Part Number 020008596 04/09/2021

Flavor Shot

Installation, Operation and Maintenance Manual

Original Document

,

Caution

Read this instruction before operating this equipment.

Refreshing the Experience

Safety Notices

As you work on Welbilt equipment, be sure to pay close

attention to the safety notices in this manual. Disregarding

the notices may lead to serious injury and/or damage to the

equipment.

Throughout this manual, you will see the following types of

safety notices:

n

Warning

Text in a Warning box alerts you to a potential personal

injury situation. Be sure to read the Warning statement

before proceeding, and work carefully.

,

Caution

Text in a Caution box alerts you to a situation in which

you could damage the equipment. Be sure to read

the Caution statement before proceeding, and work

carefully.

Procedural Notices

As you work on Welbilt equipment, be sure to read the

procedural notices in this manual. These notices supply

helpful information which may assist you as you work.

Throughout this manual, you will see the following types of

procedural notices:

Important

Text in an Important box provides you with information

that may help you perform a procedure more efficiently.

Disregarding this information will not cause damage or

injury, but it may slow you down as you work.

NOTE: Text set off as a Note provides you with simple, but

useful, extra information about the procedure you are

performing.

Read These Before Proceeding:

,

Caution

Proper installation, care and maintenance are essential

for maximum performance and trouble-free operation

of your Welbilt equipment. Read and understand this

manual. It contains valuable care and maintenance

information. If you encounter problems not covered by

this manual, do not proceed, contact Welbilt. We will be

happy to provide assistance.

Important

Routine adjustments and maintenance procedures

outlined in this manual are not covered by the warranty.

n

Warning

PERSONAL INJURY POTENTIAL

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified from

that of original manufactured specifications.

NOTE: SAVE THESE INSTRUCTIONS.

Table of Contents

Part Number 020008596 3

Section 1

General Information

Read This Manual ...............................................................................................................5

Unit Inspection ................................................................................................................... 5

Model Numbers .................................................................................................................. 5

Accessories ..........................................................................................................................5

Module Kit Contents .............................................................................................................................5

Back Room Kit Contents.......................................................................................................................5

Connectors ...............................................................................................................................................6

Serial Number Location .....................................................................................................6

Warranty Information ........................................................................................................7

Installation Instructions

General ................................................................................................................................9

Dimensions ...............................................................................................................................................9

Essential Tools ..........................................................................................................................................9

Pre-installation Checklist .....................................................................................................................9

Electrical............................................................................................................................10

General .................................................................................................................................................... 10

Minimum Circuit Ampacity .............................................................................................................. 10

Voltage .................................................................................................................................................... 10

Minimum Circuit Amperage Chart ................................................................................................ 10

Grounding Instructions ..................................................................................................................... 10

Recommended Plumbing ................................................................................................12

General .................................................................................................................................................... 12

Capacities ............................................................................................................................................... 12

Specifications Chart ............................................................................................................................ 12

Step by Step Aftermarket & Integrated Installations .................................................... 13

SV-175 Pepsi Renew Units ................................................................................................................ 13

SV-250 Pepsi Renew Renew Units ................................................................................................. 19

Back room Tasks ................................................................................................................................... 25

ADA Keypad Matrix.............................................................................................................................25

Starting Your Beverage System & Dispenser ............................................................................. 25

Section 3

Operation

General System Overview ...............................................................................................27

Component Identification................................................................................................................27

Racking.................................................................................................................................................... 27

B-I-B .......................................................................................................................................................... 27

Pumps ......................................................................................................................................................27

Programming Modes .......................................................................................................28

Program Dispense Time ................................................................................................................... 28

PURGE/SANITIZE .................................................................................................................................. 28

DISPENSING MODES ........................................................................................................................... 28

CHANGING NUMBER OF ACTIVE FLAVORS................................................................................. 28

TIME DELAY AFTER DISPENSE ......................................................................................................... 29

Control Logic Matrix.........................................................................................................30

Section 4

Maintenance

4 Part Number 020008596

Table of Contents (continued)

Cleaning Checklist .............................................................................................................................. 31

BEVCLEAN™ PROCESS ........................................................................................................................ 31

CONVENTIONAL CLEAN/SANITIZE METHOD ............................................................................. 31

Bag-In-Box System Sanitation ........................................................................................................32

Shipping, Storage and Relocation ................................................................................................. 32

Section 5

Before Calling for Service

Checklist ............................................................................................................................33

Part Number 020008596 5

Read This Manual

Welbilt developed this manual as a reference guide for the

owner/operator and installer of this equipment. Please read

this manual before installation or operation of the machine.

A qualified service technician must perform installation and

start-up of this equipment, consult Section 5 within this

manual for service assistance.

If you cannot correct the service problem, call your Welbilt

Service Agent or Distributor. Always have your model and

serial number available when you call.

Your Service Agent _________________________________

Service Agent Telephone Number _____________________

Your Local Welbilt Distributor _________________________

Distributor Telephone Number ________________________

Model Number ____________________________________

Serial Number _____________________________________

Installation Date ___________________________________

Unit Inspection

Thoroughly inspect the unit upon delivery. Immediately

report any damage that occurred during transportation to

the delivery carrier. Request a written inspection report from

a claims inspector to document any necessary claim.

n

Warning

PERSONAL INJURY POTENTIAL

Do not operate equipment that has been misused,

abused, neglected, damaged, or altered/modified from

that of original manufactured specifications.

Model Numbers

This manual covers the following models:

SV-175, SV-250 Pepsi Renew

Accessories

Portion control through adjustable dispense time, backlit

dispense nozzle with field-selectable flash sequence, built-in

dispense counter to track individual flavor sales, POP static

cling instruction sheet, easy-to-install pre-assembled valve/

control board module.

MODULE KIT CONTENTS

Switch cover with nozzle, ice chute bracket, cover mounting

bracket, internal nozzle tubing mount, control board and

valve solenoid assembly, nozzle LED

BACK ROOM KIT CONTENTS

BIB rack, BIB syrup pumps (1 for each flavor), low pressure

CO

2

regulator (0-100 PSI), 50 feet of bundled tubing (1 tube

for each flavor)

Section 1

General Information

6 Part Number 020008596

General Information Section 1

CONNECTORS

Use the following part numbers when ordering additional kits or replacement parts.

33230 (Pepsi BIBConnector)

Serial Number Location

This number is required when requesting information from your local distributor. The serial number is listed on the SERIAL

NUMBER DECAL affixed to the control board bracket.

Flavor Shot Serial Number Locations

SN XXXXXXXXX

Serial

Control

Board

Part Number 020008596 7

Section 1 General Information

Warranty Information

Consult your local Welbilt Distributor for terms and

conditions of your warranty. Your warranty specifically

excludes all beverage valve Brixing, general adjustments,

cleaning, accessories and related servicing.

Your warranty card must be returned to Welbilt to activate

the warranty on this equipment. If a warranty card is

not returned, the warranty period can begin when the

equipment leaves the Welbilt factory.

No equipment may be returned to Welbilt without a written

Return Materials Authorization (RMA). Equipment returned

without an RMA will be refused at Welbilt’s dock and

returned to the sender at the sender’s expense.

Please contact your local Welbilt distributor for return

procedures.

8 Part Number 020008596

General Information Section 1

THIS PAGE INTENTIONALLY LEFT BLANK

Part Number 020008596 9

General

These instructions are provided to assist the qualified

installer. Contact your Welbilt Service Agent or call Welbilt

Multiplex Technical Services for information regarding start-

up services.

Important

Failure to follow these installation guidelines may affect

warranty coverage.

DIMENSIONS

3.312

(8.413 cm)

5.491

(13.947 cm)

2.463

(6.256 cm)

2.372 REF

(6.024 cm)

A

3.312

(8.413 cm)

5.491

(13.947 cm)

2.463

(6.256 cm)

2.372 REF

(6.024 cm)

C

B

Flavor Shot A B C

Module* 3.31”

(8.41 cm)

5.49”

(13.95 cm)

4.84”

(12.28 cm)

ESSENTIAL TOOLS

• Tubing Cutters

• Oetiker pliers

• Phillips and slotted screwdriver

• Power drill

• Six (6) inch adjustable wrench

• Tape Measure

• 8/32” Tap

n

Warning

Carbon Dioxide (CO

2

) displaces oxygen. Exposure to a

high concentration of CO

2

gas causes tremors, which are

followed rapidly by loss of consciousness and suffocation.

If a CO

2

gas leak is suspected, particularly in a small area,

immediately ventilate the area before repairing the leak.

CO

2

lines and pumps must not be installed in an enclosed

space. An enclosed space can be a cooler or small room

or closet. This may include convenience stores with glass

door self serve coolers. If you suspect CO

2

may build up in

an area, venting of the B-I-B pumps and / or CO

2

monitors

must be utilized.

PRE-INSTALLATION CHECKLIST

When installing any system, first make sure the major

components are available. Generally the major components

necessary for an installation are:

Typical BIB System:

B-I-B connectors

B-I-B regulator set

B-I-B rack

B-I-B syrup boxes

Post Mix System:

CO

2

regulator set

Beverage dispenser

Beverage tubing

CO

2

tank

Carbonator

Stepless (Oetiker) clamps

Chain for CO

2

tank

Section 2

Installation Instructions

10 Part Number 020008596

Installation Instructions Section 2

Electrical

GENERAL

n

Warning

All wiring must conform to local, state and national codes.

MINIMUM CIRCUIT AMPACITY

The minimum circuit ampacity is used to help select the wire

size of the electrical supply. (Minimum circuit ampacity is not

the beverage/ice machine’s running amp load.) The wire size

(or gauge) is also dependent upon location, materials used,

length of run, etc., so it must be determined by a qualified

electrician.

VOLTAGE

The standard voltage for the Flavor Shot Module is 24VAC,

0.5 AMP, powered by existing valve transformer on dispenser.

MINIMUM CIRCUIT AMPERAGE CHART

Important

Due to continuous improvements, this information is

for reference only. Please refer to the dispenser serial

number tag to verify electrical data. Serial tag information

overrides information listed on this page.

Dispenser Voltage/Cycle Minimum Circuit

Amps

SV-175,

SV-250 Pepsi Renew

115/60 2.8

GROUNDING INSTRUCTIONS

n

Warning

Risk of electrical shock. Connect to a properly grounded

outlet only.

This appliance must be grounded. In the event of

malfunction or breakdown, grounding provides a path of

least resistance for electric current to reduce the risk of

electric shock. This appliance is equipped with a cord having

an equipment-grounding conductor and a grounding plug.

The plug must be plugged into an appropriate outlet that is

properly installed and grounded in accordance with all local

codes and ordinances.

n

Warning

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. The

conductor with insulation having an outer surface that

is green with or without yellow stripes is the equipment

grounding conductor. If repair or replacement of the

cord or plug is necessary, do not connect the equipment-

grounding conductor to a live terminal. Check with a

qualified electrician or serviceman if the grounding

instructions are not completely understood, or if in doubt

as to whether the appliance is properly grounded. Do

not modify the plug provided with the appliance — if it

will not fit the outlet, have a proper outlet installed by a

qualified electrician.

Part Number 020008596 11

Section 2 Installation Instructions

n

Warning

When using electric appliances, basic precautions should

always be followed, including the following:

a. Read all the instructions before using the

appliance.

b. To reduce the risk of injury, close supervision

is necessary when an appliance is used near

children.

c. Do not contact moving parts.

d. Only use attachments recommended or sold by

the manufacturer.

e. Do not use outdoors.

f. For a cord-connected appliance, the following

shall be included:

• Do not unplug by pulling on cord. To unplug,

grasp the plug, not the cord.

• Unplug from outlet when not in use and before

servicing or cleaning.

• Do not operate any appliance with a

damaged cord or plug, or after the appliance

malfunctions or is dropped or damaged in any

manner. Contact the nearest authorized service

facility for examination, repair, or electrical or

mechanical adjustment.

g. For a permanently connected appliance — Turn

the power switch to the off position when the

appliance is not in use and before servicing or

cleaning.

h. For an appliance with a replaceable lamp —

Always unplug before replacing the lamp. Replace

the bulb with the same type.

i. For a grounded appliance — Connect to a

properly grounded outlet only. See Grounding

Instructions.

12 Part Number 020008596

Installation Instructions Section 2

Recommended Plumbing

GENERAL

The Flavor Shot Module is compatible with SV series Pepsi Renew units. See the appropriate section for instructions on

attaching the module assembly to the unit.

Flavor 1

Flavor 2

Flavor 3

2 x 4 BIB Rack

Flavor 5

Flavor 6

Flavor 7

Flavor 4 Flavor 8

Flavor 1

Flavor 2

Flavor 3

1 x 3 BIB Rack

Flavor 1

Flavor 2

Flavor 3

2

x

3 BIB Rack

Flavor 4

Flavor 5

Flavor 6

BIB Rack Configurations

Flavor

Magic

Module

SET REGULATOR

20 to 30 PSI

Valve 1

Pump

1

Pump

2

Pump

3

Pump

4

Flavor 1

Flavor 2

Flavor 3

1 x 4 BIB Rack

Flavor 4

CO

2

Supply

Valve 2

PUMP

PUMP

PUMP

PUMP

SYRUP

BAG

SYRUP

BAG

SYRUP

BAG

SYRUP

BAG

VALVE

VALVE

VALVE

VALVE

CO2 TANK

SET PRESSURE 20 PSI

FLUID PATH

DISPENSE

NOZZLE

CAPACITIES

Module Valves Flow Rate Dispense Time

Flavor Shot 1 per flavor, up to 4 flavors Variable, 0.5 oz/sec nominal 0.2 - 10 seconds, adjustable in

0.2 second increments

SPECIFICATIONS CHART

MIN. MAX

Dispenser Incoming Plain Water

Pressure

40 psi dynamic 70 psi static

Ambient Temperature 40°F

(4°C)

105°F

(41°C)

B-I-B (Secondary) 75 psi or according to line run

Flavor Shot Regulator 20 psi MAX or according to line run

Part Number 020008596 13

Section 2 Installation Instructions

Step by Step Aftermarket & Integrated

Installations

Important

Integrated SV Pepsi Renew Units installations, additional

components must be field installed and are found in a box

shipped with the dispenser. 0-30 CO

2

regulator, CO

2

and

Flavor Shot syrup lines, fittings, and clamps must be field

supplied.

SV-175 PEPSI RENEW UNITS

Aftermarket

1. Disconnect electrical power to ice drink dispenser.

2. Remove the merchandiser by carefully lifting up and

then pulling outwards.

3. Remove grate from drain area and set aside.

4. Remove old Splash Panel.

A. Remove 2 (two) screws ,1 (one) screw from each

side of metal splash panel. Save screws.

B. Remove old panel by tilting bottom out and sliding

under drink levers. Set aside.

5. Remove metal Upper Splash Shield and set aside.

A. Remove 2 (two) screws, 1 (one) screw from each

side. Screws have a nut on backside.

B. Carefully pull splash shield out.

C. Set shield, screws and nuts aside.

NOTE: Save the screws and nuts. Old panel can be discarded

after new installation is complete.

6. Remove plastic electrical cover.

A. Remove 2 (two) screws, 1 (one) screw from each

side of plastic cover.

B. Release wires from plastic clip on side of panel.

C. Pull plastic cover straight out and set aside.

14 Part Number 020008596

Installation Instructions Section 2

7. Disconnect the black and white secondary wires.

8. Connect new harness.

A. Connect piggyback end of white wire to box.

B. Connect piggyback end of red wire to box.

9. Reconnect the black and white secondary wires to the

piggyback connectors on the new wiring harness.

A. Connect white wire to new white wire piggyback

connector.

B. Connect black wire to new red wire piggyback

connector.

10. Connect end of new harness to control board.

11. Reinstall plastic electrical cover.

A. Arrange wires to prevent interference with cover.

B. Replace 2 (two) screws, 1 (one) screw to each side

of plastic cover.

C. Put wires back into plastic clip on side of panel.

12. Remove plastic dispense cover from new Flavor Shot

Keypad assembly by turning and pulling outwards and

set aside.

Part Number 020008596 15

Section 2 Installation Instructions

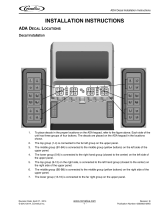

13. Route wire harness from Flavor Shot Keypad assembly as

shown below.

Control Board

Connector

ADA Keypad on

Splash Panel

Connector

14. Locate holes on either side of ice chute. Test to see if

holes are tapped by installing new screws in holes.

15. Tap holes if necessary.

A. Before tapping the holes first remove the valves

adjacent to the ice chute.

B. Tap the holes with the 8-32 tap included in the kit.

C. Replace valves adjacent to the ice chute.

16. Slide brackets of new Flavor Shot Keypad assembly

around the ice chute and hang assembly on metal frame.

NOTE: Ice chute may need to be pressed backwards to

enable the brackets of new Flavor Shot Keypad assembly to

hang onto metal frame.

17. Align cutouts of Flavor Shot Keypad assembly brackets

with two (2) pre-punched holes for mounting the Flavor

Shot module bracket, one on each side of the ice chute

in the metal frame.

18. Secure the Flavor Shot mounting brackets with the two

(2) slotted thumb screws provided to secure assembly to

metal frame.

19. Locate new metal Splash Panel and set in front of

machine with wiring harness towards top.

20. Push wiring harness from new metal Splash Panel up

through opening in right corner of upper right side

panel.

16 Part Number 020008596

Installation Instructions Section 2

21. If necessary put tape on wire harness across top of unit

to keep out of way until ready for use.

22. Locate new metal Upper Splash Shield.

SV-175 Upper

Splash Shield

23. Install new metal Upper Splash Shield.

A. Carefully push tubing with connectors from REAR of

valves down behind metal frame.

B. Pull tubing downwards to prevent crimping.

C. Slide new Upper Splash Shield in place.

D. Carefully pull tubing from rear of valves down

behind metal frame to remove any excess from

crimping behind metal frame.

24. Verify new metal Upper Splash Shield is seated into

metal side panels correctly.

25. Reinstall two (2) old screws from Upper Splash Shield

into new panel.

26. Carefully push tubing from TOP of valves down opening

of new Upper Splash Shield and behind new Flavor Shot

Keypad assembly.

Part Number 020008596 17

Section 2 Installation Instructions

27. Push tubes down through the opening of the Flavor Shot

bracket.

NOTE: You may need to press the ice chute back so the tubes

have room to move down into the bracket opening.

28. Install tubing from TOP of new valves into new Flavor

Shot dispense head.

NOTE: If tubing will not insert easily into new dispense head,

soak ends of tubing in cup of hot water for 30-60 seconds

and then try again.

29. Position new dispense head into cut out in Flavor Shot

Keypad assembly as shown below.

30. Reinstall plastic dispense cover onto bottom of new

Flavor Shot Keypad assembly.

31. Carefully pull excess tubing up and arrange the tubing

into the clips on the flange. Verify tubing does not

interfere with ice chute.

32. Install middle connector from new wiring harness from

Flavor Shot Keypad assembly to control board connector.

33. Remove tape if necessary and connect Splash Panel

ribbon cable to end of Flavor Shot Keypad wiring

harness.

18 Part Number 020008596

Installation Instructions Section 2

34. Connect conduit from syrup rack to new tubing from

rear of new valves. Push tubing into place to prevent

crimping when Splash Panel (with ADA Keypad) is

installed.

35. Tilt bottom of new metal Splash Panel (with ADA

Keypad) out and slide up under drink levers into place

while pulling excess wire from ribbon cable up to

prevent crimping.

36. Verify excess wire from Splash Panel (with ADA Keypad)

ribbon cable has been pulled up. Push excess wire into

clips around inside of unit as needed to prevent crimping

when reinstalling merchandiser.

37. Reinstall 2 (two) screws into new Splash Panel (with ADA

Keypad), 1 (one) in each side.

38. Reinstall drain grate.

39. Reinstall merchandiser.

40. If large gap exists between new Flavor Shot Keypad

assembly and merchandiser adjust assembly.

A. Remove merchandiser.

B. Loosen 3 (three) thumbscrews on Flavor Shot

Keypad assembly: one on left side, one on right side

and one on bottom.

C. Install merchandiser and press keypad assembly into

place.

D. Remove merchandiser.

E. Secure 3 (three) thumbscrews.

F. Reinstall merchandiser.

41. Connect electrical power to ice drink dispenser.

Part Number 020008596 19

Section 2 Installation Instructions

SV-250 PEPSI RENEW RENEW UNITS

Aftermarket

1. Disconnect electrical power to ice drink dispenser.

2. Remove the merchandiser by carefully lifting up and

then pulling outwards.

3. Remove grate from drain area and set aside.

4. Remove old Splash Panel.

A. Remove 2 (two) screws ,1 (one) screw from each

side of metal splash panel.

B. Remove old panel by tilting bottom out and sliding

under drink levers. Set aside.

5. Remove metal upper Splash Shield and set aside.

A. Carefully left up and pull splash shield out.

B. Set shield aside.

NOTE: Save the panel for re-assembly in later steps.

6. Remove the valves adjacent to the ice chute.

7. Locate holes on either side of ice chute. Test to see if

holes are tapped by installing new screws in holes.

8. Tap holes if necessary.

A. Tap the holes with the 8-32 tap included in the kit.

9. Remove plastic dispense cover from new Flavor Shot

Keypad assembly by turning and pulling outwards and

set aside.

20 Part Number 020008596

Installation Instructions Section 2

10. Route wire harness from Flavor Shot Keypad assembly as

shown below.

Control Board

Connector

ADA Keypad on

Splash Panel

Connector

11. Slide brackets of new Flavor Shot Keypad assembly

under the front bar and then around the ice chute and

hang assembly on metal frame.

NOTE: Ice chute may need to be pressed backwards to

enable the brackets of new Flavor Shot Keypad assembly to

hang onto metal frame.

12. Align cutouts of Flavor Shot Keypad assembly brackets

with two (2) pre-punched holes for mounting the Flavor

Shot module bracket, one on each side of the ice chute

in the metal frame.

13. Secure the Flavor Shot mounting brackets with the two

(2) slotted thumb screws provided to secure assembly to

metal frame.

14. Re-install valves adjacent to ice chute.

15. Locate new metal Splash Panel (with ADA Keypad) and

set in front of machine with wiring harness towards top.

16. Push wiring harness from new metal Splash Panel (with

ADA Keypad) up through opening in right corner of

upper right side panel.

17. If necessary put tape on wire harness across top of unit

to keep out of way until ready for use.

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

Page is loading ...

/