Page is loading ...

Operator‘s manual

Translation of the original Operating Manual

Nr. 99+9831.EN.80R.1

Plough

SERVO 45 S

(Type 9831: Chassis-Nr: + . .02067 / MaschNr: + . .03067)

SERVO 45 S PLUS

(Type 9831: Chassis-Nr: + . .02067 / MaschNr: + . .03067)

SERVO 45 S NOVA

(Type 9841: Chassis-Nr: + . .01394 / MaschNr: + . .02394)

SERVO 45 S NOVA PLUS

(Type 9841: Chassis-Nr: + . .01394 / MaschNr: + . .02394)

1500_GB-PAGE 2

Product liability, information obligation

Product liability obliges manufacturers and dealers to issue operating instructions for the machine at the point of sale and to instruct

the customer on the operation, safety and maintenance regulations governing the machine.

A confirmation is required to verify that the machine and operating instructions have been handed over correctly.

For this purpose

- Document A is to be signed and returned to Pöttinger or via the internet to www.poettinger.at

- Document B remains with the specialist dealer handing over the machine.

- The customer receives document C.

For the purposes of product liability law, every farmer is an entrepreneur.

In the terms of product liability law, damage to property is any damage arising due to the machine, but not to the machine, and an

excess (500 euros) exists for this liability.

Corporate damage to property within the terms of the product liability law is excluded from this liability.

Be advised! The operating instructions must also be handed over with any subsequent machine sale or transfer and the transferee

must be instructed in the regulations stated.

Pöttinger - Trust creates AfÀ nity - since 1871

"Quality pays for itself." Therefore we apply the highest quality standards to our products which are constantly monitored by our

in-house quality management and our management board. Because the safety, perfect function, highest quality and absolute

reliability of our machines in operation are the core competencies for which we stand.

There may be deviations between these instructions and the product as we are constantly developing our products. Therefore no

claims may be derived from the data, illustrations and descriptions. Please contact your Specialist Service Centre for any binding

information about specific features of your machine.

We would ask you to please understand that changes to the scope of supply with regard to form, equipment and technical

specifications are possible at any time.

Any form of reprint, translation or reproduction, including excerpts, requires the written approval of Pöttinger Landtechnik GmbH.

All rights according to copyright laws remain expressly reserved by Pöttinger Landtechnik GmbH.

© Pöttinger Landtechnik GmbH – 31st October 2012

Refer to PÖTPRO for additional information about your machine:

Are you looking for suitable accessories for your machine? No problem! All the information you require is here at your disposal.

Scan the QR code on the machine's type plate or look under www.poettinger.at/poetpro

And if we don't have what your looking for, then your Specialist Service Centre is there for you with help and advice.

Dokument D

GB-0600 Dokum D Servo - 3 -

PÖTTINGER Landtechnik GmbH

Industriegelände 1

A-4710 Grieskirchen

Tel. 07248 / 600 -0

Telefax 07248 / 600-2511

❑ Check SERVO Turnover Plough as per the delivery docket. Check that delivery is complete.

All safety equipment and operating devices at hand.

❑ Using the operating manual explain and go over the operation, initial start and maintenance of the machine or

implement with the customer.

❑ Fitting to the tractor has been carried out.

❑ Check that hydraulic connections to the tractor have been made and that they are correct.

❑ Hydraulic functions (turnover, cutting width adjustment) have been demonstrated and explained.

❑ Plough is set correctly to the tractor (cutting width of 1st component, drawing point).

❑ Transport and working positions have been explained.

❑ Information about optional and additional equipment has been given.

❑ It has been pointed out that to read the operating manual is imperative.

Cross where applicable. X

In accordance with Product Liability obligations, we would ask you to please check the following points.

EN

INSTRUCTIONS FOR

PRODUCT DELIVERY

In order to prove that the machine and the operating manual have been properly delivered, a confirmation is necessary.

For this purpose please do the following:

- sign the document A and send it to the company Pöttinger or via the internet to www.poettinger.at

-document B stays with the specialist factory delivering the machine.

document C stays with the customer.

- 4 -

1701_GB-INHALT_9831

CONTENTS GB

Table of contents

WARNING SIGNS

CE mark ..................................................................... 5

Meaning of warning signs .......................................... 5

ATTACHING TO TRACTOR

Preparing the tractor .................................................. 6

Hydraulic control on the lifting gear ........................... 6

Hydraulic connection ................................................. 7

Preparations on the plough ........................................ 7

Hitching to tractor ....................................................... 8

Attach the lighting unit ............................................... 8

Unhitching from tractor .............................................. 9

PLOUGH PRESET

Before driving to the field ........................................... 9

OPERATION

Caution when entering the field ................................11

Rotating the plough ...................................................11

Setting the plough inclination (11) .............................11

Setting the plough on a tractor with "Servomatic" .... 12

Ploughing with adjusting hydraulics ......................... 13

Hydraulic cutting width adjustment (SERVO

PLUS) ...................................................................... 13

OVERLOAD SAFETY

Shear bolts ................................................................14

SERVO NOVA

Fully automatic "Non-stop" overload safety ............. 15

Setting range ........................................................... 15

Gas tank (43): .......................................................... 16

Changing the pressure in the gas tank .................... 16

Advice for general maintenance ...............................17

Cleaning of machine parts ........................................17

Hydraulic unit ...........................................................17

MAINTENANCE

Setting the ploughing component tilt ........................ 18

Basic setting of the ploughing component ............... 18

SERVO 45 S Plus Nova ........................................... 19

ADDITIONAL DEVICES

Setting the disk coulter (* ......................................... 20

Spring loaded disk coulter (* .................................... 20

Pre-ploughing implements: ...................................... 21

Jockey wheels.......................................................... 22

Transport-Feeler wheel ............................................ 23

Changing to working position ................................... 23

Changing to transport position ................................. 23

Forward transport land wheel .................................. 24

Use as jockey wheel ................................................ 24

Use as transport wheel ............................................ 24

Switching into transport position .............................. 24

Switching to working position ................................... 26

Extension arm with hydraulic releasing device for

packer and trailing implements ................................ 27

Working with a trailing implement ............................ 28

TRACTION CONTROL

Traction control - mode of operation ........................ 30

Operating setting ..................................................... 30

Transport and parking setting .................................. 30

Maintenance ............................................................ 30

TECHNICAL DATA

Designated use of the plough .................................. 31

Technical data .......................................................... 31

Type plate position ................................................... 31

Optional Equipment ................................................. 33

Coulter shapes ......................................................... 35

Jockey wheels.......................................................... 35

Additional parts ........................................................ 36

Optional equipment: ................................................. 36

Plough body ............................................................. 38

VARIANTS

Type SERVO ............................................................ 40

Type SERVO NOVA ................................................. 40

Type SERVO PLUS ................................................. 40

Type SERVO NOVA PLUS ...................................... 40

SUPPLEMENT

Combination of tractor and mounted implement ...... 45

- 5 -

1600_GB-WARNING SIGNS_9831

GB

WARNING SIGNS

CE mark

The CE symbol, which is affixed by the manufacturer on

the outside of the machine, indicates that this machine

conforms to the engineering guideline regulations and the

other relevant EU guidelines.

EU Declaration of Conformity (see Attachment)

By signing the EU Declaration of Conformity, the

manufacturer declares that the machine being brought

into service complies with all relevant safety and health

requirements.

Meaning of warning signs

Do not stand in the machine's swivel range.

Never reach into the crushing danger area as long as

parts may move.

Caution! Tank under pressure. Consult the relevant

manual before undertaking detaching, repair or other

manipulations.

- 6 -

1600_GB-ATTACHING_9831

GB

ATTACHING TO TRACTOR

Preparing the tractor

Wheels

- The air pressure in the tractor rear tires must be 0.8 bar

during ploughing.

- Under heavy working conditions additional wheel weights

can be advantageous. See the tractor manufacturer's

operating manual also.

Ballast weights

• The tractor must be loaded with

sufficient ballast weight to the front, so

as to guarantee the steering and braking

capacity.

• At least 20% of the vehicle weight on

the front axle.

20%

Kg

Lifting gear

- The left and right lifting struts (4) must be the same

length.

Adjust using adjuster (3).

- If lifting struts (4) can be pinned at various positions

on the lower links, then select the back position (H). In

doing this, the tractor’s hydraulics will not be so greatly

overloaded.

- Pin (2) upper link (1) in accordance with the

manufacturer’s specifications.

Beware!

Please observe the

capacity limits

of the traction

machine used.

Setting-up for transportation

- Secure lower links with struts (5) so that attached

implement cannot swing out during transportation.

- The operating lever for the hydraulics must be secured

against lowering.

- Road transport not in position "ON-LAND"

Setting for ploughing

- Set the struts (5) so as to obtain a maximum side swing

range.

Hydraulic control on the lifting gear

Control position:

For mounting and dismounting the implement and for

transportation.

Position control is the normal setting for the lifting gear

hydraulics.

The mounted implement remains at the height (= position)

set by the servo-valve (ST).

Adjusting traction resistance, adjusting mixing:

Ploughing occurs with of one of the two operating modes.

See chapter „OPERATION“ for description.

- 7 -

1600_GB-ATTACHING_9831

ATTACHING TO TRACTOR GB

Hydraulic connection

• If the tractor has only a single-acting control valve, it is

obligatory to have an oil return line (T) installed by your

specialised workshop.

- Connect pressure line (1) and oil return pipe (2).

1 single-acting control device

or

1 double-acting control device

+ 1 double-acting control device

Preparations on the plough

Mounting axle (965 mm / 825 mm)

• Use the right mounting axle

- see also the list of exchange parts.

Safety information

For ploughs with six blades you must

use the reinforced mounting axle (10),

otherwise there is danger of breakage.

• Perform adjusting on the tractor's lifting unit

- both turning plates can be mounted in 4 different

positions (P1, P2, P3, P4)

Upper link pin

Take out the upper link pin (6) as in the figure

- secure with linch pin (K).

- 8 -

1600_GB-ATTACHING_9831

ATTACHING TO TRACTOR GB

Hitching to tractor

- Switch tractor’s hydraulics to control position.

- Attach implement to lower link and secure with linch

pin.

Note

The headstock can be brought in horizontal position by

rotating the tilt spindle (11).

Thus you facilitate the coupling on the lower link.

Then rotate back the tilt spindle (11). See chapter

„OPERATION“ also.

Position upper link (1)

- Take out the upper link (1) so that the connection point

(P1) on the plough is a little higher during operation

than the connection point (P2) on the tractor.

TD65/92/27

1

P1

P2

Adjusting of the

lower link

When the adjusting hy-

draulics of the tractor are

controlled via the lower

links, the upper link must

be unpinned from the

slotted hole (LL) of the

headstock.

Upper link adjustment

When the adjusting hydraulics of the tractor are controlled

via the upper link,both holes (RL) of the headstock must

be used.

- Couple hydraulic hoses on the tractor.

Safety

hints:

see Annex A1 pt.

8a-h

Support stand in use

1. Pin the support stand onto the bolt on the chassis.

2. Secure the support stand with the linch pin (2).

Support stand not in use:

1. Thread the support stand onto the console through the

slit

2. Secure the support stand with the linch pin (2).

896-15-084

2

Attach the lighting unit

For the transport on the public roads one must ensure

lighting according to the legal provisions. We can provide

the lighting unit as optional, easy to mount equipment.

- Insert the lighting unit in the corresponding support and

fasten with the clamp screw (KS2)

- Adjust the lighting width with the help of the clamp screw

(KS1) on the hitching device.

- Connect the lighting (ST) to the plough frame socket

- Perform functional control

ST

KS1

KS2

074-09-53

Note:

Before use, unscrew the lighting unit.

It could be damaged during ploughing

works.

Essentially, the regulator's provisions are to be complied

with.

- 9 -

1600_GB-ATTACHING_9831

ATTACHING TO TRACTOR GB

Unhitching from tractor

Hint: The share points are hardened so when set down

onto hard surface (stone, concrete, etc.), risk of breaking

exists. Therefore lower the share points onto a suitable

support (wooden board)!

- Rotate the plough frame in working position and park

the implement on stable, even ground.

- To reduce the pressure in the hydraulic lines, move the

control lever (ST) to and fro several times.

- Switch tractor’s hydraulics to control position.

- Uncouple the hydraulic hoses from the tractor.

- Swivel down the support stand and fix it with the pin.

- Take out the upper and the lower link from the implement.

Parking, cleaning and winter storage of the

implement

• Please observe the instructions in chapter

"MAINTENANCE AND REPAIR"!

- 9 -

1700-GB_VOREINSTELLUNGEN_9831

GB

PLOUGH PRESET

Before driving to the field

SERVO

SERVO NOVA

- see next page

SERVO PLUS

SERVO NOVA PLUS

1. Perform main setting according to Table B, for a

cutting width = 40 cm

2. Perform exact setting in operation.

Setting the two spindles (ZP, VF)

Pulling point (ZP)

Backfurrow (VF)

• The setting depends on the inner distance of the tractor

wheels (RA) and the set cutting width.

- More information about pulling point and backfurrow

in chapter "APPLICATION".

Table-B

for

SERVO 45 S PLUS

RA

(mm)

ZP

(mm)

VF

(mm)

1000 489 462

1100 472 454

1200 456 447

1300 438 441

1400 421 435

1500 403 429

RA

TD65/92/35

Table-B

for

SERVO 45 S NOVA PLUS

RA

(mm)

ZP

(mm)

VF

(mm)

1000 510 475

1100 497 466

1200 481 458

1300 464 451

1400 447 444

1500 430 438

TD126/98/07

VF

ZP

- 10 -

1700-GB_VOREINSTELLUNGEN_9831

PLOUGH PRESET GB

Before driving to the À eld

SERVO

1. Perform the main setting according to Table-A .

2. Perform exact setting in operation.

SERVO NOVA

1. Perform the main setting according to Table C .

2. Perform exact setting in operation.

Set cutting width.

- Loosen both hexagonal screws (SK).

- Take out the rear hexagonal screw.

- Swivel the fastening bracket until you reach the chosen cutting width

and the hexagonal screw goes into one of the holes (1, 2, 3, 4, 5).

- Retighten the hexagonal screws.

Setting the two spindles (ZP, VF)

Pulling point (ZP)

Backfurrow (VF)

• The setting depends on the inner distance of the tractor wheels (RA)

and the set cutting width (1, 2, 3, 4, 5) .

- More information about pulling point and backfurrow in chapter

"APPLICATION".

RA

TD65/92/35

Table-A

for

SERVO 45 S

1

300 mm

2

350 mm

3

400 mm

4

450 mm

5

500 mm

RA

[mm]

ZP

[mm]

VF

[mm]

ZP

[mm]

VF

[mm]

ZP

[mm]

VF

[mm]

ZP

[mm]

VF

[mm]

ZP

[mm]

VF

[mm]

1000 427 485 444 475 461 464 479 454 497 444

1100 416 480 432 469 450 458 467 447 485 437

1200 405 474 421 463 438 452 455 441 472 430

1300 394 468 410 458 427 447 443 435 461 424

1400 390 462 399 452 415 441 432 430 449 418

1500 --- --- 390 447 404 436 421 425 437 413

Table-C

for

SERVO 45 S NOVA

1

300 mm

2

350 mm

3

400 mm

4

450 mm

5

500 mm

RA

[mm]

ZP

[mm]

VF

[mm]

ZP

[mm]

VF

[mm]

ZP

[mm]

VF

[mm]

ZP

[mm]

VF

[mm]

ZP

[mm]

VF

[mm]

1000 451 498 469 488 487 478 505 470 --- ---

1100 439 492 457 481 475 471 493 462 510 453

1200 428 486 445 475 463 465 480 454 498 445

1300 417 480 434 469 451 459 468 448 486 437

1400 406 475 422 464 439 453 456 442 474 431

1500 395 469 441 458 428 447 445 436 462 425

TD 329-07-02

VF

ZP

1

3

4 5

SK

2

- 11 -

1600_GB-OPERATION_9831

GB

OPERATION

Caution when entering the field

Beware!

Danger of damage when entering the

field, if the plough is still in transport

position (horizontal position) and it is

lifted (distance A).

- if exposed to strong vibrations, the

spindle may be damaged

therefore

- enter the field with the transport wheel

or rotate the plough to working position

first

Rotating the plough

Beware!

During plough rotation, nobody is allowed

within the swing range.

Operate the rotating unit only from the

tractor seat.

For the rotating process, the plough must

be lifted fully.

The rotating unit is equipped with double-acting cylinder

and integrated automatic reversing gear.

The automatic reversing gear enables the whole turning

procedure to be carried out through only one single

switch position on the control unit (ST). (Necessary oil

quantity: 40 - 50 l/min)

TD 65/92/48

s

h

0

ST

Rotating process

The rotating process is performed in the same way with

the help of the single-acting or double-acting control

device.

For the single-acting control device you need a return

pipe on the tractor.

- Switch the control device (ST) to Lift (h).

(for the version with single-acting cylinder or memory

cylinder first you swivel in the frame), after turning you

swivel it back out. see chapter Variants.

The plough body is rotated with 180°.

- Switch the control device (ST) to Neutral (0).

After about 5 seconds, you can perform a new rotating

process.

Setting the plough inclination (11)

The plough should sit as vertical (90°) as possible to

the ground during ploughing. This position is obtained

by turning both spindles (11) as described below.

TD 65/92/25

90°

- Lift the plough 5 - 10 cm.

- Operate the control device (ST) briefly.

The plough frame rotates away from the stop spindle

(11).

- Set the inclination with the help of the spindle (11).

- Rotate the plough frame back to stop position.

- Continue ploughing and check whether the new setting

brings the plough bodies to approximately vertical

position (90°) to the ground.

- 12 -

1600_GB-OPERATION_9831

OPERATION GB

Setting the plough on a tractor with

"Servomatic"

The setting technology "SERVOMATIC" adjusts plough

and tractor optimally to one another.

The following setting controls should be carried out in order.

• Never place your hand within the area

where there is danger of crushing, as

long as there can be moving parts there.

• Do not stay in the swivel range of the

working implements.

1. Setting furrow width

- See chapter "PLOUGH PRESETTING"

2. Cutting width setting of the first plough body

(backfurrow)

The cutting width (S2) of the first plough body is set by

rotating the spindle (VF).

Cutting width (S1) too narrow

- Rotate spindle (VF) further.

Cutting width too wide

- Rotate spindle (VF) less.

Cutting width (S2) correct

- The spindle is set correctly.

See chapter "PLOUGH PRESETTING"

Hydraulic cutting width adjusting (SERVO

PLUS)

Therefore an additional double-action control unit is

necessary on the tractor.

3. Set the drawing point (Z)

Setting correct

The drawing line (ZL) runs through the mid-point (M)

of the tractor’s rear axle. No side pull occurring on the

tractor.

The plough is operating smoothly.

- Spindle (ZP) set correctly.

See chapter "PLOUGH PRESETTING"

Setting wrong

The drawing line does not run through the mid-point of

the tractor’s rear axle.

a.) When ploughing the tractor is pulled into the ploughed

area. This can only be compensated by steering in

the opposite direction.

- Rotate the spindle (ZP) further.

b.) When ploughing the tractor is pulled into the

unploughed area.

- Rotate the spindle (ZP) less.

- 13 -

1600_GB-OPERATION_9831

OPERATION GB

Ploughing with adjusting hydraulics

Observe the following so that the adjusting hydraulics

operate correctly.

- Pin the upper link (1) so that during operation the

connecting point on the plough (P1) is a little higher

than the connecting point (P2) on the tractor.

TD65/92/27

1

P1

P2

Pinning the upper link

LL, RL = pinning position for lower link adjusting.

RL = pinning position for upper link adjusting.

See chapter „ATTACHING TO THE TRACTOR“ also.

- During operation, the plough frame shall be placed

longitudinally, approximately in parallel to the field

surface.

- First, the working width is adjusted with the help of the

lifting device via the control valve (ST).

Changing ground resistance during ploughing,

depending on the model of the adjusting hydraulics,

is transmitted to the control valve via the upper link

(1) or the two lower links. The relevant impulse is then

converted causing the lifting gear to lift or lower.

One example: Upper link adjustment

The plough goes deeper into the ground.

Thus the pressure on the control valve becomes higher

through the upper link.

As a result, the control valve is switched on Lift until

the set working depth is reached again.

Note:

Also observe the operating instructions of the tractor

manufacturer.

Hydraulic cutting width adjustment

(SERVO PLUS)

The adjusting device is operated with the help of a

hydraulic cylinder. Therefore an additional double-action

control unit is necessary on the tractor.

You can also perform a stepless adjustment of the cutting

width during ploughing. The drawing line position is not

influenced by this (see "Setting the drawing point (Z)").

Advantages:

- Exact ploughing on the edges.

- Ploughing around obstacles (masts, trees etc.).

(943) 9200 GB SICHERUNG

GB

- 14 -

OVERLOAD SAFETY

Shear bolts

The ploughing components are fastened with shear bolts.

When overloaded the shear bolts break (30) and the ploughing component swings away and up.

- Remove the rest of the shear bolt.

- Loosen hexagonal bolt (31).

- Swing ploughing component back into the working position.

- Insert new shear screws and retighten both bolts.

Take note!

Only use genuine shear bolts (see spare parts list) with the corresponding dimension and quality. Under no circumstances

use bolts with greater or lesser strength.

- 15 -

1600_GB-NOVA_984

GB

SERVO NOVA

Fully automatic "Non-stop" overload

safety

For grounds that are difficult to plough, with stones or

other foreign bodies, it is recommended to use the fully

automatic overload safety.

With the SERVO-NOVA plough, every plough body

is secured individually against deteriorating by hydro-

mechanical means.

When driving over obstacle, the plough body can swing

to either side. There is no need to stop the tractor. The

plough body swings back to working position by itself.

In addition to the fully automatic "Non-stop" overload

safety, all plough bodies are protected by a shearbolt.

See chapter "OVERLOAD SAFETY“ for a description.

Setting range

• The triggering force of the overload safety can be

adjusted function of the various ground types.

Normal setting

- The pressure on the hydraulic cylinders (40) must be

approx. 10 bar higher than the nitrogen pressure in the

gas tank (43).

Nitrogen pressure in the gas tank (43) (factory

setting)

80 bar

Setting range for the pressure in the hydraulic

cylinders (40)

90 to 160 bar

If you see during practical operation that the overload

safety triggers too often, you can increase the pressure(*

in the hydraulic cylinders with the accompanying top-up

device (42) (see table).

Pres-

sure(*

Triggering

force

( bar ) ( kp )

90 1010

100 1125

110 1240

120 1350

130 1460

140 1575

150 1690

160 1800

Increasing pressure in the hydraulic cylinders:

- Stopcock in position A.

- Unscrew the sealing cap (41) on the stopcock and top-

up pipe.

- Depressurise the control valve on the tractor.

- Connect the plug-in connection (42) on the tractor.

- Open stopcock (position E). The hydraulic pressure

drops.

- Operate the control valve on tractor until the gauge

indicates the target pressure. Then close the shut-off

valve (position A).

Beware!

The stopcock must always be closed during

ploughing (position A).

- Depressurise the top-up pipe by means of the control

valve.

- Take out the top-up pipe and screw back the sealing

cap (41).

- 16 -

1600_GB-NOVA_984

SERVO NOVA GB

Gas tank (43):

The pressure in the gas tank can also be changed.

Reducing or increasing the gas pressure in the tank

depends on the various types of ground.

• In case of very light ground, you can reduce the gas

pressure to a certain extent.

Be advised!

No welding, soldering or mechanical work

may be performed on the gas container.

Changing the pressure in the gas tank

This operation may be performed only

by the customer service or a special-

ised workshop.

To reduce or increase the preload

pressure, you need a special filling

and verification device.

1. Release pressure:

a) Take out the plastic cover.

- Take out the lead mould plug (if available) in the gas

filling plug (44) with the help of a sharp tool.

b) Loosen the gas filling plug (44) only slightly.

c) Screw on the filling and verification device.

d) Open the evacuation cock on the filling device slightly.

Let out the nitrogen (N) slowly until the gauge has

reached the target pressure.

e) Close the evacuation cock, take out the filling device,

tighten the gas filling plug and put back the lead mould

plug (if provided).

2. Increase pressure:

For tank filling only use nitrogen (N), no

oxygen (danger of explosion).

f) Connect the filling device onto the nitrogen bottle.

g) Take out the plastic cap.

- Take out the lead mould plug (if available) in the gas

filling plug (44) with the help of a sharp tool.

- Loosen the gas filling plug (44) only slightly.

- Screw on the filling and verification device.

h) Screw the verification device onto the nitrogen bottle.

i) Open the evacuation cock on the filling device slightly

and fill with nitrogen until the gauge reads the target

pressure.

k) Close evacuation cock, take out the filling device, tighten

the gas filling plug and put back in the lead mould plug

(if available).

Note

All gas accumulators show a slight pressure drop after a

certain period of time, according to "HYDAC" factory

specifications.

The gas loss amounts to approx. 2-3 % pa.

It is recommended to check and if necessary correct tank

pressure after 4-5 years.

- 17 -

1600_GB-WARTUNG_9831

GB

MAINTENANCE

Advice for general maintenance

In order to keep the implement in good condition even after

a long service life, please observe the following points:

- Retighten all screws after the first hours of operation.

During the operating season

- Check all screws occasionally and retighten if necessary.

Wearing parts

- Replace worn out expendable parts in time to prevent

any stress-bearing parts from becoming damaged.

Tyre pressure

- Pay attention to the correct tyre pressure!

Check tyre pressure regularly!

• Danger of bursting when pumping up or

when tyre pressure is too great!

Cleaning of machine parts

Be advised!

Do not use a high pressure cleaner to clean bearings

and hydraulic parts.

- Danger of rust!

- Lubricate the machine after cleaning and carry out a

short trial run.

- Cleaning with too high pressure may damage the paint.

Parking in the open

When parking in the open for longer periods, clean

piston rods and then preserve with grease.

FETT

TD 49/93/2

Winter storage

- Thoroughly clean the machine beforehand.

- Put up protection against weather.

- Protect exposed parts from rust.

- Lubricate all greasing points according to lubrication

chart.

Hydraulic unit

- Check hydraulic hoses regularly for damage.

Immediately replace porous or damaged hydraulic

hoses.

Caution danager of infection!

• If there are defects in the hydraulic unit, do

not touch areas of leakage.

Before working on the hydraulic unit

- lower implement to the ground.

- When carrying out maintenance work on a raised

implement always secure it with a suitable support.

- Depressurize the hydraulic unit and turn the motor off.

Note:

The lubrication

points and the

frequency of lubri-

cation are stated

in the lubrication

chart at the end of

this Chapter.

- 18 -

1600_GB-WARTUNG_9831

GB

MAINTENANCE

Basic setting of the ploughing component

Checks must be made in the following order after replacing worn out parts:

1. Stand the plough on even ground.

2. The gap (A) between plough and share cutting edge must be the same for all ploughing components.

3. Check the gap (B1) on the last ploughing component.

B1 = 0 - 5 mm for ploughing components* of the type W, UWS

10 - 20 mm for ploughing components* of the type UW, UWS, WSS

4. Set the same measurement for gap (B) as for B1.

* The type of ploughing component is shown clearly on the manufacturer’s plate.

Setting the ploughing component tilt

If the plough is not penetrating the ground correctly, an

improvement can be obtained by turning the eccentric bush.

• The blade point in the area „S“ is set either higher or

lower depending upon the position of the eccentric bush

(A or B).

• Retighten screws after resetting.

On some models a catch plate is fitted instead of an

eccentric bush.

See "Basic setting of the ploughing component" also.

- 19 -

1600_Schmierplan_9831

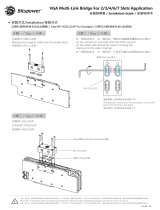

SERVO 45 S Plus Nova

10 h

2211 1 2

2

2

24

10 h

2 5

12

3

896-15-100

896-15-102

10 h

21

/