Page is loading ...

ELECTRIC ROTARY HAMMER CT0700 & CT0701

ORIGINAL INSTRUCTION

CAUTION:

Before using this

electric rotary hammer

drill or any of its

accessories, read this

manual and follow all

its Safety Rules and

Operating Instructions.

Safety

Instructions

Assembly

Operation

Maintenance

Parts List

SAVE THESE INSTRUCTIONS FOR REFERENCE

Cannon Tools Limited

Address: 20 Station Road, Rowley Regis, West Midlands, B65 0JU.UNITED KINGDOM

EC DECLARATION OF CONFORMITY

We CANNON TOOLS LTD

20 Station road, Rowley Regis, West Midlands,B65 0JU.U.K.

Declare that the following machine complies with the appropriate basic safety and

health requirements of the EC Directive based on its design and type, as brought into

circulation by us.

In case of alteration of the machine, not agreed upon by us, this declaration will lose

its validity.

Product description: ELECTRIC ROTARY HAMMER

Model: CT0700 & CT0701

Applicable EC Directives:

EC-Machinery Directive 2006/42/EC

EC-Directive of Electromagnetic Compatibility(EMC)2014/30/EU

Harmonized standards

EN 60745-1, EN 60745-2-6, EN 55014-1, EN 55014-2,

EN 61000-3-2, EN 61000-3-3

20 Station Road, Rowley Regis, West Midlands, B65 0JU.U.K.

Mr. Gurcharan Tony Singh Sanghera

Managing Director

CANNON TOOLS LTD

2017-10-31

2

SPECIFICATIONS

ROTARY HAMMER

Model

CT0700

CT0701

SDS Chuck

SDS fitting

SDS fitting

Voltage

230V~ 50Hz

110V~ 60Hz

No Load Speed

0-860/min

0-860/min

No. of strokes, under load

0-4250Bpm

0-4250Bpm

Input power

1500 W

1500 W

Drilling capacity in

Concrete mm

Steel mm

32

13

32

13

Wood mm

42

42

Weight kg

5.2

5.2

The SDS Rotary hammer power tool noise output may exceed

85dB(A) at the workplace. Wear safety-hearing protection

Note:

- the declared vibration total value has been measured in accordance with a

standard test method and may be used for

comparing one tool with another;

- the declared vibration total value may also be used in a preliminary assessment of

exposure.

Warning:

- the vibration emission during actual use of the power tool can differ from the

declared total value depending on the ways in which the tool is used;

- avoid vibration risk

Suggestion: 1) wear glove during operation

2) limit operating time and shorten trigger time.

3

WARNING

!

GENERAL SAFETY RULES

Read all safety warnings and all

instructions. Failure to follow all instructions

listed below may result in electric shock, fire

and/or serious injury. The term “power tool” in

all of the warnings listed below refers to your

mains operated (corded) power tool or

battery operated (cordless) power tool.

SAVE THESE INSTRUCTIONS

WORK AREA SAFETY

Keep work area clean and well lit.

Cluttered and dark areas invite accidents.

Do not operate power tools in explosive

atmospheres, such as in the presence of

flammable liquids, gases or dust. Power

tools create sparks, which may ignite the dust

or fumes.

Keep children and bystanders away while

operating a power tool. Distractions can

cause you to lose control.

ELECTRICAL SAFETY

Power tool plugs must match the outlet.

Never modify the plug in any way. Do not

use any adapter plugs with earthed

(grounded) power tools. Unmodified plugs

and matching outlets will reduce risk of

electric shock.

Avoid body contact with earthed or

grounded surfaces such as pipes,

radiators, ranges and refrigerators. There

is an increased risk of electric shock if your

body is earthed or grounded.

Do not expose power tools to rain or wet

conditions. Water entering the power tool

will increase the risk of electric shock.

Do not abuse the cord. Never use the cord

for carrying, pulling or unplugging the

power tool. Keep cord away from heat, oil,

sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric

shock.

When operating a power tool outdoors,

use an extension cord suitable for

outdoor use. Use of a cord suitable for

outdoor use reduces the risk of electric shock

If operating a power tool in a damp

location is unavoidable, use a residual

current device (RCD) protected supply.

Use of an RCD reduces the risk of electric

shock.

PERSONAL SAFETY

Stay alert, watch what you are doing and

use common sense when operating a

power tool. Do not use a power tool while

you are tired or under the influence of

drugs, alcohol or medication. A moment of

inattention while operating power tools may

result in serious personal injury.

Use personal protective equipment.

Always wear eye protection. Safety

equipment such as dust mask, non-skid

safety shoes, hardhat, or hearing protection

used for appropriate conditions will reduce

personal injuries.

Prevent unintentional starting. Ensure the

switch is in the off-position before

connecting to power source and/or

battery pack, picking up or carrying the

tool.

Carrying power tools with your finger on the

switch or energizing power tools that have

the switch on invites accidents.

Remove any adjusting key or wrench

before turning the power tool on. A wrench

or key left attached to a rotating part of the

power tool may result in personal injury.

Do not overreach. Keep proper footing

and balance at all times. This enables

better control of the power tool in unexpected

situations.

Dress properly. Do not wear loose

clothing or jewellery. Keep your hair,

clothing and gloves away from moving

parts. Loose clothes, jewellery or long hair

can be caught in moving parts.

If devices are provided for the connection

of dust extraction and collection facilities,

ensure these are connected and properly

used. Use of these devices can reduce dust

related hazards.

POWER TOOL SAFETY

WARNING

!

4

POWER TOOL USE AND CARE

Do not force the power tool. Use the

correct power tool for your application.

The correct power tool will do the job better

and safer at the rate for which it was

designed.

Do not use the tool if the switch does not

turn it ON or OFF. Any power tool that

cannot be controlled with the switch is

dangerous and must be repaired.

Disconnect the plug from the power

source before making any adjustments,

changing accessories or storing power

tools. Such preventive safety measures

reduce the risk of starting the power tool

accidentally.

Store idle power tools out of the reach of

children and do not allow persons

unfamiliar with the power tool or these

instructions to operate the power tool.

Power tools are dangerous in the hands of

untrained users.

Maintain power tools. Check for

misalignment or binding of moving parts,

breakage of parts and any other condition

that may affect the power tools operation.

If damaged, have the power tool repaired

before use. Many accidents are caused by

poorly maintained power tools.

Keep cutting tools sharp and clean.

Properly maintained cutting tools with sharp

cutting edges are less likely to bind and are

easier to control.

Use the power tool, accessories and tool

bits etc., in accordance with these

instructions and in the manner intended

for the particular type of power tool,

taking into account the working

conditions and the work to be performed.

Use of the power tool for operations different

from intended could result in a hazardous

situation.

SERVICE

Have your power tool serviced by a

qualified repair person using only

identical replacement parts. This will

ensure that the safety of the power tool is

maintained.

When servicing a tool, use only identical

replacement parts. Follow instructions in

the Maintenance section of this manual.

Use of unauthorized parts or failure to follow

Maintenance instructions may create a risk of

electric shock or injury.

SPECIFIC SAFETY RULES

1.Use auxiliary handle(s), if supplied with the

tool. Loss of control can cause personal

injury.

2. Hold power tool by insulated gripping

surfaces, when performing an operation

where the cutting accessory may contact

hidden wiring or its own cord. Cutting

accessory contacting a “live” wire may make

exposed metal parts of the power tool “live”

and could give the operator an electric shock.

For your safety, do not plug in your Power

tool until you have read and understood

this Owner’s Manual.

WEAR EYE PROTECTION. Use face or

dust mask along with safety goggles if

operation is dusty. Use hearing

protection, particularly during extended

periods of operation, wear safety shoes.

Wear ear protectors. Exposure to noise

can cause hearing loss

DO NOT wear jewellery, neckties or

loose clothing.

DO NOT drill material too small to be

securely held.

ALWAYS keep hands out of the path of

the drill bit. Avoid awkward hand

positions where a sudden slip could

cause your hand to move into the path of

the drill bit or saw blade.

SECURE WORKPIECE. Use clamps or

a vice to hold the work when practical. It

is safer than using your hand and it frees

both hands to operate the tool.

MAKE SURE there are no nails or

foreign objects in the part of the

workpiece to be drilled.

POWER TOOL SAFETY

5

WARNING

!

SPECIFIC SAFETY RULES – cont’d

TO AVOID INJURY from accidental

starting, always remove the Plug from

the electrical socket before installing or

removing a drill bit, accessory or

attachment.

Use a metal detector to determine if there

are gas or water pipes hidden in the work

area or call the local utility company for

assistance before beginning the operation.

Striking or cutting into a gas line will result in

explosion. Water entering an electrical device

may cause electrocution.

Always use the side handle for maximum

control over torque reaction or kick-back.

Never attempt to operate this tool with

one hand. The slip clutch engages if you

firmly control the tool during a torque reaction

or kickback.

Use thick cushioned gloves and limit the

exposure time by taking frequent rest

periods. Vibration caused by hammer-drill

action may be harmful to your hands and

arms.

Position the cord clear of rotating bit. Do

not wrap the cord around your arm or

wrist. If cord becomes entangled with the

spinning bit it could entrap you causing

serious personal injury.

Position yourself to avoid being caught

between the tool or side handle and walls

or posts. Should the bit become bound or

jammed in the work, the reaction torque of

the tool could crush your hand or leg.

Do not strike the bit with a handheld

hammer or sledge hammer when

attempting to dislodge a bound or

jammed bit. Fragments of metal from the bit

could dislodge and strike you or bystanders.

Some of the following symbols may be

used on your tool. Please study them and

learn their meaning. Proper interpretation

of these symbols will allow you to operate

the tool better and safer.

This symbol designates

that this tool complies to

European directives.

Were ear and eye

protection

Read original manual

V

volts

A

amperes

Hz

hertz

W

watt

F

farads

Kg

kilograms

h

Hours

min

minutes

s

seconds

No load speed

./min or

minˉ¹

Revolutions or

reciprocations per minute

alternating current

class II construction

1, 2, 3, ...

Speed Selector settings

Diameter

Off position

Arrow

Warning symbol

IPXX

IP symbol

Hammer symbol

Drill symbol

POWER TOOL SAFETY

HAMMER DRILL SAFETY

6

SYMBOLS

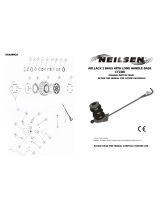

Oil gauge

Trigger

SDS chuck

Motor Housing Carbon brush

KNOW YOUR ELECTRIC HAMMER

Rotary Hammer

7

ACCESSORIES & CARTON CONTENTS

AVAILABLE ACCESSORIES

Use only accessories recommended for

this Rotary hammer . Follow instructions

that accompany accessories. Use of

improper accessories may cause injury to

the operator or damage to the rotary

hammer drill.

Do not use any accessory unless you have

completely read the instructions or Owner’s

Manual for that accessory.

Various Drills

Chuck

Disconnect the plug from the power

source before making any assembly,

adjustments or changing accessories.

Such preventive safety measures reduce the

risk of starting the tool accidentally.

Carefully unpack the tools see “Components

chart” at right hand side of this page

NOTE: See illustration of components on

Page 9.

To avoid fire or toxic reaction, never use

gasoline, naphtha, acetone, lacquer

thinners or similar highly volatile solvents

to clean the tool.

CARTON CONTENTS

WARNING

!

CARTON CONTENTS

WARNING

!

WARNING

!

8

Drill no CT0700 & CT0701

KEY

DESCRIPTION

QTY

A

Rotary Hammer

1

B

SDS Chisels

2

C

SDS Masonry drills

3

D

SDS chuck 1-1.5 to

13mm

1

E

Chuck key

1

F

Grease tub

1

G

Drill dust cap

1

H

Plastic carry case

1

I

Carbon brush

1

Always make sure the power tool is

isolated from the power supply before

fitting any attachment

Adjust the handle. See (Fig 1)

For maximum control and safer operation,

always use the auxiliary handle with this tool.

The auxiliary handle swings around to either

side, allowing easy handling of the tool in any

position. Loosen the auxiliary handle by

turning it counter clockwise, swing it to the

desired position and then tighten it by turning

clockwise.

Fig 1

Switching hammer drill on/off

The hammer drill has an On/Off switch (Fig 2)

built in to the handle. Holding the hammer

drill with both hands simply pull the trigger

and the motor will start. To switch off release

the trigger.

Switch

trigger

Fig 2

WARNING

The rotary hammer drill continues for a few

second after the trigger has been release, so

be careful when putting it down.

FIT CHISEL OR DRILL (Fig 3)

1. Slide back the locking sleeve. Caution:

Make sure the tool is switched off and

unplugged and wear protective gloves.

2. Fit the SDS-plus chisel or drill into the

chuck.

3. Make sure that the chisel or drill is fully

inserted.

4. Release the locking sleeve and check

the chisel or drill is securely fixed. To

remove the chisel or drill, slide back the

locking sleeve and pull out the chisel or

drill.

HAMMER FUNCTION (Fig 4)

The hammer/drill switch can switch the drill,

hammer and hammer/ drill functions.

To set the function, please use below

compounding of front and rear hammer/drill

switch.

Hammer/ drill mode:

Drill in masonry, concrete and natural stone.

Don't use the hammer drill function for

ceramic

tile or others material can not withstand

impact

energy.

ASSEMBLY & OPERATION

10

WARNING

!

Fig 3

Hammer mode:

Drill in masonry, concrete and natural stone.

Drilling mode:

Drilling in wood, synthetic materials and

metal.

WARNING! No function mode:

The motor turns without load,the shaft will

not turn. Do not set the switch like this.

It may damage the motor greatly.

Important! When hammer drilling

you will require a low pressure.

Too much pressure will place

unnecessary load on the motor.

Check the drill bits regularly. Re-

sharpen or replace blunt drill bits.

Do not use the chuck with SDS

connector in combination with the

hammer/hammer drill function!

Variable speed dial

Your tool is equipped with a variable speed

dial. The speed and impact force can be

adjusted by rotating the dial. Higher speeds

and impact force work best for faster

penetration when drilling or chiseling in hard

masonry material. Slower speeds work best

to reduce breakout when bits exit material

being drilled or chiseling material such as

plaster or tile (Fig. 4).

Regardless of the pressure applied on the

trigger, the tool will not operate any faster

than maximum speed setting selected.

Fig 4

This rotary hammer drill does not have

reverse direction, so always take care not

to force the drill in case the drill bit gets

stuck. Always make sure you keep the

drill going in and out to remove debris to

make sure the drill does not get stuck.

This drill does not have torque facility. It

is not recommended to use screwdriver

bits in this drill as it could damage the

screwdriver head or bit and could cause

serious injury

REMOVING ACCESSORIES

Accessories may be hot after use. Avoid

contact with skin and use proper protective

gloves or cloth to remove.

To remove an accessory, pull and hold

locking

sleeve backward and pull bit forward. All

accessories should be wiped clean after

removing.

NOTE: The high efficiency available from the

rotary hammers can only be obtained if sharp

and undamaged accessories are used. The

"cost" to maintain sharp and undamaged

accessories is more than offset by the "time

saved" in operating the tool with sharp

accessories.

WARNING

!

WARNING

!

ASSEMBLY & OPERATION

11

Warning: Always use the side grip (auxiliary

handle) and firmly

hold the tool by both side grip and switch

handle during

operations.

HAMMER DRILLING OPERATION

Set the change lever to the symbol.

Position the bit at the desired location for the

hole, then pull the switch trigger. Do not force

the tool. Light pressure gives best results.

Keep the tool in position and prevent it from

slipping away from the hole.

Do not apply more pressure when the hole

becomes clogged with chips or particles.

Instead, run the tool at an idle, then remove

the bit partially from the hole. By repeating

this several times, the hole will be cleaned

out and normal drilling may be resumed.

CAUTION:

• There is a tremendous and sudden twisting

force exerted on the tool/bit at the time of

hole break-through, when the hole becomes

clogged with chips and particles, or when

striking reinforcing rods embedded in the

concrete. Always hold the tool firmly with

both hands. Failure to do so may result in the

loss of control of the tool and potentially

severe injury.

Electrical products must not be thrown out with

domestic waste. Recycle them at the special

disposal centers provided for the purpose.

Contact your local authorities or stockiest for

advice on recycling.

GENERAL

When servicing, use only identical

replacement parts. Use of any other part

may create a hazard or cause product

damage.

DO NOT use solvents when cleaning plastic

parts. Most plastics are susceptible to

damage from various types of commercial

solvents and may be damaged by their use.

Use clean cloth to remove dirt, dust, oil,

grease et

Do not at any time allow brake fluids,

gasoline, petroleum-based products,

penetrating oils, etc. to come in contact

with plastic parts. They contain chemicals

that can damage, weaken or destroy

plastic.

DO NOT abuse power tools. Abusive

practices can damage the tool as well as the

workpiece.

Have you read “POWER TOOL

SAFETY”, “Hammer DRILL SAFETY”

and “SYMBOLS” on pages 4,5 & 6 of

this manual? If not, please do it now

before you operate this Hammer

drill. Your safety depends on it!

Every time you use the hammer drill

you should verify the following:

1. SDS bit or drill chuck is secure.

2. Work piece is properly secured

in SDS chuck or drill chuck.

3. Select drill or masonry before

you engage in the proposed

operation

4. Safety glasses are being worn.

Failure to adhere to these safety

rules can greatly increase the

chances of injury.

WARNING

!

12

WARNING

!

WARNING

!

MAINTENANCE

ASSEMBLY & OPERATION

DO NOT attempt to modify tools or create

accessories not recommended. Any such

alteration or modification is misuse and

could result in a hazardous condition

leading to possible serious injury. It will

also void the warranty.

LUBRICATION

All of the bearings in these electric tools are

lubricated with a sufficient amount of high-

grade lubricant for the life of the unit under

normal conditions. Therefore, no further

lubrication is required.

13

PARTS DIAGRAM

13

14

PARTS LIST

/