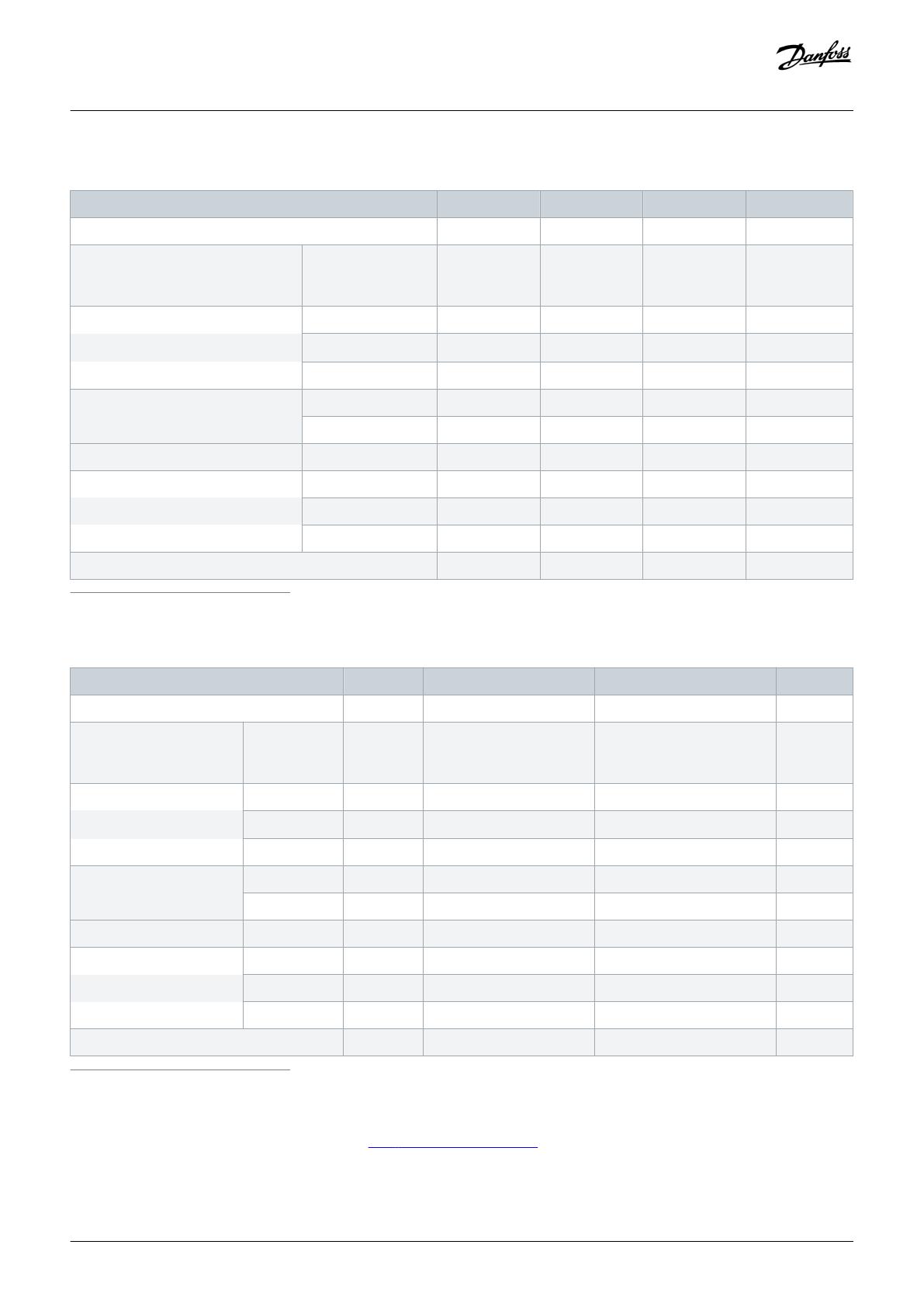

Table 5: Dimensions, Enclosure Sizes H1–H4

Enclosure Size H1 H2 H3 H4

IP class IP20 IP20 IP20 IP20

Power [kW (hp)] 3x380–480 V 0.37–1.5

(0.5–2.0)

2.2–4.0

(3.0–5.0)

5.5–7.5

(7.5–10)

11–15

(15–20)

Height [mm (in)] A 195 (7.7) 227 (8.9) 255 (10.0) 296 (11.7)

A

(1)

273 (10.7) 303 (11.9) 329 (13.0) 359 (14.1)

a 183 (7.2) 212 (8.3) 240 (9.4) 275 (10.8)

Width [mm (in)] B 75 (3.0) 90 (3.5) 100 (3.9) 135 (5.3)

b 56 (2.2) 65 (2.6) 74 (2.9) 105 (4.1)

Depth [mm (in)] C 168 (6.6) 190 (7.5) 206 (8.1) 241 (9.5)

Mounting hole [mm (in)] d 9 (0.35) 11 (0.43) 11 (0.43) 12.6 (0.50)

e 4.5 (0.18) 5.5 (0.22) 5.5 (0.22) 7 (0.28)

f 5.3 (0.21) 7.4 (0.29) 8.1 (0.32) 8.4 (0.33)

Maximum weight kg (lb) 2.1 (4.6) 3.4 (7.5) 4.5 (9.9) 7.9 (17.4)

1

Including decoupling plate.

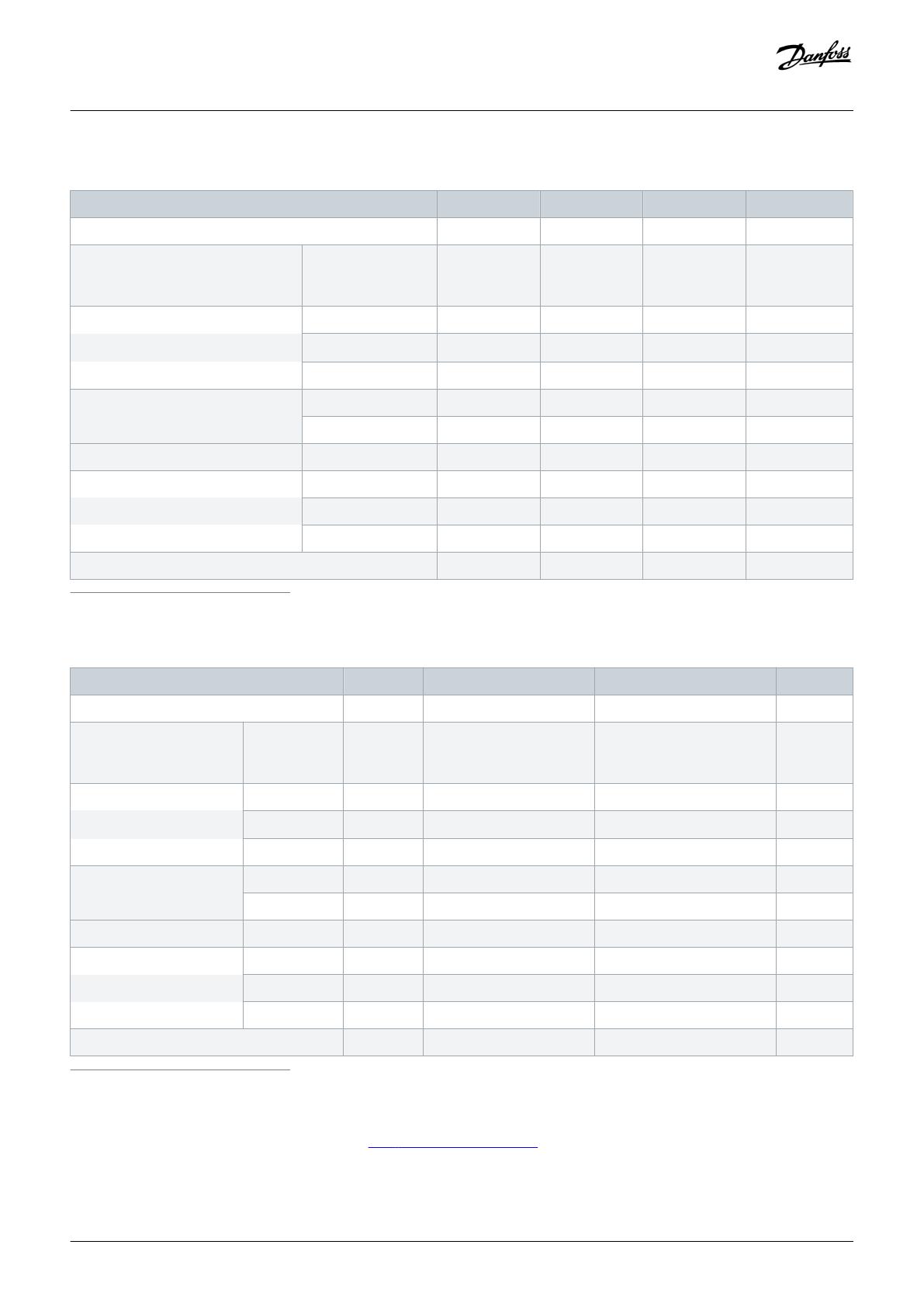

Table 6: Dimensions, Enclosure Sizes H6–H10

Enclosure Size H5 H6 H7 H8

IP class IP20 IP20 IP20 IP20

Power [kW (hp)] 3x380–480 V 18.5–22

(25–30)

30–45

(40–60)

55–75

(70–100)

90 (125)

Height [mm (in)] A 334 (13.1) 518 (20.4) 550 (21.7) 660 (26)

A

(1)

402 (15.8) 595 (23.4)/635 (25), 45 kW 630 (24.8)/690 (27.2), 75 kW 800 (31.5)

a 314 (12.4) 495 (19.5) 521 (20.5) 631 (24.8)

Width [mm (in)] B 150 (5.9) 239 (9.4) 313 (12.3) 375 (14.8)

b 120 (4.7) 200 (7.9) 270 (10.6) 330 (13)

Depth [mm (in)] C 255 (10) 242 (9.5) 335 (13.2) 335 (13.2)

Mounting hole [mm (in)] d 12.6 (0.50) – – –

e 7 (0.28) 8.5 (0.33) 8.5 (0.33) 8.5 (0.33)

f 8.5 (0.33) 15 (0.6) 17 (0.67) 17 (0.67)

Maximum weight kg (lb) 9.5 (20.9) 24.5 (54) 36 (79) 51 (112)

1

Including decoupling plate.

The dimensions are only for the physical units. When installing in an application, allow space above and below the units for cooling.

The amount of space for free air passage is listed in

3.1.1 Side-by-side Installation.

Installation

Operating Guide | VLT® HVAC Basic Drive FC 111

AQ304735638503en-0001 / 130R0265

12 | Danfoss A/S © 2020.02