Page is loading ...

Solid state equipment has operational characteristics differing from those

of electromechanical equipment. “Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls” (Publication

SGI-1.1) describes some important differences between solid state

equipment and hard–wired electromechanical devices. Because of this

difference, and also because of the wide variety of uses for solid state

equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is

acceptable.

In no event will the Allen-Bradley Company be responsible or liable for

indirect or consequential damages resulting from the use or application

of this equipment.

The examples and diagrams in this manual are included solely for

illustrative purposes. Because of the many variables and requirements

associated with any particular installation, the Allen-Bradley Company

cannot assume responsibility or liability for actual use based on the

examples and diagrams.

No patent liability is assumed by Allen-Bradley Company with respect to

use of information, circuits, equipment, or software described in this

manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of the Allen-Bradley Company is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations.

!

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

damage, or economic loss.

Attentions help you:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is especially important for

successful application and understanding of the product.

SLC, SLC 500, and SLC 5/02 are trademarks of Allen-Bradley Company, Inc.

Important User Information

Summary of Changes

SOC–1

Publication 1746-6.16 – January 1999

Summary of Changes

This publication contains new and revised information not included in the

previous version.

New Information

The Thermocouple/mV Isolated Input module, cat. no. 1746-INT4 is now a

series B module. The series B module is identical to the series A module

with the exception that the series B module is CE certified and has CSA

hazardous location approval (refer to Appendix A for complete ratings).

Compliance with European Union Directives

This series B module complies with the directives outlined in Chapter 1 of

this document.

CSA Hazardous Location Approval

This series B module complies with CSA classifications as outlined under

Specifications in Appendix A.

Revised Information

This publication also contains information formally included in a document

update, publication 1746-6.16–DU1.

Change Bars

The areas in this manual which are different from previous editions are

marked with change bars (as shown to the right of this paragraph) to indicate

the addition of new or revised information.

Allen-Bradley

Summary of Changes

SOC–2

Publication 1746-6.16 – January 1999

Preface

P–1

Publication 1746-6.16 – January 1999

Preface

Read this preface to familiarize yourself with the manual.

This preface covers the following topics:

• who should use this manual

• purpose and contents of this manual

• format conventions used in this manual

• terms and abbreviations

• Allen-Bradley support

Use this manual if you are responsible for the design, installation,

programming, or maintenance of an automation control system that uses

Allen-Bradley small logic controllers.

You should have a basic understanding of SLC 500 products. You should

understand electronic process control and be able to interpret the ladder logic

instructions required to control your application. If you do not, contact your

local Allen-Bradley representative for training before using this product.

This manual is a learning and reference guide for the 1746-INT4

Thermocouple/mV Isolated Input Module. It contains the information you

need to program, install, wire, and troubleshoot the module.

Who Should Use this Manual

Purpose and Contents

of this Manual

Allen-Bradley

Preface

P–2

Publication 1746-6.16 – January 1999

Contents of this Manual

Chapter Title Content

1 Overview

Describes module hardware features, and

operation.

2 Quick Start Serves as a Quick Start Guide for this module.

3 Installation and Wiring

Provides installation information and wiring

guidelines.

4

Preliminary Operating

Considerations

Describes the module ID code, I/O image words

used by the module, input channel characteristics,

and response to slot disabling.

5

Accessing Files

to Configure I/O

Describes how to use the software to create a new

file and configure I/O for system hardware.

6

Channel Configuration,

Data, and Status

Describes configuration and status words used by

the module. Explains how the module uses

configuration data and generates status during

operation.

7

Ladder Programming

Examples

Gives ladder logic examples for configuring and

operating the module that include verifying changes

in configuration, using the PID instruction,

monitoring status bits, and enabling autocalibration.

8

Module Diagnostics and

Troubleshooting

Explains how to interpret LEDs and correct

problems that may occur while using the module.

9

Application Programming

Examples

Describes how to write ladder logic to achieve

desired results for two example applications.

Appendices Title Content

A Module Specifications

Provides physical, electrical, environmental, and

functional specifications for the module.

B

Channel Configuration

Worksheets

Provides a worksheet to help you configure each

channel for operation.

C Thermocouple Descriptions

Gives you information about thermocouples and

the environments in which they perform best.

D Channel Calibration

Gives you the procedure to calibrate input

channels.

E

List of Terms and

Abbreviations

Gives you the terms and abbreviations used in this

manual.

F CSA Hazardous Information

Gives you the definition of the CSA hazardous

classification.

The following conventions are used throughout this manual:

• Bulleted lists such as this one provide information, not procedural steps.

• Numbered lists provide sequential steps or hierarchical information.

• Text in this

font

indicates words or phrases you should type.

• Key names appear in bold, capital letters within brackets (for example,

[ENTER]).

Format Conventions

Used in this Manual

Preface

P–3

Publication 1746-6.16 – January 1999

Related Documentation

The following documents contain information that may be helpful to you as

you use Allen-Bradley SLC products. To obtain a copy of any of those

listed, contact your local Allen-Bradley office or distributor.

For Read this Document

Document

Number

An overview of the SLC 500 family of products SLC 500 System Overview 1747-2.30

A description on how to install and use your Modular SLC 500

programmable controller

Installation & Operation Manual for Modular

Hardware Style Programmable Controllers

1747-6.2

A description on how to install and use your Fixed SLC 500

programmable controller

Installation & Operation Manual for Fixed Hardware

Style Programmable Controllers

1747-NI001

A procedural manual for technical personnel who use APS to

develop control applications

Allen-Bradley Advanced Programming Software

(APS) User Manual

9399-APSUM

A reference manual that contains status file data, instruction

set, and troubleshooting information about APS

Allen-Bradley Advanced Programming Software

(APS) Reference Manual

1747-6.15

An introduction to APS for first–time users, containing basic

concepts but focusing on simple tasks and exercises, and

allowing the reader to begin programming in the shortest time

possible

Getting Started Guide for APS 9399-APSQS

A training and quick reference guide to APS

SLC 500 Software Programmer’s Quick Reference

Guideavailable on PASSPORT at a list price of

$50.00

ABT-1747–TSG001

A procedural and reference manual for technical personnel

who use an HHT to develop control applications

Allen-Bradley Hand–Held Terminal User Manual 1747-NP002

An introduction to HHT for first–time users, containing basic

concepts but focusing on simple tasks and exercises, and

allowing the reader to begin programming in the shortest time

possible

Getting Started Guide for HHT 1747-NM009

A resource manual and user’s guide containing information

about the analog modules used in your SLC 500 system.

SLC 500 Analog I/O Modules User Manual 1746-NM003

An article on wire sizes and types for grounding electrical

equipment

National Electrical Code

Published by the

National Fire

Protection

Association of

Boston, MA.

A complete listing of current Allen–Bradley documentation,

including ordering instructions. Also indicates whether the

documents are available on CD-ROM or in multi–languages.

Allen-Bradley Publication Index SD499

A glossary of industrial automation terms and abbreviations Allen-Bradley Industrial Automation Glossary AG-7.1

Allen-Bradley

Preface

P–4

Publication 1746-6.16 – January 1999

Allen-Bradley offers support services worldwide, with over 75 Sales/Support

offices, 512 authorized Distributors and 260 authorized Systems Integrators

located throughout the United States alone, plus Allen-Bradley

representatives in every major country in the world.

Local Product Support

Contact your local Allen-Bradley representative for:

• sales and order support

• product technical training

• warranty support

• support service agreements

Technical Product Assistance

If you need to contact Allen-Bradley for technical assistance, please review

the information in the Module Diagnostics and Troubleshooting chapter first.

Then call your local Allen-Bradley representative.

Allen-Bradley

Support Services

Publication 1746-6.16 – January 1999

Chapter 1

General Description 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input

Ranges

1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware

Features

1–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic LEDs 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Overview 1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System

Operation

1–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module

Operation

1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module

Addressing

1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compatibility

with Thermocouple and Millivolt Devices and Cables

1–5.

Block

Diagram of Isolated Channel Input Circuits

1–6. . . . . . . . . . . . .

Chapter 2

Required

T

ools and Equipment

2–1. . . . . . . . . . . . . . . . . . . . . . . . . .

Procedures 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3

Electrostatic Damage 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Requirements 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Considerations

for a Fixed Controller

3–2. . . . . . . . . . . . . . . . . . . . . .

Module

Installation and Removal

3–3. . . . . . . . . . . . . . . . . . . . . . . . .

Terminal Block Removal 3–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module

Installation Procedure

3–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring

the Module

3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cold Junction Compensation (CJC) 3–5. . . . . . . . . . . . . . . . . . . . . . .

Wiring

Considerations

3–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparing

and Wiring the Cables

3–6. . . . . . . . . . . . . . . . . . . . . . . . .

Installing

the Ferrite Collar

3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4

Module

ID Code

4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module

Addressing

4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output

Image – Configuration W

ords 4–2. . . . . . . . . . . . . . . . . . . . . .

Input

Image – Data W

ords and Status W

ords 4–3. . . . . . . . . . . . . . . .

Input Channel Characteristics 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Channel

Cut-of

f Frequency

, Update T

ime, and Step Response

4–3. . .

Effective

Resolution of a Channel and Input Device

4–4. . . . . . . . . . .

Response

to Slot Disabling

4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input Response 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Response 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Notes: 4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

Module Overview

Quick Start

Installation and Wiring

Preliminary Operating

Considerations

Allen-Bradley

Table of Contentsii

Publication 1746-6.16 – January 1999

Chapter 5

Create

a New File

5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configure I/O 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Return

to an Existing File

5-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Notes: 5-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6

Channel

Configuration

6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selecting

the Correct Data Format

6–3. . . . . . . . . . . . . . . . . . . . . . .

Channel

Configuration Procedure

6–4. . . . . . . . . . . . . . . . . . . . . . . .

Using

Channel Data W

ords 6–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using

Channel Status W

ords 6–6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Detected

Faults Indicated by Bits 12-15

6–8. . . . . . . . . . . . . . . . . . . .

Chapter 7

Processor Basics 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Load

Channel Configurations for T

ransfer to the Module

7–2. . . . . . . .

Procedure 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Change

a Channel Configuration

7–3. . . . . . . . . . . . . . . . . . . . . . . .

Verify

Changes to a Channel Configuration

7–4. . . . . . . . . . . . . . . . .

Process

a Channel Input with the PID Instruction

7–5. . . . . . . . . . . . .

Monitor

Channel Status Bits

7–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 8

Module

and Channel Diagnostics

8–1. . . . . . . . . . . . . . . . . . . . . . . .

Module

Diagnostics at Power-up

8–1. . . . . . . . . . . . . . . . . . . . . . . . .

Channel Diagnostics 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED

Indicators

8–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Channel-status LEDs (Green) 8–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Open-circuit

Detection (Bit 12)

8–3. . . . . . . . . . . . . . . . . . . . . . . . . .

Out-Of-Range

Detection (Bit 13 for under range,

bit 14 for over range)

8–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Invalid

Channel Configuration (Bit 15)

8–3. . . . . . . . . . . . . . . . . . . . .

Module Status LED (Green) 8–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting Flowchart 8–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replacement Parts 8–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contacting

Allen-Bradley

8–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Notes: 8–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessing Files to Configure

I/O

Channel Configuration, Data,

and Status

Ladder Programming

Examples

Module Diagnostics and

Troubleshooting

Table of Contents iii

Publication 1746-6.16 – January 1999

Chapter 9

Basic

Example (to display a temperature)

9–1. . . . . . . . . . . . . . . . . .

Channel

Configuration

9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supplementary Example (select display in

o

C or

o

F) 9–3. . . . . . . . . . .

Channel

Configuration

9–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program

Setup

9–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program

9–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A

Electrical

Specifications

A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Physical

Specifications

A–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental

Specifications

A–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Input

Specifications

A–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overall Accuracy A–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Thermocouple

Resolution

A–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Type J Thermocouple A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Type

K Thermocouple

A–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Type

E Thermocouple

A–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix B

Channel

Configuration W

orksheets B–1. . . . . . . . . . . . . . . . . . . . . . .

Appendix C

Thermocouple Descriptions C–1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

J

T

ype Thermocouple

C–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

K

T

ype Thermocouple

C–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

T

T

ype Thermocouple

C–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

E

T

ype Thermocouple

C–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

S

and R T

ype Thermocouples C–5. . . . . . . . . . . . . . . . . . . . . . . . . . .

C

and D T

ype Thermocouples C–6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix D

About

the Procedure

D–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration

Logic

D–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration

Codes and Status

D–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibration

Procedure

D–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Notes: D–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix E

Terms

and Abbreviations

E–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix F

CSA

Hazardous Location Approval

F–1. . . . . . . . . . . . . . . . . . . . . . .

Module Specifications

Channel Configuration

Worksheets

Thermocouple

Descriptions

Channel Calibration

Terms and Abbreviations

CSA Hazardous Location

Approval

Application Programming

Examples

Allen-Bradley

Table of Contentsiv

Publication 1746-6.16 – January 1999

1

Chapter

1–1Publication 1746-6.16 – January 1999

Module Overview

This chapter describes the thermocouple/millivolt isolated input module and

explains how the SLC controller reads thermocouple or millivolt analog

input data from the module. Included is information about:

• compliance with European Union Directives

• general description and hardware features

• an overview of system and module operation

• block diagram of channel input circuits

If this product has the CE mark, it is approved for installation within

the European Union and EEA regions. It has been designed and tested to meet

the following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC Electromagnetic

Compatibility (EMC) and the following standards,

in whole or in part, documented in a technical construction file:

EN 50081-2EMC – Generic Emission Standard, Part 2 – Industrial

Environment

EN 50082-2EMC – Generic Immunity Standard, Part 2 – Industrial

Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low Voltage, by

applying the safety requirements of EN 61131–2 Programmable Controllers,

Part 2 – Equipment Requirements and Tests.

For specific information required by EN 61131-2, see the appropriate sections

in this publication, as well as the following Allen-Bradley publications:

Industrial Automation Wiring and Grounding Guidelines

(for noise immunity), publication 1770-4.1

Automation Systems Catalog, publication B111

This equipment is classified as open equipment and must be mounted in an

enclosure during operation to provide safety protection.

Compliance with

European Union Directives

Allen-Bradley

Chapter 1

Module Overview

1–2

Publication 1746-6.16 – January 1999

The module stores digitally converted thermocouple and/or millivolt (mV)

analog data in its image table for retrieval by all fixed and modular SLC 500

processors. The module supports connections from any combination of up to

four thermocouple and/or mV analog sensors.

Input Ranges

The following tables define thermocouple types and associated temperature

ranges and the millivolt analog input signal ranges that each of the module’s

input channel will support. To determine the practical temperature range of

your thermocouple, refer to the specifications in appendix A.

Thermocouple Temperature Ranges

Type

°C Temperature Range °F Temperature Range

C 0

o

C to 2317

o

C 32

o

F to 4201

o

F

D 0

o

C to 2317

o

C 32

o

F to 4201

o

F

J –210°C to 760°C –346°F to 1400°F

K –270°C to 1370°C –454°F to 2498°F

T –270°C to 400°C –454°F to 752°F

B 300°C to 1820°C 572°F to 3308°F

E –270°C to 1000°C –454°F to 1832°F

R 0°C to 1768°C 32°F to 3214°F

S 0°C to 1768°C 32°F to 3214°F

N 0°C to 1300°C 32°F to 2372°F

CJC Sensor 0°Cto 85°C 32°F to 185°F

Millivolt Input Ranges

–50 to +50 mV

–100 to +100 mV

Each input channel is individually configurable for a specific input device, and

provides open-circuit, over-range, and under-range detection and indication.

General Description

Chapter 1

Module Overview

1–3Publication 1746-6.16 – January 1999

Hardware Features

The module fits into any single slot for I/O modules in either an SLC 500

modular system or an SLC 500 fixed system expansion chassis (1746-A2). It

is a Class 1

➀

module (uses 8 input words and 8 output words).

➀ Requires use of Block T

ransfer in a remote configuration.

The module contains a removable terminal block providing connections for

four thermocouple and/or analog input devices. There are two cold-junction

compensation (CJC) sensors that compensate for the cold-junction at ambient

temperature rather than at freezing (0

o

C). There are no output channels on

the module. You configure the module with software rather than with

jumpers or switches.

Cable Tie Slots

INPUT

Self-Locking Tabs

Side Label

Removable

Terminal Block

CJC A+

CHL3–

CHL3+

CHL2–

CHL2+

CHL1–

CHL1+

CHL0–

CHL0+

Door Label

CJC Sensors

Do Not

Remove

CJC A–

Do Not

Remove

CJC B–

Do Not

Remove

CJC B+

Do Not

Remove

MODULE STATUS

0

1

2

3

CHANNEL

STATUS

THERMOCOUPLE/mV

Channel Status

LEDs (Green)

Module Status

LED (Green)

ISOLATED

ISOLATED THERMOCOUPLE / mV INPUT MODULE

Do Not

Connect

Do Not

Connect

Do Not

Connect

Do Not

Connect

Do Not

Connect

Do not connect

to this terminal

Do Not

Connect

Hardware Features

Hardware

Function

Channel Status LED Indicators Display operating and fault status of channels 0, 1, 2, and 3

Module Status LED Displays operating and fault status of the module

Side Label (Nameplate) Provides module information

Removable Terminal Block Provides electrical connection to input devices.

Door Label Permits easy terminal identification

Cable Tie Slots Secure input wiring at the module

Self-Locking Tabs Secure module in chassis slot

Allen-Bradley

Chapter 1

Module Overview

1–4

Publication 1746-6.16 – January 1999

Diagnostic LEDs

The module contains diagnostic LEDs that help you identify the source of

problems that may occur during power-up or during normal operation.

Power-up and channel diagnostics are explained in chapter 8, Module

Diagnostics and Troubleshooting.

The module communicates with the SLC 500 processor and receives +5Vdc

and +24Vdc power from the system power supply through the parallel back-

plane interface. No external power supply is required. You may install as

many thermocouple modules in the system as the power supply can support.

Thermocouple Modules

SLC Processor

Each module channel can receive input signals from a thermocouple or a mV

analog input device. You configure each channel to accept either one. When

configured for thermocouple input types, the module converts analog input

voltages into cold-junction compensated and linearized, digital temperature

readings. The module uses the National Bureau of Standards (NBS)

Monograph 125 and 161 based on IPTS-68 for thermocouple linearization.

When configured for millivolt analog inputs, the module converts analog

values directly into digital counts. The module assumes that the mV input

signal is linear.

System Operation

At power-up, the module checks its internal circuits, memory, and basic

functions. During this time the module status LED remains off. If the

module finds no faults, it turns on its module status LED.

Thermocouple

Input

Module

SLC 500

Processor

Channel Configuration W

ord

Channel Data W

ord

Thermocouple or mV

Analog Signals

Channel Status W

ord

System Overview

Chapter 1

Module Overview

1–5Publication 1746-6.16 – January 1999

After completing power-up checks, the module waits for valid channel

configuration data from your SLC ladder logic program (channel status

LEDs are off). After channel configuration data is transferred and channel

enable bits are set for one or more channels, the module turns on its channel

status LEDs. Then it continuously converts the thermocouple or millivolt

input to a value within the range you selected for the channel.

Each time the module reads an input channel, the module tests that data for a

fault, i.e. open-circuit, over-range, or under-range condition. If it detects

such a condition, the module sets a unique bit in the channel status word and

causes the channel status LED to blink.

The SLC processor reads the converted thermocouple or millivolt data from

the module at the end of the program scan, or when commanded by the

ladder program. After the processor and module determine that the data

transfer was made without error, the data can be used in your ladder program.

Module Operation

The module’s input circuitry consists of four differential analog inputs, each

with its own analog-to-digital (A/D) convertor. The A/D convertors read the

analog input signals and convert them to digital counts. The input circuitry

also continuously samples the CJC sensors and compensates for temperature

changes at the cold junction (terminal block). The figure on the following

page shows a block diagram for the analog input circuitry.

Module Addressing

The module requires eight words each in the SLC processor’s input and

output image tables. Addresses for the module in slot e are as follows:

I:e.0-3 thermocouple/mV data for channels 0-3, respectively

I:e.4-7 status data for channels 0-3, respectively

O:e.0-3 configuration data for channels 0-3, respectively

O:e.4-7 reserved for future use. Do not use.

Compatibility with Thermocouple and Millivolt Devices and Cables

The module is compatible with the following NBS MN-125 and -161 standard

types of thermocouples: B, C, D, E, J, K, N, R, S, and T and extension wire.

Refer to appendices A and C for details. The module is also compatible with a

variety of mV devices with an output of "50 or "100 mV.

Allen-Bradley

Chapter 1

Module Overview

1–6

Publication 1746-6.16 – January 1999

To minimize interference from radiated electrical noise, we recommend

twisted-pair and highly shielded cables such as the following:

For This Type of Device We Recommend This Cable (or equivalent)

Thermocouple Type J EIL Corp. J20-5-502

Thermocouple Type K EIL Corp. K20-5-510

Thermocouple Type T EIL Corp. T20-5-502

other Thermocouple types consult with EIL Corp or other manufacturers

mV devices

Alpha Suprashield XTRA-GUARD 1

5121 (1pr), 5122 (2pr), 5131 (3pr), 5141 (4pr)

Digital

V

alue

Channel 1

8 Hz

Digital

Filter

Analog to

Digital

Convertor

Open Circuit

Detection

Channel 0

+

–

+

–

+

–

+

–

+

–

+

–

CJCA Sensor

CJCB Sensor

Terminal Block Module Circuitry

I/O Chassis

Ground

Digital Value

Channel 0 &

CJC Sensor

Signal

8 Hz

Digital

Filter

Analog to

Digital

Convertor

Digital Value

Channel 2

8 Hz

Digital

Filter

Analog to

Digital

Convertor

8 Hz

Digital

Filter

Analog to

Digital

Convertor

Multiplexer

Digital Value

Channel 3 &

CJC Sensor

Signal

Multiplexer

I/O Chassis

Ground

wire braid

2

4

6

8

10

12

14

16

18

Block Diagram

of Isolated

Channel Input Circuits

2

Chapter

2–1

Publication 1746-6.16 – January 1999

Quick Start

Use this chapter as an abbreviated procedure for getting the module into

operation or as an overview if you need the additional steps described in

subsequent chapters. This chapter assumes that you understand:

• SLC 500 products

• electronic process control

• ladder logic instructions

Because this chapter is a start-up guide, it does not contain detailed

explanations. It does, however, refer to other chapters or to other SLC

publications for more information.

If you are unsure of terms used or concepts presented in this chapter, always

read the referenced chapters before trying to apply the information.

This chapter will:

• tell you what equipment you need

• explain how to install and wire the module

• show you how to set up one channel for thermocouple input

• examine the state of the LEDs at normal startup

• examine the channel status word

Have the following tools and equipment ready:

• medium blade screwdriver

• medium cross-head screwdriver

• thermocouple or millivolt sensor

• thermocouple extension wire (if needed)

• the module

• I/O chassis

• SLC processor and power supply

• programming equipment

(Programming examples in this manual demonstrate the use of

Allen-Bradley’s Advanced Programming Software for personal

computers.)

Required Tools and

Equipment

Allen-Bradley

Chapter 2

Quick Start

2–2

Publication 1746-6.16 – January 1999

1.

Unpack the Module Reference

Important:: Follow these precautions to prevent damaging the module from electrostatic discharge:

• Before handling the module, rid yourself of electric charge by touching a grounded object

• Avoid touching connector terminations and circuit components.

• When not in use, keep the module in its electrostatic shielded bag.

Unpack the module making sure that the contents include:

• module (Catalog Number 1746-INT4)

• removable terminal block (factory–installed on module) with CJC sensors attached

• this user manual (publication number 1746-6.16)

–

If the contents are incomplete, call your local Allen-Bradley representative for assistance.

2.

Review Power Requirements Reference

Review the power requirements of the modules drawing power from the chassis power supply.

• The fixed, 2-slot chassis supports 2 1746-INT4 modules. If combining an INT4 module with

a different type of module, refer to Considerations for a Fixed Controller in chapter 3.

• For a modular system, compute the total load on the system power supply using the

procedure described in the SLC Installation & Operation Manual for Modular Controllers

(publication 1747-6.2) or the SLC 500 Family System Overview (publication 1747-2.30).

Chapter 3

(Installation and

Wiring)

Appendix A

(Specifications)

3.

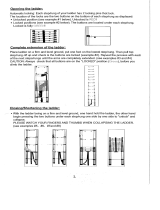

Install the Module Reference

ATTENTION: Never install, remove, or wire

modules with power applied to the chassis or

devices wired to the module.

!

Chapter 3

(Installation and

Wiring)

Make sure system power is off; then insert the the module into the I/O chassis.

In this example procedure, the module is inserted into slot 1.

Card

Guide

Top and Bottom

Module Release(s)

Procedures

/