3

Table of Contents

Table of Contents ----------------------------------------- 3

Table of Figures ------------------------------------------- 3

Introduction ------------------------------------------------- 4

Ordering Information ------------------------------------ 5

General Purpose Instruments -------------------------------- 5

Hazardous Area Instruments ---------------------------------- 5

Enclosures ---------------------------------------------------------- 5

Specifications ---------------------------------------------- 6

Input ------------------------------------------------------------------- 6

Display ---------------------------------------------------------------- 6

General --------------------------------------------------------------- 6

Rate/Totalizer ------------------------------------------------------- 7

Batch Control ------------------------------------------------------- 7

Common Open Collector & Relay (Alarm)

Specifications ------------------------------------------------------ 7

Open Collector Output ------------------------------------------ 7

Solid State Relays ------------------------------------------------ 8

4-20 mA Transmitter Output ----------------------------------- 8

MeterView XL Programming Software --------------------- 8

General Compliance Information -------------------- 9

Electromagnetic Compatibility ------------------------------- 9

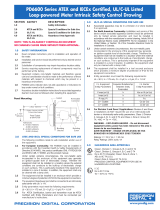

PD6626 & PD6628 Compliance Information ------ 9

Safety------------------------------------------------------------------ 9

Hazardous Area Approvals ------------------------------------ 9

Safety Information -------------------------------------- 11

Installation ------------------------------------------------ 11

Unpacking --------------------------------------------------------- 11

Panel Mounting Instructions -------------------------------- 12

Mounting Dimensions ----------------------------------------- 12

Connections ------------------------------------------------------ 13

Connectors Labeling ------------------------------------------ 13

Safe Area Current Loop (4-20 mA) Connections ------ 14

Safe Area Digital Input Connection ----------------------- 14

Safe Area 4-20 mA Output Connections ----------------- 15

Safe Area Solid State Relay Connections --------------- 15

Safe Area Open Collector Outputs ------------------------ 16

Setup and Programming ------------------------------ 17

Overview ----------------------------------------------------------- 17

Front Panel Buttons and Status LED Indicators ------ 17

MeterView XL Programming Software ------------------- 18

Display Functions & Messages----------------------------- 19

Main Menu --------------------------------------------------------- 23

Setting Numeric Values -------------------------------------- 23

Setting Up the Input Signal (INPUT) ---------------------- 24

Available Unit Classes and Units -------------------------- 25

Setting Custom Units (CUSTOM) --------------------------- 25

Scaling the 4-20 mA Input ----------------------------------- 25

Setting the Display Features (DISPLAY) ---------------- 26

Changing the Units (UNITS) -------------------------------- 26

Changing the Decimal Point Location (DEC.PT) -------- 26

Enabling or Disabling the Comma on the Bottom

Display (COMMA) ----------------------------------------------- 26

Programming the Bargraph (PD6624 & PD6628 Only)

--------------------------------------------------------------------- 26

Changing What is Displayed (TOP and BOTTOM) ----- 27

Programming the Outputs (OUTPUT) --------------------- 28

Open Collector Outputs (OPEN COLLECTR) ----------- 29

Solid State Relay Outputs (RELAY) ----------------------- 33

4-20 mA Output (4-20 mA) -------------------------------- 38

Output Control (CONTROL) ---------------------------------- 38

Advanced Features Menu (ADVANCED) ------------------ 39

Advanced Rate, Total, and Grand Total Setup (ADV

RATE, TOTAL, GTOTAL) ------------------------------------- 39

Low-Flow Cutoff (CUTOFF) ---------------------------------- 42

Noise Filter (FILTER) ---------------------------------------- 42

Enabling Password Protection (PASSWRD) ------------- 42

Programmable Function Keys User Menu (USER) ---- 43

Changing System Settings (SYSTEM) -------------------- 44

Meter Operation ------------------------------------------ 46

Front Panel Buttons Operation ----------------------------- 46

Function Keys Operation ------------------------------------- 46

Digital Input Operation ---------------------------------------- 46

Maximum/Minimum Readings ------------------------------ 46

Changing Engineering Units -------------------------------- 46

Troubleshooting ----------------------------------------- 47

Reset Meter to Factory Defaults --------------------------- 47

Determining Software Version ----------------------------- 47

Factory Default Settings ------------------------------------- 48

Troubleshooting Tips ------------------------------------------ 49

EU Declaration of Conformity for PD6622 &

PD6624 ------------------------------------------------------ 50

EU Declaration of Conformity for PD6626 &

PD6628 ------------------------------------------------------ 51

Table of Figures

Figure 1. 1/8 DIN Panel Cutout Dimensions and Panel

Mounting Details ................................................... 12

Figure 2. Meter Dimensions - Side View ....................... 12

Figure 3. Meter Dimensions - Front View ...................... 12

Figure 4. Connector Labeling for Fully Loaded Meter ... 13

Figure 5. 4-20 mA Input Connection without Backlight .. 14

Figure 6. 4-20 mA Input Connection with Backlight ....... 14

Figure 7. Digital Input Connections ................................ 14

Figure 8. 4-20 mA Output Connections .......................... 15

Figure 9. Solid State Relay Connections ....................... 15

Figure 10. Open Collector Output Connections ............. 16