Page is loading ...

TECHNICAL MANUAL

FOR

SALAD WASHER

MODEL

GM 85

SALAD WASHER

MODEL: GM 85

Table of Contents

Part 1 - Technical Information

* Introduction

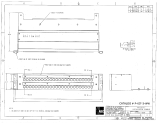

* Installation & Layout Drawing

* Warranty

Part 2 - Installation and Operation Instructions

* Section A, Installation Instructions

* Section B, Operation, Cleaning and Washing Instructions

Wash and Dry recommended Time Table

Part 3 - Electrical Schematics

* Machine Wiring Diagram

Part 4 - Replacement Parts

* Water Supply and Shower

* Wash System

* Drain and Overflow

* Base Frame and Centrifuge

* Electrical Parts

cm \mnl\mnlgm85 .doc

rlsd: 6/91

SALAD and VEGETABLE WASHER

Model: GM 85

INSTALLATION INSTRUCTIONS

Section A

A.1 PLACEMENT

A.1.1 Carefully uncrate machine. Take caution to not damage components which may be mounted on the

top or sides of the machine.

A.1.2 Set unit in place and adjust the feet to level the machine.

A.2 ELECTRICAL CONNECTIONS

A.2.1 Connect electrical lines sized for the correct voltage, current and phase of the machine. These

should agree with machine requirements indicated on the nameplate and labels in control panel.

A.2.2 A cable is supplied for the electrical connections.

NOTE: Connections must be made to a circuit breaker or fused disconnect as provided by the end-user and

required by local codes. A wiring diagram is supplied inside the control panel. Please return diagram

when finished.

IMPORTANT: As with any 3 phase system, an electrician should check all motors for proper phasing, i.e..

Pump motors must be running in direction indicated by arrow on housing.

A.2.4 The machine should be connected to an earth ground.

A.3 MECHANICAL CONNECTIONS

A.3.1 Connect a cold water line for the tank fill as tagged and noted on the piping.

A.3.2 Connect the wash tank drain and centrifuge drain.

NOTE: Drain lines must be as specified. Drain line should be properly vented and should have fall of not less

than 1/4" to the foot of proper flow. Some area plumbing codes require drains to flow into an open gap

with an opening twice the diameter of the pipe. Check with your local plumbing codes for the type of

drain connection required.

NOTE: All lines should be flushed prior to use to remove debris.

IMPORTANT: Do not reduce the size of lines as specified. All lines are sized to facilitate necessary flows,

pressures, etc.

cm wp51\mnl\mnlgm85 .doc

rlsd: 6/91

SALAD and VEGETABLE WASHER

Model: GM 85

OPERATION

Section B

Insinger/Winterhalter equipment is user-friendly, making it the easiest on the market to operate and

maintain.

By following the operation procedure and general cleaning procedures your Insinger/Winterhalter equipment

will give you years of trouble free service.

B.1 Operation Instructions

B.1.1 Turn the main switch (1) to "I". The green light (6) will light. If the white light (7) also lights,

depress the drain switch (5) to close the drain.

B.1.2 The wash tank automatically fills to its proper height.

B.1.3 The wash agitation is adjustable by the Control Switch (3). See the Washing directions, section

B.2, for timing and agitation settings.

B.1.4 The Wash Time Switch (2) is adjustable 0-15 minutes by turning the dial.

B.1.5 A Continuous Run Switch (8) is provided to by-pass the wash timer. Depress this switch to run

the wash pump continuously. Depress again to turn the pump off.

NOTE: When the Wash Time Switch (2) is used dirty water is skimmed from the tank and fresh water is

entered into the tank at short, regular intervals. Using the Continuous Run Switch (8) disengages

the skimming action to save on water consumption.

B.1.6 A centrifuge is provided under the wash tank to facilitate drying of washed produce.

B.1.7 Turn the drawer handle to the left, pull out the drawer and place the wet produce into the basket

provided.

B.1.8 Use the sieve provided to remove the cleaned produce from, the wash tank.

NOTE: Overloading the drying basket will impede the proper drying of produce.

B.1.9 Push the drawer in and lock it.

cm wp51\mnl\mnlgm85.doc

rlsd: 6/91

SALAD and VEGETABLE WASHER

Model: GM 85

OPERATION

Section B

B.1.10 Start the spin cycle by turning the Spin Time Switch (4) to the desired drying time. This

is adjustable from 0-15 minutes.

Note: The centrifuge spinner will work while the machine is in a washing cycle.

B.1.11 When the spin cycle is completed the basket with the dried produce can be removed.

IMPORTANT: Should the centrifuge drawer be opened while spinning, the motor will

automatically stop the basket.

B.1.12 After washing is completed, depress the Drain Switch (5) to open the drain valve and

drain the tank.

The following cleaning procedures should be done daily, at the end of the shift.

B.2 Cleaning Procedures, Daily

B.2.1 Remove all wash tank removable parts.

B.2.2 Clean dirt from the tanks by using the built-in shower.

B.2.5 Clean strainers of dirt build-up.

IMPORTANT: The Machine is not splash water protected therefore do not hose-down the outside

of the machine.

B.3 Washing

B.3.1 Only put as much produce in the wash tank to allow room to move freely in the water.

B.3.2 Heads of lettuce and other such vegetables should be cut to allow for better washing.

B.3.3 A short wash cycle of 2-3 minutes is recommended for lettuce. Root vegetables and

seafood can be washed longer 8-10 minutes.

B.3.4 For extremely dirty produce/seafood use the Continuous Run Switch (8) first. Then rinse

using the normal washing cycle.

cm wp51\mnl\mnlgm85.doc

rlsd: 6/91

SALAD and VEGETABLE WASHER

Model: GM 85

OPERATION

Section B

B.3.5 Use the fine sieve for washing heads of lettuce. Place the sieve under its cover in the bottom of

the tank. Coarse dirt will be washed down the drain but the sieve must be cleaned daily of fine

dirt. Take care to not knock the sieve against corners or sharp edges.

B.3.6 Be creative when washing anything in your Insinger/Winterhalter Salad Washer. It can be used

to wash shelled seafood as well as lettuce, mushrooms and anything else that will fit in the tank.

B.4 Wash & Dry Recommended Time Table

Product Wash Time Dry Time Agitation

Leafy vegetables (lettuce,spinach)

3-5 mins 3-5 mins medium

Mushrooms, carrots, strawberries

5-7 mins 3-5 mins full

Tomatoes 4-6 mins 3-5 mins light

Seafood (mussels, clams) 7-9 mins 5-7 mins full

Note: This table is intended as a guide only. All times are approximate and dependant upon the dirt on the

product. The products listed here are a small sample of items that may be washed in the Salad and

Vegetable Washer. Experience shows you will develop your own washing and drying times.

cm wp51\mnl\mnlgm85.doc

rlsd: 6/91

Illustration of Controls

1 — Main switch Position 0 OFF

Position I ON

2 — Wash time switch Position 0 OFF

Position 0—15 Length of washing time 0—15 min.

3 — Control switch

As the arrow is turned farther counterclockwise, the quantity of water

for agitation increases.

4 — Spin time switch Position 0 OFF

Position 0—15 Centrifuge spinner runs 0—15 min.

5 — Drain switch

When depressed, the drain for the wash tank is opened, and when it is

pressed again, the drain is closed.

6 — Control light (green) Lights up when the machine is ready for use.

7 — Control light (orange)

Lights up when the drain valve for the wash tank Is open (only when

the drain switch has been depressed, not while the water in the tank is

being regenerated).

8 — Continuous run switch

When depressed the pump runs continuous without water

regeneration. By pressing again it is switched off.

Spare Parts No.5/90

GM 85 (GM 170)

Summary

1. Water supply and shower Page 1 (Exploded View) 2 (Parts List)

2. Wash system Page 3 (Exploded View) 4 (Parts List)

3. Drain and overflow Page 5 (Exploded View) 6 (Parts List)

4. Base frame and centrifuge Page 7 (Exploded View) 8 (Parts List)

5. Electrical parts Page 9 (Exploded View) 10 (Parts List)

The parts marked * are also contained in other spare parts lists.

Racks and accessories see separate list.

-1-

GM 85 (GM 170) - Water supply and shower

Pos. Designation Part no. * Notes

2 Seal 19,5x24 27 09 010 *

3 Double solenoid valve 31 06 051 * 1 x GM 85, 2 X GM 170

4 Diaphragm 31 06 047 *

5 Plunger 31 06 073 *

6 Spring 31 06 049

7 Coil 31 06 052

9 Hose 13x3,5 40 02 002 *. per meter

10 T-hose connection 29 06 001 *

11 Hose elbow 0 14 40 03 001 *

12 Hose clip 14x22 28 02 301 *

13 Coupling nut 3/8" 29 07 200 *

n.p. Cutting ring 10 29 07 221 *

n.p. Copper pipe 10x1 05 20 001 *: per meter

15 Tap bottom part 29 03 211

16 Tap top part 29 03 212

17 Hose elbow 29 06 200 *

18 Hose clip 13 28 02 006 *

19 Shower hose 29 01 239

20 Slip-on angle 29 01 240

21 Shower head 29 01 507

n.p. Hose clip 20-30 28 02 306 *

23 Air chamber 40 07 024 *

24 Hose clip 9 28 02 002 *

n.p. Inlet jets 28 14 212

only GH 170

n.p. Cover (sol valve) 35 01 515

n.p. Sheet-metal nut 21 17 300

n.p. Cylinder screw 20 20 300

n.p. Double solenoid valve 31 06 063

GM 170

n.p. Coil 31 06 1 10

GM 170

-2-

-3-

GM 85 (GM 170) - Wash system

Pos. Designation Part no. * |Notes

1 Hose clip 62-32 28 02 120 *

2 Hose elbow 40 03 028 *

3 Pump 1,7 kW 220/380 V 31 02 084 * GM 85 + 170

n.p. Pump 1,7 kW 240/420 V 31 02 097

GM 85 + 170

n.p. Pump 1,7 kW 220 V 31 02 049

n.p. Pump 1,7 kW 240 V 31 02 046

n.p. Capacitors 31 13 001 *

n.p. Counter ring 27 10 014 *

n.p. Motor shaft seal 27 10 013 *

n.p. Impeller 31 02 206 *

n.p. Pump housing 31 02 204 *

n.p. 0-ring 31 02 209

4 Hose clip 152-172 28 02 123 *

5 Hose clip 47-67 28 02 115 *

6 Throttle valve 55 27 096

since 6/82

7 Pump hose 0 50x4,5x90 55 05 018 *.

8 Hinge head 28 15 020

9 Annular spring 23 12 300 *

10 Control knob with axle 55 19 051

since 10/86

11 Manifold top part 55 06 005

only manifold part

12 Seal 39x32 27 02 001 *

13 Extension 35 01 003 *

14 Coupling nut 35 01 004 *

15 0-ring 24x3 27 07 026 *

16 Angle 35 01 005 *

17 Seal 33x26 27 01 003 *

18 Locking nut 3/4" BSP 30 09 202

19 Wash jet 35 01 506

n.p. Coarse sieve 20-85.203 55 13 015

n.p. Fine sieve 20-85.205 55 13 017

n.p. Inset rack 55 01 110

n.p. Bifurcatad piece (manif.) polypr. 35 01 173.

only GM 170

n.p. Welding arc polyproylene 35 01 174

only GM 170

n.p. Coarse sieve with lap joint 55 13 016

only GM 170 right

-4-

-5-

GM 85 (GH 170) - Drain and overflow

Pos. Designation Part no. * Notes

1 Solenoid valve cpl. . 31 06 045

31 06 060 for GM 170

2 Diaphragm conversion kit 31 06 136

3 coil 31 06 053

n.p. Coil 100 % ED 240 V 31 06 095

4

Pump hose

0 50x4,5x90

55 05 018

*

5 Hose clip 47-67 28 02 115 *

6 Seal 45x33 27 09 014 *

7 Connection piece 29 04 504

8 0-ring 52x6 27 07 029

9 T-branch 30 15 501

10 Coupling pipe 55 06 004

11 Hose clip 32-52 28 02 110 *

n.p. Diaphragm 31 06 079

only GH 170 until 8/89

n.p. Coil 31 06 088

only GH 170

n.p. Siphon 40 03 022

replaces pos. 12+13

n.p. Coil 24 V 50 Hz 31 06 097

for 31 06 045

n.p. Seal plate 31 06 098

for 31 06 060

n.p. Spring large 27x120 lg. 31 06 119

for 31 06 060

n.p. Diaphragm 31 06 137

only GM 170 since 9/89

-6-

-7-

GH 85 (CM 170) - Base frame and centrifuge

Pos. Designation Part no. * Notes

n.p. Catch bowl 55 27 011

n.p. Machine cover 55 27 012

only GM 85

1 Guide profile left 28 01 033

2 Guide profile right 28 01 047

n.p. Centrifuge insert 55 01 096

Rilsan

n.p. Centrifuge basket 55 01 216

CNS

3 Rubber buffer 40 06 001

4 V-be1t 10x1060 40 08 009

5 Grooved ball bearing 28 01 003

6 Foot 35 01 064 *

7 Insert 35 01 062 *

10 Cylinder screw 20 19 300 *

11 Centrifuge motor 220/380 V 31 01 027

n.p. Motor bracket 55 14 099

n.p. Catch bowl 55 27 011

n.p. Capacitor 31 13 034

12 Limit switch 31 24 104

n.p. Centrifuge cover 35 01 522

n.p. Ball bearing inox 28 01 046

for pos. 1 or 2

n. p. Buffer 40 06 001

n. p. Forelock 28 05 041

n.p. Door handle with bolt 28 05 042

n.p. Bearing cpl. 55 27 100

n.p. V-be1t pulley (motor) 28 10 016

n.p. Cover for motor 35 01 526

n. p. Rectifier (motor) 31 13 053

n.p. Centrifuge cylinder 55 02 004

w. pulley +bearing bush

n.p. Shaft seal 27 08 002

n.p. Rubber stop buffer 40 06 015

-8-

-9-

GM 85 - Electrical parts

Pos. Designation Part no. * Notes

1 Mini-contactor 31 04 034 * 3 S 1 0 pump

2 Series terminal 3-pole 31 09 010 *

3 Mini-contactor 31 04 035 * 2 S 10 control

4 Screwing cap 31 11 048 *

5 Fuse insert 31 11 043 *

Q Fuse base 31 11 057 *

7 Earth terminal 31 09 013 *

8 Mini-contactor 31 04 022 * motor

9 Level switch 31 25 012

10 Friction spring 31 26 001 *

11

Low volt neon-glow lamp 31 08 006 *

12

Pilot light round 31 08 025

yellow - old

13

Pilot light round 31 08 001 * red - old

14 Pilot light 31 08 002 * green

15 Pilot light 31 08 026

* white

16 Seal cap transparent 31 24 006 *

17 Pressure switch 31 24 002 *

18 Control knob 55 19 036 *

19

Labyrinth seal 0 47

35 01 092

20 Circuit closer 31 24 024 *

21 Programme switch 31 05 110 15 min.

22

Timer

31 05 111

centrifuge

n.p

Control box plate 28 03 133

n.p. Control box plate 28 03 134

-10-

/