apply g rease to the inside of the hole in the

lev er mount bloc k ( Figure 23 ).

5. Seat and install the lev er mount bloc k on the

v alv e and secure it using a thic k w asher , loc k

w asher (5/16 inc h), and flang e-head bolt (8 x

20 mm) ( Figure 23 ).

6. Install the auxiliar y h y draulic lev er g ate under

the v alv e body and secure it to the v alv e and

frame using 2 new spacers and the bolts and

loc kn uts remo v ed previously ( Figure 23 ).

Note: T ak e care while installing the spacers

and n uts not to drop them into the traction

unit.

7. T hread the new auxiliar y h y draulics lev er

though the opening in the g ate and secure it

loosely to the side of the mount bloc k with 2

car riag e bolts (1/4 x 2 inc hes) and loc kn uts

(1/4 inc h) ( Figure 23 ). Before tightening

the n uts completely , adjust the height of the

lev er to the lev el of the handle of the traction

unit with the lev er all the w a y forw ard in the

fur thest right hand slot of the g ate .

8. Tighten the n uts .

9. Install the lev er spring betw een the lev er and

the g ate ( Figure 23 ).

10. Install the self-tapping screw (1/4 x 1-3/8

inc hes) into the hole on top of the g ate ( Figure

23 ).

11. Adjust the screw so that when y ou push the

auxiliar y h y draulics lev er forw ard in the center

slot, it contacts the screw just before it g oes

into the detent position.

12. Secure the screw with a loc k w asher (1/4 inc h)

and n ut (1/4 inc h) ( Figure 23 ).

13. Star t the engine and set the throttle to the F ast

position.

14. Push the lev er forw ard into the center slot and

release it. It should tra v el bac k to the neutral

position on its o wn.

15. If the lev er sta ys in the detent position, adjust

the screw until it retur ns to the neutral position

on its o wn.

16. Stop the engine and remo v e the k ey .

Step

10

Adjusting the High-Speed

Throttle Setting to 3200

rpm

No Parts Required

Procedure

T o comply with CE noise regulations , the engine

m ust be set to 3200 r pm.

1. Open the rear access co v er .

2. Cut the wire securing the throttle adjustment

screws ( Figure 24 ).

10

Figure 24

1. High-speed throttle

adjustment screw

3. Apply sealant paint or

epoxy adhesive here.

2. Jam nut

3. Loosen the jam n ut on the high-speed throttle

adjustment screw and bac k it off a few tur ns

( Figure 24 ).

4. Star t the engine and let it w ar m up for 10

min utes at 1/2 throttle .

T he engine has a mo ving f an, belts,

and other par ts that can amputate or

otherwise seriousl y injur e y ou.

• Use extr eme caution when w or king

on a r unning engine and k eep y our

hands and other body par ts w ell a w ay

fr om mo ving par ts.

• Secur e or r emo v e all loose clothing ,

jew elr y , and hair bef or e contin uing

this pr ocedur e.

5. Mo v e the throttle lev er to the F ast position.

6. Measure the engine speed with a tac hometer

and tur n the high-speed throttle adjustment

screw until the engine is set to 3200 r pm

( Figure 24 ).

7. Stop the engine and w ait for all mo ving par ts

to stop .

8. Tighten the jam n ut on the high-speed throttle

adjustment screw ( Figure 24 ).

9. Star t the engine , mo v e the throttle to the F ast

position, and c hec k the engine speed with the

tac hometer .

If the engine speed is not 3200 r pm, stop the

engine and re peat ste ps 3 through 9 .

10. Apply sealant paint or e po xy adhesi v e to the

screw threads next to the jam n ut and on the

protr uding screw threads opposite the jam n ut

( Figure 24 ).

11. Close the rear access co v er .

Step

11

Securing the Rear Access

Cover

Parts needed for this step:

1

Self-tapping screw (5/16 x 3/4 inch)

Procedure

Using a self-tapping screw (5/16 x 3/4 inc h),

secure the rear access co v er to the frame ( Figure

25 ).

Figure 25

1. Rear access cover

2. Self-tapping screw (5/16 x

3/4 inch)

11

Step

12

Installing the CE Compliant

Decals

Parts needed for this step:

1

CE information decal, 108-9738

1

European noise decal, 108-4725

1

Danger decal, 100-1701

1

Caution decal, 100-1702

1

Speed limiter decal, 100-1703

1

Control panel decal, 108-9733

4

Pinch decal, 100-8821

2

No rider decal, 100-8822

1

Hydraulic oil decal, 93-6686

1

Radiator cap decal, 106-5976

Procedure

Install the decals in the positions indicated in the

follo wing table . Place eac h decal directly o v er the

US English decal that cor responds to the CE decal

y ou are installing .

Note: Decals 106-5976, 108-9738, 108–4725,

and 100-8822 do not ha v e a US English equi v alent

installed on the traction unit.

1. T horoughly clean the area where y ou will

install the decal.

2. Dampen the area with w ater or mildly soapy

w ater .

3. P eel the decal from the bac king and install it

in place .

4. Squeeg ee across the surface of the decal,

star ting at the center of the decal and w orking

to w ard the edg es using o v erlapping strok es .

Location US English

CE

On the loader

arm crossbar

98-4682 100-1702

By the speed

limiter

98-8220 100-1703

By the hydraulic

oil ll tube

105-8432 93-6686

12

Location US English

CE

98-9051 (US English)

On top of the rear

access cover

100-1701 (CE)

4 locations on the

loader arms

100-6141 100-8821

2 locations

on the loader

arm crossbar:

on facing the

operator and one

facing forward

100-8822

On the radiator

cap

106-5976

13

Location US English

CE

108-9732

On the control

panel

108-9733

On the left side of

the frame under

the fuel tank

108-9738

On the left side of

the frame under

the fuel tank

108–4725

14

Step

13

Obtaining an Operator’s

Manual

Parts needed for this step:

1

Delaration of Conformity

Procedure

1. Discard the US English Operator’ s Manual

shipped with the traction unit.

2. Using a computer and inter net bro wser , g o to

www .T or o .com .

3. Under Ser vice and Suppor t, select Professional

and then select R equest Operator’ s Man ual.

4. Enter the infor mation requested, including

the model n umber of this kit and the serial

n umber of the traction unit.

5. F ollo w the on screen directions to do wnload

a PDF file v ersion of the man ual in the

customer’ s languag e and ha v e it printed for

them.

6. Gi v e the customer the Operator’ s Manual and

Declaration of Confor mity upon deli v er y of the

traction unit.

15

/