Page is loading ...

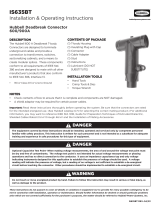

35kV 600A/900A Junctions

IS635/935JCT

Installation & Operating Instructions

IS635/935JCT Rev. D 03/21 IS635/935JCT Rev. D 03/21

Important: Read these instructions thoroughly before operating the system. Be sure that

the connectors are rated for the intended energized use. Visually inspect parts for damage

before using.

! CAUTION

The equipment covered by these instructions should be installed, operated and serviced only by competent personnel

trained in good safety practices. This instruction is written for such personnel and is not intended as a substitute for

adequate training and experience in safe procedures for this type of equipment.

! DANGER

All apparatus must be de-energized during installation or removal of parts. Do not touch or move energized product by

hand. Failure to follow this instruction may result in serious or fatal injury, as well as damage to the product.

Remove all protective shipping caps and replace with an approved insulating cap or connector prior to the junction being

submersed or the circuit energized. The protective shipping caps are intended to keep the interfaces clean during shipping

and handling and should never be used on energized equipment.

! DANGER

These instructions do not purport to cover all details or variations in equipment nor to provide for every possible contingency to be

met in connection with installation, operation or maintenance. Should further information be desired or should particular problems

arise which are not covered suciently for the purchaser’s purposes, the matter should be referred to Hubbell Power Systems, Inc.

©2021 Hubbell Incorporated.

Because Hubbell has a policy of continuous product improvement,

we reserve the right to change design and specifications without notice.

Printed in the U.S.A. | TD_03_059E

1850 Richland Ave. East • Aiken, SC 29801 | Phone: 573-682-5521

Fax: 573-682-8714 | E-mail: hpsliter[email protected]

hubbellpowersystems.com

hubbellpowersystems.com

DESCRIPTION

Hubbell 600A/900A junctions are designed and tested

to meet all requirements of IEEE Std. 386. When mated

with appropriate accessories, they can create taps,

loops, and splices in URD systems and are fully shielded

and submersible. They are typically installed in vaults

or sectionalizing cabinets and are available in three and

four position versions.

35kV class: 21.1kV

STEP 6 – INSTALLATION – JUNCTIONS WITH U-STRAPS

Step 1 – Determine Location

Identify location for the junction assembly. Mark the location for the junction assembly using the U-strap

holes as a template.

Step 2 – Mount Deadbreak Junction

Attach deadbreak junction to a flat metallic surface* using the U-strap(s) provided. Use 5/16” diameter

screws and 5/16” split lock washers. Tighten securely to prevent movement during operation.

Important: The base of the deadbreak junction conductive jacket must be grounded via contact with the

conductive mounting surface.

STEP 7 – OPERATING INSTRUCTIONS

Remove all protective shipping caps and wipe the operating interfaces clean. Lubricate each interface

with the supplied lubricant or an approved equivalent. DO NOT SUBSTITUTE. Other lubricants may be

harmful to this product or a mating connector.

Install the mating products following the instructions supplied with the mating product.

NOTES:

If a position is not to be used, cap it o with an approved insulating cap. Do not use the protective

shipping caps for this purpose as they are only intended to keep the interfaces clean during shipping and

handling.

DO NOT energize or submerge the apparatus with the shipping caps installed.

CONTENTS OF PACKAGE

(1) Multi-Point Junction

(1) SS Bracket and Mounting or U-straps

(1) Installation Instructions

(1) Lubricant – one per interface

DO NOT SUBSTITUTE

INSTALLATION TOOLS

• Hand tools

TITLE

SIZE

DWG NO.

CAT / PART / ASSY NO.

REV

DO NOT SCALE

THIS DRAWING

DRN BY

DATE

SHEET

SB

600 A 35 kV DEADBREAK-JUNCTION

U-STRAPS

HUBBELL POWER SYSTEMS, Inc.

635JXU

0

1 OF 1

11/26/2018

BvB

--

POWER SYSTEMS, INC

}

C

CC

CO

OO

ON

NN

NT

TT

TE

EE

EN

NN

NT

TT

TS

SS

S

A

AA

AR

RR

RE

EE

E

C

CC

CO

OO

ON

NN

NF

FF

FI

II

ID

DD

DE

EE

EN

NN

NT

TT

TI

II

IA

AA

AL

LL

L

A

AA

AN

NN

ND

DD

D

T

TT

TH

HH

HE

EE

E

E

EE

EX

XX

XC

CC

CL

LL

LU

UU

US

SS

SI

II

IV

VV

VE

EE

E

P

PP

PR

RR

RO

OO

OP

PP

PE

EE

ER

RR

RT

TT

TY

YY

Y

O

OO

OF

FF

F

H

HH

HU

UU

UB

BB

BB

BB

BE

EE

EL

LL

LL

LL

L

P

PP

PO

OO

OW

WW

WE

EE

ER

RR

R

S

SS

SY

YY

YS

SS

ST

TT

TE

EE

EM

MM

MS

SS

S.

..

.

N

NN

NO

OO

O

P

PP

PU

UU

UB

BB

BL

LL

LI

II

IC

CC

CA

AA

AT

TT

TI

II

IO

OO

ON

NN

N,

,,

,

W

WW

WI

II

IT

TT

TH

HH

HO

OO

OU

UU

UT

TT

T

T

TT

TH

HH

HE

EE

E

W

WW

WR

RR

RI

II

IT

TT

TT

TT

TE

EE

EN

NN

N

C

CC

CO

OO

ON

NN

NS

SS

SE

EE

EN

NN

NT

TT

T

O

OO

OF

FF

F

C

CC

CO

OO

OP

PP

PY

YY

YR

RR

RI

II

IG

GG

GH

HH

HT

TT

T

L

LL

LA

AA

AW

WW

WS

SS

S.

..

.

D

DD

DI

II

IS

SS

ST

TT

TR

RR

RI

II

IB

BB

BU

UU

UT

TT

TI

II

IO

OO

ON

NN

N

O

OO

OR

RR

R

C

CC

CO

OO

OP

PP

PI

II

IE

EE

ES

SS

S

M

MM

MA

AA

AY

YY

Y

B

BB

BE

EE

E

M

MM

MA

AA

AD

DD

DE

EE

E

H

HH

HU

UU

UB

BB

BB

BB

BE

EE

EL

LL

LL

LL

L

P

PP

PO

OO

OW

WW

WE

EE

ER

RR

R

S

SS

SY

YY

YS

SS

ST

TT

TE

EE

EM

MM

MS

SS

S

U

UU

UN

NN

NP

PP

PU

UU

UB

BB

BL

LL

LI

II

IS

SS

SH

HH

HE

EE

ED

DD

D

A

AA

AL

LL

LL

LL

L

R

RR

RI

II

IG

GG

GH

HH

HT

TT

TS

SS

S

R

RR

RE

EE

ES

SS

SE

EE

ER

RR

RV

VV

VE

EE

ED

DD

D

U

UU

UN

NN

ND

DD

DE

EE

ER

RR

R

T

TT

TH

HH

HE

EE

E

H

HH

HU

UU

UB

BB

BB

BB

BE

EE

EL

LL

LL

LL

L

P

PP

PO

OO

OW

WW

WE

EE

ER

RR

R

S

SS

SY

YY

YS

SS

ST

TT

TE

EE

EM

MM

MS

SS

S.

..

.

2/1/2019

REV DATE

1850 Richmond Ave East

Aiken, SC 29801

Phone: 803-648-8386

www.Hubbellpowersystems.com

600 A 35 kV Deadbreak Junction

Conforms to all Requirements of IEEE Std. 386 - Latest Revision

Conforms to all Requirements of IEEE Std. 386 - Latest Revision

Ratings

Maximum Continuous Voltage...........21.1 kV Phase-to-Ground

Continuous Current...........................600 A

Overload Current 4 hour rating...........900 A

___________________________________________________

Short-Time Current Ratings

0.17 Sec. Duration......................25,000 A rms Symmetrical

3.00 Sec. Duration......................10,000 A rms Symmetrical

___________________________________________________

Insulation Withstand Voltages

Basic Impulse Level.................150 kV Crest

(1.2 x 50 µSec. wave)

60 Hz (60 Sec.)......................................................50 kV rms

Partial Discharge Extinction Voltage (5 pC)................26 kV rms

___________________________________________________

Production Tests

100% factory tested for Partial Discharge and either AC 60 Hz

(45 kV for 60 Sec.) or Impulse (BIL) (125 kV 1.2 x 50

µ

Sec. wave).

4.00

"A"

1.81

6.89

3.465.00

INTERFACES COMPLIES WITH

IEEE STD. 386 INTERFACE 13

5/8-11 UNC - 2B

4" or 6"

X CATALOG # POINTS A

3 635J3U 3 11.5

4 635J4U 4

15.5

Figure 6

L1 L2

4” or 6”

Number of

positions

Spacing

Catalog No.

A L1 L2

600A 900A

2

4" 635J2U 935J2U 7.50" 5.00" 3.46"

6" 635J2XLU 935J2XLU 9.00" 4.63" 3.00"

3

4" 635J3U 935J3U 11.50" 5.00" 3.46"

6" 635J3XLU 935J3XLU 15.00" 4.63" 3.00"

4

4" 635J4U 935J4U 15.50" 5.00" 3.46"

6" 635J4XLU 935J4XLU 21.00" 4.63" 3.00"

INSTALLATION –

JUNCTIONS WITH BRACKETS

Step 1 – Attach Bracket Feet

Loosely attach bracket mounting feet to

the adjustable mounting brackets using

supplied 5/16” hardware. See Figure 1.

NOTE:

Bracket mounting feet can be aligned to

face either the inside or outside direction

based on the location and spacing of the

mounting holes on the wall.

Step 2 –Attach Adjustable Brackets

Align junction frontplate with adjustable

mounting brackets ensuring that the

desired angle has been obtained. Securely

attach bolts once the proper mounting

angle has been achieved.

See Figure 2.

Step 3 – Mounting Dimensions

Refer to Figure 3 and Table 1 for mounting

dimensions.

NOTE:

Adjustable mounting brackets can be

attached with the feet pointing out or in.

Step 4 – Tighten and Ground

Locate the full junction assembly to the final position, mark the attachment locations on the mounting

surface, and tighten the bracket mounting feet hardware in this final position. Drill holes at the marked

locations if required, and securely attach the full junction assembly to the mounting surface using

customer supplied hardware. See Figure 4.

NOTE:

Bracket and Clearance Spacing based

on feed-thrus in the parking stands.

(See Fig.4) Allow sucient space for

elbow operation.

CLEARANCE REQUIREMENTS:

• Vault Wall (Dimension A) or

Enclosure (Dimension B)

• 35kV = 3.25”

Step 5 – Tighten and Ground

Securely tighten all connections from previous assembly steps and assemble ground clamp to either

of the connection points provided on the front plate. Connect the bracket to system ground with the

grounding clamp. See Figure 5.

NOTE:

Ground clamp can accommodate wire sizes of #6 to 1/0 stranded.

! WARNING

Failure to properly ground the 600A/900A junction may lead to the presence of hazardous voltage, which can result in

serious injury or death.

IS635/935JCT Rev. D 03/21 IS635/935JCT Rev. D 03/21

Figure 1

Figure 4

Figure 2

Figure 5

Figure 3

9.56

Number of

positions

Spacing

Catalog No.

X1 X2 B1 B2 B3

600A 900A

2

4" 635J2B 935J2B 15.10" 7.50" 3.40" - 8.40" 7.90" - 13.30" 12.80" - 17.80"

6" 635J2XLB 935J2XLB 17.08" 9.00" 5.40" - 10.40" 9.90" - 15.70" 15.20" - 20.20"

3

4" 635J3B 935J3B 23.00" 11.50" 7.50" - 12.50" 12.00" - 17.00" 16.50" - 21.50"

6" 635J3XLB 935J3XLB 26.00" 15.00" 11.40" - 16.40" 15.90" - 21.70 21.20" - 26.20"

4

4" 635J4B 935J4B 27.00" 15.50" 11.50" - 16.50" 16.00" - 21.00" 20.50" - 25.50"

6" 635J4XLB 935J4XLB 32.00" 21.00" 17.40" - 22.40" 16.90" - 27.70" 27.20" - 32.20"

/