Page is loading ...

48275-18

EC1000 PROCESS

pH/ORP SYSTEM

INSTRUCTION MANUAL

© Hach Company, 1994-1997. All rights are reserved. Printed in the U.S.A. al/dk 7/97 3ed

2

3

CERTIFICATION

Hach Company certifies this instrument was tested thoroughly, inspected, and found to

meet its published specifications when it was shipped from the factory.

The EC1000 Process pH/ORP System has been tested and is certified as indicated to the

following instrumentation standards:

Product Safety

Listed by ETL to UL Standard 3101-1 (Listing # H0492805390)

Certified by ETL to CSA Standard C22.2 No. 142 (ETLc Certification # H0492805390)

Certified by Hach Company to EN 61010-1 (IEC1010-1), supporting test records by

Intertek Testing Services

Immunity

EN 50081-2 (European Generic Immunity Standard) per 89/336/EEC EMC: Supporting

test records Amador (TUV Product Services), certified compliance by Hach Company.

Required Standard/s include:

IEC 801-2 & IEC 1000-4-2 Electro-Static Discharge

IEC 801-3 Radiated RF Electro-Magnetic Fields*

IEC 801-4 Electrical Fast Transients/Burst

Emissions

Emissions per 89/336/EEC EMC: Supporting test records by Intertek Testing Services

(ETL), certified compliance by Hach Company.

Required Standard/s include:

EN 55011 (CISPR 11) Emissions, Class B Limits

CANADIAN INTERFERENCE-CAUSING EQUIPMENT REGULATION, IECS-003, Class A

Supporting test records by Intertek Testing Services (ETL), certified compliance by

Hach Company.

This Class A digital apparatus meets all requirements of the Canadian Interference-

Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le

matériel brouilleur du Canada.

FCC PART 15, Class "A" Limits:

Supporting test records by Intertek Testing Services (ETL), certified compliance by

Hach Company.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may

cause undesired operation.

* Electromagnetic Radiation of 3 Volts/meter or greater can cause instrument inaccuracy. For complete accuracy details in an

RF environment, refer to the Supplementary Compliance Information in this manual.

4

Changes or modifications to this unit not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide

reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in a residential

area is likely to cause harmful interference, in which case the user will be required to

correct the interference at his own expense.

Shielded cables must be used with this unit to ensure compliance with the Class A FCC

limits. Because this instrument operates on and generates radio frequency energy,

interference to radio and television reception may occur. If such interference does occur,

the operator should take the necessary steps to correct the interference. The following

techniques of reducing the interference problems are applied easily.

1. Disconnect power from the EC1000 Controller to verify that it is the source of

the interference.

2. If the EC1000 Controller is plugged into the same outlet as the device with which it is

interfering, try another outlet.

3. Move the EC1000 Controller away from the device receiving the interference.

4. Reposition the receiving antenna for the device receiving the interference.

5. Try combinations of the above.

CERTIFICATION, continued

5

TABLE OF CONTENTS

CERTIFICATION ..........................................................................................................................................................3

SPECIFICATIONS ........................................................................................................................................................9

SAFETY PRECAUTIONS ..........................................................................................................................................13

OPERATION ..............................................................................................................................................................15

SECTION 1 GENERAL INFORMATION ...........................................................................................................17

1.1 Instrument Description ...........................................................................................................................................17

1.2 EC1000 pH/ORP Controller ...................................................................................................................................17

1.3 Electrolyte Pump ....................................................................................................................................................17

1.4 Hach One Process pH Electrode ............................................................................................................................ 21

1.4.1 Sodium Error .............................................................................................................................................. 21

1.5 Hach One ORP Electrode ....................................................................................................................................... 21

1.6 Industrial Process pH Electrode .............................................................................................................................22

1.7 Sample Handling System .......................................................................................................................................22

1.7.1 Submersible ................................................................................................................................................ 22

1.7.2 Flow-Thru Cell ........................................................................................................................................... 22

1.7.3 In-Line ........................................................................................................................................................22

1.8 Principle of Operation ............................................................................................................................................23

SECTION 2 OPERATION ......................................................................................................................................25

2.1 Operating the User-Programmable Setup ............................................................................................................... 25

2.1.1 Moving Around the Menu ..........................................................................................................................25

2.1.2 Editing a Setup Value .................................................................................................................................25

2.1.3 Restoring Default Settings .......................................................................................................................... 27

2.2 Setup Menu .............................................................................................................................................................28

2.2.1 Alarms ........................................................................................................................................................28

2.2.2 Recorder Output .........................................................................................................................................29

2.2.3 PID Output .................................................................................................................................................. 30

2.2.4 Recorder 2 ................................................................................................................................................... 33

2.2.5 Initial Setup .................................................................................................................................................33

2.2.5.1 Temperature Compensation Setup ............................................................................................... 33

2.2.6 Keylock ....................................................................................................................................................... 35

2.2.7 Reference Solution Timer ...........................................................................................................................36

2.2.8 Warnings ..................................................................................................................................................... 36

2.3 Calibration ..............................................................................................................................................................37

2.3.1 pH Calibration ............................................................................................................................................ 38

2.3.1.1 Two-Point Calibration with Auto Recognition of Hach Buffers ................................................. 39

2.3.1.2 One-Point Grab Sample Calibration ............................................................................................ 40

2.3.1.3 Calibration Procedure Variations ................................................................................................. 40

2.3.1.4 One Point Calibration with a Buffer ............................................................................................ 41

2.3.1.5 Calibration Review .......................................................................................................................41

2.3.2 Temperature Calibration .............................................................................................................................41

2.3.3 ORP Calibration/mV Zero ..........................................................................................................................42

2.3.3.1 Preamp Zero .................................................................................................................................42

2.3.3.2 ORP Electrode Check ..................................................................................................................43

2.3.3.3 mV Offset .....................................................................................................................................43

6

SECTION 3 SERIAL INTERFACE .......................................................................................................................45

3.1 Optional Serial Interface Board ..............................................................................................................................45

3.2 Data Communications Format/Setup ......................................................................................................................45

3.3 Print Format ............................................................................................................................................................45

3.4 Remote Input Commands .......................................................................................................................................46

SECTION 4 PID CONTROL ..................................................................................................................................49

4.1 pH Controller Basics ...............................................................................................................................................49

4.2 Instrument Settings .................................................................................................................................................49

4.2.1 Set Point ......................................................................................................................................................49

4.2.2 Dead Band ...................................................................................................................................................49

4.2.3 Preset ...........................................................................................................................................................49

4.3 Gain .........................................................................................................................................................................49

4.3.1 Reset (Integral) ............................................................................................................................................52

4.3.2 Rate (Derivative) .........................................................................................................................................52

4.3.3 Curve ...........................................................................................................................................................52

INSTALLATION/MAINTENANCE .....................................................................................................................55

SECTION 5 INSTALLATION ...............................................................................................................................57

5.1 Unpacking the Instrument .......................................................................................................................................57

5.2 Industrial Process pH Electrode Preparation ..........................................................................................................57

5.3 Mounting the Controller .........................................................................................................................................57

5.3.1 Panel Mounting ...........................................................................................................................................57

5.3.2 Wall Mounting ............................................................................................................................................59

5.3.3 Pole Mounting .............................................................................................................................................59

5.4 Mounting the Pump .................................................................................................................................................59

5.5 Installing the pH/ORP Electrode ............................................................................................................................60

5.5.1 In-Line Electrode Installation .....................................................................................................................62

5.5.2 Submersible Sensor Installation ..................................................................................................................62

5.5.3 Flow-Thru Cell Installation .........................................................................................................................62

5.6 Wiring the Meter .....................................................................................................................................................63

5.6.1 Wire Preparation .........................................................................................................................................64

5.6.2 Power ...........................................................................................................................................................65

5.6.2.1 Line Voltage Selection for Meter .................................................................................................66

5.6.3 Alarms .........................................................................................................................................................66

5.6.4 Recorder and Controller ..............................................................................................................................66

5.6.5 Electrode Wiring .........................................................................................................................................67

5.6.6 Electrode Output Connections ....................................................................................................................67

5.7 Pump Wiring ...........................................................................................................................................................68

5.7.1 Line Voltage Selection for Electrolyte Pump .............................................................................................69

SECTION 6 BASIC START-UP ..............................................................................................................................71

6.1 Introduction .............................................................................................................................................................71

6.2.1 Assembling the Electrolyte Line .................................................................................................................71

6.2.2 Connection to the Pump Module .................................................................................................................71

6.2.3 Connection to the pH Electrode ..................................................................................................................71

6.3 Purging the System .................................................................................................................................................72

6.4 Calibration ...............................................................................................................................................................73

SECTION 7 SERIAL INTERFACE .......................................................................................................................75

7.1 Installation ...............................................................................................................................................................75

7.2 RS-232C Interface Configuration ...........................................................................................................................77

7.3 Current Loop Configuration ...................................................................................................................................77

TABLE OF CONTENTS, continued

7

SECTION 8 ELECTRODE AND PUMP MAINTENANCE ............................................................................... 81

8.1 Electrode Maintenance ...........................................................................................................................................81

8.1.1 General Electrode Maintenance .................................................................................................................. 81

8.1.2 Removing Existing Electrode .....................................................................................................................81

8.1.3 Sensor Replacement ................................................................................................................................... 81

8.1.4 Replacing Electrolyte ................................................................................................................................. 82

8.1.5 Crystal Formation in Reference Tube ........................................................................................................84

8.1.6 Purging the System .....................................................................................................................................84

8.1.7 Storage and Conditioning ........................................................................................................................... 84

8.1.7.1 pH Electrode Storage and Conditioning ...................................................................................... 84

8.1.7.2 ORP Electrode Storage and Conditioning .................................................................................... 84

8.1.7.3 Industrial pH Electrode Shelf Life and Storage ........................................................................... 86

8.1.8 pH Electrode Cleaning ................................................................................................................................86

8.1.9 ORP Electrode Cleaning .............................................................................................................................87

8.1.10 Industrial pH Electrode Cleaning ............................................................................................................... 87

8.2 Pump Maintenance .................................................................................................................................................87

8.2.1 Changing Pump Tubing ..............................................................................................................................87

8.3 Fuse Replacement ................................................................................................................................................... 88

8.3.1 Meter Fuse Replacement ............................................................................................................................88

8.3.2 Pump Fuse Replacement ............................................................................................................................ 90

8.4 Pump Motor Replacement ......................................................................................................................................90

SECTION 9 TROUBLESHOOTING .....................................................................................................................91

9.1 Troubleshooting the EC1000 Controller ................................................................................................................91

9.1.1 Test Diagnostic Menu .................................................................................................................................91

9.1.2 Error Codes .................................................................................................................................................94

9.1.3 System Warnings ........................................................................................................................................95

9.2 Troubleshooting the pH Electrode ......................................................................................................................... 96

9.3 Troubleshooting the ORP Electrode ...............................................................................................................98

SECTION 10 SCHEMATICS ................................................................................................................................. 103

GENERAL INFORMATION ...............................................................................................................................107

REPLACEMENT PARTS .........................................................................................................................................109

HOW TO ORDER ......................................................................................................................................................113

REPAIR SERVICE ....................................................................................................................................................114

APPENDIX A Process pH Electrode Without Internal Preamp ........................................................................... 115

APPENDIX B Supplemental Compliance Information ......................................................................................... 117

INDEX ......................................................................................................................................................................... 119

TABLE OF CONTENTS, continued

8

9

SPECIFICATIONS

(Specifications subject to change without notice.)

CONTROLLER SPECIFICATIONS

Ranges: pH: -2 to 16 pH; mV: -2000 to +2000 mV; Temperature: -5 to +105 °C

Accuracy*: pH: ±0.02 pH; mV: ±1.0% of reading, ±35 mV non-calibrated;

Temperature: ±1.5 °C before calibration with electrode, ±0.4 °C after calibration with

electrode.

Resolution: pH: 0.01 pH; mV: 0.1 mV; Temperature: 0.1 °C

Repeatability: pH: ±0.02 pH; mV: ±0.1 mV; Temperature: ±0.2 °C

Temperature Calibration: 1 or 2 point with zero and slope adjustments

Temperature Compensation: -5 to +105 °C for Nearnst equation (auto/manual);

0 to 60 °C for auto buffer recognition

Solution Temperature Correction: Corrected to 25 °C, 0.1 to -0.1 pH units/°C slope

Operating Temperature: -10 to 60 °C

Storage Temperature: -40 to 60 °C

Humidity Range: 5 to 90% RH non-condensing

Relative mV Adjustment: The mV zero may be offset to any point in the ±2000 range

Alarms: Alarms 1 and 2: Usable in any of operating modes, (pH/mV/Temperature).

Programmable for either low or high set point alarm. Alarm relays SPDT with contacts

rated at 5A resistive load at 30 Vrms (42.4 Vpk).

Recorder Output: Isolated 4-20 mA (adjustable to 0-20 mA at 900 ohms)

Controller Output: Proportional, Integral, Derivative. Additional resistors can be used to

provide 0 to 10 V, 0 to 1 V, or 0 to 100 mV outputs.

Input/Output (optional): RS-232C and 20 mA current loop

Signal Average: 0 to 10 seconds

Reading Update: Every 0.4 seconds

Power Requirements: 115/230 Vac (±17%), 50/60 Hz, 8 watts

Controller Enclosure: NEMA 4X/IP66 (rear connections). Suitable for 1/2-inch conduit.

Wall, panel or pole mounted. For indoor use.

Controller Dimensions: 14.4 cm x 14.4 cm x 12.5 cm deep (5.67" x 5.67" x 4.9" deep).

Panel cutout size: 14 cm x 14 cm (5.5" x 5.5")

* Intermittent Electromagnetic Radiation of 3 Volts per meter or greater may cause measurement inaccuracy. For complete

accuracy details in an RF environment, see the Supplemental Compliance Information in this manual.

10

Hach One

®

PROCESS pH SPECIFICATIONS

pH Range: 0 to 14 pH

Accuracy*: pH: ±0.02 pH; Temperature: ±1.5 °C before calibration, ±0.4 °C after

calibration

Repeatability: pH: ±0.02 pH (calibrated at 25 °C and measured at 25 °C);

Temperature: ±0.2 °C

Temperature Range: 0 to 60 °C

Pressure Range: 0 to 35 psi (241 kPa)

Slope: 58 mV± 2 mV/pH units at 28 °C

Reference Element: Ag/AgCl double junction

Electrode Diameter: 28.6 mm (1.125") at tip

Electrode Length: 20.3 cm (8")

Reference Tubing Length: 6.1 m (20 feet) optional 50 feet

Cable Length: 6.1 m (20 feet). Expandable to 1000 feet

Submersion Application: Operational to a depth of 40 feet

Electrical Output: Two 4-20 mA current loops, directly proportional to mV and

temperature

Electrode Housing: Kynar (lower body)/Noryl (polyphenylene oxide) (upper body)

Hach One ORP ELECTRODE SPECIFICATIONS

mV Range: -2000 to 2000 mV

Temperature Range: 0 to 60 °C

Pressure Range: 0 to 35 psi (241 kPa)

Accuracy*: mV: ±10 mV; Temperature: ±1.5 °C before calibration, ±0.4 °C after

calibration

Repeatability: mV: ±2 mV; Temperature: ±0.2 °C

Sensing Element: Platinum disc (99.998% pure)

Reference Element: Ag/AgCl double junction

Reference Potential: 32 ±5 mV vs. SCE

Electrode Diameter: 28.6 mm (1.125") at tip

Electrode Length: 20.3 cm (8")

Reference Tubing Length: 6.1 m (20 feet) optional 50 feet

Cable Length: 6.1 m (20 feet). Expandable to 1000 feet

Submersion Application: Operational to a depth of 40 feet

Electrical Output: Two 4-20 mA current loops, directly proportional to mV and

Temperature

Electrode Housing: Kynar (lower body)/Noryl (polyphenylene oxide) (upper body)

* Calibrated at 25 °C and measured at 25 °C and at atmospheric pressure.

SPECIFICATIONS, continued

11

INDUSTRIAL PROCESS pH ELECTRODE SPECIFICATIONS

pH Range: 0 to 12 pH

Reproducibility: ±2% of reading

Temperature and Pressure Range: 0 to 80 °C at 0 to 100 psig; 0 to 100 °C at

ambient pressure

Slope: (pH 4 to pH 7) @ 25 °C: >170 mV

Reference Element: Ag/AgCl

Electrode Diameter: 28.2 mm (1.11") at tip

Electrode Length: 175 mm (6.9")

Electrode Housing: CPVC

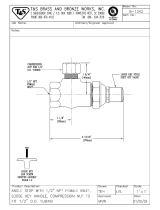

PUMP MODULE SPECIFICATIONS

Pressure Range: 0 to 35 psi (241 kPa)

Operating Temperature Range: -20 to 60 °C

Humidity Range: 5 to 90% RH non-condensing

Reagent Usage: Reference solution capacity for a minimum of 1 month of operation

Power Requirements: 115/230 Vac (±17%), 50/60 Hz, 9 VA, 8 watts

Enclosure: NEMA 4X/IP66—Wall mounting, with 1/2-inch NPT for conduit

connections. For indoor use.

MOUNTING KIT SPECIFICATIONS

SUBMERSION APPLICATION

Maximum Submersion Depth: 40 feet (due to restrictions on reference tubing length)

Maximum Velocity at Electrode Tip: 15 km/hour

IN-LINE APPLICATION

Maximum Pressure: 35 psi (241 kPa)

Maximum Flow Rate: 40 L/minute

Minimum Flow Rate: 10 mL/minute

FLOW-THRU CELL APPLICATION

Maximum Flow Rate: 750 mL/minute

Minimum Flow Rate: 1 mL/minute

SPECIFICATIONS, continued

12

13

SAFETY PRECAUTIONS

Before attempting to unpack, set up, or operate this instrument, please read this entire

manual. Pay particular attention to all warnings, cautions and notes. Failure to do so could

result in serious injury to the operator or damage to the equipment.

To ensure the protection provided by this equipment is not impaired, this equipment

MUST NOT be installed or used in any manner other than that which is specified in

this manual.

Use of Hazard Information

If multiple hazards exist, the signal word corresponding to the greatest hazard shall

be used.

DANGER

Indicates a potentially or imminently hazardous situation which, if not avoided, could result in

death or serious injury

CAUTION

Indicates a potentially hazardous situation that may result in minor or moderate injury

NOTE

Information that requires special emphasis

Precautionary Labels

Please pay particular attention to labels and tags attached to the instrument. Personal

injury or damage to the instrument could occur if not observed.

This symbol, if noted on the instrument, references the instruction manual for

operational and/or safety information.

Section 5.4 Installing the pH/ORP Electrode

Section 5.5 Wiring Meter

Section 5.5.2 Power

Section 5.6 Wiring Pump

Section 7.1 Installation

Section 8.1.7 pH Electrode Cleaning

Section 8.1.8 ORP Electrode Cleaning

Section 8.1.9 Industrial pH Electrode Cleaning

14

WARNING

Handling chemical samples, standards, and reagents can be dangerous. Review the necessary

Material Safety Data Sheets and become familiar with all safety procedures before handling

any chemicals.

ADVERTENCIA

La manipulación de muestras químicas, patrones y reactivos puede ser peligrosa. Antes de

manipular cualquier productor químico, conviene leer las Fichas Técnicas de Seguridad y

familiarizarse con los procedimientos de sugeridad.

ADVERTÊNCIA

A manipulação de amostras, padrões e reagentes químicos pode ser perigosa. Reveja as necessárias

Fichas Técnicas de Segurança do Material e familiarizese com os procedimentos de segurança

antes de manipular quaisquer substãncias químicas.

ATTENTION

La manipulation des échantillons chimiques, étalons et réactifs peut être dangereuse. Lire les fiches

de données de sécurité des produits nécessaires et se familiariser avec toutes les procédures de

sécurité avant de manipuler tout produit chimique.

WARNHINWEIS

Da das Arbeiten mit chemikalischen Proben, Standards, Reagenzien und Abfällen mit Gefahren

verbunden ist, empfiehlt die Hach Company dem Benutzer dieser Produkte dringend, sich vor der

Arbeit mit sicheren Verfahrensweisen und dem richtigen Gebrauch der Chemikalien oder

Biogefahrgut vertraut zu machen und alle entsprechenden Materialsicherheitsdatenblätter

aufmerksam zu lesen.

15

OPERATION

16

17

SECTION 1 GENERAL INFORMATION

1.1 Instrument Description

The EC1000 Process pH/ORP Monitoring System consists of the Series EC1000

Controller, a Hach One Pump Module, and a Hach One Process pH or ORP Electrode

assembly. The system monitors a sample stream for its pH value within the range of 0 to

14, or its millivolt potential from -2000 to +2000 mV, and its temperature ranging from

0 to 60 °C. The system also indicates when preset high and low alarm limits are exceeded,

provides relay closures for external devices, and provides output currents to drive a

recorder and remote process control equipment. Each of these items are described in

detail in the following sections.

1.2 EC1000 pH/ORP Controller

The controller is menu driven with PID capability and is housed in a NEMA 4X/IP66

enclosure (see Figure 1 on page 18). It is set up to receive two current loop inputs from a

pH or ORP probe preamplifier, and to provide a continuous readout of the sample pH or

millivolt value as well as the sample temperature. Output capabilities of the controller

include two 4-20 mA outputs for recording and controlling pumps and optional RS-232C

and 20 mA current loop serial port. Alarm features include user programmable Alarm 1

and Alarm 2 setpoint selections for any one of the operating modes (pH, millivolt, or

temperature) with SPDT relay contacts. The alarm can be a combination of

operating modes:

(Example 1)

Alarm 1-pH High Alarm

Alarm 2-Temperature High Alarm

(Example 2)

Alarm 1-pH Low Alarm

Alarm 2-Temperature Low Alarm

The EC1000 Controller can be mounted up to 1000 feet from the electrode. The pump

module can be mounted up to 50 feet from the electrode.

1.3 Electrolyte Pump

Note: The electrolyte

pump is not used with the

self-pressurized Industrial

Process pH Electrode with

self-pressurized

electrolyte, Cat. No.

48276-00. See Section 1.6

Industrial Process pH

Electrode.

The pump used on this system is a low pressure linear peristaltic pump, which operates up

to 35 psi. The pump is housed in a NEMA 4X enclosure, and allows for a maximum of

50 feet separation from the electrode. It continuously pumps electrolyte through a free-

flowing junction in the electrode (500 mL of electrolyte [Cat. No. 24291-49]) lasts

approximately 30 days). The pump module contains a refillable electrolyte reservoir (see

Figure 2 on page 20).

18

Figure 1 Controller Front Panel

19

Table 1 Controller Front Panel

Item Name Function

1 LED Display Main display field. Consists of eight 14-segment alpha-numeric 0.54″ high red LED characters.

During normal operation, this field displays either the pH or mV value (depending on the mode of

operation selected). This field also displays menu messages, edit menu values, and error messages.

See

Figure 1

.

2 Secondary

Display Field

The secondary display field consists of three 7-segment numeric 0.3″ high green LED digits.

During normal operation, this field displays temperature. In the setup menu, this field displays

abbreviations to help indicate which branch of the setup menu the operator is in. See

Figure 1.

3 SETUP key This key enters the setup menu. The setup is entered when it is pressed.

4 pH/mV key During normal operation (instrument displaying pH/mV), this key toggles the reading between

pH and mV. If the instrument is in any of the menus, pressing this key returns the instrument to

normal operation.

5 ENTER key This key, within the menus, either moves a level deeper into the menus, or accepts an edited selection.

6 CLEAR key This key, within the menus, either clears changes in an edit portion of a menu, or backs up one menu

level. If this instrument is in an edit portion of a menu selection, and the value is changed, then this key

restores the original value. Otherwise, this key causes the menu selection to back up one level; if the

menu is at the top level, this key returns the instrument to normal operation (instrument

displaying pH/mV).

7 RIGHT

ARROW key

This key, in an edit portion of a menu selection, selects the next digit to the right to edit. The selected

digit flashes. When the instrument is in one of the non-editing portions of the calibration/setup menus,

or in normal operation (instrument displaying pH/mV), this key is not valid; if pressed, an INVALID

message flashes on the main display.

8 HOLD/DOWN

ARROW key

During normal operation (instrument displaying pH/mV), this key functions as a hold. When pressed,

the outputs (alarm relays, recorder, and controller outputs) alternately hold at the current value, or

release to normal operation. When the outputs are held, the first character in the main display

flashes an H. (

Note: The H appears only during normal operation; in the menus, the H does not

appear.

) After the outputs are in the hold state for 30 minutes, they automatically release. When

the instrument is in one of the calibration/setup menus, this key scrolls down through the menu

selections. When the instrument is in an edit portion of a menu selection, this key decreases the

selected (flashing) digit.

9 ALARM ACK/

UP ARROW

key

During normal operation (instrument displaying pH/mV), this key functions as an alarm acknowledge.

When pressed, the alarms are alternately disabled or enabled. When the alarms are disabled, the

three alarm indicators flash, and the alarm relays are in the non-alarm state. After the alarms are

disabled for 30 minutes, they automatically enable. When the instrument is in one of the

calibration/setup menus, this key scrolls up through the menu selections. When the instrument is in an

edit portion of a menu selection, this key increases the selected (flashing) digit.

10 CAL key This key enters the calibration menu. From this menu, the pH electrode, temperature probe, and mV

offset can be calibrated, and the calibration reviewed.

11 System warning Red LED. Indicates a probe failure or controller malfunction. Refer to Table 4 on page 42 for specific

system warnings that appear on the main LED display. For most system warnings, the user must query

the system to determine the warning. See

Figure 1

.

12 Alarm 2 Red LED. User programmable setpoint alarm. See

Figure 1.

13 Alarm 1 Red LED. User programmable setpoint alarm. See

Figure 1.

20

Figure 2 Pump Module

/