Page is loading ...

Instructions-Parts

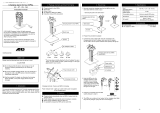

E-Flo® E-Flo®

E-Flo®

DC DC

DC

2–Ball 2–Ball

2–Ball

Piston Piston

Piston

Pumps Pumps

Pumps

333389A

EN

Electric Electric

Electric

drive drive

drive

piston piston

piston

pumps pumps

pumps

for for

for

low low

low

to to

to

medium medium

medium

volume volume

volume

paint paint

paint

circulation circulation

circulation

applications. applications.

applications.

For For

For

professional professional

professional

use use

use

only. only.

only.

Important Important

Important

Safety Safety

Safety

Instructions Instructions

Instructions

Readallwarningsandinstructionsinthismanual.

Save Save

Save

these these

these

instructions. instructions.

instructions.

See Technical Data for Maximum

Working Pressure.

See page 3 for model part numbers and

approvals information.

PROVENQUALITY.LEADINGTECHNOLOGY.

Contents Contents

Contents

Models...............................................................3

RelatedManuals................................................3

Warnings...........................................................4

Installation..........................................................7

Location......................................................7

MountthePump..........................................7

PowerSupplyRequirements.........................7

ConnectthePowerSupply...........................10

Grounding...................................................11

FluidLineAccessories.................................12

FillWithOilBeforeUsingEquipment.............12

FlushBeforeUsingEquipment......................12

ControlModuleAccessory............................12

Operation...........................................................13

Startup........................................................13

Shutdown....................................................13

PressureReliefProcedure............................13

Maintenance......................................................14

PreventiveMaintenanceSchedule................14

ChangetheOil.............................................14

CheckOilLevel...........................................14

BearingPre-Load.........................................14

Wet-Cups....................................................14

Flushing......................................................14

Troubleshooting..................................................15

Repair................................................................16

Dura-FloLowers..........................................16

XtremeLowers............................................17

ReassembletheCouplingAdapterandTie

RodstotheMotor...........................19

Parts..................................................................20

XtremePumpAssembly...............................20

Dura-FloPumpAssembly.............................22

PumpMatrix................................................24

Dimensions........................................................26

MountingHolePatterns.......................................27

StandMount................................................27

WallMount..................................................28

PerformanceCharts............................................29

TechnicalData...................................................32

Notes................................................................33

GracoStandardWarranty....................................34

2

333389A

Models

Models Models

Models

Thesixdigitpartnumberforyourequipmentis

printedontheequipmentidenticationlabel(L).

Refertothetablebelowforinformationregardingthe

congurationofyourequipment.

SeePumpMatrix,page24

,foracompletelistof

pumppartnumbers.

E E

E

- -

-

Flo Flo

Flo

DC DC

DC

Pump Pump

Pump

Part Part

Part

Number Number

Number

Conguration Conguration

Conguration

First First

First

and and

and

Second Second

Second

Digit Digit

Digit

Third Third

Third

Digit Digit

Digit

Fourth Fourth

Fourth

Digit Digit

Digit

Fifth Fifth

Fifth

Digit Digit

Digit

Sixth Sixth

Sixth

Digit Digit

Digit

Digit Digit

Digit

Lower Lower

Lower

Size Size

Size

Digit Digit

Digit

Motor Motor

Motor

Control Control

Control

Approvals Approvals

Approvals

Digit Digit

Digit

Pump Pump

Pump

Material Material

Material

Packings Packings

Packings

Digit Digit

Digit

Mounting Mounting

Mounting

Type Type

Type

7145CC3BasicATEX/FM/

IECEx

4Carbon

Steel

3Xtreme

2Leather

0None

8180CC4AdvancedATEX/FM/

IECEx

5Stainless

Steel

4Leather

1PTFE

1Stand

9220CC7BasicATEX/IECEx/

TIIS/KCS

6Stainless

Steel

PTFE

Leather

2Wall

ES

0290CC8AdvancedATEX/IECEx/

TIIS/KCS

II II

II

2 2

2

G G

G

c c

c

IIA IIA

IIA

T3 T3

T3

NOTE: NOTE:

NOTE:

SeetheE-FloDCMotormanualformotorapprovalsinformation.

Related Related

Related

Manuals Manuals

Manuals

Manual Manual

Manual

No. No.

No.

Description Description

Description

3A2526

Instructions-PartsManual,E-FloDCMotor

3A2527

Instructions-PartsManual,forE-FloDCControlModuleKit

311762Instructions-PartsManual,XtremeLowers

311827Instructions-PartsManual,Dura-FloLowers

333389A 3

Warnings

Warnings Warnings

Warnings

Thefollowingwarningsareforthesetup,use,grounding,maintenance,andrepairofthisequipment.The

exclamationpointsymbolalertsyoutoageneralwarningandthehazardsymbolsrefertoprocedure-specic

risks.Whenthesesymbolsappearinthebodyofthismanual,referbacktotheseWarnings.Product-specic

hazardsymbolsandwarningsnotcoveredinthissectionmayappearthroughoutthebodyofthismanual

whereapplicable.

WARNING WARNING

WARNING

FIRE FIRE

FIRE

AND AND

AND

EXPLOSION EXPLOSION

EXPLOSION

HAZARD HAZARD

HAZARD

Flammablefumes,suchassolventandpaintfumes,inwork work

work

area area

area

canigniteorexplode.Tohelp

preventreandexplosion:

•Useequipmentonlyinwellventilatedarea.

•Eliminateallignitionsources;suchaspilotlights,cigarettes,portableelectriclamps,and

plasticdropcloths(potentialstaticarc).

•Keepworkareafreeofdebris,includingsolvent,ragsandgasoline.

•Donotplugorunplugpowercords,orturnpowerorlightswitchesonoroffwhenammable

fumesarepresent.

•Groundallequipmentintheworkarea.SeeGrounding Grounding

Grounding

instructions.

•Useonlygroundedhoses.

•Holdgunrmlytosideofgroundedpailwhentriggeringintopail.Donotusepaillinersunless

theyareantistaticorconductive.

•Stop Stop

Stop

operation operation

operation

immediately immediately

immediately

ifstaticsparkingoccursoryoufeelashock,Donotuse

equipmentuntilyouidentifyandcorrecttheproblem.

•Keepaworkingreextinguisherintheworkarea.

ELECTRIC ELECTRIC

ELECTRIC

SHOCK SHOCK

SHOCK

HAZARD HAZARD

HAZARD

Thisequipmentmustbegrounded.Impropergrounding,setup,orusageofthesystemcan

causeelectricshock.

•Turnoffanddisconnectpoweratmainswitchbeforedisconnectinganycablesandbefore

servicingorinstallingequipment.

•Connectonlytogroundedpowersource.

•Allelectricalwiringmustbedonebyaqualiedelectricianandcomplywithalllocalcodes

andregulations.

BURN BURN

BURN

HAZARD HAZARD

HAZARD

Equipmentsurfacesanduidthat’sheatedcanbecomeveryhotduringoperation.Toavoid

severeburns:

•Donottouchhotuidorequipment.

MOVING MOVING

MOVING

PARTS PARTS

PARTS

HAZARD HAZARD

HAZARD

Movingpartscanpinch,cutoramputatengersandotherbodyparts.

•Keepclearofmovingparts.

•Donotoperateequipmentwithprotectiveguardsorcoversremoved.

•Pressurizedequipmentcanstartwithoutwarning.Beforechecking,moving,orservicing

equipment,followthePressure Pressure

Pressure

Relief Relief

Relief

Procedure Procedure

Procedure

anddisconnectallpowersources.

4

333389A

Warnings

WARNING WARNING

WARNING

000000

000000

000000

000000

000000

000000

SKIN SKIN

SKIN

INJECTION INJECTION

INJECTION

HAZARD HAZARD

HAZARD

High-pressureuidfromdispensingdevice,hoseleaks,orrupturedcomponentswillpierce

skin.Thismaylooklikejustacut,butitisaseriousinjurythatcanresultinamputation.Get Get

Get

immediate immediate

immediate

surgical surgical

surgical

treatment. treatment.

treatment.

•Engagetriggerlockwhennotdispensing.

•Donotpointdispensingdeviceatanyoneoratanypartofthebody.

•Donotputyourhandovertheuidoutlet.

•Donotstopordeectleakswithyourhand,body,glove,orrag.

•FollowthePressure Pressure

Pressure

Relief Relief

Relief

Procedure Procedure

Procedure

whenyoustopdispensingandbeforecleaning,

checking,orservicingequipment.

•Tightenalluidconnectionsbeforeoperatingtheequipment.

•Checkhosesandcouplingsdaily.Replacewornordamagedpartsimmediately.

TOXIC TOXIC

TOXIC

FLUID FLUID

FLUID

OR OR

OR

FUMES FUMES

FUMES

Toxicuidsorfumescancauseseriousinjuryordeathifsplashedintheeyesoronskin,

inhaled,orswallowed.

•ReadMSDSstoknowthespecichazardsoftheuidsyouareusing.

•Storehazardousuidinapprovedcontainers,anddisposeofitaccordingtoapplicable

guidelines.

PERSONAL PERSONAL

PERSONAL

PROTECTIVE PROTECTIVE

PROTECTIVE

EQUIPMENT EQUIPMENT

EQUIPMENT

Wearappropriateprotectiveequipmentwhenintheworkareatohelppreventseriousinjury,

includingeyeinjury,hearingloss,inhalationoftoxicfumes,andburns.Thisequipmentincludes

butisnotlimitedto:

•Protectiveeyewear,andhearingprotection.

•Respirators,protectiveclothing,andglovesasrecommendedbytheuidandsolvent

manufacturer.

333389A 5

Warnings

WARNING WARNING

WARNING

EQUIPMENT EQUIPMENT

EQUIPMENT

MISUSE MISUSE

MISUSE

HAZARD HAZARD

HAZARD

Misusecancausedeathorseriousinjury.

•Donotoperatetheunitwhenfatiguedorundertheinuenceofdrugsoralcohol.

•Donotexceedthemaximumworkingpressureortemperatureratingofthelowestrated

systemcomponent.SeeTechnical Technical

Technical

Data Data

Data

inallequipmentmanuals.

•Useuidsandsolventsthatarecompatiblewithequipmentwettedparts.SeeTechnical Technical

Technical

Data Data

Data

inallequipmentmanuals.Readuidandsolventmanufacturer’swarnings.Forcomplete

informationaboutyourmaterial,requestMSDSfromdistributororretailer.

•Donotleavetheworkareawhileequipmentisenergizedorunderpressure.

•TurnoffallequipmentandfollowthePressure Pressure

Pressure

Relief Relief

Relief

Procedure Procedure

Procedure

whenequipmentisnotinuse.

•Checkequipmentdaily.Repairorreplacewornordamagedpartsimmediatelywithgenuine

manufacturer’sreplacementpartsonly.

•Donotalterormodifyequipment.Alterationsormodicationsmayvoidagencyapprovals

andcreatesafetyhazards.

•Makesureallequipmentisratedandapprovedfortheenvironmentinwhichyouareusingit.

•Useequipmentonlyforitsintendedpurpose.Callyourdistributorforinformation.

•Routehosesandcablesawayfromtrafcareas,sharpedges,movingparts,andhotsurfaces.

•Donotkinkoroverbendhosesorusehosestopullequipment.

•Keepchildrenandanimalsawayfromworkarea.

•Complywithallapplicablesafetyregulations.

6 333389A

Installation

Installation Installation

Installation

Installationofthisequipmentinvolvespotentially

hazardousprocedures.Onlytrainedandqualied

personnelwhohavereadandwhounderstand

theinformationinthismanualshouldinstallthis

equipment.

Location Location

Location

Whenselectingthelocationfortheequipment,keep

thefollowinginmind:

•Theremustbesufcientspaceonallsidesof

theequipmentforinstallation,operatoraccess,

maintenance,andaircirculation.

•Ensurethatthemountingsurfaceandmounting

hardwarearestrongenoughtosupporttheweight

oftheequipment,uid,hoses,andstresscaused

duringoperation.

•Theremustbeastart/stopcontrol(C)

withineasyreachoftheequipment.See

TypicalInstallation,page9

.

Mount Mount

Mount

the the

the

Pump Pump

Pump

Stand Stand

Stand

Mount Mount

Mount

SeeStandMountingHolePattern,page27

1.Selectalevelsurfaceforthestandtobemounted

to.

2.SecurethestandtotheoorwithM19(5/8in.)

bolts.Useboltsthatengageatleast152mm

(6in.)intotheoortopreventthepumpfrom

tipping.

3.Placethepumpandaccessoriesoverthe

bracket’smountingholesandsecurewithbolts

(5)andwashers(4)supplied.

4.Useshimstolevelthepumpasrequired.

Wall Wall

Wall

Mount Mount

Mount

SeeWallMountingHolePattern,page28.

1.Selectasolidpositiononawallforthemounting

bracket.Thewallshouldbecapableofsupporting

thepumpandaccessoriesthatwillbeattached

tothebracket,anyadditionalweightoftheuid

usedinthepump,andanystressorstrainthat

maybeappliedduringpumpoperation.

2.Drillfour7/16in.(11mm)diameterholesforthe

mountingbolts,approximately5ft(1.5m)above

theoor,usingthewallbracketasatemplate.

Useanyofthethreemountingholegroupings

3.Boltthebracketsecurelytothewall.Usebolts

designedtoholdinthewall’sconstruction.

4.Placethepumpandaccessoriesoverthe

bracket’smountingholesandsecurewithscrews

(5)andwashers(4)supplied.

Power Power

Power

Supply Supply

Supply

Requirements Requirements

Requirements

Improperwiringmaycauseelectricshockorother

seriousinjuryifworkisnotperformedproperly.

Haveaqualiedelectricianperformanyelectrical

work.Besureyourinstallationcomplieswithall

National,StateandLocalsafetyandrecodes.

Thesystemrequiresadedicatedcircuitprotected

withacircuitbreaker.Seetablebelowforpower

supplyrequirements.

Table Table

Table

1 1

1

. .

.

Power Power

Power

Supply Supply

Supply

Specications Specications

Specications

Model Model

Model

Voltage Voltage

Voltage

Phase Phase

Phase

Hz Hz

Hz

Current Current

Current

EM0021

EM0022

200–250

Vac

150/6020A

333389A

7

Installation

Hazardous Hazardous

Hazardous

Area Area

Area

Cabling Cabling

Cabling

and and

and

Conduit Conduit

Conduit

Requirements Requirements

Requirements

Explosion Explosion

Explosion

Proof Proof

Proof

Allelectricalwiringinthehazardousareamustbe

encasedinClassI,DivisionI,GroupDapproved

explosion-proofconduit.FollowallNational,State,

andLocalelectriccodes.

Aconduitseal(D)isrequiredwithin18in.(457mm)

ofthemotorfortheUSandCanada.SeeFig.3.

Allcablesmustberatedat70°C(158°F).

Flame Flame

Flame

Proof Proof

Proof

(ATEX) (ATEX)

(ATEX)

Useappropriateconduit,connectors,andcable

glandsratedforATEXII2G.FollowallNational,

State,andLocalelectriccodes.

Allcableglandsandcablesmustberatedat70°C

(158°F).

8 333389A

Installation

Typical Typical

Typical

Installation Installation

Installation

NON NON

NON

- -

-

HAZARDOUS HAZARDOUS

HAZARDOUS

AREA AREA

AREA

HAZARDOUS HAZARDOUS

HAZARDOUS

AREA AREA

AREA

Figure1TypicalInstallation

Key Key

Key

for for

for

Fig. Fig.

Fig.

1 1

1

A

ElectricalSupply(mustbesealedconduit

approvedforuseinhazardouslocations)

B

FusedSafetySwitch,withlock

CStart/StopControl(mustbeapprovedfor

useinhazardouslocations)

D

ExplosionProofConduitSeal.Required

within18in.(457mm)ofthemotorforthe

USandCanada.

Key Key

Key

for for

for

Fig. Fig.

Fig.

1 1

1

E

FluidPressureGauge

F

FluidShutoffValve

GPumpGroundWire.Twogroundterminals

areprovidediflocalcoderequiresredundant

groundingconnections.

HFluidDrainValve

333389A 9

Installation

Connect Connect

Connect

the the

the

Power Power

Power

Supply Supply

Supply

Improperwiringmaycauseelectricshockorother

seriousinjuryifworkisnotperformedproperly.

Haveaqualiedelectricianperformanyelectrical

work.Besureyourinstallationcomplieswithall

localcodesandregulations.

1.Ensurethatthefusedsafetyswitch(B,Fig2)is

shutoffandlockedout.

Figure2LockedOutFusedSafetySwitch

2.SeeFig.3.Installastart/stopcontrol(C)inthe

electricalsupplyline(A),withineasyreachof

theequipment.Thestart/stopcontrolmustbe

approvedforuseinhazardouslocations.

3.Opentheelectricalcompartment(S)onthe

motor.

4.Bringthepowerwiresintotheelectrical

compartmentthroughthe3/4–14npt(f)inletport.

Connectthewirestotheterminals,asshown.

Torquetheterminalnutsto25in-lb(2.8N•m)

maximum.Do Do

Do

not not

not

over-torque. over-torque.

over-torque.

5.Closetheelectricalcompartment.Torquethe

coverscrewsto15ft-lb(20.3N•m).

Figure3ConnectthePowerWires

Notes Notes

Notes

for for

for

Fig. Fig.

Fig.

3 3

3

Tightenallterminalnutsto25in-lb(2.8N•m)

maximum.Do Do

Do

not not

not

over over

over

- -

-

torque. torque.

torque.

Tightencoverscrewsto15ft-lb(20.3N•m).

Aconduitseal(D)isrequiredwithin18

in.(457mm)ofthemotorfortheUSand

Canada.

10 333389A

Installation

Grounding Grounding

Grounding

Thisequipmentmustbegroundedtoreducethe

riskofstaticsparkingandelectricshock.Electric

orstaticsparkingcancausefumestoigniteor

explode.Impropergroundingcancauseelectric

shock.Groundingprovidesanescapewireforthe

electriccurrent.

1.Pump: Pump:

Pump:

SeeFig.4.Loosenthegroundscrewand

attachagroundwire.Tightenthegroundscrew

securely.Connecttheotherendoftheground

wiretoatrueearthground.

NOTE: NOTE:

NOTE:

Advancedmodelsrequireinstallation

ofthe24P822ControlModule.Allpumps

connectedtoacommoncontrolmodulemustbe

groundedtothesamegroundpoint.Different

groundpoints(unequalpotential)maycause

currenttoowthroughcomponentcables,

causingincorrectsignals.

Figure4GroundWire

2.Fluid Fluid

Fluid

hoses: hoses:

hoses:

Useonlyelectricallyconductive

hoseswithamaximumof500ft.(150m)

combinedhoselengthtoensuregrounding

continuity.Checktheelectricalresistanceof

hoses.Iftotalresistancetogroundexceeds25

megohms,replacehoseimmediately

3.Fluid Fluid

Fluid

supply supply

supply

container: container:

container:

Followyourlocalcode.

333389A

11

Installation

Fluid Fluid

Fluid

Line Line

Line

Accessories Accessories

Accessories

InstallthefollowingaccessoriesasshowninFig.

1,usingadaptersasnecessary.Alluidlinesand

accessoriesmustberatedtothemaximumworking

pressureof400psi(2.8MPa,28.0bar).

•Fluid Fluid

Fluid

drain drain

drain

valve valve

valve

(H): (H):

(H):

requiredinyoursystem,to

relieveuidpressureinthehoseandcirculation

system.

•Fluid Fluid

Fluid

pressure pressure

pressure

gauge gauge

gauge

(E): (E):

(E):

formoreprecise

adjustmentoftheuidpressure.

•Fluid Fluid

Fluid

shutoff shutoff

shutoff

valve valve

valve

(F): (F):

(F):

shutsoffuidow.

Fill Fill

Fill

With With

With

Oil Oil

Oil

Before Before

Before

Using Using

Using

Equipment Equipment

Equipment

SeeFig.5.Beforeusingtheequipment,openthell

cap(P)andaddGracoPartNo.16W645ISO220

silicone-freesyntheticgearoil.Checktheoillevelin

thesightglass(K).Filluntiltheoillevelisnearthe

halfwaypointofthesightglass.Theoilcapacityis

approximately1.5quarts(1.4liters).Do Do

Do

not not

not

overll. overll.

overll.

NOTE: NOTE:

NOTE:

Two1quart(0.95liter)bottlesofoilare

suppliedwiththeequipment.

Figure5SightglassandOilFillCap

Flush Flush

Flush

Before Before

Before

Using Using

Using

Equipment Equipment

Equipment

Thepumpuidsectionwastestedwithlightweight

oil,whichisleftintheuidpassagestoprotectparts.

Toavoidcontaminatingyouruidwithoil,ushthe

equipmentwithacompatiblesolventbeforeusing

theequipment.

Control Control

Control

Module Module

Module

Accessory Accessory

Accessory

TheControlModuleAccessoryisrequiredwith

AdvancedE-FloDCmotorstoprovidetheinterface

foruserstoenterselectionsandviewinformation

relatedtosetupandoperation.SeetheControl

ModuleAccessoryKitmanualforinstallationand

operationinformation.

12

333389A

Operation

Operation Operation

Operation

Startup Startup

Startup

Tooperatethepump,followtheStartupinstructions

fortheBasicorAdvancedmotorintheMotormanual.

TheAdvancedE-FloDCmotorsrequireinstallationof

the24P822ControlModuleAccessoryKittoprovide

theinterfaceforuserstoenterselectionsandview

informationrelatedtosetupandoperation.Seethe

ControlModuleAccessoryKitmanualforinstallation

andoperationinformation.

Runthepumpataslowspeeduntiltheuidlinesare

primedandallairisforcedoutofthesystem.

NOTE: NOTE:

NOTE:

Xtremepumpsshouldnotbeusedfor

waterbornepaints.

Shutdown Shutdown

Shutdown

FollowthePressureReliefProcedure,page13.Stop

thepumpatthebottomofitsstroketopreventuid

fromdryingontheexposeddisplacementrodand

damagingthethroatpackings.

Pressure Pressure

Pressure

Relief Relief

Relief

Procedure Procedure

Procedure

Thisequipmentstayspressurizeduntilpressureis

manuallyrelieved.Tohelppreventseriousinjury

fromsplashinguidandmovingparts,followthe

PressureReliefProcedurewhenyoustopspraying

andbeforecleaning,checking,orservicingthe

equipment.

1.Disengagethestart/stopcontrol(C).SeeFig.1.

2.Shutoffandlockoutthefusedsafetyswitch(B).

3.Opentheuiddrainvalve(H),havingawaste

containerreadytocatchdrainage.Leaveopen

untilyouarereadytopressurizesystemagain.

333389A 13

Maintenance

Maintenance Maintenance

Maintenance

Preventive Preventive

Preventive

Maintenance Maintenance

Maintenance

Schedule Schedule

Schedule

Theoperatingconditionsofyourparticularsystem

determinehowoftenmaintenanceisrequired.

Establishapreventivemaintenancescheduleby

recordingwhenandwhatkindofmaintenanceis

needed,andthendeterminearegularschedulefor

checkingyoursystem.

Change Change

Change

the the

the

Oil Oil

Oil

NOTE: NOTE:

NOTE:

Changetheoilafterabreak-inperiodof

200,000–300,000cycles.Afterthebreak-inperiod,

changetheoilonceayear.

1.SeeFig.6.Placeaminimum2quart(1.9liter)

containerundertheoildrainport.Removethe

oildrainplug(25).Allowalloiltodrainfromthe

motor.

2.Reinstalltheoildrainplug(25).Torqueto25–30

ft-lb(34–40N•m).

3.SeeFig.7.Openthellcap(P)andaddGraco

PartNo.16W645ISO220silicone-freesynthetic

gearoil.Checktheoillevelinthesightglass(K).

Filluntiltheoillevelisnearthehalfwaypointof

thesightglass.Theoilcapacityisapproximately

1.5quarts(1.4liters).Do Do

Do

not not

not

overll. overll.

overll.

4.Reinstallthellcap.

Figure6OilDrainPlug

Check Check

Check

Oil Oil

Oil

Level Level

Level

SeeFig.7.Checktheoillevelinthesightglass(K).

Theoillevelshouldbenearthehalfwaypointofthe

sightglasswhentheunitisnotrunning.Iflow,open

thellcap(P)andaddGracoPartNo.16W645ISO

220silicone-freesyntheticgearoilasrequired.The

oilcapacityisapproximately1.5quarts(1.4liters).

Do Do

Do

not not

not

overll. overll.

overll.

Figure7SightglassandOilFillCap

Bearing Bearing

Bearing

Pre Pre

Pre

- -

-

Load Load

Load

SeeFig.7.Thebearingpre-loads(R)arefactory

setandarenotuseradjustable.Donotadjustthe

bearingpre-loads.

Wet Wet

Wet

- -

-

Cups Cups

Cups

Checkthewet-cupdaily.Keepthewet-cup1/3lled

withGracoThroatSealLiquid(TSL™)orcompatible

solvent.

Flushing Flushing

Flushing

•Flushbeforechanginguids,beforeuidcandry

intheequipment,attheendoftheday,before

storing,andbeforerepairingequipment.

•Flushatthelowestpressurepossible.Check

connectorsforleaksandtightenasnecessary.

•Flushwithauidthatiscompatiblewiththeuid

beingdispensedandtheequipmentwettedparts.

14

333389A

Troubleshooting

Troubleshooting Troubleshooting

Troubleshooting

NOTE: NOTE:

NOTE:

Checkallpossibleremediesbeforedisassemblingthepump.

NOTE: NOTE:

NOTE:

TheLEDonthemotorwillblinkifanerrorisdetected.SeeError Error

Error

Code Code

Code

Troubleshooting Troubleshooting

Troubleshooting

inthemotor

manualforfurtherinformation.

Problem Problem

Problem

Cause Cause

Cause

Solution Solution

Solution

Inadequatepowersupply.

SeePowerSupplyRequirements,

page7

.

Exhausteduidsupply.Rellandreprimepump.

Cloggeduidoutletline,valves,

etc.

Clear.

Pumpoutputlowonbothstrokes.

Wornpistonpacking.

Replace.Seelowermanual.

Heldopenorwornballcheck

valves.

Checkandrepair.Seelower

manual.

Pumpoutputlowononlyone

stroke.

Wornpistonpacking.

Replace.Seelowermanual.

Nooutput.Improperlyinstalledballcheck

valves.

Checkandrepair.Seelower

manual.

Exhausteduidsupply.Rellandreprimepump.

Heldopenorwornballcheck

valves.

Checkandrepair.Seelower

manual.

Pumpoperateserratically.

Wornpistonpacking.

Replace.Seelowermanual.

Inadequatepowersupply.

SeePowerSupplyRequirements,

page7.

Exhausteduidsupply.Rellandreprimepump.

Cloggeduidoutletline,valves,

etc.

Clear.

Pumpwillnotoperate.

Fluiddriedonpistonrod.Disassembleandcleanpump.

Seelowermanual.Infuture,stop

pumpatbottomofstroke.

333389A 15

Repair

Repair Repair

Repair

Dura Dura

Dura

- -

-

Flo Flo

Flo

Lowers Lowers

Lowers

Disassembly Disassembly

Disassembly

Toavoidcrushinginjuriesormusclestrains,use

cautionwhendisconnectingthelower,itcanweigh

upto25kg(55lbs).

1.Stopthepumpatthebottomofitsstroke.

2.Relievethepressure.See

thePressureReliefProcedure,page13

.

3.Disconnectthehosesfromthelowerandplug

theendstopreventuidcontamination.

4.Loosenthecouplingnut(11)andremovethe

collars(10).SeeFig.8.

5.Removethecouplingnutfromthepistonrod(R).

6.Unscrewthelocknuts(8)fromthetierods(6).

7.Separatethemotor(3)andlower(7).

Torepairthelower,seetheDura-FloLower

instructionmanual311827.Thereareno

user-serviceablepartsinthemotor.Contactyour

Gracorepresentativeforassistance.

Reassembly Reassembly

Reassembly

NOTE: NOTE:

NOTE:

Ifthecouplingadapter(9)andtierods(6)

havebeendisassembledfromthemotor(3),see

ReassembletheCouplingAdapterandTieRodsto

theMotor,page19

1.Assemblethecouplingnut(11)tothepistonrod

(R).SeeFig.8.

2.Orientthelower(7)tothemotor(3).Position

thelower(7)onthetierods(6).Lubricatethe

threadsofthetierods(6).

3.Screwthetierodlocknuts(8)ontothetierods

(6).Tightenthelocknuts(8)andtorqueto50-60

ft-lb(68-81N•m).

4.Insertthecollars(10)intothecouplingnut(11).

Tightenthecouplingnut(11)ontothecoupling

adapter(9)andtorqueto90–100ft-lb(122–135

N•m).

5.Flushandtestthepumpbeforereinstalling

itinthesystem.Connecthosesandush

thepump.Whileitispressurized,checkfor

smoothoperationandleaks.Adjustorrepair

asnecessarybeforereinstallinginthesystem.

Reconnectthepumpgroundwirebefore

operating.

NOTE: NOTE:

NOTE:

WhenusedwithE-FloDCmotors,Dura-Flo

lowersrequirecheckvalve(35)tobeinstalled.

Figure8Dura-FloPumpAssembly

16 333389A

Repair

Xtreme Xtreme

Xtreme

Lowers Lowers

Lowers

Disassembly Disassembly

Disassembly

Toavoidcrushinginjuriesormusclestrains,use

cautionwhendisconnectingthelower,itcanweigh

upto25kg(55lbs).

1.Stopthepumpatthebottomofitsstroke.

2.Relievethepressure.See

thePressureReliefProcedure,page13.

3.Disconnectthehosesfromthelowerandplug

theendstopreventuidcontamination.

4.Removeclip(2)andslidecouplingcover(10)up

toremovethecoupling(11).

5.Unscrewthenuts(8)andremovethelower(7).

Useawrenchtoholdthetierodatstokeepthe

rodsfromturning.

Torepairthelower,seetheXtremeLowerinstruction

manual311762.Therearenouser-serviceableparts

inthemotor.ContactyourGracorepresentativefor

assistance.

333389A

17

Repair

Reassembly Reassembly

Reassembly

NOTE: NOTE:

NOTE:

Ifthecouplingadapter(9)andtierods(6)

havebeendisassembledfromthemotor(3),see

ReassembletheCouplingAdapterandTieRodsto

theMotor,page19

1.Orientthelower(7)tothemotor(3).Position

thelower(7)onthetierods(6).Lubricatethe

threadsofthetierods(6).

2.Screwthetierodlocknuts(8)ontothetierods

(6).Tightenthelocknuts(8)andtorqueto50-60

ft-lb(68-81N•m).

3.Raisethemotorshaft.Placethecouplingcover

(10)ontothecouplingadapter(9)andlowerthe

motorshaft.Placethecoupling(11)ontothe

lower(7)andslidethecouplingcover(10)over

thecoupling(11).Insertclip(2).

4.Flushandtestthepumpbeforereinstalling

itinthesystem.Connecthosesandush

thepump.Whileitispressurized,checkfor

smoothoperationandleaks.Adjustorrepair

asnecessarybeforereinstallinginthesystem.

Reconnectthepumpgroundwirebefore

operating.

NOTE: NOTE:

NOTE:

WhenusedwithE-FloDCmotors,Xtreme

lowersrequirecheckvalve(33)tobeinstalled.Figure9XtremePumpAssembly

18 333389A

Repair

Reassemble Reassemble

Reassemble

the the

the

Coupling Coupling

Coupling

Adapter Adapter

Adapter

and and

and

Tie Tie

Tie

Rods Rods

Rods

to to

to

the the

the

Motor Motor

Motor

NOTE: NOTE:

NOTE:

Usethisprocedureonlyifthecoupling

adapter(9)andtierods(6)havebeendisassembled

fromthemotor(3),toensureproperalignmentofthe

motorshafttothepistonrod(R).

1.SeeFig.10.Screwthetierods(6)intothemotor

(3)andtorqueto50-60ft-lb(68-81N•m).

2.Screwthecouplingadapter(9)intothemotor

shaftandtorqueto90–100ft-lb(122–135N•m).

3.Reassemblethepumptothemotor.Use

theapplicableinstructionsforyourpump;

Dura-Flo,page16orXtreme,page18.

Figure10PumpAssembly

333389A 19

/