6 / 10

5. Remove the retainer plate (pos. 4) with the pistons (pos. 22).

6. BMP 0,3: Remove the spring guide (pos. 26) and spring (pos. 7)

BMP 0,6 - 2,1: Remove the retainer guide (pos. 5), spring guide (pos. 26) and spring (pos. 7).

7. Remove the pin (pos. 3) and O-ring (pos. 13).

8. Lift the cylinder barrel (pos. 8) with valve plate (pos. 9) out of the port flange (pos. 14).

9. Remove the port plate (pos. 10) and the pins (pos. 11 and 12).

10.Place the cylinder barrel (pos. 8) with valve plate (pos. 9) on the table and twist them apart with a screwdriver.

11.Remove the backup and O-rings (pos. 20 and 21) of the valve plate (pos. 9).

4.3 Assembly

4.3.1 Checking

Check all wear parts before assembling the pump, see 4.4 Checking the wear parts.

4.3.2 Fitting the pistons and valve plate

1. Fit the O-ring (pos. 13) and the pins (pos. 3, 11 and 12) on the port flange (pos. 14).

2. Fit the port plate (pos. 10).

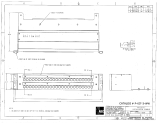

3. Fit the backup rings (pos. 20) and O-rings (pos. 21) on the valve plate (pos.9); one pair per piston. Moisten

them with soapy water, see fig. 4.

4. Fit the valve plate (pos. 9) on the cylinder barrel (pos. 8). Press the parts together using your hands, see

fig. 5. There must be a gap of 1.5 to 2.5 mm.

5. Put the cylinder barrel with valve plate together with the port part.

6. BMP 0,3: Fit the spring guide (pos. 26) and spring (pos. 7)

BMP 0,6 - 2,1: Fit the spring guide (pos. 26), spring (pos. 7) and retainer guide (pos. 5).

7. Fit the retainer plate (pos. 4) with the chamfered end against the barrel, and insert the pistons (pos. 22).

8. Fit the pump housing (pos. 1). Note the position of the pin (pos. 3).

9. Turn the pump and press it together using your hand.

10.Lubricate the screws (pos. 18) with Gardolube and tighten them with 22 ± 1 [Nm].

4.3.3 Fitting the shaft seal

1. Place the guide/lid (pos. 16) on the table with the turned down end upwards.

2. Fit the stationary shaft seal part (pos. 15) with the rubber gasket downwards using the punch (B

).

3. Fit the O-ring (pos. 34) on the guide/lid (pos. 16) and lubricate it with Rocol 22.

4. Fit the thread bush (A

) on the shaft and moisten it with soapy water.

5. Fit the rotating shaft seal part (pos. 15) with the seal face upwards using the punch (B

).

6. Fit the guide/lid (pos. 16) on the pump.

7. Lubricate the screws (pos. 17) with Gardolube and tighten them with 7 ± 1 [Nm].

8. Check that the shaft can be pressed 0.5 to 1 mm with your hand.

4.3.4 Fitting the coupling

1. Fit the coupling half.

2. Tighten the set screw.

3. Fit the coupling insert on the coupling half.

4. Fit the coupling guard and screws.

5. Mount the pump on the motor.

6. Tighten the pump to the motor with the screws and washers.

Fig. 4 Backup rings and O-rings

Fig. 5 Fitting the valve plate