Page is loading ...

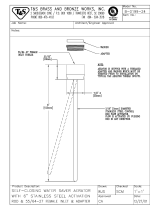

FormNo.3425-502RevA

ProCore

®

SR54,SR54-S,SR70,

SR70-S,andSR72Aerator

ModelNo.09931—SerialNo.318000119andUp

ModelNo.09932—SerialNo.318000113andUp

ModelNo.09933—SerialNo.318000113andUp

ModelNo.09934—SerialNo.318000113andUp

ModelNo.09935—SerialNo.318000143andUp

Registeratwww.Toro.com.

OriginalInstructions(EN)

*3425-502*A

ThisproductcomplieswithallrelevantEuropean

directiveswhenalltheappropriatesetupprocedures

havebeencompleted;fordetails,pleaseseethe

separateproductspecicDeclarationofConformity

(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Thismachineisintendedforusebyprofessional,

hiredoperatorsincommercialapplications.This

machineisdesignedprimarilyforworkinglargeareas

onwell-maintainedlawnsinparks,golfcourses,

sportselds,andoncommercialgrounds.Usingthis

productforpurposesotherthanitsintendedusecould

provedangeroustoyouandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

Visitwww.T oro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,or

additionalinformationcontactanAuthorizedService

DealerorT oroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcode(ifequipped)ontheserial

numberplatetoaccesswarranty,parts,andother

productinformation.

g235770

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

2

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................4

Setup........................................................................7

1RemovingtheAeratorfromthe

Crating............................................................8

2ConnectingtheLowerLinkArms......................8

3ConnectingtheHydraulicTopLink...................9

4InstallingtheDepthGauge..............................11

5ConnectingtheTractionUnitUpper

Link...............................................................12

6VerifyingtheHydraulicT opLink

Setup............................................................12

7CheckingthePTOAngle................................13

8FittingthePTOShaft......................................13

9InstallingthePTOShield................................15

10ConnectingthePTOShaft...........................15

11AdjustingtheSwayLinks..............................17

12LevelingtheAeratorSide-to-Side.................17

13InstallingtheTines.......................................18

14SettingtheTineDepth..................................18

15InstallingtheRearGuard.............................18

16RemovingtheStorageStands.....................19

17InstallingtheLatchLock...............................20

18ApplyingtheCEDecalandtheProduction

YearDecal....................................................20

ProductOverview...................................................22

Specications..................................................22

Attachments/Accessories.................................22

BeforeOperation.................................................23

BeforeOperationSafety...................................23

OutcrossTractionUnitControls........................23

TractionUnitControls.......................................23

PrinciplesofOperation.....................................23

TractionUnitPTOSpeed..................................23

TrainingPeriod.................................................24

BeforeAerating................................................24

DuringOperation.................................................24

DuringOperationSafety...................................24

SlopeSafety.....................................................25

AeratingProcedures.........................................25

SubsoilCultivation............................................25

HardGround.....................................................26

Longer/LargerTines.........................................26

MultiRowAdapterHeads.................................26

RootZoneLifting..............................................26

AdjustingtheTineAngle(ModelsSR54,

SR54-S,SR70andSR70-S).........................26

AdjustingtheTineAngle(ModelSR72).............27

AdjustingtheTineDepth(ModelsSR54-S

andSR70-S).................................................27

AdjustingtheTineDepth(ModelsSR54,

SR70,andSR72)..........................................27

AdjustingtheHeadReturnSprings...................28

TransportOperation.........................................29

OperatingTips.................................................29

AfterOperation....................................................29

AfterOperationSafety......................................29

CleaningandInspectingtheMachine...............29

Maintenance...........................................................31

RecommendedMaintenanceSchedule(s)...........31

MaintenanceSafety..........................................31

LiftingtheMachine...........................................31

GreasingthePTOShaftandRoller

Bearings........................................................32

GearboxOilSpecication.................................32

CheckingtheGearboxOil.................................32

ChangingtheGearboxOil................................33

Inspecting/AdjustingtheDriveChain................33

AdjustingtheDriveChain.................................33

LubricatingtheDriveChain...............................34

AdjustingthePTOClutch..................................34

FastenerT orqueSpecications........................34

CheckingtheSprings........................................35

AdjustingtheHoleSpacing...............................35

RemovingtheAeratorfromtheTraction

Unit...............................................................35

Troubleshooting................................................36

Storage...................................................................37

StorageSafety..................................................37

StoringtheMachine..........................................37

3

Safety

GeneralSafety

Thisproductiscapableofcausingpersonalinjury.

Alwaysfollowallsafetyinstructionstoavoidserious

personalinjury.

•Readandunderstandthecontentsofboththis

Operator’sManualandtheoperator’smanualof

thetractionunitbeforeusingthismachine.Ensure

thateveryoneusingthisproductknowshowtouse

thismachineandthetractionunitandunderstands

thewarnings.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepthemachineasafedistanceawayfrom

bystanderswhileitismoving.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethemachine.

•Stopthemachine,shutofftheengine,engagethe

parkingbrake,removethekey,andwaitforall

movingpartstostopbeforeservicing,fueling,or

uncloggingthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol

,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthismanual.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

decal117-7052

117–7052

1.ReadtheOperator’sManual,donotoilthechaindrive.

decal100-3612

100–3612

1.Entanglementhazard—stayawayfrommovingparts,keep

allguardsandshieldsinplace.

decal127-4235

127-4235

1.Entanglementhazard,shaft—stayawayfrommovingparts.

2.ReadtheOperator'sManual;PTOspeedandinput

direction.

3.Usethecliptosecurethelashcablewhennotinuse.Use

thelashcabletosupporttheshaftwhenthemachineis

disconnectedfromthetowvehicle.

decal117-7051

117-7051

1.Crushinghazardofhandorfoot—keepbystandersaway.

4

decal92-1581

92–1581

decal92-1582

92–1582

decal117-7050

117-7050

1.Warning—readtheOperator'sManual.

2.Warning—removetheignitionkeyandreadtheinstructionsbeforeservicingorperformingmaintenance.

3.Warning—donotoperatethismachineunlessyouaretrained.

4.Entanglementhazard,belt—stayawayfrommovingparts,keepallguardsinplace.

5.Crushinghazardofhandorfoot—keepbystandersasafedistanceawayfromthemachine.

6.Crushinghazardofhandandbody—supportmachineonstandwhennotinuse.

7.Fallinghazard—donotcarrypassengers.

decal120-0625

120-0625

1.Pinchpoint,hand—keephandsaway.

5

decal121-6926

121-6926

1.Tinedepth—deep2.Tinedepth—shallow

decal133-8061

133-8061

6

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Qty.

Use

1

Nopartsrequired

–

Removetheaeratorfromthecrating.

Hitchpin2

2

Lynchpin2

Connectthelowerlinkarms(theSR54

andSR54-Saeratorsshipwiththehitch

pinsandlynchpinsinstalled).

Hydraulictoplink1

Hydraulichose—106cm(3-1/2ft)

1

Hydraulichose—76cm(2-1/2ft)

1

Extensionbracket2

Rotationalbracket1

3

Hosequickcouplings2

Connectthehydraulictoplink(Models

SR54,SR70,andSR72).

Depthgauge1

Slideblock

1

Machinescrew(#10x1/2inch)

2

Screw(1/4x2-1/2inch)

2

Tubeclamp1

Weldplate1

4

Depthdecal1

Installthedepthgauge.

Spring-loadedtoplink

1

Linkpin3

5

Lynchpin3

Connecttheupperlink(ModelsSR54-S

andSR70-S).

6

Nopartsrequired

–

Verifythetoplinksetup.

7

Nopartsrequired

–

CheckthePTOangle.

8

PTOshaft

1

FitthePTOshaft.

9

PTOshield

1

InstallthePTOshield.

Pin(suppliedwiththePTOshaft)

1

10

Nut(suppliedwiththePTOshaft)

1

ConnectthePTOshaft.

11

Nopartsrequired

–

Adjusttheswaylinks.

12

Level(notsupplied)

1Leveltheaeratorside-to-side.

13

Tines(asrequired)

–

Installthetines.

14

Nopartsrequired

–

Setthetinedepth.

Rearguard1

Screw(3/8x3-1/4inch)

4

Flatwasher(0.438x1inch)

12

Locknut4

15

Endcap2

Installtherearguard.

7

ProcedureDescription

Qty.

Use

16

Nopartsrequired

–

Removethestoragestands.

Lockplate2

Tapbolt2

17

Retainingring2

Installthelatchlock.

CEdecal

1

18

Productionyeardecal1

ApplytheCEdecalandtheproduction

yeardecal.

MediaandAdditionalParts

Description

Qty.

Use

Operator'sManual

1

Readbeforeoperatingtheaerator

Springwires(SR54andSR54-S)

6Replacementspringwires

Springwires(SR70andSR70-S)

8Replacementspringwires

Springwires(SR72)

4Replacementspringwires

Springwires(SR72)

2Replacementspringwires

PTOOperatorsManual

1

Readbeforeoperatingtheaerator

1

RemovingtheAeratorfrom

theCrating

NoPartsRequired

Procedure

1.Removetheaeratorfromthecrating.

2.Removetheboltssecuringtheaeratorstorage

standstotheshippingpalletandremovethe

aeratorfromthepallet.

3.Removethestoragestandsfromtheaerator.

Retainthemforstorageuse.

Note:TheSR54-SandtheSR70-Sdonot

haveshippingstands.

4.Placetheaeratoronaat,levelsurfacewiththe

frontrolleronthegroundandablockofwood

positionedundertheheads.

2

ConnectingtheLowerLink

Arms

Partsneededforthisprocedure:

2Hitchpin

2Lynchpin

Procedure

1.EnsurethatthePTOisdisengaged.

2.Backthetractionunitsquarelytotheaerator

untilthelowerlinkarmsalignwiththemounting

brackets.

Note:Theaeratorgearboxshaftshouldalign

withthetractionunitPTOshaft(centeredonthe

tractionunit).Ifshaftsmisalign,adjustthelower

linkarms,fromsidetosideuntiltheshaftsalign.

3.Engagetheparkingbrake,shutofftheengine,

andremovethekey.Waitfortheengineand

allmovingpartstostopbeforeleavingthe

operator'sseat.

Note:Formaximumgroundclearance,secure

thehitchpinsintheaeratoratthelowermounting

bracketholes,whensoequipped.T odetermine

8

whentousetheuppermountingholes,referto

10ConnectingthePTOShaft(page15).

SR54andSR54-SAeratorsonly

Note:Thefactoryinstallsthehitchpinsand

lynchpinsontotheSR54andSR54-Saerators

beforeshipping.

4.Securethelowerlinkarmstotheaerator

mountingpinswithlynchpins(Figure3).

g016127

Figure3

1.Aeratormountingpin3.Lynchpin

2.Lowerlink

SR70,SR70-S,andSR72Aeratorsonly

5.Securethelowerlinkarmstotheaerator

mountingbracketswithhitchpinsandlynchpins

(Figure4).

g016183

Figure4

1.Hitchpin3.Lowerlink

2.Aeratormountingbracket4.Lynchpin

3

ConnectingtheHydraulic

TopLink

ModelsSR54,SR70,andSR72

Partsneededforthisprocedure:

1Hydraulictoplink

1

Hydraulichose—106cm(3-1/2ft)

1

Hydraulichose—76cm(2-1/2ft)

2Extensionbracket

1Rotationalbracket

2Hosequickcouplings

Procedure

Note:Makesurethatthesuppliedcouplingsare

correctforthetractionunit.Ifnot,contactthetraction

unitmanufacturertoobtainthecorrectcouplings.

Yourtractionunitmusthaveadoubleacting

spoolvalvewithanoperatorcontrolleverand2

quick-releasecouplings12.7mm(1/2inch)atthe

rearofthetractionunit.Thefactoryprovides2quick

couplingstotontothehydraulictoplinkhoses

(1/2-14NPTFhoseendthreadsize).

Usetheprocedurethatfollowstoinstallthehoses

anddeterminetheneedfortheextensionorrotation

blocks.Thisinformationalsohelpsyoutodetermine

thedepthrangeoftheaerator.

1.Securetheconnectinglinkendofthehydraulic

toplinktothetractionunitwiththepinssupplied

withthetractionunit(Figure5).

Positionthehydraulictoplinksothattherod

endistowardtheaeratorandthecylinderports

aligntowardtheauxiliarypowerhydraulicsof

thetractionunit.

Note:Ifyoumustpositionthehydrauliccylinder

withtheportsfacingupward,usetherotational

blockinsteadofthestandardmountingblockto

repositionthecylinder(Figure5).Youmayuse

a90°hydraulicttinginsteadoftherotational

block(90°ttingsarenotincluded).

Installtherotationalblockasfollows:

A.Removethecotterpinandpinsecuring

thestandardconnectinglinktothecylinder

(Figure5).Removetheconnectinglink

fromthecylinder.

9

B.Installtherotationalblocktothecylinder

withthepinspreviouslyremoved(Figure5).

g010840

Figure5

1.Aeratorhitchpin7.Tractionunitlinkpin

2.Hydraulictoplink

8.Clevisandlynchpin

3.Rotationalblock9.Hydraulichose—76cm

(2-1/2ft)

4.Connectinglink

10.Hydraulichose—106cm

(3-1/2ft)

5.3inchextensionblock11.Hosequickcouplings

6.5inchextensionblock12.Tractionunithydraulic

ports

2.Connectthelonghydraulichose—106cm(3-1/2

ft)tothehydraulictoplinkportthatisclosestto

theaeratorFigure5.Applypipe-threadsealing

tapeorcompoundtothehosethreadstoprevent

anyleaks.

3.Connecttheshorthydraulichose—76cm(2-1/2

ft)tothehydraulictoplinkportthatisclosestto

thetractionunit(Figure5).Applypipe-thread

sealingtapeorcompoundtothehosethreadsto

preventanyleaks.

4.Installquickcouplingstothehydraulichoses

(1/2-14NPTFhoseendthreadsize).Apply

pipe-threadsealingtapeorcompoundtothe

hosethreadstopreventanyleaks.

5.Connectthe2hydraulichosequickcouplingsto

theportsprovidedonthetractionunit.

6.Starttheengineofthetractionunitandoperate

thespoolvalvetochecktheextendandretract

motionofthehydraulictoplink.

Note:Iftheliftingandloweringtheaeratordoes

notagreewiththetractionunitcontroloperation,

reversethehoseconnectionsatthetractionunit.

7.Securetherodendofhydraulictoplinktothe

mostforwardholepossibleintheaeratorbracket

withlinkpinandlynchpin(Figure6orFigure7).

Important:Whensecuringtherodendof

thehydrauliclink,usethemostforward

mountingholesinthemountingbracketso

thatthereisenoughclearanceforthebarrel

ofthecylinderwhenretracted.

g016184

Figure6

SR54andSR70mountingshown

1.Rodendofcylinder

3.Linkpin

2.Lynchpin

4.Aeratorbracket(forward

holes)

g016185

Figure7

SR72mountingshown

1.Lynchpin3.Linkpin

2.Aeratorbracket

4.Rodendofcylinder

Ifthehydrauliccylinderdoesnotreachthe

aeratormountingbracket,useanextension

blockinsteadofthestandardmountingblockto

10

connectthecylindertothetractionunit(Figure

5).

Note:Ifyouinstalltheextensionblockand

needtoretractthecylindertoinstallit,the

aeratortineheadswillgetclosertotheground.

Installtheextensionblocksasfollows:

A.Removethecotterpinandpinsecuring

thestandardconnectinglinktothecylinder

(Figure5).Removetheconnectinglink

fromthecylinder.

B.Installtherequiredlengthextensionblock

tothecylinderwiththepinspreviously

removed(Figure5).

4

InstallingtheDepthGauge

ModelsSR54,SR70,andSR72

Partsneededforthisprocedure:

1Depthgauge

1

Slideblock

2

Machinescrew(#10x1/2inch)

2

Screw(1/4x2-1/2inch)

1Tubeclamp

1Weldplate

1Depthdecal

Procedure

1.Mountthedepthgaugetotheatsideofthe

slideblockwith2machinescrews(#10x1/2

inch),positioningthecomponentsasshownin

Figure8.

g024283

Figure8

1.Screw

5.Depthdecal

2.Depthgauge

6.Cylinder

3.Machinescrew(2)

7.Weldplate

4.Slideblock

8.Tubeclamp

2.Usingthetubeclamp,weldplateand2screws

(1/4x2-1/2inches),looselymountthedepth

gaugetotherodendofthetoplinkcylinder

(Figure8).Makesurethattheclampsareloose

enoughtoallowthemtorotatetothedesired

position.

3.Makesurethatthetopofthecylinderisclean

enoughtoexcepttheinstallationofadecal.

4.Afxthedepthdecaltothetopofthecylinder

atalocationthatisvisiblefromtheoperating

positionanddoesnotinterferewithhydraulic

hosesorotherobstructions(Figure8).Alignthe

endofthedecalwiththeletter“J”towardthe

aerator.

5.Checktomakesurethecylinderrodcanextend

andretractfullywithoutinterferingwithother

tractionunitoraeratorcomponents.Whenthe

depthgaugeinpositionedcorrectly,tighten

mountingscrews.

6.Runtheaeratoronatestplottodeterminethe

desiredsettingandnotethecorresponding

positiononthedepthindicator.

Ifneeded,youcanadjustthecylinderwhile

operationtheaeratortoadeepersetting(toward

“J”)orshallowersetting(toward“A”).

11

Note:Thelettersonthedecalcorrespondtoa

relativedepth.

5

ConnectingtheTraction

UnitUpperLink

ModelsSR54-SandSR70-S

Partsneededforthisprocedure:

1

Spring-loadedtoplink

3Linkpin

3Lynchpin

Procedure

1.Mountthespring-loadedtoplinktotheaerator

bracketwith2linkpinsandlynchpins(Figure9)

2.Loosenthelocknutonthetractionunitupper

link.Adjusttheupperlinklengthuntilitaligns

withtheclevisonthespring-loadedtoplinkof

theaerator(Figure9).

g010966

Figure9

1.Spring-loadedtoplink

4.Lynchpin

2.Upperlink5.Locknut

3.Linkpin

3.Connectthetractionunitupperlinktotheclevis

onthespring-loadedtoplinkandsecurewitha

linkpinandlynchpin(Figure9).

4.Greasethethreadedsteelupperlinktubes.

5.Measurethelengthofthespringinthetoplink.

6.Rotatetheupperlinkuntilthespringcompresses

approximately13mm(1/2inch)(Figure9).

7.Tightenthelocknuttosecuretheupperlinkinto

position.

6

VerifyingtheHydraulicTop

LinkSetup

NoPartsRequired

Procedure

Extendingthehydrauliccylinderincreasesthetine

depth.

1.Fullyextendthehydrauliccylindertodetermine

thelocationofthetineheadsandtoverifyifthey

contacttheground.

Note:Onundulatingturf,theoperatorcan

adjustthecylindertomaintaintinedepth

(crestingahill)butitwillbenecessarytohave

thetineheadssetabout5cm(2inches)below

ground.

•Ifthetineheadscontacttheground,turf

damagemayoccur.

Ifthetineheadscontacttheground,adjust

thelocationofthecylinderendstomovethe

topoftheaeratorclosertothetractionunit.

•Ifthetineheadsdonotcontacttheground,

youcaninstallextensionbrackets(included

withaerator)ontothetoplinktomovethe

tineheadsclosertotheground.

2.Retractthehydrauliccylindertoliftthetine

heads.

Important:WhenconnectingthePTO,

donottolifttheaeratorhigherthanis

necessary.Liftingthemachinetoohigh

willcausethePTOshaftknucklestobreak

(Figure10).ShutoffthePTOwhenyouraise

theaerator.YoucanoperatethePTOupto

anangleof25°,butdonotexceeda35°angle

whentheaeratorisatitshighestposition;

otherwise,severeshaftdamagemayoccur.

12

g010803

Figure10

1.Damagewilloccurhere.

7

CheckingthePTOAngle

NoPartsRequired

Procedure

Important:BeforecheckingthePTOangle,

removethetines.

1.Withtheaeratorpositionedonthegroundand

loweredtothedeepestlocation,useanangle

indictortomeasuretheanglebetweenthePTO

andtheaerator.

2.Lifttheaeratorandfullyretractthehydraulictop

linkcylinder.

3.Usinganangleindictor,checktheangle

betweenthePTOandtheaerator.

4.Ifyourmeasurementisgreaterthan35°,perform

1ofthefollowingtoadjustthetractionunitso

thatyoucannotraisetheaeratorpast35°.

•Usetheliftstopofthetractionunit(if

equipped).

•Movethelowerlinkstoahighermounting

hole(ifequipped).

8

FittingthePTOShaft

Partsneededforthisprocedure:

1

PTOshaft

Procedure

1.Parkthetractionunitandaeratoronalevel

surface.

2.Raisetheaeratorcompletelyandfullyretractthe

hydraulictoplinkcylinderorupperlink(Figure

11).

g010798

Figure11

3.Measurethedistancefromthelockinggroove

attheendofthetractionunitPTOshafttothe

lockinggrooveattheaeratorgearboxshaft

(Figure12).

Recordthismeasurementhere:

EXAMPLE:67CM(26-1/2

INCHES)

g237884

Figure12

1.Measurehere2.Lockinggroove

4.Lowertheaeratortothegroundandfullyextend

thehydraulictoplinkcylinderorupperlink

(Figure13).

13

g010807

Figure13

5.Measurethedistancefromthelockinggroove

attheendofthetractionunitPTOshafttothe

lockinggrooveattheaeratorgearboxshaft

(Figure14).

Recordthismeasurementhere:

EXAMPLE:70CM(27-1/2

INCHES)

g237883

Figure14

1.Measurehere2.Lockinggroove

6.Measurethedistancefromthecenteroflocking

pinballattheendofthePTOshafttothecenter

ofthelockingpinontheotherend(Figure15).

Recordthismeasurementhere:

EXAMPLE:81CM(32INCHES)

g237882

Figure15

1.Measurehere

7.Usingthesmallerofthe2measurementsin

Figure14andFigure12,subtractthatdistance

fromthedistanceinFigure15.Example:81cm

(32inches)minus67cm(26-1/2inches)equals

14cm(5-1/2inches).

8.Theexamplemeasurementsshowthattheshaft

is14cm(5-1/2inches)toolong.Addanextra

1.2cm(1/2inch)toensurethatthePTOshaft

doesnotbottomoutwhenyoulifttheaerator

toitshighestposition.

EXAMPLE:14CM(5-1/2INCHES)PLUS1.2CM(1/2

INCH)EQUALS15CM(6INCHES)

9.FullyslidetogetherthePTOshafttubes.Verify

thattheinsidetubedoesnotprotrudeintothe

crossandbearingsectionoftheoutertube

(Figure16).Ifthishappens,youneedtocutoff

moreoftheinsidetube—proceedtonextstep.

10.Measurethedistancetheinsidetubeprotrudes

intothecrossandbearingsectionoftheouter

tube(Figure16).Addthisdistancetothe

dimensionattainedinstep8.

g237881

Figure16

1.Cutoff

2.Insidetube

11.Separatethe2halvesofthePTOshaft(Figure

17).

12.Measurethedistancefromtheendofeachtube

toitssafetyshield(Figure17).

Recordthemeasurementshere

and.

g237887

Figure17

13.Usingthedimensionsdeterminedinstep8,

locate,mark,andcutofftheshieldandtube

fromeachPTOhalf(Figure18andFigure19).

14

Note:Cutoffmoreoftheinsidetubeifit

protrudesintothecrossandbearingsectionof

theoutertube.

g237888

Figure18

g237889

Figure19

14.Usingthedimensionsdeterminedinstep11,

locate,markandcutoffjustthesafetyshieldsto

exposethetubes(Figure20andFigure21).

g237890

Figure20

g237891

Figure21

15.Carefullyremoveanyburrsfromtheendsofthe

tubeswithaleandremoveallthelingsfrom

thetubes.

16.Greasetheinsidetube.

Note:Thetelescopingtubesmustalways

overlapby1/2oftheirlengthduringnormal

operationandatleast1/3oftheirlengthduring

allworkingconditions.Duringtransport,when

thedrivelineisnotrotating,thetelescoping

tubesmusthaveasuitableoverlaptomaintain

alignmentofthetubesandallowthemtoslide

freely.

9

InstallingthePTOShield

Partsneededforthisprocedure:

1

PTOshield

Procedure

1.Removethe4bolts,lockwashers,andat

washerssecuredtotherearoftheaerator

gearbox(Figure22).

g010849

Figure22

1.PTOshield

4.Bolt

2.Flatwasher5.Accesspanel

3.Lockwasher

2.MountthePTOshieldtotheaeratorgearbox

withthefastenerspreviouslyremoved(Figure

22).

Aligntheaccesspanel(Figure22)ofthePTO

shieldtothetoporthesidedependingonthe

aeratorframeconguration.

15

10

ConnectingthePTOShaft

Partsneededforthisprocedure:

1

Pin(suppliedwiththePTOshaft)

1

Nut(suppliedwiththePTOshaft)

Procedure

Note:Youcanopentheaccesspanel(Figure22)to

easetheremovalandinstallationofthePTOshaft

mountingfasteners.

1.RemovethepinandnutfromthePTOshaft

(Figure23).

2.ConnecttheclutchendofthePTOshafttothe

aeratorgearboxinputshaftwithpinandnut

previouslyremoved(Figure23).

Note:Youcaninsertpinonlyoneway.

g010850

Figure23

1.Gearboxinputshaft

3.Pin

2.PTOshaftcoupler

4.Nut

Note:CloseandlatchthePTOshieldaccess

panelifopened.

Note:Ensurethatthepinfullyinsertsintothe

yokeofthePTO.

3.ConnectthePTOshafttothetractionunitPTO

shaft(Figure24).

g007328

Figure24

1.Tractionunitoutputshaft3.PTOshaft

2.PTOshaftcoupler

4.SlidethePTOshaftforwardasfarasthetraction

unitallows.

5.PullbackthelockingcollartosecurethePTO

shaftinplace.SlidethePTOshaftbackand

forthtoensurethatitisproperlylocked.

6.ConnecttheshieldsafetychainstothePTO

shieldandthetractionunitbracket(Figure

25).Ensurethatthechainsremainslackwhen

raisingandloweringtheaerator.

g010852

Figure25

1.Safetychains

Note:T oavoidexcesslift,connecttheliftarms

ofthetractionunitintothetopholesofthelift

bracket,ifequipped(Figure26).Themaximum

angleonthePTOshaftis35°.

16

g010804

Figure26

1.Topholes

Important:Donotlifttheaeratorhigher

thannecessarywhenconnectingthePTO.

Liftingthemachinetoohighwillcausethe

PTOshaftknucklestobreak(Figure27).

ShutoffthePTOwhenliftingtheaerator.You

canoperatethePTOuptoa25°angle,but

neverexceeda35°anglewhentheaeratoris

atitshighestposition.

7.VerifythatthePTOshielddoesnotinterferewith

theclutch.

g010803

Figure27

1.Breakagewilloccurhere.

11

AdjustingtheSwayLinks

NoPartsRequired

Procedure

Wheninstalledcorrectly,theaeratoriscenteredwith

thePTO-shaftcenterlineofthetractionunit.Adjust

theswaylinkstocentertheaerator.

Important:ThePTOshaftshouldbeasstraight

aspossibletothetractionunitPTOshaft.

1.Adjusttheswaylinksonthelowerliftarmsto

minimizeside-to-sideswaytoamaximumof25

mm(1inch)ateachside(Figure28).

g007333

Figure28

1.Swaylink

2.Adjustthelowerlinksinboarduntiltheycontact

theaeratormountingplates;refertothetraction

unitoperator'smanualforadditionalinstallation

andadjustmentprocedures.

Note:Thisreducesthestressonthepins.

3.Ifthetractionunithasswaychainsinsteadof

swaylinks,installwashersbetweenthelower

linkarmandlynchpintoreducetheoverhung

loadontheliftpins.

12

LevelingtheAerator

Side-to-Side

Partsneededforthisprocedure:

1

Level(notsupplied)

Procedure

1.Parkthetractionunitandaeratoronarm,level

surface.

2.Placealevelontopoftheaeratorframeto

checkforlevelside-to-side(Figure29).

17

g010854

Figure29

1.Level

3.Turntheadjustablelinkbody(ifprovided)to

raiseorlowerthelinkarmuntiltheaeratorlevels

side-to-side.

Note:Refertothetractionunitoperator's

manualforadditionaladjustmentprocedures.

13

InstallingtheTines

Partsneededforthisprocedure:

–

Tines(asrequired)

Procedure

Youcanchoosefromawideselectionoftinesforthe

aerator.Choosethetinetype,size,andspacings

requiredforthejob.RefertothePartsCatalogforthe

listofaccessories.

1.Ensurethatthestandsorsupportblocksfully

supporttheaerator.

2.Turnoffthetractionunitengineandremovethe

key.

3.Loosentheclampingboltsandremovethe

previouslyusedtines(Figure30).

g016131

Figure30

1.Tine

2.Clampingbolt

4.Slidethenewtinesintotheholessizedtotthe

tinesselected.Neverusesmalldiametertines

inthelargediameterholes;thetinesshouldt

closelyinthehole.Besuretoslidethetineup

intotheheaduntilitbottomsout.

Note:Positionhollowcoringtineswiththe

ejectionslottotherear.Positionsolidtineswith

thetinetipanglefacingthemachine(Figure30).

5.Tightentheclampingboltsrmlytosecurethe

tines.Donotuseimpacttools.

6.Setthetineangleforthenewtines;refer

toAdjustingtheTineAngle(ModelsSR54,

SR54-S,SR70andSR70-S)(page26)or

AdjustingtheTineAngle(ModelSR72)(page

27).

7.Beforeaeratingformalturfforthersttime

afterinstallingtines,testtheaeratoronaless

importantareasothatyoucantryalternative

tractionunitgearsandnetunetheadjustment

toachievetheholespacingandturfappearance

desired.

14

SettingtheTineDepth

ModelsSR54-SandSR70-S

NoPartsRequired

Procedure

Setthetinedepth;refertoAdjustingtheTineDepth

(ModelsSR54-SandSR70-S)(page27).

18

15

InstallingtheRearGuard

Partsneededforthisprocedure:

1Rearguard

4

Screw(3/8x3-1/4inch)

12

Flatwasher(0.438x1inch)

4Locknut

2Endcap

Procedure

1.Inserttheendcapsintotheendsoftherear

guardtubes(Figure31).

g016186

Figure31

1.Rearguard3.Uppermountinghole

2.Endcap4.Lowermountinghole

2.Aligntheholesintherearguardmountingtubes

withtheholesintheaeratorsideplates(Figure

31).

Note:OnSR54-SandSR70-Smodels,mount

theendsofthetubestothelowersideplate

mountingholesiftheaeratortinedepthissetin

PositionA(Figure32).Usetheuppermounting

holesfordepthsettingPositionsBorC.

g016181

Figure32

3.Securetheguardmountingtubestotheside

plateswith4screws,atwashers,andnuts

(Figure31).

Note:Usetheremainingwashers,asrequired,

tollanygapbetweenthetubesandtheaerator

sideplates.

16

RemovingtheStorage

Stands

NoPartsRequired

PreparingModelsSR54andSR70

1.Raisetheaeratorroller(s)7.5to15cm(3to6

inches)offtheground.Placesupportblocks

undertheroller(s).

2.Removethebolts,lockwashers,andnuts

securingthestoragestandstoeachendofthe

aerator(Figure33).

19

g010857

Figure33

1.Bolts3.Nut

2.Lockwasher

4.Storagestand

3.Removethestoragestands.

4.Usethestoragestandswheneveryouremove

theaeratorfromthetractionunit.

PreparingModelSR72

1.Raisetheaeratorroller(s)7.5to15cm(3to6

inches)offtheground.Placesupportblocks

undertheroller(s).

2.Removethebolts,lockwashers,andnuts

securingthestoragestandstoeachendofthe

aerator(Figure34).

g010967

Figure34

1.Bolts3.Nut

2.Lockwasher

4.Storagestand

3.Removethestoragestands.

4.Usethestoragestandswheneveryouremove

theaeratorfromthetractionunit.

Note:Wheninstallingthestoragestands,

ensurethatthestandsmounttotheinsideofthe

rollerplatessothatthelowerframetuberests

onthetopofthestands.

Note:ModelsSR54-SandSR70-Sdonothave

storagestands.

17

InstallingtheLatchLock

CEOnly

Partsneededforthisprocedure:

2Lockplate

2Tapbolt

2Retainingring

Procedure

1.Positionthelatchplateoverthehoodlatchwhile

aligningthemountingholewiththeholeinthe

sideplate(Figure35).

g016161

Figure35

1.Retainingring3.Latchplate

2.Mountinghole4.Tapbolt

2.Securethelatchplatetothesideplatewithatap

boltandaretainingring(Figure35).

3.Repeattheprocedureontheotherhoodlatch.

20

/