Page is loading ...

compact dc power distribution

HDX

™

Setup and OperatiOn Manual

SETUP AND OPERATION MANUAL

Comm/net Systems, Inc.

4237 – 24th Avenue West

Seattle, WA 98199

TEL: 206.282.8670

FAX: 206.282.8684

www.commnetsystems.com

24/7 Sales & Service

To purchase Comm/net Systems solutions, contact your

Comm/net Systems representative at: (800) 274-0544

or e-mail: sales@commnetsystems.com

About Comm/net Systems

Comm/net Systems, Inc. (CSI) is the leader in high power density communications power

systems. Comm/net oers comprehensive power and communications site systems integration

and deployment services via a national footprint of regional branch oces. Additional

information can be found at www.commnetsystems.com.

© 2015 Comm/net Systems, Inc. All rights reserved. Comm/net Systems, and the Comm/

net Systems logo are registered trademarks of Comm/net Systems, Inc. in the United States

and other countries. All other trademarks, service marks, registered marks, or registered

service marks are the property of their respective owners. Comm/net Systems assumes no

responsibility for any inaccuracies in this document. Comm/net Systems reserves the right to

change, modify, transfer, or otherwise revise this publication without notice.

Document Number: 048-693-30

Revision Level: r02

Published: July 2015

compact dc power distribution

HDX

™

HDX™

SETUP AND OPERATION MANUAL

TABLE OF CONTENTS

HDX™

SETUP AND OPERATION MANUAL

ABOUT THIS MANUAL

Table of Contents

Section 1: Purpose and Applicability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

1.1 Product Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Section 2: Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

2.2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Section 3: Unpacking and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

3.1 Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Section 4: Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

4.1 Installation Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

4.1.1 Elevated Operating Ambient . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

4.1.2 Reduced Air Flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

4.1.3 Mechanical Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

4.1.4 Circuit Overloading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

4.1.5 Reliable Earthing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

4.1.6 Disconnect Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

4.2 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

4.3 Chassis Ground Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Table 1. Ground Terminal Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

4.4 Alarm Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

4.5 Input Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Table 2. Input Breaker and Fuse Ratings Per Panel Rating . . . . . . . . . . . . . . . . . . . . . . 5

Table 3. Termination Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

4.6 Output Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Table 4. Output information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4.7 Rear Safety Cover Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

4.8 Installing Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

4.9 Installing Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

4.9.1 Breaker Inventory For HDX ABC 10 . . . . . . . . . . . . . . . . . . . . . . .8

4.9.2 Breaker Inventory For All Other Models . . . . . . . . . . . . . . . . . .8

4.10 Installation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Appendix A: Product Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

A.1 Electrical Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Table 5. Specications per model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

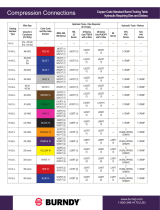

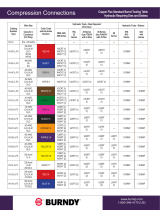

A.2 Supported Lugs for Termination . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 6. Input Connections (Applies to 016-410-10 and 016-412-10) . . . . . . . . . . . . . 10

Table 7. Input connections (Applies to 016-450-10, 016-451-10, and 016-452-10) . . . . . 10

Table 8. Output connections (Applies to all models) . . . . . . . . . . . . . . . . . . . . . . . . 10

Table 9. Ground lug information (Applies to 016-410-10 and 016-412-10) . . . . . . . . . . 10

Table 10. Ground lug information (Applies to 016-450-10, 016-451-10, 016-452-10,) . . . 10

A.3 Supported Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Table 11. Breaker specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Appendix B: Mechanical Illustrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

About This Manual

To reduce the risk of damage to equipment, injury, or death; and to ensure proper

installation and operation of Comm/net Systems products, please be sure to read and

understand the entirety of this manual and any other supplied documentation. Keep

this document in a safe and accessible place for future reference.

Safety and Alert Symbols

The following symbols may appear in this manual, other supplied documentation, or on Comm/net Systems product labeling. The meaning of

this indication is explained below.

NOTICE

INDICATES IMPORTANT INFORMATION REGARDING THE COMPLETE AND PROPER FUNCTION OF A PRODUCT.

TYPICALLY REFERS TO MONITORING CONFIGURATION OR OTHER NONDANGEROUS SITUATIONS.

CAUTION

INDICATES A HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, COULD DAMAGE

EQUIPMENT/PROPERTY OR COULD RESULT IN MINOR OR MODERATE INJURY.

WARNING

INDICATES A HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, COULD RESULT IN INJURY OR DEATH.

DANGER

INDICATES A HAZARDOUS SITUATION WHICH, IF NOT AVOIDED, WILL RESULT IN SERIOUS INJURY OR DEATH.

Product support

If you have any questions concerning Comm/net Systems products and services, contact our support sta. Our knowledgeable support team

can provide product technical support and answer other questions regarding Comm/net products and services.

In addition to contacting Comm/net Support directly via phone or e-mail, our online help desk is available 24 hours a day, 7 days a week. The

help desk includes answers to commonly asked questions and self-help articles as well as an online ticket submission system if you need to

contact Comm/net after normal business hours.

y Comm/net support is available by phone or e-mail Monday – Friday from 8am – 4:30pm Pacic Standard Time.

y The online web portal is available 24/7 to submit support requests and general questions, or view the FAQ and self-help articles.

NOTE: All questions submitted to the web portal will be answered during normal business hours.

y Phone: 1-800-274-0544

y E-mail: [email protected]

y Online Web Portal: https://commnetsystems.freshdesk.com

HDX™

SETUP AND OPERATION MANUAL

PAGE VI

HDX™

SETUP AND OPERATION MANUAL

PURPOSE AND APPLICABILITY PAGE 1

THIS PAGE INTENTIONALLY LEFT BLANK

Section 1: Purpose and Applicability

The purpose of this document is to detail the installation and operation instructions

for the HDX Compact DC Power Distribution Center.

1.1 Product Model

This document applies to Comm/net Systems, Inc product with model congurations:

y 016-410-10 HDX 300 Isolated A/B Input

y 016-412-10 HDX 300 Single Input A/B

y 016-450-10 HDX 400 Isolated A/B Input

y 016-451-10 HDX 400 Single Input A/B

y 016-452-10 HDX ABC 10 Isolated Diode Routed Input

Section 2: Theory of Operation

2.1 Introduction

The HDX is a compact DC distribution center for rack-mount telecom and broadband

applications.

2.2 Features

y High-reliability breaker distribution

y Supports AM style bullet terminal breakers

y Up 100A max per breaker channel (see electrical specications)

y LEDs indicate status at a glance

y Form C alarm contacts

y Adjustable brackets for 19" or 23" rack mount installation

Section 3: Unpacking and Inspection

The Comm/net Systems HDX Compact DC Power Distribution Center was carefully

packaged at the factory to withstand the normal rigors of shipping. However, you

should carefully inspect the box and contents to conrm that no damage has occurred

in transit. Most shipping carriers require notication of shipping damage within twenty-

four hours of delivery, and it is the responsibility of the recipient to inspect the shipment

immediately upon receipt.

3.1 Package Contents

Included with your product are the following items:

y HDX DC Distribution Center

y Mounting hardware kit with necessary screws and washers

y Rear plastic bus bar safety shield

Figure 1. HDX Panel with rack mount brackets

Figure 2. HDX Panel with rear plastic safety shield

HDX™

SETUP AND OPERATION MANUAL

PAGE 2 PURPOSE AND APPLICABILITY

HDX™

SETUP AND OPERATION MANUAL

INSTALLATION PAGE 3

THIS PAGE INTENTIONALLY LEFT BLANK

Section 4: Installation

The HDX panel can be installed in any standard 19-inch or 23-inch relay rack. The

panel itself occupies only 2RU, but it is recommended that space be left free above and

below the panel to ease cable routing. It is common to mount the HDX panel at the

topmost rack position.

NOTICE

THIS PRODUCT MUST BE INSTALLED WITHIN A RESTRICTED

ACCESS LOCATION WHERE ACCESS IS THROUGH THE USE

OF A TOOL, LOCK AND KEY, OR OTHER MEANS OF SECURITY,

AND IS CONTROLLED BY THE AUTHORITY RESPONSIBLE

FOR THE LOCATION. THIS PRODUCT MUST BE INSTALLED

AND MAINTAINED ONLY BY QUALIFIED TECHNICIANS.

4.1 Installation Preparation

When selecting an installation location, ensure that all of the following conditions are

met before proceeding.

4.1.1 Elevated Operating Ambient

If you install the panel in a closed or multi-unit rack assembly, the operating ambient

temperature of the rack environment may be greater than room ambient. Therefore,

take care to install the equipment in an environment compatible with the maximum

ambient temperature (TMA) specied in Section 5.

4.1.2 Reduced Air Flow

Installation of the equipment in a rack should be such that the amount of air ow

required for safe operation of the equipment is not compromised.

4.1.3 Mechanical Loading

Mounting of the equipment in the rack should be such that a hazardous condition is

not achieved due to uneven mechanical loading.

4.1.4 Circuit Overloading

Give consideration to the connection of the equipment to the supply circuit and

the eect that overloading of the circuits might have on overcurrent protection and

supply wiring. Use appropriate consideration for equipment nameplate ratings when

addressing this concern.

4.1.5 Reliable Earthing

Maintain reliable earthing of rack-mounted equipment. Pay particular attention to

supply connections other than direct connections to the branch circuit (e.g., use of power

strips).

4.1.6 Disconnect Device

A readily accessible disconnect device must be incorporated in the building

installation wiring.

HDX™

SETUP AND OPERATION MANUAL

PAGE 4 INSTALLATION

HDX™

SETUP AND OPERATION MANUAL

INSTALLATION PAGE 5

17.000

.760

.640

1.050

1.000

.760

1/4-20 STUDS

1/4-20 STUDS

.625

.625

MAIN RETURN

CONNECTION

.625

.625

CHASSIS GROUND

Threaded for 1/4”-20

1.431

1.111

0

R.141 TYP.

0

.235

3.235

3.470

11.167

8.592

9.342

C OUTPUT

RETURN

+48V

A HOT INPUT

-48V

A INPUT

POWER LED

B INPUT

POWER LED

BREAKER TRIP

LED

FORM C

DRY CONTACT

ALARM CONN.

B HOT INPUT

-48V

Figure 3. HDX Ground Terminal Location

A1

A2

A3

A4

A5

A6

B1

B2

B3

B4

B5

B6

B

AM BREAKER

HOT -48V OUTPUTS

A SIDE OUTPUT RETURN +48V

B SIDE OUTPUT RETURN +48V

REAR VIEW

A INPUT DC HOT (-)

CONNECTION

B INPUT DC HOT (-)

CONNECTION

GLASTIC ISOLATOR BETWEEN

A AND B RETURN BUS BARS FOR

A/B INPUT VERSIONS. RETURN BUS

IS ELECTRICALLY ISOLATED A TO B.

B INPUT DC RETURN (+)

CONNECTION.

A INPUT DC RETURN (+)

CONNECTION.

A1

A2

A3

A4

B1

B2

B3

B4

C

D

DETAIL B

GMT FUSE

HOT OUTPUT

-48V

GMT FUSE

RETURN OUTPUT

+48V

6 - N.O.

5 - N.C.

4 - COM

3 - N.O.

2 - N.C.

1 - COM

DETAIL C

SET SCREW FORM "C"

ALARM CONTACTS.

SEE NOTE 1.

DETAIL D

RJ45 ALARM CONTACTS

JACKS ARE DAISY CHAINED

PIN DETAILS IN TABLE A.

SEE NOTE 1.

2 4 6 8 2 4 6 8

1 3 5 7

1 3 5 7

1 - COM

2 - N.C.

3 - N.O.

4 - COM

5 - N.C.

6 - N.O.

TABLE "A"

MAJOR

MINOR

(NOT USED)

NOTES:

CIRCUIT BREAKER TRIP AND FUSE FAIL ALARM

1.

AVAILABLE ON MAJOR ALARM CONTACTS.

Figure 4. Alarm Connections

×2

×1

×2

×32

Figure 6. The 016-1651-10 Adapter Kit

Primary Components Shown

Figure 5. Panel Inputs From Top to Bottom: 016-410-10,

016-412-10, 016-450-10, 016-451-10, 016-452-10

B AB

DC HOT INPUTS (-) DC RETURN INPUTS (+)

A

B AB

DC HOT INPUTS (-) DC RETURN INPUTS (+)

A

B AB

DC HOT INPUTS (-) DC RETURN INPUTS (+)

A

DC HOT INPUTS (-)

DC RETURN INPUTS (+)

DC HOT INPUTS (-) DC RETURN INPUTS (+)

4.5 Input Connections

WARNING

y INPUTS MUST BE PROTECTED BY A LISTED CIRCUIT BREAKER

OR BRANCH RATED FUSE. REFER TO "TABLE 2. INPUT

BREAKER AND FUSE RATINGS PER PANEL RATING" ON

PAGE 5 FOR MAXIMUM FUSE AND BREAKER SIZES.

y MULTIPLE POWER SOURCES ARE PRESENT, ENSURE

ALL INPUT POWER FEEDS ARE NOT ENERGIZED BEFORE

INSTALLING THEM. ELECTRICAL INSTALLATION SHOULD

ONLY BE PERFORMED BY QUALIFIED PERSONNEL WITH

PROPER TOOLS AND PROTECTIVE SAFETY EQUIPMENT.

NOTICE

y MAKE SURE THAT ALL FEEDER CABLES HAVE

HEAT SHRINK APPLIED PRIOR TO TERMINATION,

AND THAT NOOXIDE COMPOUND IS APPLIED TO

ALL COPPERTOCOPPER CONNECTIONS.

y SEE "APPENDIX A: PRODUCT SPECIFICATIONS"

FOR COMPRESSION LUG SPECIFICATIONS,

TOOLING, AND ORDERING INFORMATION.

y IF USING A 350KCMIL LUG OR LARGER, AN 016165110

ADAPTER KIT IS REQUIRED TO ALLOW PROPER CONNECTION.

Step 1. Install the incoming DC feeder cables for the power inputs and power returns.

Refer to "Table 3. Termination Information"

TABLE 2. INPUT BREAKER AND FUSE RATINGS PER PANEL RATING

Model Rating Max input Fuse /

CiRCuit BReakeR size

200A 250A

300A 375A

400A 500A

TABLE 3. TERMINATION INFORMATION

input teRMination

type

hole/stud

size

CenteR to

CenteR

Bus BaR

width

ReCoMMended

toRque value

Hot Threaded Insert 3/8-16 1 in 1 in 225 in-lbs

Return Threaded Insert 1/4-20 5/8 in 1 in 70 in-lbs

4.2 Mounting

Select the equipment rack location for installation of the panel. Orient the rack

mount ears appropriately for either 19 in. or 23 in. rack mount conguration. Attach the

mounting ears with included 1/4 - 20 hardware. Depending on the attachment point

selected, the panel will either be ush or mid-mounted in the rack.

4.3 Chassis Ground Connection

CAUTION

DO NOT ENERGIZE THE PANEL BEFORE

CHASSIS GROUND IS CONNECTED.

The chassis ground is located in the side of the panel (see "Figure 3. HDX Ground

Terminal Location"). A two hole lug landing position is provided. See table below for

termination information screw is provided for attaching a chassis ground cable. A

minimum of #4 AWG chassis ground cable is required for 016-452-10 model; a minimum

of #2 AWG chassis ground cable is required for all other models.

TABLE 1. GROUND TERMINAL SPECIFICATIONS

gRound teRMinal speCiFiCations

Model Numbers All Models

Landing Type Threaded Insert

Hole Size 1/4

Center-to-Center 5/8

Recommended Torque 90 in·lbs

4.4 Alarm Wiring

Install alarm wiring. On the rear of the panel, there is an 8p8c modular jack (RJ-45) for

alarm connections. Models with GMT fuse positions also have a green 6-position alarm

terminal block next to the RJ-45 jacks. See table "A" for alarm pin out. Refer to drawings

in Appendix B for the locations of these alarm connections.

The following models feature an additional RJ-45 jack to allow for daisy chaining:

y 016-410-10, 016-412-10

y 016-450-10, 016-451-10

HDX™

SETUP AND OPERATION MANUAL

PAGE 6 INSTALLATION

HDX™

SETUP AND OPERATION MANUAL

INSTALLATION PAGE 7

4.7 Rear Safety Cover Installation

WARNING

FAILURE TO INSTALL THE REAR SAFETY COVER

WILL CREATE AN ELECTRICAL HAZARD.

Step 1. Install the included #8-32 panhead screws into the threaded holes on the sides

of the panel.

Step 2. Slide the cover onto the screws installed, then tighten down the screws to

secure the cover.

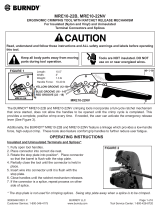

4.8 Installing Fuses

NOTICE

y USE BUSSMANN GMT TYPE FUSES ONLY.

y FUSES MUST CARRY A 450A INTERRUPT RATING.

Step 3. Ensure that connected loads are in the OFF position

Step 4. Fully nsert a fuse of sucient ampacity into the position to be fed.

Step 5. Turn on the circuit breaker.

Step 6. Turn on the connected load.

4.9 Installing Breakers

Refer to "Table 11. Breaker specications" on page 11 for a list of supported

breakers

Step 7. Ensure breaker to be used is in the OFF position.

Step 8. Ensure that connected loads are in the OFF position.

Step 9. Insert a breaker of sucient ampacity into the position to be fed.

Step 10. Ensure that the breaker is fully seated.

Step 11. Turn on the connected load.

Step 12. Inventory the breakers (See "4.9.1 Breaker Inventory For HDX ABC 10" and

"Breaker Inventory For All Other Models" on page 8)

4.6 Output Connections

CAUTION

DO NOT PERFORM THIS STEP ON CIRCUITS WITH FUSES

OR BREAKERS INSTALLED. ENSURE NO POWER IS PRESENT

ON THE CIRCUIT BEING WIRED BEFORE PROCEEDING.

NOTICE

y MAKE SURE THAT ALL CABLES HAVE INSULATED

TERMINALS OR HEAT SHRINK APPLIED PRIOR TO

TERMINATION, AND THAT NOOXIDE COMPOUND IS

APPLIED TO ALL COPPERTOCOPPER CONNECTIONS.

y SEE "APPENDIX A: PRODUCT SPECIFICATIONS"

FOR TERMINAL SPECIFICATION, TOOLING,

AND ORDERING INFORMATION.

TABLE 4. OUTPUT INFORMATION

Model

nuMBeR

teRMination

type

hole/stud

size

Max ConneCtoR

width

ReCoMMended

toRque value

016-410-10 Through Hole 1/4 in. 0.62 in. 70 in∙lbs

Screw Terminal M3 (#6) 1/4 in. 5 in∙lbs

016-412-10 Through Hole 1/4 in. 0.62 in. 70 in∙lbs

Screw Terminal M3 (#6) 1/4 in. 5 in∙lbs

016-450-10 Through Hole 1/4 in. 0.62 in. 70 in∙lbs

016-451-10 Through Hole 1/4 in. 0.62 in. 70 in∙lbs

016-452-10 Through Hole 1/4 in. 0.62 in. 70 in∙lbs

y 016-410-10 has a total of 12 AM breaker positions (6A/6B) and 8 GMT fuses (4A/4B)

y 016-412-10 has a total of 12 AM breaker positions and 8 GMT fuses

y 016-450-10 has a total of 16 AM breaker positions (8A/8B)

y 016-451-10 has a total of 16 AM breaker positions

y 016-452-10 has a total of 10 AM breaker positions

Step 2. On the rear panel, locate the “stair-step” terminal block for the fused outputs.

Note that each output terminal is numbered from right to left to correspond

with the fuse holder on the front panel. The top terminals in the terminal block

are connected to the return bus bar for each input bus. The bottom row of

terminals are the fused outputs for each fuse holder as numbered. Refer to

Appendix B.

Step 3. Connect the wires to the equipment loads to be fed by the fuse panel fused

outputs to these terminal block connections. The return (+) wire connects to

the bottom terminal and the hot (-) wire connects to the top terminal for each

fuse position. Use appropriate crimp spade or ring lugs on the wires that will

be connected to the terminal block fused outputs. Ensure no stray wire strands

short out to adjacent terminals, and route the wires in an organized fashion

with cable ties or lacing twine down the equipment rack to the equipment

loads.

HDX™

SETUP AND OPERATION MANUAL

PAGE 8 INSTALLATION

HDX™

SETUP AND OPERATION MANUAL

INSTALLATION PAGE 9

HDX™

SETUP AND OPERATION MANUAL

PAGE 9

1 2 3 4

ROCKER DOWN

A4

A3

A2

A1

Figure 7. The Breaker Inventory Button and LED

Figure 8. Setting a Dip Switch

4.9.1 Breaker Inventory For HDX ABC 10

Upon rst power up there will be a red LED ashing to indicate breaker inventory

needs to be performed. Anytime the circuit breaker compliment is changed, you will

need to update the breaker inventory for correct monitoring of breaker status.

Step 1. Step 1: Lift breaker compartment door. Turn on any circuit breakers you wish to

have monitored.

Step 2. Step 2: Press and hold the blue button. See "Figure 7. The Breaker Inventory

Button and LED". Hold the button until the red BREAKER INVENTORY LED turns

on and subsequently turns o. This should take about 5 seconds.

Step 3. Breaker inventory will remain in the controller memory even if power is lost.

NOTE: If a new breaker is installed and turned on after an inventory has been taken, it will

cause an alarm until the breaker inventory is updated.

4.9.2 Breaker Inventory For All Other Models

Anytime the circuit breaker compliment is changed, you will need to update the

breaker inventory for correct monitoring of breaker status.

Step 1. Lift the front cover of the panel. The circuit board on the inside of the door has

a series of dip switches that are used to inventory breakers. Each switch is

labeled with a silk screen on the board indicating which channel the switch

will inventory.

Step 2. Locate an arrow printed near the dip switch labeled "IN". To inventory a breaker

press the dip switch so that side facing the "IN" arrow is depressed.

In "Figure 8. Setting a Dip Switch"A1 and A2 (switch 1 and 2) are inventoried

breakers. A3 and A4 (switch 3 and 4) are not in inventory.

4.10 Installation Checklist

Rack mount ears mounted securely to the panel and the rack?

Chassis ground cable connected?

Input power cables (A Hot, A Return, B Hot, B Return) securely bolted to the

correct bus bars and heat shrink installed?

Alarm cable connected and wired correctly to remote monitoring device (if

required)?

Output feed cables landed to correct polarity?

Wire lacing or cable ties installed to provide strain relief?

Breakers installed in the correct positions and fully seated?

Rear safety cover installed?

Appendix A: Product Specications

A.1 Electrical Specications

NOTICE

USE BUSSMANN GMT TYPE FUSES ONLY.

FUSES MUST CARRY A 450A INTERRUPT RATING.

TABLE 5. SPECIFICATIONS PER MODEL

016-410-10 016 -412-10 016-450-10 016-451-10 016-452-10

Type of Input A/B Isolated Input Single Input A/B Isolated Input Single Input

Diode Redundant

Routing Circuit

Circuits 12(6A/6B) 12 16 (8A/8B) 16 10

Input Voltage -48VDC -48VDC -48VDC -48VDC -48VDC

Input Current 300A Max 300A Max 400A Max 400A Max 200A Max

Maximum Input

Interruption Device 375A 375A 500A 500A 250A

Interrupt Rating 450A 450A 10kA 10kA 10kA

Maximum GMT Fuse Size 15A 15A N/A N/A N/A

Maximum per Circuit

Current (GMT) 10.5A 10.5A N/A N/A N/A

Maximum AM Breaker

Size 100A 100A 100A 100A 100A

Maximum per Circuit

Current (AM Breaker) 100A 100A 100A 100A 100A

Maximum Continuous

Load on 8-15A GMT Fuses 70% Fuse Rating 70% Fuse Rating N/A N/A N/A

Maximum Continuous

Load on <8A GMT Fuses 80% Fuse Rating 80% Fuse Rating N/A N/A N/A

Max Operating Altitude 2000m 2000m 2000m 2000m 2000m

Max Ambient

Temperature 45° C 45° C 45° C 45° C 45° C

Width 17 in. 17 in. 17 in. 17 in. 17 in.

Height 3.5 in. (2RU) 3.5 in. (2RU) 3.5 in. (2RU) 3.5 in. (2RU) 3.5 in. (2RU)

Depth 12.5 in. 12.5 in. 12.5 in. 12.5 in. 12.5 in.

Weight 10 lbs (without breakers) 10 lbs (without breakers) 10 lbs (without breakers) 10 lbs (without breakers) 10 lbs (without breakers)

UL File Number Listing Pending Listing Pending Listing Pending Listing Pending Listing Pending

UL Standard Listing Pending Listing Pending Listing Pending Listing Pending Listing Pending

HDX™

SETUP AND OPERATION MANUAL

PAGE 10 INSTALLATION

HDX™

SETUP AND OPERATION MANUAL

INSTALLATION PAGE 11

HDX™

SETUP AND OPERATION MANUAL

PAGE 10

HDX™

SETUP AND OPERATION MANUAL

PAGE 11

A.3 Supported Breakers

TABLE 11. BREAKER SPECIFICATIONS

aMpaCity CoMM/net paRt # desCRiption ManuFaCtuReR ManuFaCtuReR paRt #

5 470-401-10

5 amp; am breaker Plug-in type; midtrip (5/16 bullet

terminals) Carling Technoligies CS1-B0-12-450-A21-MG

10 470-235-10

10 amp; am breaker Plug-in type; midtrip (5/16 bullet

terminals) Carling Technoligies CS1-B0-12-610-A21-MG

15 470-409-10

15 amp; am breaker Plug-in type; midtrip (5/16 bullet

terminals) Carling Technoligies CS1-B0-12-615-A21-MG

20 470-402-10

20 amp; am breaker Plug-in type; midtrip (5/16 bullet

terminals) Carling Technoligies CS1-B0-12-620-A21-MG

25 470-412-10

25 amp; am breaker Plug-in type; midtrip (5/16 bullet

terminals) Carling Technoligies CS1-B0-12-625-A21-MG

30 470-403-10

30 amp; am breaker Plug-in type; midtrip (5/16 bullet

terminals) Carling Technoligies CS1-B0-12-630-A21-MG

35 470-267-10

35 amp; am breaker Plug-in type; midtrip (5/16 bullet

terminals) Carling Technoligies CS1-B0-12-635-A21-MG

40 470-407-10

40 amp; am breaker Plug-in type; midtrip (5/16 bullet

terminals) Carling Technoligies CS1-B0-12-640-A21-MG

45 470-408-10

45 amp; am breaker Plug-in type; midtrip (5/16 bullet

terminals) Carling Technoligies CS1-B0-12-645-A21-MG

50 470-405-10

50 amp; am breaker Plug-in type; midtrip (5/16 bullet

terminals) Carling Technoligies CS1-B0-12-650-A21-MG

60 470-400-10

60 amp; am breaker Plug-in type; midtrip (5/16 bullet

terminals) Carling Technoligies CS1-B0-12-660-A21-MG

70 470-411-10

70 amp; am breaker Plug-in type; midtrip (5/16 bullet

terminals) Carling Technoligies CS1-B0-12-670-A21-MG

80 470-406-10

80 amp; am breaker Plug-in type; midtrip (5/16 bullet

terminals) Carling Technoligies CS1-B0-12-680-A21-MG

90 470-476-10

90 amp; AM breaker Plug-in type; Aux Switch Pin Only;

MidTrip (5/16 bullet Terminals); Argus Plants Carling Technoligies CS1-B0-12-690-A21-MG

100 470-404-10

100 amp; am breaker Plug-in type; midtrip (5/16 bullet

terminals) Carling Technoligies CS1-B0-12-810-A21-MG

A.2 Supported Lugs for Termination

TABLE 6. INPUT CONNECTIONS APPLIES TO 01641010 AND 01641210

wiRe gauge suppoRted CoMM/net paRt # ManuFaCtuReR ManuFaCtuRe paRt # CRiMp die RequiRed

#1 AWG 538-298-10 Burndy YAZV1C2TC14FX Burndy, U1CRT-1, W1CRT1, W1CVT, X1CRT1

#0 AWG 538-243-10 Burndy YAZ252TC14 Burndy U2CABT, W25RT, W25VT, X25RT

#00 AWG 538-114-10 Burndy YAZV262TC14FX Burndy U26RT, W26RT, W26VT, X26RT

#000 AWG 538-297-10 Burndy YAZV272TC14FX Burndy U27RT, W27RT, W27VT, X27RT

#0000 AWG 538-124-10 Burndy YAV28L2ENT14FX Burndy U28RT, W28RT, W28VT, X28RT

350 kcmil 538-070-10 Burndy YAZ342NT38FX, Blue, 19 Burndy U32RT, W32RT, W32VT, Y81KFT

TAB LE 7. INPUT CONNECTIONS APPLIES TO 01645010, 01645110, AND 01645210

wiRe gauge suppoRted CoMM/net paRt # ManuFaCtuReR MaCtuFaCtuRe paRt # CRiMp die RequiRed

#1 AWG 538-021-10 Burndy YAZV1C2TC38FX Burndy U1CRT, W1CRT1, W1CVT, X1CRT1

#0 AWG 538-127-10 Burndy YAZV252TC38FX Burndy U25RT, W25RT, W25VT, X25RT

#00 AWG 538-099-10 Burndy YAZV262TC38FX Burndy U26RT, W26RT, W26VT, X26RT

#000 AWG 538-296-10 Burndy YAZV272TC38FX Burndy U27RT, W27RT, W27VT, X27RT

#0000 AWG 538-220-10 Burndy YAV28L2NT38FX Burndy U28RT, W28RT, W28VT, X28RT

350 kcmil 538-070-10 Burndy YAZ342NT38FX, Blue, 19 Burndy U32RT, W32RT, W32VT, Y81KFT

500 kcmil 538-131-10 Burndy YA38L2NT38FX Burndy U38XRT(2), Pink, L99

TABLE 8. OUTPUT CONNECTIONS APPLIES TO ALL MODELS

wiRe gauge suppoRted;

teRMinal type

CoMM/net paRt # ManuFaCtuReR ManuFaCtuRe paRt # CRiMp tool RequiRed

#16-14 AWG; Ring Terminal 538-068-10 TE Connectivity 34158 TE Connectivity 58433-3 with Die Assembly 58423-1

#10-12 AWG Ring Terminal 538-280-10 TE Connectivity 329697 TE Connectivity 169400 with Die Assembly 169404

#16-14 AWG; Spade Terminal 538-038-10 TE Connectivity 52955 TE Connectivity 58433-3 with Die Assembly 58423-1

#12-10 AWG; Spade Terminal 538-119-10 TE Connectivity 52961 TE Connectivity 58433-3 with Die Assembly 58423-1

#8 AWG 538-018-10 Burndy YAZ8C2TC14FX, Red, 49 Burndy U8CRT, W8CVT, W8CRT, X8CRT

#6 AWG 538-094-10 Burndy YAZV6C2TC14FX, Blue, 7 Burndy U5CRT, W5CVT, W5CRT, X5CRT

#6 AWG 538-165-10* Burndy YAZV6C2TC14FX90, Blue, 7 Burndy U5CRT, W5CVT, W5CRT, X5CRT

#4 AWG 538-085-10 Burndy YAZV4C2TC14FX, Gray, 8 Burndy U4CRT, W2CVT, W2CRT, X2CRT

#2 AWG 538-173-10 Burndy YAV2CL2NT14FX, Brown, 10 Burndy U2CRT, W4CVT, W4CRT, X4CRT

#2 AWG 538-275-10 Burndy YAV2CL2NT14FX90, Brown, 10 Burndy U2CRT, W4CVT, W4CRT, X4CRT

#2 AWG 538-284-10 Burndy YAZV2C2NT14FX90, Brown, 10 Burndy U2CRT, W4CVT, W4CRT, X4CRT

TABLE 9. GROUND LUG INFORMATION APPLIES TO 01641010 AND 01641210

wiRe gauge suppoRted CoMM/net paRt # ManuFaCtuReR ManuFaCtuRe paRt # CRiMp tool RequiRed

#6 AWG 538-094-10 Burndy YAZV6C2TC14FX Burndy U5CRT, W5CRT, W5CVT, X5CRT, Y1MRTC

#4 AWG 538-085-10 Burndy YAZV4C2TC14FX, Gray, 8 Burndy U2CRT, W4CVT, W4CRT, X4CRT

TABLE 10. GROUND LUG INFORMATION APPLIES TO 01645010, 01645110, 01645210,

wiRe gauge suppoRted CoMM/net paRt # ManuFaCtuReR ManuFaCtuRe paRt # CRiMp tool RequiRed

#2 AWG 538-089-10 Burndy YAZV2C2TC14FX, Brown, 10 Burndy U4CRT, W2CVT, W2CRT, X2CRT

HDX™

SETUP AND OPERATION MANUAL

PAGE 12 INSTALLATION

HDX™

SETUP AND OPERATION MANUAL

INSTALLATION PAGE 13

HDX™

SETUP AND OPERATION MANUAL

PAGE 12

HDX™

SETUP AND OPERATION MANUAL

PAGE 13

A1

A2

A3

A4

A5

A6

B1

B2

B3

B4

B5

B6

B

AM BREAKER

HOT -48V OUTPUTS

A SIDE OUTPUT RETURN +48V

B SIDE OUTPUT RETURN +48V

REAR VIEW

A INPUT DC HOT (-)

CONNECTION

B INPUT DC HOT (-)

CONNECTION

GLASTIC ISOLATOR BETWEEN

A AND B RETURN BUS BARS FOR

A/B INPUT VERSIONS. RETURN BUS

IS ELECTRICALLY ISOLATED A TO B.

B INPUT DC RETURN (+)

CONNECTION.

A INPUT DC RETURN (+)

CONNECTION.

A1

A2

A3

A4

B1

B2

B3

B4

C

D

DETAIL B

GMT FUSE

HOT OUTPUT

-48V

GMT FUSE

RETURN OUTPUT

+48V

6 - N.O.

5 - N.C.

4 - COM

3 - N.O.

2 - N.C.

1 - COM

DETAIL C

SET SCREW FORM "C"

ALARM CONTACTS.

SEE NOTE 1.

DETAIL D

RJ45 ALARM CONTACTS

JACKS ARE DAISY CHAINED

PIN DETAILS IN TABLE A.

SEE NOTE 1.

2 4 6 8 2 4 6 8

1 3 5 7

1 3 5 7

1 - COM

2 - N.C.

3 - N.O.

4 - COM

5 - N.C.

6 - N.O.

TABLE "A"

MAJOR

MINOR

(NOT USED)

NOTES:

CIRCUIT BREAKER TRIP AND FUSE FAIL ALARM

1.

AVAILABLE ON MAJOR ALARM CONTACTS.

Figure 10. Rear Detail HDX 300 A/B Isolated Input Model 016-410-10

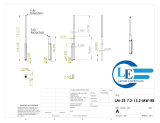

MOUNTING BRACKET

SCREWS. REMOVE TO

ADJUST TO 23" DEPTH.

SEE SHEET 3 FOR MORE

DETAIL.

COUNTERSINK HARDWARE USED

FOR 19" CONFIGURATION. PANHEAD

HARDWARE USED FOR 23"

CONFIGURATION. ALL HARDWARE

INCLUDED

R

.141

TYP.

0

3.470

.235

3.235

A POWER INPUT LED

B POWER INPUT LED

BREAKER/FUSE TRIP LED

0

1.111

1.431

8.592

9.342

10.667

B SIDE HOT INPUT

-48V

A SIDE HOT INPUT

-48V

A SIDE OUTPUT

RETURNS +48V

B SIDE OUTPUT RETURNS

+48V

.625

.625

THREADED FOR 1/4-20 TYP.

B SIDE MAIN RETURN

CONNECTION.

CHASSIS GROUND

.625

.625

1/4-20 STUDS

1/4-20 STUDS

.760

.640

1.050

TYP.

0

1.763

3.013

16.032

17.000

12.232

11.226

0

.572

.961

1.271

2.283

3.470

A

RJ ALARM JACKS

SET SCREW ALARM CONNECTIONS

6-32 SET

SCREWS

THREADED FOR 3/8-16

DETAIL A

A RETURN +48V

B RETURN

+48V

A HOT -48V

B HOT -48V

MOUNTING BRACKET / REAR COVER DETAIL

REAR VIEW

Figure 9. Connection Detail HDX 300 A/B Isolated Input Model 016-410-10

Appendix B: Mechanical Illustrations

HDX™

SETUP AND OPERATION MANUAL

PAGE 14 INSTALLATION

HDX™

SETUP AND OPERATION MANUAL

INSTALLATION PAGE 15

HDX™

SETUP AND OPERATION MANUAL

PAGE 14

HDX™

SETUP AND OPERATION MANUAL

PAGE 15

MOUNTING BRACKET

SCREWS. REMOVE TO

ADJUST TO 23" DEPTH.

COUNTERSINK HARDWARE USED

FOR 19" CONFIGURATION. PANHEAD

HARDWARE USED FOR 23"

CONFIGURATION. ALL HARDWARE

INCLUDED

R

.141

TYP.

0

3.470

.235

3.235

POWER INPUT LED

BREAKER/FUSE TRIP LED

0

1.111

1.431

8.592

9.342

10.667

HOT INPUT

-48V

OUTPUT

RETURNS +48V

.625

.625

THREADED FOR 1/4-20 TYP.

MAIN RETURN

CONNECTION.

CHASSIS GROUND

.625

.625

1/4-20 STUDS

1/4-20 STUDS

.760

.640

1.050

TYP.

0

1.763

3.013

15.940

17.000

12.140

11.226

0

.572

.961

1.271

2.283

3.470

A

RJ ALARM JACKS

SET SCREW ALARM CONNECTIONS

6-32 SET

SCREWS

THREADED FOR 3/8-16

DETAIL A

RETURN +48V

HOT -48V

MOUNTING BRACKET / REAR COVER DETAIL

REAR VIEW

Figure 12. Connection Detail HDX 300 Single Input Model 016-412-10

18.047

18.359

3.000

R

.141

TYP.

22.047

22.359

3.000

R

.141

0

10.914

19" MOUNTING

BRACKETS

CABLES ACCESS

FOR A RETURN +48V

CABLES ACCESS

FOR B RETURN +48V

CABLES ACCESS FOR RJ STYLE ALARM.

DESIGNED AS A KNOCKOUT FEATURE.

CABLES ACCESS FOR A HOT -48V

CABLES ACCESS FOR B HOT -48V

CABLE ACCESSCABLE ACCESS

19" RACK MOUNT ORIENTATION

23" RACK MOUNT ORIENTATION

TOP VIEW WITH REAR COVER

BOTTOM VIEW WITH REAR COVER

Figure 11. Top and Bottom View HDX 300 A/B Isolated Input Model 016-410-10

HDX™

SETUP AND OPERATION MANUAL

PAGE 16 INSTALLATION

HDX™

SETUP AND OPERATION MANUAL

INSTALLATION PAGE 17

HDX™

SETUP AND OPERATION MANUAL

PAGE 16

HDX™

SETUP AND OPERATION MANUAL

PAGE 17

18.047

18.359

3.000

R

.141

TYP.

22.047

22.359

3.000

R

.141

0

10.914

19" MOUNTING

BRACKETS

CABLES ACCESS

FOR RETURN +48V

CABLES ACCESS

FOR RETURN +48V

CABLES ACCESS FOR RJ STYLE ALARM.

DESIGNED AS A KNOCKOUT FEATURE.

CABLES ACCESS FOR HOT -48V

CABLE ACCESSCABLE ACCESS

19" RACK MOUNT ORIENTATION

23" RACK MOUNT ORIENTATION

TOP VIEW WITH REAR COVER

BOTTOM VIEW WITH REAR COVER

Figure 14. Top and Bottom View HDX 300 Single Input Model 016-412-10

1

2

3

4

5

6

7

8

9

10

11

12

B

AM BREAKER

HOT -48V OUTPUTS

OUTPUT RETURN +48V

REAR VIEW

INPUT DC HOT (-)

CONNECTION

INPUT DC RETURN (+)

CONNECTION.

INPUT DC RETURN (+)

CONNECTION.

1

2

3

4

5

6

7

8

C

D

DETAIL B

GMT FUSE

HOT OUTPUT

-48V

GMT FUSE

RETURN OUTPUT

+48V

6 - N.O.

5 - N.C.

4 - COM

3 - N.O.

2 - N.C.

1 - COM

DETAIL C

SET SCREW FORM "C"

ALARM CONTACTS.

SEE NOTE 1.

DETAIL D

RJ45 ALARM CONTACTS

JACKS ARE DAISY CHAINED

PIN DETAILS IN TABLE A.

SEE NOTE 1.

2 4 6 8 2 4 6 8

1 3 5 7

1 3 5 7

1 - COM

2 - N.C.

3 - N.O.

4 - COM

5 - N.C.

6 - N.O.

TABLE "A"

MAJOR

MINOR

(NOT USED)

NOTES:

CIRCUIT BREAKER TRIP AND FUSE FAIL ALARM

1.

AVAILABLE ON MAJOR ALARM CONTACTS.

Figure 13. Rear Detail HDX 300 Single Input Model 016-412-10

HDX™

SETUP AND OPERATION MANUAL

PAGE 18 INSTALLATION

HDX™

SETUP AND OPERATION MANUAL

INSTALLATION PAGE 19

HDX™

SETUP AND OPERATION MANUAL

PAGE 18

HDX™

SETUP AND OPERATION MANUAL

PAGE 19

Figure 16. Rear Detail HDX 400 A/B Isolated Input Model 016-450-10

A

B INPUT DC RETURN (+)

CONNECTION.

B SIDE OUTPUT RETURN + 48 V

GLASTIC ISOLATOR BETWEEN

A AND B RETURN BUS BARS FOR

A/B INPUT VERSIONS. RETURN BUS

IS ELECTRICALLY ISOLATED A TO B

A SIDE OUTPUT RETURN + 48V

A INPUT DC RETURN (+)

CONNECTION.

B INPUT DC HOT (-)

CONNECTION

A INPUT DC HOT (-)

CONNECTION

DETAIL A

RJ45 ALARM CONTACTS

JACKS ARE DAISY CHAINED

PIN DETAILS IN TABLE A

SEE NOTE 1.

NOTES:

1. CIRCUIT BREAKER TRIP ALRAM

AVAILABLE ON MAJOR ALARM

CONTACTS.

1 - COM

2 - N.C.

3 - N.O.

4 - COM

5 - N.C.

6 - N.O.

TABLE "A"

MAJOR

MINOR

(NOT USED)

R.141 TYP.

0

.235

3.235

3.470

A POWER INPUT LED

B POWER INPUT LED

BREAKER TRIP LED

0

1.431

1.111

8.592

9.342

11.167

A SIDE OUTPUT

RETURNS +48V

B SIDE OUTPUT RETURNS

+48V

A SIDE HOT INPUT

-48V

B SIDE HOT INPUT

-48V

.625

.625

CHASSIS GROUND

B SIDE MAIN RETURN

CONNECTION

1/4-20 TYP

MOUNTING BRACKET/ REAR COVER DETAIL

COUNTERSUNK HARDWARE USED

FOR 19" CONFIGURATION. PANHEAD

HARDWARE USED FOR 23"

CONFIGURATION. ALL HARDWARE INCLUDED

MOUNTING BRACKET

SCREWS. REMOVE TO

ADJUST TO 23" DEPTH.

.760

.625

.625

.760

1.050

.640

1.000

1.050

17.000

1/4-20 STUDS 1/4-20 STUDS

RJ ALARM JACKS

Figure 15. Connection Detail HDX 400 A/B Isolated Input Model 016-450-10

HDX™

SETUP AND OPERATION MANUAL

PAGE 20 INSTALLATION

HDX™

SETUP AND OPERATION MANUAL

INSTALLATION PAGE 21

HDX™

SETUP AND OPERATION MANUAL

PAGE 20

HDX™

SETUP AND OPERATION MANUAL

PAGE 21

Figure 18. Connection Detail HDX 400 A/B Single Input Model 016-451-10

R.141 TYP.

0

.235

3.235

3.470

POWER INPUT LED

BREAKER TRIP LED

0

1.431

1.111

8.592

9.342

11.167

OUTPUT RETURNS

+48V

HOT INPUT

-48V

.625

.625

CHASSIS GROUND

MAIN RETURN

CONNECTION

1/4-20 TYP

MOUNTING BRACKET/ REAR COVER DETAIL

COUNTERSUNK HARDWARE USED

FOR 19" CONFIGURATION. PANHEAD

HARDWARE USED FOR 23"

CONFIGURATION. ALL HARDWARE INCLUDED

MOUNTING BRACKET

SCREWS. REMOVE TO

ADJUST TO 23" DEPTH.

.760

.625

.625

.760

1.050

.640

1.000

1.050

17.000

1/4-20 STUDS 1/4-20 STUDS

RJ ALARM JACKS

KNOCKOUT FEATURE CABLE ACCESS

0

11.464

CABLE ACCESS FOR

A AND B SIDE HOT -48V

DESIGNED AS A KNOCKOUT

FEATURE

CABLE ACCCESS

FOR A RETURN +48V

CABLE ACCCESS

FOR B RETURN +48V

BRACKETS

18.047

18.359

3.000

R.141 TYP

3.000

22.047

22.359

19" RACK MOUNT ORIENTATION

23" RACK MOUNT ORIENTATION

BOTTOM VIEW WITH REAR COVER

TOP VIEW WITH REAR COVER

Figure 17. Top and Bottom View HDX 400 A/B Isolated Input Model 016-450-10

HDX™

SETUP AND OPERATION MANUAL

PAGE 22 INSTALLATION

HDX™

SETUP AND OPERATION MANUAL

INSTALLATION PAGE 23

HDX™

SETUP AND OPERATION MANUAL

PAGE 22

HDX™

SETUP AND OPERATION MANUAL

PAGE 23

Figure 20. Top and Bottom View HDX 400 A/B Single Input Model 016-451-10

KNOCKOUT FEATURE CABLE ACCESS

0

11.464

CABLE ACCESS FOR

HOT -48V

DESIGNED AS A KNOCKOUT

FEATURE

CABLE ACCCESS

FOR RETURN +48V

CABLE ACCCESS

FOR RETURN +48V

BRACKETS

18.047

18.359

3.000

R.141 TYP

3.000

22.047

22.359

19" RACK MOUNT ORIENTATION

23" RACK MOUNT ORIENTATION

BOTTOM VIEW WITH REAR COVER

TOP VIEW WITH REAR COVER

Figure 19. Rear Detail HDX 400 A/B Single Input Model 016-451-10

A

DC RETURN (+)

CONNECTION.

OUTPUT RETURN + 48 V

OUTPUT RETURN + 48V

DC RETURN (+)

CONNECTION.

DC HOT (-)

CONNECTION

DETAIL A

RJ45 ALARM CONTACTS

JACKS ARE DAISY CHAINED

PIN DETAILS IN TABLE A

SEE NOTE 1.

NOTES:

1. CIRCUIT BREAKER TRIP ALRAM

AVAILABLE ON MAJOR ALARM

CONTACTS.

1 - COM

2 - N.C.

3 - N.O.

4 - COM

5 - N.C.

6 - N.O.

TABLE "A"

MAJOR

MINOR

(NOT USED)

HDX™

SETUP AND OPERATION MANUAL

PAGE 24 INSTALLATION

HDX™

SETUP AND OPERATION MANUAL

INSTALLATION PAGE 25

HDX™

SETUP AND OPERATION MANUAL

PAGE 24

HDX™

SETUP AND OPERATION MANUAL

PAGE 25

Figure 22. Top and Bottom View HDX A/B/C Diode Routed Input Model 016-452-10

KNOCKOUT FEATURE CABLE ACCESS

0

11.464

CABLE ACCESS FOR

A AND B SIDE HOT -48V

DESIGNED AS A KNOCKOUT

FEATURE

CABLE ACCCESS

C RETURN +48V

CABLE ACCCESS

C RETURN +48V

MOUNTING

BRACKETS

18.047

18.359

3.000

R.141 TYP

3.000

22.047

22.359

19" RACK MOUNT ORIENTATION

23" RACK MOUNT ORIENTATION

BOTTOM VIEW WITH REAR COVER

TOP VIEW WITH REAR COVER

Figure 21. Connection Detail HDX A/B/C Diode Routed input Model 016-452-10

17.000

.760

.640

1.050

1.000

.760

1/4-20 STUDS

1/4-20 STUDS

.625

.625

MAIN RETURN

CONNECTION

.625

.625

CHASSIS GROUND

1.431

1.111

0

R.141 TYP.

0

.235

3.235

3.470

11.167

8.592

9.342

C OUTPUT

RETURN

+48V

A HOT INPUT

-48V

A INPUT

POWER LED

B INPUT

POWER LED

BREAKER TRIP

LED

FORM C

DRY CONTACT

ALARM CONN.

B HOT INPUT

-48V

HDX™

SETUP AND OPERATION MANUAL

PAGE 26

THIS PAGE INTENTIONALLY LEFT BLANK

NOTES:

About Comm/net Systems

Comm/net Systems, Inc. (CSI) is the leader in high power density

communications power systems. Comm/net oers comprehensive

power and communications site systems integration and deployment

services via a national footprint of regional branch oces. Additional

information can be found at www.commnetsystems.com.

Corporate Headquarters

Comm/net Systems, Inc.

4237 – 24th Avenue West

Seattle, WA 98199

TEL: 206.282.8670

FAX: 206.282.8684

www.commnetsystems.com

24/7 Sales & Service

To purchase Comm/net Systems solutions, contact your

Comm/net Systems representative at: (800) 274-0544

or e-mail: sales@commnetsystems.com

© 2015 Comm/net Systems, Inc. All rights reserved. Comm/net Systems, and the Comm/net Systems logo are registered trademarks of Comm/net Systems, Inc. in the United States and other countries. All other

trademarks, service marks, registered marks, or registered service marks are the property of their respective owners. Comm/net Systems assumes no responsibility for any inaccuracies in this document. Comm/net

Systems reserves the right to change, modify, transfer, or otherwise revise this publication without notice.

Document Number: 048-693-30 | Revision Level: r02 | Published: June 2015

/