Page is loading ...

Field-Installable Pre-Polished Optical Fiber Connectors

www.signamax.com

999 N.W. 159

th

Drive

Miami, FL 33169

800.446.2377

305.944.7710

Fax: 305.949.4483

Copyright 2007 Signamax/AESP, Inc. All rights reserved

Signamax Connectivity Systems is a trademark of AESP, Inc.

Specifications subject to change

Connectivity Solutions

INSTALLATION INSTRUCTIONS

FPC

-

02 Rev.A JAN

-

2016

1

The following installation instructions are intended to be

used when installing the following Signamax optical

Connectors and the optional fiber Jig Assemble Tool:

FPCxx-SCxx-02

FPCxx-LCxx-02

NOTES:

1. Optical fiber connectors shown in these instructions used for

example purpose only; actual product maybe slightly different in

dimensions and design detail.

2. Picture of tool used for example purpose only; actual tools may

differ from those shown.

3. All illustrations are not to scale

Make sure you have all necessary

tools for the job:

• Cable jacket stripping tool

• Optical fiber stripping tool

• Optical fiber cleaving tool

• Lint-free cloth wipes

• Optical fiber cleaning fluid

• Metric ruler and marker pen

WARNING:

• Wear safety glasses before handling

optical fiber to protect the eyes.

• Never look into the end of a connector or

an optical fiber which may have a laser

coupled to it.

1

2

3

4 5

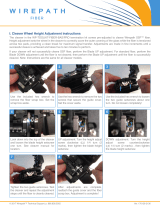

Identify components of the connectors kits:

1: 250-µm Tube 2: Fiber Connector 3: 900-µm Boot

4: Jig - Connector Holder 5: Jig -Fiber Holder

( 4 & 5 Sold Separately )

3

Be sure there is no space between

the wedge and connector, if there is,

push the wedge and connector

together to realign.

Set connector tightly onto

ridge of “U” shaped Jig. (#4)

Open covers 1, 2, 3. Make sure

the guide is not visible. If visible,

push the back-end into the fiber

holder.

5

Place the 900-µm boot on the fiber cable, if applicable

then slide 250-µm tube on the fiber. Angle cut first.

!

2

Remove the fiber guide on the cleaver by using the

allen key located at the bottom of the cleaver and

turning counter clock-wise.

4

Field-Installable Pre-Polished Optical Fiber Connectors

www.signamax.com

999 N.W. 159

th

Drive

Miami, FL 33169

800.446.2377

305.944.7710

Fax: 305.949.4483

Copyright 2007 Signamax/AESP, Inc. All rights reserved

Signamax Connectivity Systems is a trademark of AESP, Inc.

Specifications subject to change

Connectivity Solutions

INSTALLATION INSTRUCTIONS

FPC

-

02 Rev.A JAN

-

2016

Place the Jig with the

fiber onto cleaver

8

9

While hold the jig, cleave the

fiber.

Set the fiber holder to the guide

rail. Be sue the fiber aligns with

the U-groove.

Slide the fiber forward holder

slowly until it stop.

Open the middle cover and continued moving

forward until you hear a “click” sound. Small

amount of bending is normal in the middle.

Open lock lever and push

the sides to release and

remove the wedge.

Open cover 1 and 2.

Remove connector from jig and

slide boot up until it clicks onto

the connector

Verify good termination by using

a visible light source.

Good Connection: Bad Connection:

No Light Visible Light

10

11

12

13

14

15

Slide the tube up and set the fiber

and tube into the holder using the

above dimensions. Once fiber is

set, close the first 2 covers starting

the one closest to the fiber.

7

Check your cleaved

fiber length by placing

Jig and Holder together.

6

Strip 35 mm of 900- and 250-µm coating from fiber and

Clean the fiber with a lint-free wipe and fiber preparation fluid

By re-inserting the wedge

into the connector, fiber

connector could be re-

terminated.

!

/