a subsidiary of Mercury Aircraft

1135 NW 159 Dr., Miami, Florida 33169

Tel: (305) 625-2451 or (800) 762-7565 • Fax: (305) 623-0475

DS-5

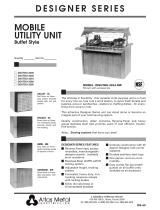

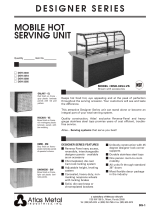

D E S I G N E R S E R I E S

VISCAYA - VS

Brass finish on frame -

rich mahogany plastic

laminate panels with

trim molding.

OMNI - OM

Gray finish on frame -

plastic laminate panels

of operator’s choice.

OAKWOOD - OW

Brass finish on frame -

light oak plastic lami-

nate panels.

Quantity Item No.

MOBILE COLD

SERVING UNIT

Refrigerated Cold Pan

DESIGNER SERIES FEATURES

Reversa Panel easy access,

reversible, interchangeable

designer panels - available

as an accessory

Chromeplated, die cast

Cam-lock locking system

Adjustable height, leveling

casters

Concealed, heavy-duty, non-

marking neoprene wheels

with locking brakes

Solid, die-cast brass or

chromeplated brackets

Unibody construction with 45

degree designer look corner

supports

Durable stainless steel tops

One person room-to-room

mobility

All units fit through standard

36” doors

Most flexible decor package

in the industry

Keeps salads, sandwiches, desserts... chilled entrees or appetizers,

fresh, crisp and appealing throughout the serving occasion. Your

customers will see and taste the difference.

This attractive Designer Series unit can stand alone or become an

integral part of your total serving system.

Quality construction, Atlas’ exclusive Reversa-Panel and heavy

gauge stainless steel tops promise years of cost efficient, trouble-

free service.

Atlas... Serving systems that serve you best!

DSRM-3240

DSRM-3254

DSRM-3268

DSRM-3285

MODEL #DSRM-3254-VS

Shown with accessories

D E S I G N E R S E R I E S

a subsidiary of Mercury Aircraft

1135 NW 159 Dr., Miami, Florida 33169

Tel: (305) 625-2451 or (800) 762-7565 • Fax: (305) 623-0475

DS-6

TOP: Top constructed of 16 gauge, type 304 stain-

less steel, die-formed, welded, buffed and

polished to a uniform finish. The cold pan will

accommodate 12” x 20” pans of 2-1/2” and 4”

depth, and fractional size pans. OMNI: The Edge

runs the full length of the top and consists of a

double 45 degree angle with a polished finish.

LINER: The inner liner shall be 18 gauge, type 304

stainless steel, one piece construction, all

welded, ground and polished to a uniform finish.

All corners are covered with a minimum 1/4”

radius. The liner has copper tubing firmly sol-

dered to the top 3” of all sides. A 3/4” dia. drain

with strainer, 4!’ PVC nipple, and valve is provid-

ed.

INSULATION: The pan is fully insulated with high

density polystyrene, 1” thick on all sides, 1-1/2”

thick on the bottom and enclosed with a 22 gauge

galvanized steel outer liner.

BODY: End mullions are die-formed, 18 gauge

paint grip steel, all welded box beam construc-

tion. Interior sides are enclosed with 20 gauge

paint grip steel panels attached to the end

mullions. End mullions are joined at the top, front

and rear by an apron running the full-length of the

unit; apron is 6-1/2” on the front and 8” on the rear.

Corner sections are formed with 45 degree angles

on the front for the designer look. End mullions are

joined at the bottom with a full length angle iron

frame, supporting a removable stainless steel

bottom shelf. Steel surfaces are finished with

urethane based paint.

FRONT AND SIDES: Constructed of rigidized

honeycomb material with plyshield plywood

stringers. Panel is framed with 5/8” x 1” polyethy-

lene and a plastic laminate front. Rears is finished

with a backing sheet to insure watertight integri-

ty. OMNI: 45 degree designer corners are painted

bright gray with a urethane based paint. Solid

color mica panels in operator’s choice.

OAKWOOD: 45 degree designer corners are mir-

ror finish brasslook. Light oak-look mica panels

complete the appearance package. VISCAYA: 45

degree designer corners are, mirror finish brass-

look. Rich mahogany-look mica front panels fea-

ture stained and sealed hardwood trim.

ADJUSTABLE CASTERS: N.S.F listed, 5” diameter,

non-marking neoprene rubber tired swivel

casters. Two casters have foot operated locking

brakes. All Designer Series units feature Atlas’

exclusive adjustable height, leveling casters.

LOCKING DEVICES: When two or more units are

ordered. Atlas’ unique cam-lock locking system

includes an exclusive interlocking stainless lock

under the top counter on the customer’s side and

a positive action cam-lock on the operator’s side.

ELECTRICAL: 15 amp, 120 volt, 60 cycle, single

phase operation with an illuminated on/off

switch located on the operator’s side and a 6 foot

long, 3-wire cord and plug (NEMA-5-15P). A cord

holder is provided, under the end mullion on

operator’s right, unless specified otherwise.

REFRIGERATION SYSTEM: A 1/4 HP (1/2 HP on

DSRM-3285 only) self-contained condensing unit

with a hermetically sealed compressor is provid-

ed along with a factory pre-set temperature

pressure control, which is field adjustable. The

condensing unit is provided with an enclosure of

18 gauge steel. A removable grill is included for

air circulation and access to the refrigera-

tion system.

2ACCESSORIES:

Tray slide, 12” wide, solid, ribbed, fold-

down. OMNI: all stainless steel with high-

lighted edge; OAKWOOD & VISCAYA: all

stainless steel.

Work shelf, 8” wide, stainless steel, flat,

fold-down.

Double deck display case, with

Laminated Glass shelves and sneeze guards.

OMNI; stainless steel frame and chrome plated

brackets; OAKWOOD & VISCAYA; millwork

frame with plastic laminate finish and brass

plated brackets.

Laminated glass and sneeze guards for

display case (set of four).

Buffet canopy, features Atlas’ unique

flip-top sneeze guard on customer’s side

only - SAR Plexiglas. Canopy body is of millwork

construction with plastic laminate

finish. OMNI: stainless steel top with highlighted

edge and chrome plated brackets; OAK-

WOOD & VISCAYA: stainless steel top with brass

plated brackets.

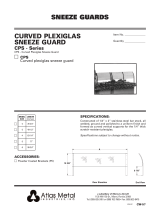

Curved Plexiglas sneeze guard.

Fluorescent light under high shelf or canopy.

Stainless steel legs with adjustable feet,

in lieu of casters.

Stainless steel middle shelf.

Stainless steel sliding doors.

Reversa-Panel an alternate plastic laminate

is substituted for backing sheet on the rear. The

panel may then be reversed in the field, without

the use of tools, to create an alternate look.

Specifications subject to change without notice.

SPECIFICATIONS:

NOTE:

When ordering OMNI, add - OM to model number;

When ordering VISCAYA, add - VS to model number;

When ordering OAKWOOD, add - OW to model number.

DSRM-3240

DSRM-3254

DSRM-3268

DSRM-3285

MOBILE COLD SERVING UNIT

Refrigerated Cold Pan

MODEL “A” COLD PAN DIMENSIONS

DSRM-3240 40” 25”L x 20”W x 4-5/8”D

DSRM-3254 54” 37-1/2”L x 20”W x 4-5/8”D

DSRM-3268 68” 54-1/4”L x 20”W x 4-5/8”D

DSRM-3285 85” 69-1/8”L x 20”W x 4-5/8”D

NOTE: Furnished with adapter bars.

10/08-SC

31”

Plan View

A

35 3/8”

Rear Elevation

End View

-

1

1

-

2

2

Atlas Metal Industries DSRM-3268 Datasheet

- Category

- Sandwich makers

- Type

- Datasheet

Ask a question and I''ll find the answer in the document

Finding information in a document is now easier with AI

Related papers

-

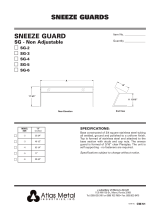

Atlas Metal Industries SG-5 Datasheet

Atlas Metal Industries SG-5 Datasheet

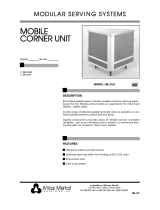

-

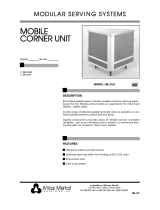

Atlas Metal Industries BL-CU-O Datasheet

Atlas Metal Industries BL-CU-O Datasheet

-

Atlas Metal Industries DSUTBU-3230 Datasheet

Atlas Metal Industries DSUTBU-3230 Datasheet

-

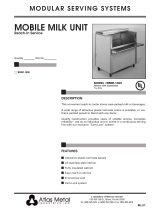

Atlas Metal Industries BMM-1000 Datasheet

Atlas Metal Industries BMM-1000 Datasheet

-

Atlas Metal Industries BL-CU-O Datasheet

Atlas Metal Industries BL-CU-O Datasheet

-

Atlas Metal Industries AD-35 Datasheet

Atlas Metal Industries AD-35 Datasheet

-

Atlas Metal Industries BLU-2-BU User manual

Atlas Metal Industries BLU-2-BU User manual

-

Atlas Metal Industries DSH-3268 Datasheet

Atlas Metal Industries DSH-3268 Datasheet

-

Atlas Metal Industries BLU-3 Datasheet

Atlas Metal Industries BLU-3 Datasheet

-

Atlas Metal Industries CPS Datasheet

Atlas Metal Industries CPS Datasheet

Other documents

-

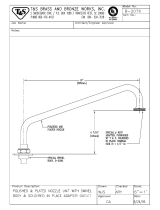

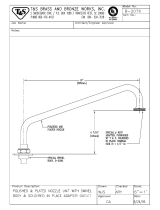

T & S Brass & Bronze Works B-2076 Datasheet

T & S Brass & Bronze Works B-2076 Datasheet

-

ShelterLogic 10072 Specification

ShelterLogic 10072 Specification

-

Ekena Millwork SH36X04X04DE Installation guide

-

Greenheck 462105 Support Mullions for use in Oversize Openings Operating instructions

-

Ekena Millwork CM15LI User manual

-

Legrand sfc_install_AtlasBracket (PDF) Installation guide

-

Burkert 3285 User manual

-

Steel-Line Steel-Line SC12 Aluminium Roller Grille Owner's manual

-

Sony DSR-11 User manual

-

Legrand TS-Motorized Installation guide