Page is loading ...

SAM-e

Engineering Manual

Includes technical specifications,

guidelines, and options for selection and

application of SAM-e and Mini SAM-e Short

Absorption Manifolds

1503529-F | 22 JUNE 2015

Your guide to selecting and specifying Nortec SAM-e Short Absorption Manifolds!

Thank you for choosing Nortec.

Proprietary Notice

This document and the information disclosed herein are proprietary data of NORTEC. Neither this document nor the

information contained herein shall be reproduced used, or disclosed to others without the written authorization of NORTEC.,

except to the extent required for installation or maintenance of recipient‟s equipment. All references to the Nortec name

should be taken as referring to NORTEC.

Liability Notice

Nortec does not accept any liability for installations of humidity equipment installed by unqualified personnel or the use of

parts/components/equipment that are not authorized or approved by Nortec.

Copyright Notice

Copyright 2011, NORTEC. All rights reserved.

Contents

1 General

1 Features

3 Determining the Steam

Absorption Distance

7 Static Air Pressure

7 Condensate Losses

8 Correct Choice of Product

Applications

15 Product Selection

16 Step 1 Header Selection

24 Step 2 Steam Tube Selection

27 Step 3 SAM-e Steam Inlet

Configuration Selection

30 Select Options

35 Installation Drawings

45 Specification

51 Appendix Inlet Adapter

Configurations

1 | SAM-e Engineering

Nortec Short Absorption Manifold (SAM-e)

The SAM-e is Nortec‟s best performing steam absorption system for use in Air Handling Units and duct systems

where short steam absorption distance is critical.

Precisely controlled clean steam is distributed uniformly into the air stream by the SAM-e without any

condensate spray. Steam distribution takes place via distributor tubes with integrated nozzles. The steam is

kept dry as condensate is drained through the main header.

The stainless steel distribution tubes are typically mounted vertically but may also be mounted horizontally (10º

slope) for vertical airflow applications. The distribution tubes come equipped with evenly-spaced stainless steel

nozzles, providing optimum steam distribution.

The nozzles extend into the center of the distribution tube ensuring only condensate-free steam is released.

Condensate drains out of the distribution tubes through the header, eliminating the need for jacketed tubes. A

permanent bond between the nozzle and distribution tube is made when the nozzle is pressed into the tube. The

nozzles and tubes have the same thermal expansion characteristics guaranteeing a permanent union. The

precise manufactured orifices ensure consistent output from each nozzle.

Features

Inlets/Outlets located on same side, one access point required.

All stainless steel distributors and nozzles ensure permanent bond.

Stainless steel header with rubber grommet seals for easy installation of distribution tubes.

Tubes available in 409 or 304 stainless steel to fit every budget.

Available with optional stainless steel insulating shielding for increased energy efficiency and

decreased condensate losses.

Adjustable mounting frame available for quick and easy installation.

Available with 3", 6", 9”, or 12” center to center distributor spacing – (SAM-e).

Available in 3” and 6” center to center distributor spacing - (mini SAM-e).

Atmospheric or pressure steam source.

Ten-year limited warranty (two years on tube coupling seals).

Note: SAM-e Header / Separator assembly distributes the steam evenly along its length and allows

condensate to settle for easy removal through the trap.

SAM-e Engineering | 2

Figure 1: SAM-e

Figure 2: Cross-section of distributor pipe

3 | SAM-e Engineering

Determining the Steam Absorption Distance

A certain amount of time is required for complete absorption when injecting steam into the air.

During this time, steam moves a fixed distance from the distribution manifold before it is fully absorbed into a

moving air stream.

The absorption distance is the distance required for steam to be fully absorbed by the airstream. Identifying this

distance is essential to ensure that unabsorbed steam does not condense on downstream components.

The system should be designed to eliminate the possibility of wetting internal components by positioning the

manifold in an optimum location and by maximizing the available distance for steam absorption.

Shorter absorption is not always desirable. Sizing a SAM-e to produce unnecessarily short absorption distances

may result in increased condensate losses and require a larger humidifier to compensate. It is important to

balance available absorption distance with SAM-e capacity.

Absorption distance may be calculated visiting nortechelp.com.

Additional Information

Data is based on velocities between 200 fpm (1 m/s) and 2500 fpm (12.7 m/s).

Available absorption distance: the distance between SAM-e and first obstruction (coil, elbow, damper, etc.) that

steam may contact. Traces of steam may pass this obstruction, but will not condense, leaving obstructions dry.

Absorption distance is a function of various conditions including; duct temperature, duct humidity level, duct

static pressure, and air flow rate. Changes in duct geometry, flow rates, or flow conditions will require

recalculating SAM-e performance. It is always recommended to size SAM-e to “worst case” conditions.

Note: Visit www.humidity.com to download our Humidification Engineering & Loadsizing Program

(H.E.L.P.) to help calculate absorption distances.

SAM-e Engineering | 4

Static Air Pressure

Table 1 shows the static pressure loss created by a SAM-e in various velocities.

Table 1: Air Pressure Loss in AHU / Duct

Air Velocity

[ fpm (m/s) ]

Air Pressure Loss [ in(mm) of water column ]

SAM-e Tube Spacing

3” (762 mm)

6” (152 mm)

9” (229 mm)

12” (305 mm)

500 (2.5)

0.01 (0.3)

0.01 (0.3)

No measurable data

750 (3.8)

0.03 (0.8)

0.01 (0.3)

1000 (5.1)

0.05 (1.3)

0.02 (0.5)

1250 (6.4)

0.07 (1.8)

0.03 (0.8)

1500 (7.6)

0.09 (2.3)

0.04 (1.0)

0.01 (0.3)

0.01 (0.3)

1750 (8.9)

0.10 (2.5)

0.06 (1.5)

0.01 (0.3)

0.01 (0.3)

2000 (10.2)

0.12 (3.0)

0.08 (2.0)

0.01 (0.3)

0.01 (0.3)

Condensate Losses

Some of the steam generated by NORTEC humidifiers will condense due to SAM-e. To compensate for this

loss in capacity, calculated humidification load must be increased accordingly. Please refer to Table 2.

Nortec recommends the installation of a condensate drain on the steam-line run prior to entering the SAM-e.

This will prevent condensate from the lines from entering the SAM-e.

Table 2: Condensate Loss for Un-insulated SAM-e

Air Velocity

[ fpm (m/s) ]

Condensate Losses [ % of Maximum Capacity ]

Atmospheric Steam

Pressurized Steam

55ºF (13°C)

70ºF (21°C)

55ºF (13°C)

70ºF (21°C)

500 (2.5)

15%

12%

8%

5%

1000 (5.1)

20%

15%

10%

7%

Note: These values may increase or decrease due to many unknown conditions or

variables. This is only a guideline.

5 | SAM-e Engineering

The SAM-e is available with optional stainless steel insulation for headers and tubes. Insulation is desirable to

reduce air-stream heat gain, reduce condensate losses, and improve energy efficiency. Please refer to Table 3

when estimating condensate losses with insulated SAM-e‟s.

Table 3: Condensate Loss for Insulated SAM-e

Air Velocity

[ fpm (m/s) ]

Condensate Losses [ % of Maximum Capacity ]

Atmospheric Steam

Pressurized Steam

55ºF (13°C)

70ºF (21°C)

55ºF (13°C)

70ºF (21°C)

500 (2.5)

5%

4%

6%

3%

1000 (5.1)

10%

8%

8%

5%

Correct Choice of Product Applications (within SAM-e)

The SAM-e has been designed exclusively for use in building ventilation duct systems where short absorption is

critical. Nortec offers various humidification technologies to suit virtually all applications and can recommend the

most appropriate system for each case.

Note: These values may increase or decrease due to many unknown conditions or variables. This is only a

guideline.

SAM-e Engineering | 6

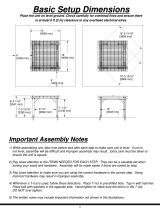

Figure 3: General SAM-e Dimensions

7 | SAM-e Engineering

Table 4: SAM-e Dimensions – Width

Duct Width

Dimension A

Frame Width - Bottom

Dimension B

Frame Width - Top

Dimension C

Header Assembly Width

in

mm

in

mm

in

mm

in

mm

18

457

13.1

333

14.9

378

16.3

413

24

610

19.1

486

20.9

530

22.3

57

30

762

25.1

638

26.9

683

28.3

72

36

914

31.1

791

32.9

835

34.3

87

42

1067

37.1

943

38.9

987

40.3

102

48

1219

43.1

1095

44.9

1140

46.3

117

54

1372

49.1

1248

50.9

1292

52.3

133

60

1524

55.1

1400

56.9

1445

58.3

148

66

1676

61.1

1553

62.9

1597

64.3

163

72

1829

67.1

1705

68.9

1749

70.3

178

78

1981

73.1

1857

74.9

1902

76.3

194

84

2134

79.1

2010

80.9

2054

82.3

209

90

2286

85.1

2162

86.9

2207

88.3

224

96

2438

91.1

2315

92.9

2359

94.3

239

102

2591

97.1

2467

98.9

2511

100.3

255

108

2743

103.1

2619

104.9

2664

106.3

270

114

2896

109.1

2772

110.9

2816

112.3

285

120

3048

115.1

2924

116.9

2969

118.3

300

126

3200

121.1

3077

122.9

3121

124.3

316

132

3353

127.1

3229

128.9

3273

130.3

331

138

3505

133.1

3381

134.9

3426

136.3

346

144

3658

139.1

3534

140.9

3578

142.3

361

SAM-e Engineering | 8

Table 5: SAM-e Dimensions – Height

Duct Height

Dimension D

Steam Tube Height

Dimension E Min.

Minimum Overall Height

Dimension E Max.

Maximum Overall Height

in

mm

in

mm

in

mm

in

mm

18

457

5.5

140

17

432

24.7

627

24

610

11.5

292

23

584

30.7

779

30

762

17.5

445

29

737

36.7

931

36

914

23.5

597

35

889

42.7

1084

42

1067

29.5

749

41

1041

48.7

1236

48

1219

35.5

902

47

1194

54.7

1389

54

1372

41.5

1054

53

1346

60.7

1541

60

1524

47.5

1207

59

1499

66.7

1693

66

1676

53.5

1359

65

1651

72.7

1846

72

1829

59.5

1511

71

1803

78.7

1998

78

1981

65.5

1664

77

1956

84.7

2151

84

2134

71.5

1816

83

2108

90.7

2303

90

2286

77.5

1969

89

2261

96.7

2455

96

2438

83.5

2121

95

2413

102.7

2608

102

2591

89.5

2273

101

2565

108.7

2760

108

2743

95.5

2426

107

2718

114.7

2913

114

2896

101.5

2578

113

2870

120.7

3065

120

3048

107.5

2731

119

3023

126.7

3217

126

3200

113.5

2883

125

3175

132.7

3370

132

3353

119.5

3035

131

3327

138.7

3522

138

3505

125.5

3188

137

3480

144.7

3675

144

3658

131.5

3340

143

3632

150.7

3827

9 | SAM-e Engineering

Figure 4: General Mini SAM-e Dimensions

SAM-e Engineering | 10

Table 6: Mini SAM-e Dimensions – Width

Duct Width

Dimension A

Mini SAM-e Width

in

mm

in

mm

12

305

11.1

281

18

457

17.1

433

24

610

23.1

586

Table 7: Mini SAM-e Dimensions – Height

Duct Height

Dimension B

Mini SAM-e Height

Dimension C

Mini Steam Tube Height

in

mm

in

mm

in

mm

8

203

7.9

200

4.4

113

10

254

9.9

251

6.4

164

12

305

11.9

302

8.4

214

14

356

13.9

352

10.4

265

16

406

15.9

403

12.4

316

18

457

17.9

454

14.4

367

20

508

19.9

505

16.4

418

22

559

21.9

556

18.4

468

24

610

23.9

606

20.4

519

11 | SAM-e Engineering

Product Selection

SAM-e Engineering | 12

Step 1 – SAM-e Header Selection

Nortec offers a ranges of manifolds to cover various capacities and duct sizes. The absorption distance and

capacity required determines the center-to-center spacing between each steam tube. There are four options: 3”

(76 mm) or 6” (152 mm) or 9” (229 mm) or 12” (305 mm). Mini SAM-e‟s are only available with 3” and 6”

spacing. The smaller the spacing, the more tubes the header can accommodate, thus giving a better absorption

distance and greater capacity, but at the cost of higher condensate losses.

The header / separator remain the same for atmospheric or pressurized steam, and for vertical or horizontal

flow applications.

Atmospheric manifolds with a capacity over 801 lb/hr (362 kg/hr) include a second steam inlet on the header.

Consult factory submittal drawings for specific details.

Select the header part number associated with your duct or air handling unit‟s width.

For example, if duct width is 80” (2032 mm), select part number 1503279 for 3” (76 mm) center-to-center

spacing.

Some smaller duct sizes are too small to accommodate a full-size SAM-e, and a Mini SAM-e must be used. As a

rule-of-thumb, when duct width is less than 30” (762mm), a Mini SAM-e is the best choice.

Air Handling Unit (AHU) Installation

In some LiveSteam installations where there is no available room to install steam components such as F&T

traps, separator, etc., a stand may be ordered. Stands are available in 12- or 20- inch heights, and allow traps

and components to be installed in the duct along with the SAM-e. If a stand is required, the overall height of the

SAM-e must be reduced by the height of the selected stand. This enables proper steam tube selection. SAM-e

width must also be reduced to allow components to fit in the duct beside the SAM-e. Please refer to LiveSteam

Engineering Manual for component sizes.

Table 8: SAM-e Stand Kits

Dimension A

[ in (mm) ]

Part Number

12" (305)

1509947

20" (508)

1509948

Note: Refer to SAM-e submittal drawings for more information. All stand kits are complete with both left

and right stands and required fasteners.

13 | SAM-e Engineering

Figure 5: Header / Separator Assembly

Figure 6: SAM-e Stand

SAM-e Engineering | 14

Table 9: SAM-e Header / Separator Assembly, Atmospheric Steam – 3” Centers

ATMOSPHERIC STEAM – 3” HEADERS

Duct Width

[ in (mm) ]

Steam

Tube Qty

Header

Part Number

Maximum Capacity Atmospheric Steam [ lb/hr (kg/hr) ]

Type A

Type B

Type B+

Type C

18 (457)

3

1503269

45 (20)

105 (48)

165 (75)

225 (102)

24 (610)

5

1503270

75 (34)

175 (79)

275 (125)

375 (170)

30 (762)

7

1503271

105 (48)

245 (111)

385 (175)

525 (238)

36 (914)

9

1503272

135 (61)

315 (143)

495 (225)

675 (306)

42 (1067)

11

1503273

165 (75)

385 (174)

605 (274)

800 (363)

Double Inlet

1503291

-

-

825 (374)

48 (1219)

13

1503274

195 (88)

455 (206)

715 (324)

800 (363)

Double Inlet

1503292

-

-

-

975 (442)

54 (1372)

15

1503275

225 (102)

525 (238)

800 (363)

-

Double Inlet

1503293

-

-

825 (374)

1125 (510)

60 (1524)

17

1503276

255 (116)

595 (270)

800 (363)

-

Double Inlet

1503294

-

-

935 (424)

1200 (544)

66 (1676)

19

1503277

285 (129)

665 (301)

800 (363)

-

Double Inlet

1503295

-

-

1045 (474)

1200 (544)

72 (1829)

21

1503278

315 (143)

735 (333)

800 (363)

-

Double Inlet

1503296

-

-

1155 (524)

1200 (544)

78 (1981)

23

1503279

345 (156)

800 (363)

-

-

Double Inlet

1503297

-

805 (365)

1200 (544)

-

84 (2134)

25

1503280

375 (170)

800 (363)

-

-

Double Inlet

1503298

-

875 (396)

1200 (544)

-

90 (2286)

27

1503281

405 (183)

800 (363)

-

-

Double Inlet

1503299

-

945 (428)

1200 (544)

-

96 (2438)

29

1503282

435 (197)

800 (363)

-

-

Double Inlet

1503300

-

1015 (460)

1200 (544)

-

102 (2591)

31

1503283

465 (211)

800 (363)

-

-

Double Inlet

1503301

-

1085 (492)

1200 (544)

-

108 (2743)

33

1503284

495 (224)

800 (363)

-

-

Double Inlet

1503302

-

1155 (523)

1200 (544)

-

114 (3048)

35

1503285

525 (238)

800 (363)

-

-

Double Inlet

1503303

-

1200 (544)

-

-

120 (3048)

37

1503286

555 (251)

800 (363)

-

-

Double Inlet

1503304

-

1200 (544)

-

-

126 (3200)

39

1503287

585 (265)

800 (363)

-

-

Double Inlet

1503305

-

1200 (544)

-

-

132 (3353)

41

1503288

615 (279)

800 (363)

-

-

Double Inlet

1503306

-

1200 (544)

-

-

138 (3505)

43

1503289

645 (292)

800 (363)

-

-

Double Inlet

1503307

-

1200 (544)

-

-

144 (3658)

45

1503290

675 (306)

800 (363)

-

-

Double Inlet

1503308

-

1200 (544)

-

-

144+

(3658+)

Consult Factory

15 | SAM-e Engineering

Table 10: SAM-e Header / Separator Assembly, Pressure Steam – 3” Centers

PRESSURE STEAM – 3” Headers

Duct Width

[ in (mm) ]

Steam Tube

Qty

Header

Part Number

Maximum Capacity Pressure Steam [ lb/hr (kg/hr) ]

Type A

Type B

Type B+

Type C

18 (457)

3

1503269

45 (20)

105 (48)

165 (75)

225 (102)

24 (610)

5

1503270

75 (34)

175 (79)

275 (125)

375 (170)

30 (762)

7

1503271

105 (48)

245 (111)

385 (175)

525 (238)

36 (914)

9

1503272

135 (61)

315 (143)

495 (225)

675 (306)

42 (1067)

11

1503273

165 (75)

385 (174)

605 (274)

825 (374)

48 (1219)

13

1503274

195 (88)

455 (206)

715 (324)

975 (442)

54 (1372)

15

1503275

225 (102)

525 (238)

825 (374)

1125 (510)

60 (1524)

17

1503276

255 (116)

595 (270)

935 (424)

1275 (578)

66 (1676)

19

1503277

285 (129)

665 (301)

1045 (474)

1425 (646)

72 (1829)

21

1503278

315 (143)

735 (333)

1155 (524)

1575 (713)

78 (1981)

23

1503279

345 (156)

805 (365)

1265 (574)

1745 (790)

84 (2134)

25

1503280

375 (170)

875 (396)

1375 (624)

1875 (849)

90 (2286)

27

1503281

405 (183)

945 (428)

1485 (674)

2025 (917)

96 (2438)

29

1503282

435 (197)

1015 (460)

1595 (723)

2175 (985)

102 (2591)

31

1503283

465 (211)

1085 (492)

1705 (773)

2325 (1053)

108 (2743)

33

1503284

495 (224)

1155 (523)

1815 (823)

2475 (1121)

114 (3048)

35

1503285

525 (238)

1225 (555)

1925 (873)

2625 (1189)

120 (3048)

37

1503286

555 (251)

1295 (587)

2035 (923)

2775 (1257)

126 (3200)

39

1503287

585 (265)

1365 (618)

2145 (973)

2925 (1325)

132 (3353)

41

1503288

615 (279)

1435 (650)

2255 (1023)

3075 (1393)

138 (3505)

43

1503289

645 (292)

1505 (682)

2365 (1073)

3200 (1450)

144 (3658)

45

1503290

675 (306)

1575 (713)

2475 (1123)

3200 (1450)

144+ (3658+)

Consult Factory

SAM-e Engineering | 16

Table 11: SAM-e Header / Separator Assembly, Atmospheric Steam – 6” Centers

ATMOSPHERIC STEAM – 6” HEADERS

Duct Width

[ in (mm) ]

Steam

Tube Qty

Header

Part Number

Maximum Capacity Atmospheric Steam [ lb/hr (kg/hr) ]

Type A

Type B

Type B+

Type C

18 (457)

2

1503309

30 (14)

70 (32)

110 (50)

150 (68)

24 (610)

3

1503310

45 (20)

105 (48)

165 (75)

225 (102)

30 (762)

4

1503311

60 (27)

140 (63)

220 (100)

300 (136)

36 (914)

5

1503312

75 (34)

175 (79)

275 (125)

375 (170)

42 (1067)

6

1503313

90 (41)

210 (95)

330 (150)

450 (204)

48 (1219)

7

1503314

105 (48)

245 (111)

385 (175)

525 (238)

54 (1372)

8

1503315

120 (54)

280 (127)

440 (200)

600 (272)

60 (1524)

9

1503316

135 (61)

315 (143)

495 (225)

675 (306)

66 (1676)

10

1503317

150 (68)

350 (159)

550 (249)

750 (340)

72 (1829)

11

1503318

165 (75)

385 (174)

605 (274)

800 (363)

Double Inlet

1503331

-

-

-

825 (374)

78 (1981)

12

1503319

180 (82)

420 (190)

660 (299)

800 (363)

Double Inlet

1503332

-

-

-

900 (408)

84 (2134)

13

1503320

195 (88)

455 (206)

715 (324)

800 (363)

Double Inlet

1503333

-

-

975 (442)

90 (2286)

14

1503321

210 (95)

490 (222)

770 (349)

800 (363)

Double Inlet

1503334

-

-

-

1050 (476)

96 (2438)

15

1503322

225 (102)

525 (238)

800 (363)

-

Double Inlet

1503335

-

-

825 (374)

1125 (510)

102 (2591)

16

1503323

240 (109)

560 (254)

800 (363)

-

Double Inlet

1503336

-

-

880 (399)

1200 (544)

108 (2743)

17

1503324

255 (116)

595 (270)

800 (363)

-

Double Inlet

1503337

-

-

935 (424)

1200 (544)

114 (3048)

18

1503325

270 (122)

630 (271)

800 (363)

-

Double Inlet

1503338

-

-

990 (449)

1200 (544)

120 (3048)

19

1503326

285 (129)

665 (301)

800 (363)

-

Double Inlet

1503339

-

-

1045 (474)

1200 (544)

126 (3200)

20

1503327

300 (136)

700 (317)

800 (363)

-

Double Inlet

1503340

-

-

1100 (499)

1200 (544)

132 (3353)

21

1503328

315 (143)

735 (333)

800 (363)

-

Double Inlet

1503341

-

-

1155 (524)

1200 (544)

138 (3505)

22

1503329

330 (149)

770 (349)

800 (363)

-

Double Inlet

1503342

-

-

1200 (544)

-

144 (3658)

23

1503330

345 (156)

805 (365)

800 (363)

-

Double Inlet

1503343

-

-

1200 (544)

-

144+ (3658+)

Consult Factory

17 | SAM-e Engineering

Table 12: SAM-e Header / Separator Assembly, Pressure Steam – 6” Centers

PRESSURE STEAM – 6” Headers

Duct Width

[ in (mm) ]

Steam Tube

Qty

Header

Part Number

Maximum Capacity Pressure Steam [ lb/hr (kg/hr) ]

Type A

Type B

Type B+

Type C

18 (457)

2

1503309

30 (14)

70 (32)

110 (50)

150 (68)

24 (610)

3

1503310

45 (20)

105 (48)

165 (75)

225 (102)

30 (762)

4

1503311

60 (27)

140 (63)

220 (100)

300 (136)

36 (914)

5

1503312

75 (34)

175 (79)

275 (125)

375 (170)

42 (1067)

6

1503313

90 (41)

210 (95)

330 (150)

450 (204)

48 (1219)

7

1503314

105 (48)

245 (111)

385 (175)

525 (238)

54 (1372)

8

1503315

120 (54)

280 (127)

440 (200)

600 (272)

60 (1524)

9

1503316

135 (61)

315 (143)

495 (225)

675 (306)

66 (1676)

10

1503317

150 (68)

350 (159)

550 (249)

750 (340)

72 (1829)

11

1503318

165 (75)

385 (174)

605 (274)

825 (374)

78 (1981)

12

1503319

180 (82)

420 (190)

660 (299)

900 (408)

84 (2134)

13

1503320

195 (88)

455 (206)

715 (324)

975 (442)

90 (2286)

14

1503321

210 (95)

490 (222)

770 (349)

1050 (476)

96 (2438)

15

1503322

225 (102)

525 (238)

825 (374)

1125 (510)

102 (2591)

16

1503323

240 (109)

560 (254)

880 (399)

1200 (544)

108 (2743)

17

1503324

255 (116)

595 (270)

935 (424)

1275 (578)

114 (3048)

18

1503325

270 (122)

630 (271)

990 (449)

1350 (612)

120 (3048)

19

1503326

285 (129)

665 (301)

1045 (474)

1425 (646)

126 (3200)

20

1503327

300 (136)

700 (317)

1100 (499)

1500 (680)

132 (3353)

21

1503328

315 (143)

735 (333)

1155 (524)

1575 (713)

138 (3505)

22

1503329

330 (149)

770 (349)

1210 (549)

1650 (748)

144 (3658)

23

1503330

345 (156)

805 (365)

1265 (574)

1725 (782)

144+ (3658+)

Consult Factory

/