Notas importantes para el instalador

1. Lea todas las instrucciones contenidas en este manual

antes de instalar la estufa.

2. Saque todo el material usado en el embalaje del

compartimiento del horno antes de conectar el

suministro el_ctrico o de gas a la estufa.

3. Observe todos los c6digos y regiamentos pertinentes.

4. Deje estas instrucciones con el comprador.

5. Nota: Para la utilizaci6n a m6s de 2 000 pies de aitura,

la potencia del aparato deber6 ser reducida de 4 por

ciento a cada 1 000 pies adicionales.

Nora Importante para el Consumidor

Conserve estas instrucciones y el Manual del Usuario para

referencia futura.

IMPORTANTES INSTRUCCIONES

DE SEGURIDAD

Instalaci6n de esta estufa debe cumpiir con todos los

c6digos locales, o en ausencia de c6digos locales con

ei C6dicjo Nacionai de Gas Combustible ANSI Z223.1/

NFPA .54--0itima edici6n.

El dise_o de esta estufa ha sido certificado por ia CSA

Internacionai. En 8ste como en cuaiquier otto artefacto

que use gas y cjenere calor, hay ciertas precauciones de

secjuridad que usted debe seguir. Estas ser6n encontradas

en el Manual dei Usuario, iSalo cuidadosamente.

° AsegOrese de que la estufa sea instalada y conectada

a tierra en farina aproplada par un instalador

callficado o par un t_cnlco.

° Esta estufa debe ser el_ctrlcamente puesta a fierra de

acuerdo con los c6dlgos locales, o en su ausencla, con

el C6dlgo El_ctrlca Naclanal ANSi/NFPA No. 70, 01fima

edlci6n. Yea ias instrucciones para ia puesta a tierra.

° Antes de instalar la estufa en un 6rea cuyo plsa

este recublerto con lln61eo u afro tipo de plso

slnt_tlco, aseg_rese de que _stos puedan reslstlr

una temperatura de par Io menos 90°F sabre la

temperatura amblental sin provacar encoglmlenta,

defarmaci6n a decolaraci6n. No instale la estufa sobre

una alfombra al menos que coloque una piancha de

material aislante de por Io menos 1/4 pulcjada, entre

ia estufa y ia aifombra.

* Toclaslas estufas pueclen volcarse.

. Estopoclria resultar en lesiones personales.

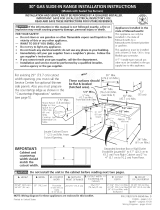

" Instale el dispositivo anti vuelcos que se ha

empacaclo junto con esta estufa.

Para rectucir el riesgo de que se vuelque la

estufa, hay que asegurarla adecuaclamente

colo candole los soportes antivuelco que

se proporcionan. Para comprobar siestos

estan instalados y apretaclos en su lugar

como se clebe, ase el borcle trasero superior de la estufa y

cuidado samente incline la hacia aclelante para asegurar

que la estufa se ancle.

° Aseg0rese de que el material que recubre las

paredes alrededor de la estufa, pueda reslstlr el

calor generada par la estufa.

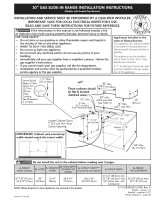

* No obstruya el flujo del alre de combusti6n en la

ventilaci6n del horno nl iampoco alrededor de la

base o debaja del panel inferior delantera de la

estufa. Evite tocar las aberturas o 6reas cercanas

de la ventilaci6n, ya que pueden estar muy calientes

durante el funcionamiento del horno. La estufa requiere

aire fresco para la combusti6n apropiada de los

quemadores.

II_ Nunca deje hi,as solos o desa|endldos

en un c_rea donde un artefacto estc_ slendo usado. A

medida que los ni_os crecen, ens_eles el uso apropiado

y de secjuridad para todos los artefactos. Nunca deje

la puerta del horno abierta cuando la estufa est6

desatendida.

No se pare, apoye o slen|e en las puertas

o calories de esta estufa pues puede resuffar en serlas

leslones y puede tambi_n causar da_a a la estufa.

° No almacene articulos que puedan interesar a los

nifios en los gablnetes sabre la estufa. Los ni_os

pueden quemarse seriamente tratando de trepar a la

estufa para alcanzar estos articulos.

" Los gablneies de almacenamlenio sabre la esiufa

deben set evltados, para ellmlnar la necesldad de

tener que pasar sabre los quemadores superlores de

la estufa para ffegar a elias.

* Ajuste el tama5a de la llama de los quemadares

superlores de tal manera que _sta no sobrepase el

horde de los utensillos de coclnar. La llama excesiva

es peligrosa.

° No use el homo coma espaclo de almacena_e. Esto

crear6 una situaci6n potencialmente peligrosa.

* Nunca use la estufa para caleniar el cuarto. El usa

proloncjado de la estufa sin la adecuada ventilaci6n

puede resultar pelicjroso.

* No almacene nl uHllce gasollna u arras vapores y

ffquldos inflamables en la proxlmldad de _ste o de

cualquler afro artefacto el_ctrlco. Puede provocar

incendio o expiosi6n.

° En caso de una interrupti6n del servicio el_ctrico, es

posible de encender los quemadores de superficie

a mano. Para encender un quemador de superficie,

acerque un f6sforo encendido del cabezal del

quemador, y gire delicadamente el bot6n de control

de superficie a LITE (encendido). Tener cuidado al

encender los quemadores a mano.

* Ajuste todos los controles a la poslci6n "OFF"

(apagada) despu_s de haber hecho una operaci6n

con fiempo programado.

PARA MODELOS AUTOLIMPIANTES:

° Saque la asadera, affmentos o cualquler otto utensillo

antes de usar el clclo de autollmpieza del homo.

Limpie todo exceso de derrame de alimentos. Siga las

instrucciones de prelimpiado en el Manual del Usuario.

* A dlferencla de la gama est6ndar coclnas de gas,

ESTA PLANCHA DE COCINA NO ES MOVIBLE. No

intente quitar la plancha de cocina.

19